Abstract

The US Environmental Protection Agency’s Mine Waste Technology Program (MWTP) has emphasized the development of biogeochemically-based treatment technologies for mitigation of acid rock drainage (ARD). Progressive technology demonstrations by the MWTP over the past 15 years have resulted in improved operation of sulfate-reducing bacteria (SRB) bioreactors. Although using SRB to treat ARD is now fairly widespread, it was uncommon in the early 1990s when the MWTP used this innovative biotechnology. The first and longest running demonstration was an in situ bioreactor installed within the flooded subsurface workings of the Lilly/Orphan Boy Mine in 1994. The second project, at the Calliope Mine, compared the performance of several SRB bioreactor configurations and operational attributes, including lime pretreatment and reactor temperature. The third demonstration, at the Golden Sunlight Mine, consisted of two treatment steps with a recycle stream. The fourth project was an investigation of existing bioreactor designs and resulted in an improved bioreactor configuration. Significant findings included: (1) a mineshaft could be used as a long-term, in situ bioreactor, (2) SRB thrive in temperature extremes, (3) sulfide recycle effectively avoids contact of ARD with bacterial populations, and (4) ideal bioreactor substrate provides short-term and long-term nutrients, good support matrix, and enhanced permeability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thousands of remote abandoned hardrock ore mines in the United States and around the world discharge acidic, metal-laden waters to receiving streams. The combination of acidity, heavy metals, and sediment loading associated with the acid rock drainage (ARD) from these abandoned mines can have severe detrimental environmental impacts on receiving ecosystems. Pollution prevention, emphasizing at-source control when possible, is the best long-term solution to this problem.

The Congressionally Mandated Mine Waste Technology Program (MWTP) emphasizes the development and demonstration of treatment technologies that provide satisfactory short- and long-term solutions to the remedial problems facing abandoned ore mines and the ongoing compliance problems associated with active mines throughout the United States. Technical direction for the MWTP is provided by the US Environmental Protection Agency (EPA) Office of Research and Development’s National Risk Management Research Laboratory in Cincinnati, Ohio. The MWTP is administered by the Department of Energy’s Western Environmental Technology Office in Butte, Montana and implemented by their performing contractor, MSE Technology Applications, Inc. (MSE).

Field demonstrations and research conducted by the MWTP and many others (Figueroa et al. 2004; Gusek 2002; McGregor et al. 1999; Skousen et al. 2000; Tsukamoto and Miller 2002; Wildeman and Updegraff 1998) have shown that sulfate-reducing bacteria (SRB) can be used to effectively treat ARD. The SRB use organic carbon (i.e., CH2O) as an electron donor to reduce sulfate to sulfide (as H2S) and produce alkalinity in the form of bicarbonate (Reaction 1). The H2S then reacts with dissolved metal cations to precipitate relatively stable metal sulfides (Reaction 2). Besides lowering the concentrations of sulfate and dissolved metals, SRB produce bicarbonate buffers and decreases the acidity of the ARD. This is a well documented process (Doshi 2006; Elliot et al. 1998; Gusek 2004; Johnson and Hallberg 2005; Neculita et al. 2007; Younger et al. 2002).

Biological sulfate reduction, with subsequent precipitation of metal sulfides, is not the only metal removal mechanism in organic-based treatment systems. Other mechanisms include cation exchange of metals (typically with lower valence cations) by the organic-rich substrate, precipitation of metal hydroxides, and the sequential adsorption of metals by precipitated ferric hydroxide. Adsorption of metals by the organic substrate plays an important initial metal removal role; however, in most cases, it only causes a temporary retention of metals, as the mechanisms are pH dependent and metals have different adsorption affinities. Over time, less readily sorbed metals, such as manganese, may be released back into solution in exchange for more readily sorbed metals. Adsorption of metals by organic materials is also limited by the quantity of sorption sites in the organic matrix.

Mine Waste Technology Program Field SRB Demonstrations

Many abandoned mine sites are located in difficult to access, remote settings without networked power. Traditional treatment options, such as lime neutralization, can be difficult and costly to implement at such sites. However, at-source control, passive technologies using SRB offer many advantages, such as effectively removing metals, requiring less maintenance, and being economical to construct and operate. The following MWTP SRB-based biotechnology projects consisted of anaerobic bioreactor designs, each with a unique aspect that made it innovative.

