Abstract

Anaerobic digestion (AD) is an efficient process for the conversion of predominantly organic waste into biogas. However, when those wastes have a lignocellulosic composition, the process is slower with low rates of biogas production potential. In these cases, the increment with other wastes, known as anaerobic codigestion (AcoD), proves to be effective, especially when animal waste is included. The objective of the study is to obtain the best waste proportion (manure/agricultural waste) according to the volume of biogas produced during the biodegradability test under investigation of the effects of different temperatures (from 36 to 60 °C). The preliminary investigation consisted of sampling and drying the wastes with analytical tests (TS, VS, COD, TOC, N, P, pH, and moisture), what did allow to determine the proportions to be used in the experimental research. The biodegradability test was evaluated in different proportions of substrate (banana leaf) and inoculum (bovine manure) (1:1; 1:2; 1:9; 0:1) under mesophilic and thermophilic conditions. During the test, different temperatures were tested, starting from 36 up to 60 °C, gradually increasing from 2 to 2 °C, every 3 or 5 days, to adapt the anaerobic microorganisms. The investigated proportions presented production different from biogas (in volume), which can be explained by the composition of the proportions and variability of proposed temperatures. The 1:9 proportion was that one which obtained the highest cumulative biogas yield among the proportions, with 113.00 mL/g VS. The results show that the tested AcoD has adaptability when undergone to the variation of temperature, with better profit of biogas in thermophilic temperatures, mainly for the proportion 1:9; when the best condition was considered for the profit of biogas for the employed wastes, in the conditions of the research.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Agribusiness involves different sectors, from rural production, agro-industries and agricultural input to transport and marketing of agricultural goods [1] being responsible for the largest volume of biomass produced in the world [2]. Given this scenario, the process of anaerobic codigestion (AcoD) has stood out as one of the alternatives for the generation of renewable energy through the use of biogas [3,4,5,6,7] and for the reduction of the environmental impact (produced by the unsuitable destination of the waste) [8,9,10].

Anaerobic codigestion (AcoD) is a process it looks for the improvement of the anaerobic digestion performance of organic waste, optimizing the production of biogas (better yield in volume and quality) [7, 11, 12]; due to increased nutrient availability, bulk density of waste, variability of the substrate, dilution of toxicity of compounds [13,14,15]. Due to AcoD be adaptable to waste with different characteristics [16], this facility makes it possible to accelerate the process of degradation and reduction of solid content [17, 18], contributing to process stability in anaerobic reactors (nutritional balance) [19,20,21] by increasing the diversity of microorganisms [20, 21]. The main product in the process is biogas [22,23,24] and as a by-product there is the production of a solid substrate called digestate, with potential for use as fertilizer [25, 26].

The process of AcoD in mesophilic temperature is considered more stable when compared to the thermophilic, due to a bigger variety of microorganisms (hydrolytic, acidogenic, acetogenic and methanogens) what are favored by the temperature range [27]. The thermophilic temperatures applied to AcoD is more advantageous compared to mesophilic [28]; in thermophilic range, the reaction speed is higher, resulting in greater efficiency in biogas and better stabilization of organic matter, consequently in a higher biogas production [29]. However, despite the advantages, AcoD in thermophilic range presents low stability and reactor acidification and consequently inhibition of biogas production [28, 30].

Another important factor for the AcoD process is the total solid concentration (TS); being considered an important parameter in the choice of waste [31]. The process of AcoD with TS concentration from 10 up to 20% is advantageous over liquid digestion (TS < 10%) due to the greater flexibility in the type of substrate, especially biomass composed mainly of lignin, cellulose and hemicellulose, such as agricultural wastes. Performing anaerobic AcoD with this TS concentration (10–20%), the process requires reduced particles, requiring less energy consumption of the process of heating the proportion [32].

When it comes to the choice of agribusiness biomass to be used in the AcoD process, they commonly allow the use of high availability waste in the region [33,34,35,36], seasonality [37] in addition to the transport of waste [38] seeking to reduce its environmental impact (atmospheric emissions) by keeping waste disposed of in the field [39].

However, one of the main difficulties in the use of animal manure in isolation is the presence of low carbon (C) and high nitrogen (N) content (mainly for pig and poultry manure) [40]; therefore, use in combination with other organic wastes such as agricultural waste [41,42,43], banana wastes [44] may accelerate and/or optimize the process. The high carbohydrate content of agricultural biomass is considered an excellent substrate for biogas production through solid state AcoD [45].

