Abstract

The sedimentation behaviour of travertine-processing wastewater containing a high concentration of suspended solids was investigated using different coagulation and flocculation methods. In batch experiments, four types of coagulants [FeC13, Al2(SO4)3, PACl, NaAlO2], six types of flocculants (40% MMW–40% HMW cationic, 30% MMW, 40% MMW, 40% HMW anionic and nonionic) and three types of natural materials (NMs) (sepiolite, zeolite, and pumice) were used to treat wastewater with an initial turbidity of 570–880 NTU. The optimum process conditions (dosage, mixing time/speed, sedimentation time, and pH) were investigated for each. Sedimentation performance was assessed by the effluent turbidity (T eff) values of the treated water. The best performances obtained were 99.3% (T eff = 4 NTU), 99.1% (T eff = 8 NTU), and 97.8% (T eff = 18 NTU) with 40% HMW anionic-cationic flocculants, zeolite, and FeCl3, respectively. Sludge properties, including sludge settling velocity (mm/min), sludge density (g/cm3), suspended solids (SS) content (mg/L), and sludge solids (%) were determined and compared under optimized conditions. The type of additive significantly affected performance. Travertine processing wastewater flocculation with polymeric materials and NMs, especially zeolite, was more favourable than coagulants in terms of both turbidity removal and sludge quality. Since zeolite is a NM, additional studies on using and recycling of the generated sludge as an industrial feedstock would be worthwhile.

Zusammenfassung

Das Sedimentationsverhalten von Feststoffen, die in hohen Konzentrationen im Abwasser einer Travertinverarbeitung enthalten sind, wurde unter Anwendung verschiedener Flockungsmethoden untersucht. In Batch-Experimenten wurden vier Flockungsmittel (FeCl3, Al2(SO4)3, PACl, NaAlO2), sechs Flockungshilfsmittel (40%MMW- 40%HMW kationisch, 30%MMW, 40%MMW, 40%HMW anionisch und kationisch) und drei natürliche Materialien (Sepidolith, Zeolith, Bimsstein) bei Anfangstrübungen von 550-880 NTU getestet. Für alle wurden die optimalen Bedingungen ermittelt: Dosis, Rührgeschwindigkeit und –zeit, Sedimentationszeit und pH-Wert. Als Bewertungskriterium für die Sedimentationsleistung der verschiedenen Methoden diente die Trübung des behandelten Wassers (Teff). Die besten Reinigungsleistungen lagen bei 99.3% (Teff=4 NTU), 99.1% (Teff=8 NTU) und 97.8% (Teff=18 NTU) mit 40% HMW anionisch-kationischem Flockungshilfsmittel, Zeolit bzw. FeCl3. Die Schlammeigenschaften (Sedimentationsgeschwindigkeit in mm/min, Schlammdicht in g/cm3, Feststoffgehalt in % und in mg/L) wurden unter optimalen Bedingungen bestimmt und verglichen. Die Art der eingesetzten Stoffe beeinflusste signifikant die Sedimentationsleistung. Die Behandlung mit Polymeren und natürlichen Materialien, insbesondere Zeolith, ist sowohl wegen der Trübeentfernung als wegen der Schlammeigenschaften gegenüber Flockungsmitteln zu bevorzugen. Da Zeolith ein natürliches Material ist, wären Untersuchungen zur Nutzung und zum Recycling des erzeugten Schlammes als Sekundärrohstoff in der Industrie wünschenswert.

凝结剂、絮凝剂和天然材料去除石灰石石料加工厂废水浊度

应用多种凝结剂和絮凝剂研究了石灰石石料加工厂含高浓度悬浮固体废水的沉淀行为。用四种凝结剂(FeC13、Al2(SO4)3、PACl和NaAlO2)、六种絮凝剂(40%MMW- 40%HMW 阳离子、30% MMW、40% MMW、40% HMW 阴离子和无离子)和三种天然材料(NMs)(海泡石、沸石和浮石) 批次试验方式处理了初始浊度570-880 NTU的石料加工厂废水。研究了每种处理试剂的最佳处理条件(剂量、混合时间/速度、沉淀时间和pH值)。利用出流液浊度(Teff)值评价沉淀效率。40% HMW 阴-阳离子絮凝剂、沸石和FeCl3的最佳效率分别为99.3% (Teff=4 NTU)、99.1% (Teff=8 NTU)、和97.8% (Teff=18 NTU)。对比了污泥沉降速度(mm/min)、污泥密度(g/cm3)、悬浮固体含量(SS)(mg/L)和污泥固体(%)等污泥质量指标。添加剂类型严重影响沉淀效率。聚合和天然絮凝剂(尤其是沸石)在同时去除石料加工厂废水浊度和保证污泥质量方面比凝结剂更具优势。沸石是天然材料,使用和回收水处理产生的污泥作为工业原料更值得深入研究。