-

(1)

SRB subsurface bioreactor: an in situ passive bioreactor installed within the flooded subsurface workings of the Lilly/Orphan Boy Mine in Montana and operated for 11 years between 1994 and 2005;

-

(2)

On-site SRB bioreactor comparison: several on-site SRB bioreactors were configured in parallel at the Calliope Mine in Montana, which allowed design and operational attributes, such as lime pretreatment and temperature, to be evaluated;

-

(3)

SRB-driven sulfide precipitation demonstration: an SRB-based process with an innovative solution recycle loop conducted at the Golden Sunlight Mine in Montana; and

-

(4)

Improvements in engineered bioremediation for ARD: an innovative portable modular bioreactor configuration demonstrated at Black Hawk, Colorado.

The lessons learned from these projects addressed engineering design criteria, including the selection of different organic media, maintenance of system permeability, and strategies for mitigation of ARD. The projects are described in chronological order below.

Project 1: SRB Subsurface Bioreactor (Lilly/Orphan Boy Mine)

From 1994 to 2005, the MWTP demonstrated an innovative, passive, in situ biological technology to treat and control ARD emanating from the remote, abandoned Lilly/Orphan Boy Mine near Helena, Montana. Platforms were suspended about 9 m (30 ft) below the static water level in the mineshaft and two injection wells were drilled into the tunnel near the shaft intersection. An organic substrate consisting of approximately 70% cow manure, 20% decomposed wood chips, and 10% alfalfa straw was placed in the shaft and supported by the suspended platforms; the remainder was pumped into the tunnel through holes drilled from the surface. The upwelling ARD in the shaft passed through the organic matter. A cross-sectional view of the underground configuration is shown in Fig. 1. Biological treatment took place in the substrate regions, and the treated water subsequently flowed out of the mine through the portal. The bioreactor was installed in August 1994 and analytical data was collected for 11 years.

This field demonstration was conducted to evaluate the use of SRB to mitigate metal-contaminated ARD in situ. A literature search (Gusek 2002) found that this project was the first to use the novel approach of employing the underground mine as a treatment vessel. Using monitoring wells, the performance of the SRB system was monitored through the collection and analysis of samples from within the mine tunnel (shaft sampled) and at the portal (Fig. 1). Key parameters measured to ascertain the treatment efficacy of the design included concentrations of dissolved metals, total metals, alkalinity, dissolved oxygen (DO), sulfate, sulfide, biochemical oxygen demand, chemical oxygen demand, and volatile fatty acids as well as temperature, pH, and redox potential (Eh). Nearly all of the analytical parameters showed positive trends toward the treatment of ARD (Canty 1999, 2000; Nordwick and Bless 2002).

Chemical parameters of treated and untreated Lilly/Orphan Boy Mine ARD are shown in Table 1. Flow rates varied from 8 to 30 L/min [2–8 gallons per minute (gpm)] with the higher rates occurring during spring runoff. Hydraulic residence time (HRT) was not calculated due to uncertainties associated with the volume of substrate in the mine workings. The pretreatment data is an average of several samples taken from the shaft and portal of the mine from September 1993 until August 1994. Post-treatment data was collected from the portal and tunnel in March and May 2001, 7 years into the demonstration. This data was selected because it is typical for the demonstration and illustrates the substantial changes in portal water chemistry experienced during spring runoff. Tunnel sample data for the same period shows much less seasonal variation.

Overall, the rates of contaminant removal (during non-runoff periods) for aluminum, cadmium, copper, and zinc were greater than it was for arsenic, manganese, and iron. The data also indicated that higher metal removals were obtained within the tunnel; by the time the water reached the portal, an increase in metals had occurred. The pH of the mine water increased almost immediately after implementation of the technology, which was attributed to the buffering capacity of the organic substrate. During the spring runoff period, pH and water quality were lower in the portal than in the tunnel, where pH remained near neutral. This was likely due to oxygenated surface water runoff penetrating through the ground above the portal, flowing into the tunnel, and then solubilizing historic metal precipitates and becoming contaminated as it passed through the tunnel. Water quality during the spring months may also have been affected by a greater amount of ARD infiltration from fractures within the tunnel walls.