The cultivation of the banana produces a large quantity (in volume) of post-harvest organic waste (pseudocaps, peduncles, leaves, and peels), representing about 70% of the total weight of fresh plants [46]. Fernandes et al. [47] mentioned that for each tonne of fruit harvested, approximately 4 tonnes are lignocellulosic wastes (3 tonnes of pseudostem, 160 kg of stems, 480 kg of leaves and 440 kg of skins). These residues are often left on the ground, causing emission of volatile organic compounds, greenhouse gases [48, 49]. In the state of Santa Catarina, 720.259 tons of bananas were produced in the 2017 harvest, representing 10.7% of the national production; 66.8% of the total produced in the state is attributed to the municipalities of Corupá (23.7%), Luiz Alves (19.2%), Massaranduba (9.0%), Jaraguá do Sul (8.1%) and São João do Itaperiú (6.8%) [53, 133].

In relation to the bovine herd, in the state of Santa Catarina, in the year 2016, the herd totaled 4.79 million head, 72.13% female and 27.87% male [133]. In the State, beef cattle farming has approximately 132,590 establishments and dairy bovines with 71,054 establishments [134].

This way, optimizing the AcoD process of the residues from the agribusiness sector, by means of the optimum ratio between the wastes, besides maintaining an adequate temperature condition, will promote benefits such as: better degradability of the wastes and higher yield in the production of biogas. In view of the above, this study seeks the determination of an optimum proportion (waste:agricultural waste) according to the volume of biogas produced during the biodegradability test, with an additional investigation of temperature variability in the yield of biogas production in the AcoD process.

Materials and methods

Inoculum and substrate collection and sampling

The animal waste was collected in a private property, in the Itajaí Valley region in the state of Santa Catarina, Brazil and immediately transferred to the laboratory for cooling until starting the test. In the laboratory, the bovine waste was manually homogenized with the aid of a shovel and then, small portions were taken to determine the solids content (TS), moisture, nitrogen (N), phosphorus (P), total organic carbon (TOC), and chemical demand of oxygen (COD); the rest of the sample was conditioned in a plastic bag and kept under refrigeration (4 °C) until the beginning of the incubation to avoid fermentation, a procedure also performed by other researchers [50]. Twenty-four hours prior to use, the sample was taken off and left at room temperature.

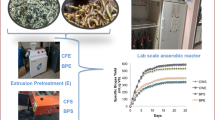

In relation to the substrate, banana leaf is collected in a rural property in the region of Itajaí-Açú Valley region, in the State of Santa Catarina, Brazil. The waste was dried in the sun and, in a laboratory, the grinding of the waste (3–5 cm) was done through a knife mill (high rotation for processing, with production capacity of 50–200 kg/h and engine power of 10 HP); since the smaller the granulometry, the larger the surface area and porosity of the samples [51]. The milling stage is recommended by Krause et al. [52], especially for smaller trials (100–250 mL bottle), as used in this study.

Waste characterization

The parameters monitored for each waste were moisture (%), total organic carbon (TOC), nitrogen (N), total phosphorus (P), ionic potential (pH), chemical oxygen demand (COD) obtained by the colorimetric method and total solids (TS), and volatile solids (SV) obtained by the gravimetric method [54], all of them were verified prior to and at the end of the process. The performance of the AcoD process was evaluated by daily and cumulative biogas yield and volatile removal efficiency (VS). Table 1 shows the analytical methods used to determine the characterization parameters.

Experimental design and set up

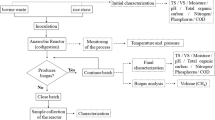

The experimental phase consisted of the assembly and monitoring of anaerobic bench digesters, through BMP test, to evaluate the potential methane production in agricultural wastes and animal waste. The biodigesters (BMP) consisted of 250-mL borosilicate flasks, with a screw cap fitted with a gas outlet valve and manometer (reading range 0–2.5 kgf/cm, scale of 0.20 kgf/cm) to read the bottles’ internal pressure (Fig. 1).

It should be noted that before the mixtures were inserted into the reactors, the system was checked to identify possible leakage. The verification consisted of applying a pressure of 0.3 kgf/cm in each reactor and immersing them in a bucket of water to cover its lid and observing for 1 min if there was the release of air bubbles coming from the reactor. After observation time, it was also checked if there was a decrease in the pressure indicated by the manometer. When no leaking was detected in the system, the air inside the reactor was sucked by a vacuum pump. In case of leaking, the reactor was opened, and the sealing procedure was performed again to correct the flaw. In some cases, reactors with significant failures have been replaced [125].