Resumen

El comportamiento en la sedimentación de aguas residuales del tratamiento de travertino, que contienen una alta concentración de sólidos en suspensión, fue estudiada usando diferentes métodos de coagulación y floculación. Se usaron cuatro tipos de coagulantes (FeC13, Al2(SO4)3, PACl, NaAlO2), seis tipos de floculantes (40%MMW- 40%HMW catiónico, 30%MMW, 40%MMW, 40%HMW aniónico y no iónico) y tres tipos de materiales naturales (NMs) (sepiolita, zeolita y piedra gómez) en experimentos en batch para tratar aguas residuales con una turbidez inicial de 570-880 NTU. Se investigaron las condiciones óptimas del proceso (dosaje, tiempo de mezclado/velocidad, tiempo de sedimentación y pH) en cada caso. El comportamiento sedimentativo fue evaluado por los valores de turbidez del efluente (Teff) del agua tratada. Las mejores eficiencias obtenidas fueron 99,3% (Teff=4 NTU), 99,1% (Teff=8 NTU) y 97,8% (Teff=18 NTU) con floculantes 40% HMW aniónico-catiónico, zeolita y FeCl3, respectivamente. Las propiedades del lodo, incluyendo la velocidad de sedimentación (mm/min), la densidad del lodo (g/cm3), contenido de sólidos en suspensión (SS) (mg/L) y sólidos en el lodo (%) se determinaron y compararon bajo condiciones optimizadas. El tipo de aditivo afectó significativamente la eficiencia del proceso. El procesamiento de las aguas residuales por floculación usando materiales poliméricos y NMs, especialmente zeolita, fue más favorable que con los coagulantes en términos de remoción de turbidez y calidad del lodo. Como la zeolita es un NM, valdrían la pena realizar estudios adicionales sobre el uso y el reciclado del lodo generado como una materia prima industrial maximum heights of bed and residual bed separations. These technologies were applied to the 1307 working face in the Xinji No. 1 coal mine, in Huainan, Anhui Province. Menacing bed separation was identified in the nappe fault zone. The maximum heights of the bed and residual bed separations were 5.92~6.90 m and 1.97~2.30 m, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Travertine is a natural stone commonly used as a construction and building material worldwide because of its physical properties and durability (Del Curaa et al. 2012; Ersoy et al. 2009). In natural stone processing, wastewaters containing a high amount of suspended solids are generated during the cutting, washing, wiping, and polishing operations (Solak et al. 2009). A medium-scale natural stone processing plant uses about 50–150 m3 of water per day with 20% loss (Kavakli 2003). Therefore, water recycling is vital for both the economics of the plant and to protect water resources. However, the recycled water may contain colloid-sized grains due to insufficient clarification. These colloids in the recycled water can cause problems during the processing; they can damage the cutting blades and cause the pipes to clog (Acar 2001; Ersoy et al. 2009).

Highly turbid waters containing fine, suspended solids are problematic (Guibai and Gregory 1991) due to their low settling velocity and because fine particles (< 50 µm) can cause poor solid–liquid separation during sedimentation. Solid concentration, particle shape, density and surface properties, and the liquid’s viscosity and density all affect sedimentation (Oteyaka et al. 2005). Coagulation and flocculation are commonly used to remove turbidity from water and wastewater. Coagulation is achieved by added hydrolyzing metallic salts for agglomeration of colloids into groups (Wang et al. 2014). The mechanisms are ionic layer compression, adsorption, and charge neutralization Flocculation occurs by polymer bridging, charge compensation or neutralisation, polymer-surface complex formation and depletion, and/or by combination of these mechanisms (Gregory 1985; Mpofu et al. 2003, 2004). Polymers are widely used flocculants that can be synthesized in various molecular masses and ionic forms (Gregory and Barany 2011; Kim and Palamino 2009). Clay minerals have been used as flocculants (Beall 2003; König et al. 2012; Lagaly 2006; Rytwo et al. 2011) in olive mill wastewater, wine industry wastewater, etc. (Mousavi et al. 2006; Rytwo et al. 2011, 2013). The coagulation-flocculation process is influenced by coagulant/flocculant type, dosage, solids concentration, solution pH, mixing intensity, and duration (Yu et al. 2011). Increasing the number of particles in the water causes particle agglomeration, resulting in faster and easier sedimentation (Ipekoglu 1997).

Studies on removal of turbidity of natural stone suspensions are very common (Ersoy 2005; Ersoy et al. 2009; Nishkov and Marinov 2003; Nyström et al. 2003; Seyrankaya et al. 2000; Tasdemir and Kurana 2012), whereas there are very limited studies on coagulation methods (Ehteshami et al. 2016; Ersoy et al. 2009; Solak et al. 2009). Although coagulation with inorganic salts, together with polymeric flocculation, has been suggested for various industrial wastewaters, the main disadvantages of such a treatment are the high quantities of chemical sludge. Natural materials (NMs) have been used to reduce chemical sludge release, but the use of clay minerals and pumice in natural stone wastewater purification has not been reported. This study included three NMs for coagulation–flocculation. The purposes of the study were to optimize the coagulation/flocculation conditions, to investigate and compare the effectiveness of the various coagulants, flocculants, and NMs, and to optimize process conditions (mixing, dosage, time, pH) with respect to the properties of the resultant treatment sludge.