To summarize, several lessons were learned from the SRB subsurface bioreactor:

-

It was initially envisioned that the life of this bioreactor would be only a couple of years, at best. However, the original carbon biomass placed in the Lilly/Orphan Boy Mine was able to sustain SRB activity far longer than expected. Valuable insight was gained into the longevity of SRB treatment systems.

-

Since the water was apparently re-contaminated with metals as it passed through the tunnel and out the portal, it is recommended that future designs for in situ bioreactors account for this. Installation of a passive bioreactor system downstream of the portal was suggested to help alleviate this problem.

-

A substantial decrease in most metals concentrations and an increase in pH were demonstrated. Metals effectively removed included zinc, aluminum, cadmium, and copper. The SRB treatment was not very effective for removal of iron, arsenic, and manganese. However, it should be noted that these metals were removed at the subsequent Integrated, Passive Biological Treatment System demonstration conducted at the Surething Mine in Montana, where SRB treatment was combined with an aerobic bioreactor optimized for manganese removal (Nordwick 2008).

Project 2: On-Site SRB Bioreactor Comparison (Calliope Mine)

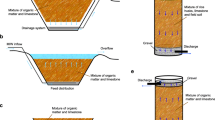

The primary objective of the on-site SRB bioreactor comparison project was to assess several bioreactor configurations and monitor their ability to produce a high-quality effluent at the ARD source. The bioreactors were constructed at the Calliope Mine site near Butte, Montana. Three horizontal flow SRB bioreactors were built, two underground and one above ground. Each bioreactor was filled with a combination of organic matter and cobbles placed in two or four chambers. One of the underground bioreactors (Bioreactor II) had a crushed limestone and organic matter pretreatment section that was added to evaluate its effect on SRB to improve pH and lower oxidation-reduction potential (ORP). The other underground reactor (Bioreactor III) had no pretreatment. The above ground bioreactor (Bioreactor IV) also had a pretreatment section composed of crushed limestone and organic matter and was exposed to the atmosphere to evaluate the effects of temperature variation and freezing. The bioreactors operated from 1998 to 2001, and have been discussed in more detail elsewhere (Zaluski et al. 2001, 2003). The general layout of the bioreactors is shown in Fig. 2.

The below-ground bioreactor (II) with the pretreatment section was 21.8 m (71.5 ft) in length and the other below-ground bioreactor without a pretreatment component (III) was 18.6 m (61 ft). Both were constructed in trapezoidal trenches that were 4.3 m (14 ft) wide at the top and 1.2 m (4 ft) wide at the bottom. The above ground bioreactor was 22.1 m (72.5 ft) in length and constructed in a 3.7 m (12 ft) wide metal half-culvert. The chambers, filled with organic matter or limestone, were each 1.5 m (5 ft) in length. The flow rate of 3.8 L/min (1 gpm) corresponded to a calculated 5½-day residence time for the ARD in the bioreactors with the pretreatment section and a 4½-day residence time for the other bioreactor.

The organic matter was a mixture of 80% cow manure and 20% cut straw by volume. The straw was added as a bulking agent to provide secondary porosity to the mix. TerraCellTM material, a high-density polyethylene commonly used in landscaping for slope stabilization, formed a cellular containment system (CCS) to house the organic matter. Each layer of TerraCellTM was positioned 60º from horizontal to offset cells with respect to cells of adjacent layers. Each layer was 15.2 cm (6 in.) thick and contained 27.9 cm (11 in.) by 21.6 cm (8.5 in.) rhombohedral-shaped cells (Fig. 3). The CCS prevented organic matter from settling to the bottom of the bioreactor, thus allowing the flow of ARD through the entire cross-sectional area without channeling.

Bioreactor performance was monitored monthly by recording pH, Eh, DO, and temperature of influent and effluents. Analyses included SRB population numbers, alkalinity, sulfate, sulfide, and dissolved metals concentrations. Chemical parameters of treated and untreated Calliope water collected in June 1999 are shown in Table 2. Results showed that the bioreactors effectively removed aluminum, zinc, cadmium, and copper on a consistent basis. Iron results were mixed: Bioreactors III and IV were fairly effective, while Bioreactor II was not. While the level of manganese was slightly reduced, none of the bioreactors effectively removed sulfate. The level of arsenic in the effluent was either unchanged or increased, probably due to release of adsorbed arsenic from ferrihydrite due to reducing conditions, as described by Robins and Huang (1988). Greater detail on this system can be found in papers by Zaluski et al. (2001, 2003).