It was chosen as an initial parameter to determine the proportions the series of solids, preferably total solids (ST). Proper selection of inoculum and substrate is considered a crucial factor when performing biodegradability tests to determine biogas and methane production potential [42, 55]. The moisture chosen for this work was 85%, within the recommended range for biogas generation in [125]. pH in each reactor was adjusted whenever necessary. The initial solid concentration in the system has been adjusted to 15–20% based on previous research such as Xin et al. [56]; Yan et al. [57]. The leaf:bovine manure proportions were determined based on the TS concentration. In this sense, four reactors were incubated (in triplicate): 1:1 ratio; 1:2 ratio; 1:9 ratio; 0:1 ratio; to present statistical significance.

The interval of solids used does not imply the need to add water to reduce solids loading, since the use of large amounts of water in industrial processes is viewed with caution as an increasingly scarce resource. The experiments were performed with bovine manure with banana leaves. The reactors were assembled in triplicate to calculate the standard deviation of the results obtained to produce biogas (in volume). However, the experiments were not always finished in triplicate due to the loss of reactors due to uncontrolled leakage.

After sealing the reactor’s caps, a current of nitrogen gas (N2) (99.9% of purity) was applied for a period of approximately 5 min, thus ensuring, according to Li et al. [58]; Barua et al. [59], Xu et al. [60], the conditions of anaerobiosis and internal pressure. Subsequently, the N2 pressure was relieved up to 0.10. This value is symbolic and was defined to assist in visualizing possible gas leaks throughout the test.

Then, they were placed in the incubator (MA1415/275), batch system, at temperatures ranging from 36 up to 60 °C, increasing by 2 °C every 3–5 days to adapt the anaerobic microorganisms present in the waste mass [61]. The gradual increase in temperature every 2 °C is because microorganisms can tolerate temperature fluctuations of ± 3 °C without negatively affecting biogas production [62]. A control reactor with only a sample of bovine manure was used and incubated to verify the amount of biogas produced using only such waste and making it possible to see the difference when using the banana leave mixed in the waste.

Monitoring of anaerobic codigestion

The method used to determine the volume of biogas produced was the manometric method [63, 64]. To obtain the produced volume, the following were monitored daily:internal pressure of the bottles, obtained by reading the manometers attached to the digestors and the external (environment) obtained through the Epagri website. The pressure values were then converted into biogas volume [65]. To obtain the actual biogas values (banana leaf), the volume of biogas obtained was subtracted from the biogas value produced in the control reactor (with bovine manure only), according to the procedure described by Holliger et al. [66].

Volatile solid removal efficiency (VS)

To evaluate the performance of the AcoD process, the efficiency of VS removal was analyzed, since, according to Athanasoulia et al. [67], during the AcoD, VS are converted to biogas. The VS removal percentages were calculated based on the VS concentrations before and after the tests, as recommended in Eq. (1) reported by Li et al. [68]

where VSi is the VS at the initial; VSf is the VS at the final.

Statistical analysis

Averages and standard deviation were submitted for analysis of variance (ANOVA) and after, to the Tukey Test, at 5% of significance, using Excel 2010® software and past (version 3.21). Principal component analysis (PCA) was also used to check which parameters (time and/or temperature) had the greatest influence on the biogas production of each treatment.

AcoD process kinetics in batch reactors

The experimental results of the biogas yields were validated with modified Gompertz model [69, 70], represented by Eq. (2). The performance of the model was evaluated using the coefficient of determination R2

where M(t) is the cumulative biogas yield (volume) over time (mL); A refers to the maximum biogas production potential (mL/g), μmax is the maximum production rate or velocity; (mL/day); \(\lambda\) is the lag phase duration time (days); t is the incubation time (days) and e is the Euler number (2.71828).

Results and discussion

Physical–chemical characterization

Before the incubation of the binary mixtures, it carried out the characterization of the wastes in an isolated way. Table 2 shows the results (mean values) of the analyses of the following initial parameters: total solids (TS), volatile solids (VS), moisture content (%) for each waste. The parameters were determined in triplicate.