Materials and Methods

Travertine Suspension

The travertine suspension was obtained from a marble processing plant in Konya-Turkey. The travertine powder was mixing with the cooling water during the wet-cutting of the marble blocks, thus forming a suspension that flowed directly to the collection pond. Samples were taken from the inlet of the wastewater pond. The solids ratio of the samples was 5.97%, pH was 7.5, and the turbidity was 570–880 NTU. Considering this turbidity interval, treatment performance was calculated based on the initial turbidity of the wastewater sample. The XRD pattern of the travertine powders in the suspension showed that they consisted of calcite (Fig. 1); their chemical composition was: CaO, 54.57; Al2O, 0.13; SiO2, 0.67; Fe2O3, 0.070; MgO, 0.67; Na2O, 0.028; K2O, 0.007; MnO, 0.005; and loss on ignition, 43.74%. Particle size analysis of travertine powder was carried out using a Mastersizer 2000; 80% of it was less than 40 μm (Fig. 2).

Coagulants, Flocculants, and NMs

Alum [Al2(SO4)3·18H2O], ferric chloride [FeCl3·6H2O], poly-aluminum chloride (PACl), and sodium aluminate (NaAlO2·nH2O) were used as coagulants. Polyacrylamide based flocculants (Table 1) and three types of NMs, zeolite, sepiolite, and pumice, were studied as flocculants. A Manisa Gordes (Turkey) region zeolite sample was obtained from Enli Madencilik Co, Ltd.; an Eskisehir-Sivrihisar (Turkey) region sepiolite sample was obtained from Dogus Madencilik Inc.; and an Isparta-Gelincik (Turkey) region pumice sample was obtained from Isbas Inc. The NM samples used were ground and sieved to 0.106–0.300 mm (Table 2).

Zeta Potential Measurements

The zeta potential (ZP) of the samples was measured in constant ionic strength (0.01 M NaCl) distilled water with ZetaPlus apparatus from Brookhaven. Prior to measurements, samples were dispersed at a 0.1% (w/v) solid ratio in distilled water. As experimental studies were performed in pH 6–11 interval, the pH was adjusted to values between 5.5 and 11. Ca(OH)2 and H2SO4 (Merck) solutions were used to adjust the pH, and pH control was provided by a digital pH meter. The sample was stirred for 5 min at room temperature. In the electrophoresis cell, the ZP of each sample was measured three times, each was recorded as the average of ten measurements in a run. Consequently, the ZP changes as a function of pH (between 5.5 and 11) were noted.

Treatment Experiments

Experiments were carried out in jar tests. The travertine suspension was pre-conditioned for 10 min at 500 rpm to obtain a well-dispersed suspension; then, the coagulant/flocculant/NM was dosed using prepared stock solutions or directly weighed powders (for the NMs). The suspensions were stirred (mixing time and speed were studied as independent variables) and left to settle for 30 min. Then, the supernatant sample was withdrawn from a fixed distance below the air–liquid interface and the turbidity of the samples was measured. The performance of the sedimentation processes was assessed using Eq. (1) (Osborne 1978; Ozkan and Yekeler 2004).

where T 0 is the initial turbidity (NTU) of the suspension and T eff is the turbidity of the supernatant after the process.

The effect of pH was studied by first adjusting it to between 6 and 11; then, the suspension was conditioned at 500 rpm for 3 min, the coagulant/flocculant/NM was dosed, and the same procedure described above was applied.

Determination of Sludge Properties

Sludge settling velocity (mm/min), sludge density (SD) (g/cm3), solids percent (%), and sludge suspended solids (SS) content (mg/L) were determined at the end of coagulation–flocculation experiments. Sludge settling velocities were calculated as the slope of the initial linear part of the interface height vs time curve (Δ interface height/Δ time). SDs were determined by Eq. 2 after weighing the known volume of the sludge.

SS concentration was determined gravimetrically by filtering the known volume of the sludge using constant weight 0.45 µ filter paper and drying the filter paper with the sludge cake at 105 °C. Solids percentage in the sludge was calculated using the SD and SS values.

Results and Discussion

Zeta Potential and pH Effects

None of the samples reached their isoelectric point (IEP) between pH 5.5 and 11 (Fig. 3), which encapsulated the pH interval of the experimental studies (6 and 11). The ZPs of the samples were measured at − 14.43, − 31.54, − 31.63, and − 24.57 mV (with an average standard deviation of ± 2.3) at the natural pH (7.5) for sepiolite, zeolite, pumice, and travertine, respectively. As the suspension pH increased, the negative charge of all of the NMs increased as well. The decreased ZP may be explained by adsorption of OH− ions onto the positive charge centers that are present on the particle surfaces of the sepiolite, zeolite, and pumice or deprotonation of surface hydroxyl groups. This is common for various metal oxides and metal hydroxides (Alkan et al. 2005; Celik and Ersoy 2005; Ersoy et al. 2010). Negative surface charge was reported at the same pH range for travertine (Ersoy 2005; Tasdemir and Kurama 2012), who reported that the porous structure of the travertine surface and the distinctive nature of the adsorbed organic and inorganic impurities strongly affected their surface properties and that negative ZP usually resulted from organic matter adsorption.