At the end of the project, the bioreactors were decommissioned and the solid matrix was sampled for total metals, sulfate, sulfide, nitrogen, phosphorous, and total organic carbon (TOC) (Zaluski et al. 2003). Figure 3 shows before and after photographs of one of the organic chambers. Bacteriological analyses were also conducted to determine SRB population numbers in the organic substrate and in the limestone. Aqueous samples were collected from the previously inaccessible bottom of the crushed limestone and cobble chambers and analyzed for metals (Zaluski et al. 2003).

The autopsy of the bioreactors revealed that metal removal mechanisms changed over time. Initially, prior to establishment of SRB populations, processes occurred at low pH and a reasonably high load of metals. Later, there was evidence of reactions that were characteristic for water of neutral pH with lower dissolved metal content (Zaluski et al. 2003). The abundance of TOC (20% by weight) in the organic matter chamber at the end of the project confirmed that the project started with excess carbon. This assumed that the residual nutrient was fully metabolizable. However, since the system was not operated until failure, exact nutrient quantity requirements could not be calculated. In addition, since cow manure organic matter reduced the permeability of the matrix, it was recommended that future designs reduce the ratio of manure to straw to enhance flow.

The CCS worked well to prevent settling of organic matter and ensure uniform flow of ARD throughout the entire cross-section of the organic carbon with no obvious preferential flow paths or channeling. The configuring of the bioreactors to direct flow in a horizontal plane (rather than in the vertical direction) was successful. Once SRBs were established in the bioreactors and supplied with organic matter, an active population was maintained at temperatures ranging from 2 to 16°C.

Results also showed that only zinc, copper, and cadmium were removed as sulfides due to SRB activity. SRB activity was verified by performing SRB-specific heterotrophic plate counts. It was also inferred by the production of sulfide in the effluent of all reactors (Table 2) and the pervasive characteristic odor of hydrogen sulfide emanating from the reactors. The data also showed that the sulfate concentration was typically greater in each reactor effluent than in the influent. The reason for this is unknown but was possibly due to excess sulfate in the organic nutrient. Based on physical appearances, it was assumed that iron, manganese, aluminum, and arsenic were indirectly affected by SRB by forming hydroxides and carbonates in response to increased pH. Most of these compounds precipitated within the organic matter. Greater detail is contained in the final report for this project (Zaluski 2002).

Summarizing the results of the On-Site SRB Bioreactor Comparison:

-

Much of the metal removal observed during the first few months of operation was attributed to adsorption by the organic matrix. Once sorption sites filled and SRB populations became established, metals, such as zinc, copper, and cadmium, were effectively removed (removal efficiencies ≥ 85%) from the ARD as sulfides as a result of SRB activity.

-

A population of SRB greater than 103 cells/mL measured in the effluent was sufficient to maintain high removal levels (removal efficiencies ≥ 85%). Data showed that winter freezing of a well-established SRB population had little or no effect on their activity for the remainder of the year.

-

Although the limestone chamber slightly increased effluent pH, it did not appreciably impact bioreactor performance. Evidence of metal sulfides precipitating in the organic carbon chambers, together with the observation of no precipitant attached to the cobblestones, indicated that the cobble chamber was not essential.

-

Water that accumulated at the bottom of the bioreactors contained large amounts of suspended ferric and aluminum hydroxides that resulted from the increase in pH caused by biological action.

-

Bioreactor III, a below-ground reactor, had a repetitive plugging problem. Examination of the plugged bioreactor showed a light brownish color in the upstream portion of the organic carbon adjacent to the ARD inlets. The high percentage of iron and aluminum hydroxides in the removed plug indicated that the plugging was due to chemical reactions (i.e., hydroxide precipitation) within the ARD distribution system.

-

The high concentrations of metals detected in the solid matrix of the bioreactors were further proof that these systems efficiently remove metals from ARD.

-

Best results were observed when the ARD residence time in the organic matter was at least 12 h.