It can be seen in Table 2 that of the TS, most were quantified as SV. The waste presents relatively high contents of TS and VS and, therefore, its use is attractive for AcoD tests for biogas production [31, 135]. Although they have a similar organic matter, content, they are completely different wastes in their composition and distribution of components. The organic fraction of bovine manure is rich in microorganisms and its organic compounds are found in the formation of the cell and its biological structures, while in agricultural waste, the fraction is organized mainly in the form of polymers, consisting of cellulose, hemicellulose and lignin [126].

The values found in relation to TS and VS parameters, for bovine manure, are cited in CIBiogás Technical Note No. 03/2019 [127]: TS of 20% and VS of 82.2% and reported by Orrico Junior et al. [128] with TS 19.2% and SV 80.9%. The high VS content in the wastes means a relatively high energy content, which is desirable from the economic point of view regarding biogas energy production. The low C/N ratio of bovine manure facilitates the balancing of the C/N ratio inside the reactor, between the substrates and the inoculum [129, 130].

According to the analysis, the banana leaf presented low moisture content. Considering the characteristic of anaerobic codigestion and the low moisture content of agricultural wastes, small portions can be used in the process of anaerobic codigestion with bovine manure [131]. However, the AD process of agricultural substrates is slow due to the recalcitrant structure of lignocellulose [58, 68] and due to its high content of solids, which is proven with the results summarized in Table 2. Thus, the AD of agricultural substrates is usually applied in a codigestion system, appearing as a possibility when using a co-substrate in the codigestion material that already contains microorganisms that may act in the consortium with those present in a reactor, especially methanogenic ones, such as bovine manure. Bovine manure presented a high moisture content, making it act as a solvent for dry biomass (agricultural wastes), making it useful as a base substrate for codigestion.

In general, lignocellulosic biomass like banana leaf has the potential to contribute significantly to biogas production. The banana leaf presented an enough biodegradable structure for the production of biogas; although it presents significant traces of lignocellulosic content, like cellulose, hemicellulose and lignin. For the banana leaf, the more significant content of cellulose may influence the resistance to biological degradation and significantly reduce its accessibility to enzymes that degrade cellulose and help the production of biogas. An important fact to be mentioned is that the lignin content is the lowest among the lignocellulosic plots, helping the access of microorganisms in the mixture of determined residues. This fact is interesting because normally, lignin provides greater rigidity to the cell wall, being more resistant to biological degradation than to cellulose and hemicellulose [124, 136]. To improve the degradability of the mixture, mechanical pretreatment of the banana leaf was performed.

All wastes used in the research (bovine manure and banana leaf) were previously characterized before incubation. Table 3 shows the detailed physical–chemical characteristics for each proportion referring to the biodegradability test of the binary mixtures of banana leaf with bovine manure. The parameters were determined in triplicate.

It was found that the largest reductions occurred in the proportion 1:9, with ST reduction efficiency of 47% and a VS reduction of 53%. The proportion 1:1 achieved a reduced efficiency of TS of 29% and SV by 23%; proportion 1:2 achieved a reduction of ST of 28% and VS of 23% and 0:1 (control) achieved a reduced efficiency of TS of 24% and VS by 37%. Solid removal presents process efficiency in biogas production, mainly in reducing VS concentration; considered an important parameter to indicate the degree of degradation of waste [71, 72] and potential for biogas production of the proportion [73, 74]. It was also found that the banana leaves showed to be a highly degradable substrate for anaerobic digestion (TS = 90.5% and VS = 90.2%) when compared to the removal percentages of the proportion containing only the bovine manure (TS = 21.8% and VS = 84.6%), that is, the banana leaf presents relatively high levels of TS and VS, and its use is attractive use for AcoD testing for biogas production purposes [75, 76]. By adding the agricultural substrate, the reduction in VS has decreased, suggesting that the fraction limits the degradation of the substrate. The same trend was observed by Ohuchi et al. [123] in the AcoD of silage with bovine manure. The unsuitable water content in the reactor results in a rapid accumulation of volatile fatty acids, especially for easily digestible raw materials that hinder the activity of methanogenic bacteria, leading to low biogas production [132].

Significant reductions have occurred, especially for the COD parameter. The high quantity of bovine manure presents high COD value, as observed in the control. The most significant reductions were 1:10 (53%); 1:2 (36%); 0:1 (33%) and 1:1 (30%) allowing a higher biogas production.