Natural Sedimentation of Travertine Suspension

The natural stability of the travertine suspension was evaluated at its natural pH (7.5) (Fig. 4). After 30 min, settling velocity and turbidity were determined as 0.66 mm/min and 87–135 NTU (85% turbidity removal efficiency); the decrease in sedimentation rate continued for at least 10 h (Fig. 4). The travertine suspension had a relatively high stability due to the high negative surface charge of the particles (Fig. 3). After the first 24 h, interface height reached its final value, which did not change when the suspension was left to settle for two more days. Such turbid water cannot be used in the marble processing plant as cooling water since the colloidal particles can cause blade deformation by scratching the blade surface during the cutting process.

Effects of Additive Dosage on Sedimentation

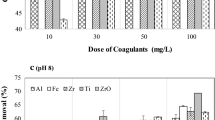

At the original pH (7.5), 120 s (s) mixing time, 200 rpm mixing speed, and 30 min of settling time, sedimentation efficiency increased with increasing dosage at low dosages, but slightly fluctuated as dosage was increased (Fig. 5a, b). The use of higher flocculant dosages resulted in decreased efficiencies. However, overall efficiencies were higher than 90% for most of the studied cases. The concentration of the coagulant/flocculant is important in fine particle coagulation and flocculation; an insufficient dosage causes insignificant coagulation/flocculation while high concentrations may restabilize the suspension (Tao et al. 2000).

The optimum coagulant dosages were determined as 20 mg/L for FeCl3 and Al2(SO4)3, 10 mg/L for PACl, and 300 mg/L for NaAlO2. Chloride-based coagulants were more efficienct (96–98%), with lower T eff (18.4–29.3 NTU), which is a finding parallel to that described by Ersoy et al. (2009). Al2(SO4)3 and NaAlO2 provided 95% efficiency and 36 NTU T eff at optimum dosages (Fig. 5a).

In flocculation, the highest efficiency (99.5%, T eff = 3 NTU) was achieved with 40% HMW anionic and cationic flocculants at a 2 mg/L dosage (Fig. 5b). For the other flocculants, optimal dosages, corresponding T eff values, and calculated turbidity removal efficiencies achieved were: 1 mg/L, 8 NTU, 98.5%; 6 mg/L, 8 NTU, 98.5%, 8 mg/L, 12.9 NTU, 97.7%; and 2 mg/L, 27.4 NTU, 95% for a 30% MMW anionic flocculant, 40% MMW anionic flocculant, a non-ionic flocculant, and a 40% MMW cationic flocculant, respectively. Cationic flocculants are suitable choices according to electrostatic interaction when the particles are negatively charged. Flocculant adsorption is not only due to functional interactions with the surface, but also depends on the molecular weight of the flocculant and rate of polymer chain dissolution. Longer polymer chain lengths and higher molecular weight flocculants form larger but more porous flocs, which have less strength, whereas it is vice versa for low molecular weight flocculants (Hogg 2000). High molecular weight flocculants are extremely effective in promoting floc growth in suspensions (Hogg et al. 1993; Owen et al. 2002) and can be adsorbed onto several particle surfaces simultaneously to become a three-dimensional matrix.

The charge densities of ionic flocculants also affect their effectiveness. Seyrankaya et al. (2000) observed that low-charged anionic flocculants had a better settling rate and water clarity. Moreover, as the ionization degree increases, the polymer chain stretches, which makes interparticle bridging easier (Sabah and Cengiz 2004; Stutzman and Siffert 1977). For example, 28% anionic flocculant gave the best settling rate, while a 34% anionic flocculant gave the best clarity at low dosages (Ersoy 2005). However, in this study, 30% and 40% anionic flocculants had similar efficiencies but at sixfold higher dosage of the 40% MMW anionic flocculant.

In the sedimentation tests in which NMs were involved, the highest overall turbidity removal performance was achieved with zeolite (6000 mg/L, 8 NTU, 99%), followed by sepiolite (6000 mg/L, 23 NTU, 97%), and pumice (3000 mg/L, 35 NTU, 96%) (Fig. 5c). NMs help increase solids and enhance the sweep floc mechanism. Since the surface charges of particles were all negative (Fig. 3), the influence of adsorption and charge neutralization mechanisms had already been eliminated. Zeolite had the highest density (Table 2), resulting in better settling. Moreover, channels in the zeolite and sepiolite structures enable them to host zeolitic water and other molecules inside their structures. Entrapped water may add substantially to its weight (Demirel et al. 1995). Pumice has 30–45%, zeolite 80–135%, and sepiolite 100–200% by weight, water absorption capacity (Table 2). This absorbed water might increase the bulk density of the zeolite and sepiolite, making them more effective than the pumice.

Turbidity removal performances of the clays were closer to coagulants and flocculants, but at higher dosages, similar to previous studies (Onen and Yel 2013; Tarlan-Yel and Onen 2010). The densities of zeolite and sepiolite were lower than Al2(SO4)3 and FeCl3. As the maximum residual turbidity of the treated water should be less than 15 NTU (Ersoy 2005), this was only achieved by the zeolite. However, the clay-travertine sludge is a potentially more valuable by-product since the sludge is composed of natural materials.