As a result of this project, several recommendations were made to improve construction of future SRB bioreactors. The first was to place a cover on top of the bioreactors to provide a uniform reducing environment within the entire vertical profile. Another suggestion was to design a system to allow for occasional breakdown and removal of plugging material from the bioreactor inlet. The cobble chamber was not necessary and was not recommended for future designs. Because of excess organic matter, smaller quantities were recommended for similar applications, with no change to the residence time. Finally, future designs should raise the reactor outlet to favor accumulation of precipitant in the bottom of the bioreactor.

Project 3: SRB-Driven Sulfide Precipitation Demonstration (Golden Sunlight Mine)

The SRB-driven sulfide precipitation and recycle demonstration project had an innovative recycle loop. This demonstration was conducted at the Golden Sunlight Mine (GSM) near Whitehall, Montana. The system, designed collaboratively by MSE and GSM, consisted of a two-step process using a settling pond and a bioreactor (Figs. 4, 5). It was determined that this type of configuration would provide appropriate conditions for SRB growth by keeping the low pH, metal-contaminated ARD from having direct contact with the SRB. The demonstration goal was to achieve a 75% reduction in the dissolved metals loading in the effluent.

The settling pond had a design residence time of 32 days based on the expected ARD flow rate of 11.4 L/min (3 gpm). Metals were removed from the ARD through precipitation of insoluble metal sulfides and metal hydroxides. Biologically generated sulfide contained in the recirculation stream from the bioreactor reacted with metal ions to precipitate metal sulfides. As the bicarbonate alkalinity was generated, the pH increased, and aluminum and ferric iron ions were precipitated as metal hydroxides. Two products were created in the settling pond: a metal precipitate sludge and ARD-neutralized water. The sludge was occasionally removed from the bottom of the settling pond and the neutralized water was recycled back into the bioreactor.

The bioreactor was used for SRB growth and generation of sulfide and bicarbonate ions. This reactor had a design residence time of 20 days based on the expected ARD flow rate of 11.4 L/min (3 gpm), but was operated at 7.6 L/min which resulted in a HRT of about 30 days. Initially, the bioreactor was filled with a mixture of 75% crushed limestone and 25% manure. The limestone had two functions: substrate for biofilm growth and additional alkalinity source. The manure also had two functions: seed the reactor with SRB populations and provide initial labile carbon energy source for microbiological activity. During the demonstration, methanol was added as a supplementary nutrient.

The field portion of this project began in late 2001. The ARD was fed to the reactor system at a rate of approximately 7.6 L/min (2 gpm). As shown in Fig. 5, a split-stream of the effluent was recycled to the settling pond and the remainder of the treated effluent was discharged to the mine site water treatment plant. The recycle rate of the bioreactor effluent ranged from 42 to 83 L/min (11–22 gpm) and was adjusted to provide a pH above 5.5 when mixed with the influent. The treated water contained sulfide and bicarbonate ions. Monthly samples were collected from the reactor influent, the interface between the two reactors, and reactor effluent.

The quality of the effluent was greatly improved over that of the influent. The system pH, ORP, DO, and temperatures shown in Table 3 show reducing conditions and reduced acidity typical of SRB processes. Sulfate was reduced by 40% from influent values that were initially over 30,000 mg/L, but was not optimized since sulfate removal was not a project objective. Table 4 shows that the 75% reduction objective was easily achieved for aluminum, copper, iron, and zinc, but not for manganese.

To summarize:

-

The innovative aspect of this project: avoiding direct contact of the acidic, metal-laden ARD with the bacterial population was very successful. This allowed the bioreactor to start up quickly and operate more efficiently than conventional bioreactor systems.

-

The bioreactor started working almost immediately and continued to be effective at very low temperatures through the first winter. In May 2002, the bioreactor began operating less efficiently due to plugging. Good quality water was still being produced, but plugging occurred because solids overflowed into the bioreactor from the full settling pond. This situation was remedied, and the bioreactor continued to operate until April 2003.

-

Problems encountered with this system were associated with reactor plugging; future designs of this nature should allow for frequent cleanout of the precipitated metals. In addition, larger rocks should be used in the bioreactor to increase porosity and reduce plugging.