Effect of Mixing Time on Sedimentation

Mixing conditions influence the coagulation/flocculation process efficiency and floc properties (Rossini et al. 1999; Yu et al. 2011; Zhao et al. 2014) Although a short period of rapid mixing was necessary for good turbidity removal, prolonged rapid mixing can impair performance. Therefore, in this step, effects of mixing time (15–180 s) for coagulation and flocculation were investigated (Fig. 6).

The appropriate mixing time for coagulation was 90 s for Al2(SO4)3 and 120 s for the other coagulants. Al2(SO4)3 coagulation efficiency slightly decreased at longer mixing times (Fig. 6a). 120 s of mixing was used for all of the flocculants. The efficiencies achieved at this duration were 99% (T eff = 3 NTU) for anionic and cationic flocculants, and 98% (T eff = 4 NTU) for the non-ionic flocculant. About 98% (T eff = 14 NTU) and 96% (T eff = 24 NTU) efficiencies were achieved in the first 15 s of mixing with anionic and cationic flocculants, respectively (Fig. 6b). Mixing time had no effect on sedimentation performance when pumice was used whereas, when zeolite and sepiolite were used, 99% (T eff = 8 NTU) and 97% (T eff = 23 NTU) turbidity removal efficiencies were obtained at 90 and 120 s, respectively (Fig. 6c). Increased mixing time decreased sedimentation efficiencies because accumulation of coagulants/flocculants onto particle surfaces cause stearic hindrance and instability, which obstructs coagulation/flocculation and increases suspension turbidity.

Effect of Settling Time on Sedimentation

After mixing, the suspensions were left to settle; floc sedimentation was tracked (Fig. 7). 10 min of settling was sufficient for flocculants to achieve ultimate efficiency; over 90% occurred within the first 5 min. The other additives required 25 min of settling. Non-ionic flocculant performance for turbidity removal was not as high as for the other flocculants. Flocculant-particle interactions were faster than coagulants and NMs; the flocculants adsorbed onto the particles quicker and formed stronger flocs through a bridging mechanism. Flocs obtained with coagulants were weaker and smaller, which produced lower settling velocities (Fig. 7).

Effect of Mixing Speed on Sedimentation

Mixing speed is an important variable in floc formation. It should be sufficient for homogeneity and collisions but not high enough to create shear forces and floc degradation. The ultimate mixing speed for NaAlO2 was 150 rpm, whereas turbidity removal efficiency for the other coagulants increased up to 200 rpm (Fig. 8a). Higher mixing speed was required for the coagulants to create homogeneity and to complete the chemical reaction. Optimum mixing speeds for the flocculants were 120 rpm, although 99% efficiency could be achieved at 45 rpm for anionic flocculants (Fig. 8b). On the other hand, optimum mixing speeds for the minerals were much lower: 45 rpm for zeolite and pumice, 60 rpm for sepiolite. Clay colloids in the suspension increase its viscosity and can change fluid properties, depending on their particle surface area and charge. For example, sepiolite can form viscous, stable suspensions in water and other liquids, even at very low concentrations, because of its fibrous structure (Irkec 1993; Mart et al. 2001). Such sepiolite suspensions are non-Newtonian fluids, and increased mixing speeds increase the stability of the suspension, which results in less efficient sedimentation.

Effect of pH on Sedimentation

The suspension pH plays a significant role in coagulation and flocculation because it changes the stability of the particles, and affects ionization, hydrolysis, and dispersion. An acidic pH dissolves marble, therefore water to be used for marble processing should be neutral or alkaline. For economical and environmental considerations, treatment at neutral or weakly alkaline conditions is preferred so that pH adjustment is not required for water reuse. Therefore the effect of pH was studied for the 6.5–9 interval (Fig. 9).

Optimum sedimentation efficiencies were achieved at the original pH of the suspension (7.5), and as alkalinity increased, efficiency decreased (Fig. 9a). However, NaAlO2 was not affected by the pH since it is a high performance alkaline coagulant with a high buffering capacity. Two mechanisms can be attributed to coagulation of the travertine powders: adsorption of the cationic metal-hydroxide products (Ersoy et al. 2009) and deposition of positively charged colloidal precipitates, such as Al(OH)3 and Fe(OH)3, onto the negatively charged travertine powder. Charge neutralization by either mechanism eliminates the repulsive forces between the particles (Ersoy et al. 2009). At low pH, positively charged hydroxide compounds can destabilize negatively charged colloids easily by charge neutralization. However, depending on the alkalinity and coagulant dosage, some of the hydroxide precipitates that form will be negatively charged [e.g. Al(OH)4 −], which negatively affects coagulation. This may explain the relatively low efficiency at low pHs with alum and FeCl3 (Fig. 9a). In an alkaline medium, the sweep floc mechanism becomes effective as metal hydroxides precipitate. Therefore, at pH values higher than the original solution pH, higher coagulant dosage is required to achieve the same efficiency as the sweep floc mechanism becoming dominant.

The suspension pH can change charge characteristics of the polymer chains and their conformation in solution, thus directly affecting the flocculating power of the polymer (Ersoy 2005; Sabah and Cengiz 2004). The highest flocculation efficiency was obtained at the original pH while the minimum flocculation efficiency occurred at pH 11 for all of the polymers (Fig. 9b). This may be due to the stabilization effect of OH− ions at high pH on the negatively charged travertine particles. As pH increased, the anionicity of the macromolecules increased, and the surface of the particles became more negatively charged; therefore, repulsion naturally occurs. When NMs were used, the pH was not affected (Fig. 9c).

Comparison of Turbidity Removals and Sludge Properties

The suggested optimal treatment conditions and corresponding properties of the treatment sludge are listed in Tables 3 and 4, together with achieved turbidity removal efficiencies. Two different efficiencies were reported in Table 3 for each case. The first (additional efficiency) is the improvement compared to the efficiency achieved without any dosage. This was calculated by using the 87–135 NTU as T 0 in Eq. (1). The second one is overall turbidity removal efficiency, which was calculated by taking the 570–880 NTU as T 0 . The data indicate that wastewater turbidity was removed at very high efficiencies for all cases, and additional effciencies (improvements of the process by optimization of the conditions) varied.

Statistical analysis was performed to indicate whether the efficiencies were significantly different, both within the groups (coagulants, flocculants, and NMs) and between the groups. One-way ANOVA (analysis of variance) indicated that the treatment efficiencies were significantly different for the coagulants and NMs. The calculated ANOVA F values of samples were compared to standard F values (F 2,6,0.05 = 5.14) found from standard tables of ANOVA (F coagulants=23.29 > F 2,6,0.05 = 5.14 and F minerals = 5.53 > F 2,6,0.05 = 5.14). This indicates that the type of coagulant or NM influenced treatment efficiency. However, the efficiencies of the flocculants were not significantly different (F flocculants = 2.49 < F 2,6,0.05 = 5.14).

Moreover, ANOVA between the groups resulted in smaller F values than the reference value for both overall efficiency and additonal efficiency (F overall = 10.84 > F 2,3,0.05 = 9.55 and F additional = 11.38 > F 2,3,0.05 = 9.55). Therefore, it can be concluded that the type of additive used significantly affects turbidity removal performance. Hence, although all the overall efficiencies in Table 3 were close to each other, the type of coagulant/flocculant/NM significantly affected performance.

The type of additive material also influenced the treatment sludge properties. Higher SD, SS, and solids percentage are preferred so that the sludge can be handled and processed more easily (Metcalf and Eddy 2003). A sludge with higher settling velocity does not necessarily decrease turbidity in the supernatant. In some suspensions, a clearer supernatant can be obtained with slower settling (Ersoy et al. 2009; Gregory 1989). Similarly, a distinct relationship between SD and sludge solids percent cannot be described from the data in Tables 3 and 4. A sludge with a higher solids percentage may be less dense. Sludge SS is another important sludge quality parameter. Each of these parameters was affected by both the physical properties of the sludge solids and the chemical properties of the coagulant/flocculant used. Among the coagulants, the sludge obtained with FeCl3 had the highest settling velocity and solids percentage, while its density and SS were the lowest. Although the ultimate supernatant turbidity obtained with NaAlO2 was the highest, the sludge obtained had the highest SS content because of hydroxide precipitates.

The sludge obtained with anionic flocculant had the highest settling velocity and solids percentage among the flocculants (Table 4), mainly because of interparticle bridging. Cationic flocculants cause flocculation via electrostatic charge patching, which is less effective than bridging, resulting in a lower solids percentage and density. Non-ionic flocculants had a completely different effect. The highest sludge SS (920,000 mg/L) and SD were due to high (8 mg/L) dosages (Tables 3, 4). Due to its polymer chain structure, interparticle bridging is more difficult (Cengiz et al. 2004), which decreased turbidity removal efficiency. Despite the low sludge solids percentage, zeolite produced the sludge with higher SD, SS, and settling velocities. Among the three groups of additives, the most effective were the 40% HMW anionic and cationic flocculants, and the coagulant, FeCl3, with 99.4, 99.1, and 97.8% turbidity removal efficiencies, respectively. The most effective NM was the zeolite, which produced the best sludge. These findings indicated that flocculation with polymeric materials and NMs are better than coagulants in terms of both turbidity removal and sludge quality.

Conclusion

Suspended particles in travertine processing wastewater were removed by coagulation and flocculation. The effectivenesses of three types of additives (chemical coagulants, polymeric flocculants, and NMs) were compared. The highest sedimentation efficiency (99.4%, T eff = 3NTU) was achieved with 40% HMW anionic and cationic flocculants. Among the coagulants, chloride-based coagulants (FeCl3 and PACl) resulted in higher overall turbidity removal (97.8% with T eff = 18 NTU and 96.5% with T eff = 29 NTU, respectively). In the sedimentation tests with the NMs, the highest performance was achieved with zeolite (99.1%, T eff = 8 NTU), followed by sepiolite (97.4%, T eff = 23 NTU), and pumice (96%, T eff = 36NTU). These indicated that both flocculation and coagulation were effective in the treatment of such wastewaters. Sedimentation efficiency decreased with longer mixing times. 10 min settling was sufficient for flocculants to achieve ultimate efficiency, whereas 25 min was required for coagulants and NMs. Higher mixing speed was required for the coagulants to achieve homogeneity and to complete the chemical reaction. Peak sedimentation efficiencies were achieved at the original pH of the suspension (7.5). Turbidity of the suspension increased with pH with the flocculants and coagulants, while no pH effect was observed in sedimentation with the NMs.