Project 4: Improvements in Engineered Bioremediation for ARD

Another MWTP research project consisted of an investigation to improve SRB bioreactor treatment performance. The objectives of the laboratory portion of this project were to: (1) develop a bioreactor design with a reactive material not prone to plugging and easily replaceable if exhausted; (2) develop a bioreactor cartridge system that is easily transported to remote ARD sites; and (3) quantify reactivity of organic material and develop software to optimize bioreactor size and other design parameters.

To meet the first objective, a literature study was conducted to develop a database of organic matter used as an electron donor in SRB bioreactors. Analysis of this database revealed that: (1) the best long-term bioreactor performance is achieved by using a mixture of substrates with varying degrees of biodegradability; (2) an easily biodegradable substrate is essential for the startup of a bioreactor; (3) a substrate with a low biodegradation rate enhances long-term performance; and (4) loss of organic carbon permeability decreases operation longevity.

After analyzing this information, it was determined that a mixture of cow manure and walnut shells would constitute an effective SRB substrate. Cow manure is easily biodegradable and contains bioavailable nitrogen as ammonium, essential for SRB growth. Walnut shells have a high percentage of organic carbon (up to 60%) and an ability to provide a long-term carbon source. Due to their shape, walnut shells can also increase the porosity of the substrate mix and provide an internal structure that prevents settling, thus preserving high permeability of the organic medium.

Off site bench-scale investigations were conducted on the permeability of the manure and walnut shell medium. This was done using cells configured for horizontal and (upward) vertical flow fed with organic matter of different walnut shells to manure ratios. Vertical distribution of ARD flowing upward was measured in a 2.4 m (8 ft) tall, 1.8 m (6 ft) diameter cell filled with a 1:1 mixture of walnut shells and manure. These measurements showed that the hydraulic head declined rapidly in the lowest portion of the organic medium, indicating reduced permeability. This, together with subsequent analysis of the medium, confirmed that small particles of manure have a tendency to migrate to the lower portion of the reactor, reducing its permeability. This discovery made it clear that, although the use of high permeability media is important, horizontal flow is also critical to maintaining high reactor permeability.

To meet the second project objective, a reactive cartridge consisting of a 2.4 m (8 ft) diameter tank filled with bags each containing approximately 19 L (5 gallons) of the cow manure and walnut shell mixture was proposed. Each plastic netting bag had a loop on the top to be used for lowering the bag into the tank and to allow for easy bag removal for organic matter replacement (Figs. 6, 7). The tank could be placed below or above ground. In addition, the tank was fitted with inlet, outlet, and overflow pipes and contained large vertical cleanup ports to remove accumulated sediment and/or precipitated metal sulfides.

The third project objective was to quantify reactivity of organic material and develop software to optimize design parameters and bioreactor size. An experimental set-up was developed to determine the sulfate reduction rate and a routine was defined using the PHREEQC geochemical model to simulate chemical reactions occurring as flow proceeds through the system. A spreadsheet model called BEST (bioreactor economics, size and time of operation) was developed to size the bioreactors in conjunction with PHREEQC. Model input variables included measured concentration of metals in the ARD, pH of the ARD, sulfate reduction rate, an assumed rate of organic carbon depletion, and flow rate. The BEST model is available from the MWTP.

The replicate SRB bioreactors (RC-1 and RC-2) utilizing this optimized design were built by MSE in cooperation with the Colorado School of Mines and began operation at Black Hawk, Colorado in January 2007. The reactors processed ARD in parallel from the same feed source. Construction and installation of these reactors were essentially identical. The primary difference was that RC-1 was exposed to more sunlight during operation than RC-2, which was located in a more shaded area. Increased warming of RC-1 resulted in slightly less freezing during the winter. Figure 8a shows that excellent removal of cadmium, copper, and zinc from the ARD was achieved, typically more than 99%. As with previous designs, consistent iron removal was not achieved in these reactors (Fig. 8b).

Table 5 shows major water quality parameters measured during the project. The samples are the most recent data available, taken on January 16 2008, 1 year after the reactors started. Copper, cadmium, and zinc were effectively removed while iron, manganese, and sulfate were not.