The contribution of each coagulation/flocculation mechanism to the overall process efficiency and sludge quality differed, depending on the water quality and additive used. A distinct relationship between SD and sludge solids percentage could not be defined. The most effective additives of each of the three groups were FeCl3, the 40% HMW anionic flocculant, and the zeolite. Better settleability, dewaterability, and higher solids content of the resultant treatment sludge were obtained with zeolite. Flocculation with polymeric materials and NMs are more favourable than coagulants in terms of both turbidity removal and sludge quality. Zeolite, sepiolite, and pumice performances were comparable to successful chemical coagulants and flocculants. By using such NMs, a non-chemical sludge containing the marble particles was obtained. An investigation of the potential of this non-chemical treatment sludge as an industrial feedstock is recommended.

References

Acar H (2001) Particular points in construction and operation of water recycling systems for marble processing plants. Proc, 3rd Marble Symp, Afyon/Turkey, pp 289–296 (in Turkish)

Alkan M, Demirbas O, Dogan M (2005) Electrokinetic properties of sepiolite suspensions in different electrolyte media. J Colloid Interf Sci 281:240–248

Beall GW (2003) The use of organo-clays in water treatment. Appl Clay Sci 24:11–20

Celik MS, Ersoy B (2005) Mineral nanoparticles: electrokinetics. In: Schwarz JA, Contescu CI, Putyera K (eds) Encyclopedia of nanoscience and nanotechnology. Marcel-Dekker Inc, New York, pp 1991–2005

Cengiz İ, Sabah E, Erkan ZE (2004) A research on the flocculation performance of traditional and UMA technology polymers. Mining Mag 43(1):15–20 (in Turkish)

Del Curaa MÁG, Benaventea D, Martínez JM, Cuetoa N (2012) Sedimentary structures and physical properties of travertine and carbonate tufa building stone. Constr Build Mater 28:456–467

Demirel H, Karapınar N, Akça K (1995) The use of bentonite and other clays as adsorbent. In: Köse H, Kızıl M (eds), Proc, industrial mineral symp, İzmir, pp 21–31 (in Turkish)

Ehteshami M, Maghsoodi S, Yaghoobnia E (2016) Optimum turbidity removal by coagulation/flocculation methods from wastewaters of natural stone processing. Desalin Water Treat 57:20749–20757

Ersoy B (2005) Effect of pH and polymer charge density on settling rate and turbidity of natural stone suspensions. Int J Miner Process 75:207–216

Ersoy B, Tosun I, Günay A, Dikmen S (2009) Turbidity removal from wastewaters of natural stone processing by coagulation/flocculation methods. Clean Soil Air Water 37(3):225–232

Ersoy B, Sariisik A, Dikmen S, Sariisik G (2010) Characterization of acidic pumice and determination of its electrokinetic properties in water. Powder Technol 197:129–135

Gregory J (1985) The use of polymeric flocculants. Proc, engineering foundation conf on flocculation, sedimentation and consolidation, the Clister Sea Island. American Inst of Chemical Engineers, Georgia, pp 125–137

Gregory J (1989) Fundamental of flocculation. Crit Rev Environ Contr 19(3):185–230

Gregory J, Barany S (2011) Adsorption and flocculation by polymers and polymer mixtures. Adv Colloid Interf Sci 169:1–12

Guibai L, Gregory J (1991) Flocculation and sedimentation of high-turbidity waters. Water Res 25(9):1137–1143

Hogg R (2000) Flocculation of dewatering. Int J Miner Proc 58:223–236

Hogg R, Bunnaul P, Suharyono H (1993) Chemical and physical variables in polymer-induced flocculation. Miner Metall Proc 10:81–85

Ipekoğlu U (1997) Dewatering methods. Dokuz Eylul Univ, İzmir (in Turkish)

Irkeç T (1993) Utilization areas of sepiolite and results of research project of MTA-GIRIN consultation. MTA Nat Resour Econ Bull Ankara 2(5–6):32–37 (in Turkish)

Kavakli M (2003) Treatment, control and characteristics of marble processing plant wastewaters. Proc, 4th Marble Symp, İzmit, pp 313–326 (in Turkish)

Kim S, Palomino AM (2009) Polyacrilamide-treated kaolin: a fabric study. Appl Clay Sci 45:270–279

König TN, Shulami S, Rytwo G (2012) Brine wastewater pretreatment using clay minerals and organoclays as flocculants. Appl Clay Sci 67–68:119–124

Lagaly G (2006) Colloid clay science. In: Bergaya F, Theng BKG, Lagaly G (eds) Handbook of clay science. Elsevier, Amsterdam, pp 309–377

Mart U, Yüzer H, Sabah E, Çelik MS (2001) Viscosity behaviour of sepiolite in water-based systems. In: Karakaya ÇM, Karakaya N (eds), Proc, 10th national clay symp, Konya, pp 121–128 (in Turkish)

Metcalf and Eddy (2003) In: Tchobanoglous G, Burton FL, Stensel HD (eds) Wastewater engineering: treatment and reuse, 4th edn. McGraw-Hill, New York

Mousavi SM, Alemzadeh I, Vossoughi M (2006) Use of modified bentonite for phenolic adsorption in treatment of olive oil mill wastewater. Iran J Sci Technol 30:613–619

Mpofu P, Mensah JA, Ralston J (2003) Investigation of the effect of the polymer structure type on flocculation rheology and dewatering behaviour of kaolinite dispersions. Int J Miner Proc 71:247–268

Mpofu P, Addai-Mensah J, Ralston J (2004) Flocculation and dewatering behaviour of smectite dispersions: effect of polymer structure type. Miner Eng 17:411–423

Nishkov I, Marinov M (2003) Calcium carbonate microproducts from marble treatment waste. In: Mineral processing in the 21st centrury. Djiev Trade, Sofia, pp 700–705

Nyström R, Backfolk K, Rosenholm JB, Nurmi K (2003) Flocculation of calcite dispersions induced by the adsorption of highly cationic starch. Colloids Surf A 219:55–66

Onen V, Yel E (2013) Adsorption of ferrocyanide onto raw and acid-activated clinoptilolite and sepiolite: equilibrium modelling by error minimization. Clay Miner 48:613–626

Osborne DG (1978) Recovery of slimes by a combination of selective flocculation and flotation. Trans Inst Min Metall C 87:189–193

Oteyaka B, Yamık A, Uçar A, Şahbaz O, Yılmaz B (2005) Precipitation behavior of Seyitömer clays. Proc, 19th international mining congress and exhibition of Turkey, pp 297–303 (in Turkish)

Owen AT, Fowel PD, Swift JD (2002) The impact of polyacrylamidem flocculant solution age on flocculation performance. Int J Miner Process 67:123–144

Ozkan A, Yekeler M (2004) Coagulation and flocculation characteristics of celestite with different inorganic salts and polymers. Chem Eng Process 43:873–879

Rossini M, Garrido JG, Galluzzo M (1999) Optimization of the coagulation–flocculation treatment: influence of rapid mix parameters. Water Res 33:1817–1826

Rytwo G, Rettig A, Gonen Y (2011) Organo-sepiolite particles for efficient pretreatment of organic wastewater: application to winery effluents. Appl Clay Sci 51:390–394

Rytwo G, Lavi R, Rytwo Y, Monchase H, Dultz S, König TN (2013) Clarification of olive mill and winery wastewater by means of clay–polymer nanocomposites. Sci Total Environ 442:134–142

Sabah E, Cengiz İ (2004) The effects of ionic groups of polyacrylamides on sedimentation behaviours of wastes of coal preparation plants. Proc, 14th coal congress, pp 113–140

Seyrankaya A, Malayoglu U, Akar A (2000) Flocculation conditions of marble from industrial wastewater and environmental consideration. In: Ozbayoglu G (ed) Mineral processing on the verge of the 21st century. Balkema, Rotterdam, pp 645–652

Solak M, Kiliç M, Yazici H, Şencan A (2009) Removal of suspended solids and turbidity from marble processing wastewaters by electrocoagulation: comparison of electrode materials and electrode connection systems. J Hazard Mater 172:345–352

Stutzman T, Siffert B (1977) Contribution to the adsorption mechanism of acetamide and polyacrylamide on to clays. Clay Clay Miner 25:392–406

Tao D, Groppo JG, Parekh BK (2000) Enhanced ultrafine coal dewatering using flocculation filtration processes. Miner Eng 13:163–171

Tarlan-Yel E, Onen V (2010) Performance of natural zeolite and sepiolite in the removal of free cyanide and copper-complexed cyanide ([Cu(CN)3]2–). Clay Clay Miner 58(1):110–119

Tasdemir T, Kurama H (2012) Fine particle removal from natural stone processing effluent by flocculation. Eng Prog Sust Energy 32(2):317–324

Wang C, Harbottle D, Liu Q, Xu Z (2014) Current stage of fine mineral tailings treatment: a critical review on theory and practice. Miner Eng 58:113–131

Yu WZ, Gregory J, Campos L, Li G (2011) The role of mixing conditions on floc growth, breakage and re-growth. Chem Eng J 171:425–430

Zhao J, Su R, Guo X, Li W, Feng N (2014) Role of mixing conditions on coagulation performance and flocs breakage formed by magnesium hydroxide. J Taiwan Inst Chem Eng 45:1685–1690

Acknowledgements

This study was supported by the Coordinatorship of Selcuk University Scientific Research Projects (Grant 09201104).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Onen, V., Beyazyuz, P. & Yel, E. Removal of Turbidity from Travertine Processing Wastewaters by Coagulants, Flocculants and Natural Materials. Mine Water Environ 37, 482–492 (2018). https://doi.org/10.1007/s10230-017-0499-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-017-0499-4