Initially, the organic matter consisted of a ratio of 0.8 walnut shells to 0.2 manure by volume. After experimenting with several mixtures and additives, the best performing organic matter contained three components—walnut shells, corn stover, and cow manure mixed at 0.75, 0.20, and 0.05 volumetric proportions, respectively. Another improvement consisted of a separate chamber containing only walnut shells located at the inlet of the bioreactor. This highly permeable region was designed to precipitate most of the ferric hydroxide, thus minimizing plugging in the main portion of the reactor. The organic matter can easily be removed periodically without jeopardizing the integrity of the bioreactor.

This exercise identified the following major findings:

-

The literature search identified 36 organic substrates that were being used as SRB substrates. Of these, 29 were considered indirect (recalcitrant) organic substrates since they require decomposition by other microorganisms to provide SRB nutrition. Examples are composts, wood/paper wastes, food production byproducts (molasses, whey, and potato), hay, straw, manure, and sewage sludge. The remaining seven substrates were considered direct organic substrates because they do not need decomposition by other microorganisms to be usable by SRB. These include methanol, ethanol, acetate, lactate, formate, pyruvate, and sucrose.

-

Substrate mixtures containing both easily biodegradable materials and more recalcitrant materials are most effective for supporting SRB growth. Easily biodegradable substrate ensures a quick start of the bioreactor and more recalcitrant materials provide best long-term performance. Ideal substrate mixtures also provide adequate surface area for biofilm development, buffering and adsorption capacity, and good hydraulic conductivity.

-

The suitability of a substrate mixture for treating a particular composition of ARD is best determined empirically using laboratory-scale tests.

-

A recalcitrant organic substrate containing walnut shells and cow manure was developed that satisfies most of the conditions defined in the literature study for an efficient mixture to treat ARD. For the Black Hawk bioreactors, this organic mix was optimized by replacing some manure with corn stover, which is also easily biodegradable but has more organic carbon than manure. A small amount of cow manure was retained in the mix for its SRB-essential ammonia.

-

A modular SRB treatment system is recommended. This consists of reactive cartridges configured in parallel or in series depending on ARD flow rate and quality (metal load and pH), cleanup objectives, and available space. The configuration and number of reactive cartridges can be determined through the BEST computer simulator developed for this project.

-

It is recommended that the reactive cartridge be a commercially available HDPE or polypropylene plastic tank to accommodate the organic medium and serve as an SRB bioreactor. The tank can be installed either above or below-ground, as required by the site conditions, and an appropriate piping system installed to convey the ARD into the reactive cartridge.

-

The reactive cartridges should be filled with bags of walnut shell, manure, and corn stover organic medium. Bags made of plastic netting commonly used by grocery shops for pre-packed fruits are recommended, since these have loops at the top to facilitate placement and removal of the bags from the reactive cartridge.

-

A cleanup port, a sump for precipitate, an overflow outlet, and a valve to control flow should be built into the reactive cartridge. Anaerobic conditions are created by placing a tarp on the top of organic medium. A rigid lid with locks placed on the top of the reactive cartridge will protect it from the weather and vandalism.

Overall Summary

This communication was written to inform readers about four biological treatment projects conducted by the MWTP at mine sites during the past 15 years. These field demonstrations have shown that SRB bioreactors are a cost effective, viable treatment alternative for ARD. Each subsequent project benefited from the successes and failures of previous projects, both in the MWTP and elsewhere. Significant findings for these projects included: (1) a mineshaft could be used as an innovative, long-term, in situ bioreactor, (2) SRB populations can thrive in temperature extremes, (3) sulfide recycle is an effective means of avoiding direct contact of ARD with bacterial populations, and (4) ideal SRB bioreactor substrate consists of one that provides short-term and long-term nutrients, a good support matrix, and enhanced permeability.

References

Canty MC (1999) Overview of the sulfate-reducing bacteria demonstration project under the mine waste technology program. Min Eng 51(6):93–99

Canty MC (2000) Innovative in situ treatment of acid mine drainage using sulfate-reducing bacteria. In:Proceedings of the 5th international conference on acid rock drainage (ICARD), Society of Mining Metallurgy and Exploration, pp 1139–1147

Doshi SM (2006) Bioremediation of acid mine drainage using sulfate-reducing bacteria. US Environmental Protection Agency, Office of Solid Waste and Emergency Response and Office of Superfund Remediation and Technology Innovation, p 65

Elliot P, Ragusa S, Catcheside E (1998) Growth of sulfate-reducing bacteria under acidic conditions in an upflow anaerobic bioreactor as a treatment system for acid mine drainage. Water Res 32:3724–3730

Figueroa L, Seyler J, Wildeman T (2004) Characterization of organic substrates used for anaerobic bioremediation of mining impacted waters. In: Jarvis A (ed) Proceedings of the international mine water association conference, Newcastle, England, pp 43–52

Gusek JJ (2002) Sulfate-reducing bacteria design and operating issues: is this the passive treatment technology for your mine drainage? In: Proceedings of the 2003 national association of abandoned mine land programs annual conference, Park City, UT, Technical paper session 15, part 3, pp 1–14

Gusek JJ (2004) Scaling up design challenges for large scale sulfate reducing bioreactors. In: Proceedings of the 2004 National Meeting of the American Society of Mining and Reclamation and the 25th WV surface Mine Drainage Task Force, Morgantown, WV, pp 752–765

Johnson DB, Hallberg KB (2005) Acid mine drainage remediation options: a review. Sci Total Environ 338:3–14

McGregor R, Blowes D, Ludwig R, Pringle E, Pomeroy M (1999) Remediation of heavy metal plume using a reactive wall. In: Proceedings of the 5th international in situ and on-site bioremediation symposium, vol 5, issue 4, San Diego, CA, USA. Battelle Press, USA, pp 19–24

Neculita CM, Zagury GJ, Bussiere B (2007) Passive treatment of acid mine drainage in bioreactors using sulfate-reducing bacteria: critical review and research needs. J Environ Qual 36:1–16

Nordwick SM (2008) Final report—an integrated, passive biological treatment system. Mine Waste Technology Program, Activity III, project 16. http://www.epa.gov/minewastetechnology

Nordwick SM, Bless DR (2002) Integrated, passive biological treatment process for acid mine drainage. In: CD Proceedings of the conference on hard rock mining 2002, Denver, Co, USA, New media poster session, p 2

Robins RG, Huang JCY (1988) The adsorption of arsenate ion by ferric hydroxide. In: Proceedings of the arsenic metallurgy symposium TMS/AIME annual conference, Phoenix, AZ, USA

Skousen J, Sexstone A, Ziemkiewicz P (2000) Acid mine drainage treatment and control. In: Barnhisel R, Daniels W, Darmody R (eds) Reclamation of drastically disturbed lands. American Society of Agronomy, Madison, pp 131–168

Tsukamoto TK, Miller GC (2002) Sustainable bioreactors for treatment of acid mine drainage at the Leviathan Mine. In: CD Proceedings of the conference on hard rock mining 2002, Denver, CO, USA, platform session 10, p 3

Wildeman T, Updegraff D (1998) Passive bioremediation of metals and inorganic contaminants. In: Macalady DL (ed) Perspectives in environmental chemistry. Oxford University Press, New York, pp 473–495

Younger P, Banwart S, Hedin R (2002) Mine water: hydrology, pollution, remediation. Kluwer, London, p 442

Zaluski MH, Trudnowski JM, Canty MC, Harrington Baker MA (2001) Status and performance of engineered SRB reactors for acid mine drainage control. In: Proceedings of the 6th international symposium on in situ and on-site bioremediation. Battelle Press, USA, pp 35–42

Zaluski MH (2002) Final report—sulfate-reducing bacteria reactive wall demonstration, USEPA Mine Waste Technology Program, Activity III, project 12

Zaluski MH, Trudnowski JM, Harrington Baker MA, Bless DR (2003) Post-mortem findings on the performance of engineered SRB field bioreactors for acid mine drainage control. In: Proceedings of the 6th ICARD, Cairns, Australia, pp 845–853

Acknowledgments

This research was funded under Interagency Agreement DW899388-70-01-1 between the US Environmental Protection Agency and the US Department. of Energy and was conducted by MSE Technology Applications, Inc. at the Western Environmental Technology Office, Butte, Montana (DOE Contract DE-AC09-96EW96405).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bless, D., Park, B., Nordwick, S. et al. Operational Lessons Learned During Bioreactor Demonstrations for Acid Rock Drainage Treatment. Mine Water Environ 27, 241–250 (2008). https://doi.org/10.1007/s10230-008-0052-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-008-0052-6