Regarding the P parameter, 1:9 proportion presented a reduction of 84%; 1:2 proportion, a reduction of 27%; 0:1 proportion to 22% and 1:1 proportion to 19%. Schwantes et al. [77], studying the anaerobic digestion of organic wastes of plant origin for the production biofertilizer, found that concentration P ranges from 1.0 to 1.8 mg/L, considered by the authors as insufficient for plant nutritional purposes and similar to the final phosphorus concentrations in this study.

The highest concentration of N was reported for the proportions containing the highest concentrations of animal manure (1:9 and 0:1), as according to Awasthi et al. [42] and Ormaechea et al. [43], animal waste presents a high nitrogen content in its composition. The largest reduction was found in 1:9 to 47%; followed by 0:1 to 40%; 1:2 to 34% and 1:4 to 30%. The greatest N reductions in the proportions, probably occur due to high concentration of carbon in the wastes and also due to removal of N-volatile forms such as NH3, components of the biogas [78]; already the low N reduction can be associated with the acidification of wastes in the reactor, compromising the degradation of more complex compounds, such as macronutrients [79,80,81].

In relation to pH, 1:1 (pH = 8.2) 1:2 (pH = 7.9) and 1: 9 (8.3) were above ideal values (6.5–8.5) [82, 83]. Karlsson et al. [84] mentioned that the increase in pH is due to the degradation of N-rich wastes (such as bovine manure) that increase the alkalinity of the medium (release of ammonia) and when reacting with CO2 gives formation to ammonium bicarbonate. Although, for biogas production, pH values close to neutrality are indicated, in general, such factor did not cause low production efficiency, in this research. Zhang et al. [121] report that the pH ranging from 7.2 to 7.4 is related to the ammonia that was present nitrogen, favoring the process of anaerobic co-digestion, as verified for the proportion 1:9.

In summary, the increase in pH and the reduction in solids are indications of the conversion of organic matter, but the amount of biogas produced is the most valuable parameter for calculating the process yield [85].

Daily rate and cumulative production of biogas

The test was monitored for a period of 60 days, with verification of the biogas production potential being daily; through the pressure variation obtained in the manometers. Figure 2 shows the daily biogas yield of each proportion (in triplicate) as a function of temperature variability.

The first biogas production peaks occurred right at the beginning of the tests: 2nd day for 1:1; 1:2 and 1:9; with a biogas volume of 23.69 mL/g VS, 55.29 mL/g VS and 65.50 mL/g VS, respectively. It is considered a phase without delay, showing the acclimatization of microorganisms and availability of readily biodegradable organic material [86] increasing biogas yield in a standard of “zigzag” [72]. It can be observed that the daily yield is little slower and lower when the substrate content is close to that of the inoculum (1:1 and 1:2) when compared to 1:9. This same low yield trend was reported by Ohuchi et al. [123] where the possible cause of inhibition was associated with the high organic load in the proportions with larger fractions of agricultural substrate. Parralejo et al. [87] reported that a higher concentration of animal manure can accelerate biogas production and reduce degradation time. The 0:1 proportion reached earlier biogas production peaks than the others, on the first day it reached 25.08 mL/g VS and on the second day, the maximum peak production with 74.57 mL/g VS. This fact shows the importance of animal additives in the accelerating of digestion and production of biogas, due to the balanced nutrients present in the manure [88, 89], confirming the theory that manure presents the capacity to accelerate the degradation of the agricultural substrate, allowing the growth of hydrolyzing microorganisms [121, 122, 124]. The daily yield was continued until 36th day (1:1; 1:2 and 1:9), although production was not uniform.

The shortest latency period (days) in biogas production was 2 days; thus indicating the possibility that the banana leaf fraction presents in its composition, easily biodegradable material [75, 76] and in bovine manure (high concentration of solids, carbohydrates, proteins, and fats) [79, 90] enabling faster production of biogas [91]. The second peak may be related to the microbial solubilization of starch and other complex substances present in banana leaves (fractions of hemicellulose and cellulose) [92, 93].

The cumulative yield was defined by Hansen et al. [94] as the maximum biogas produced, how is presented in Fig. 3.

It can be seen in Fig. 3 that the proportions presented a distinct behavior and may be associated with an increase of the growth of microorganisms in relation to the rich wastes that were inserted. The proportions 1:1 and 1:2 showed a cumulative biogas yield below the control. In this sense, the 1:1 ratio obtained a cumulative biogas yield of 69.87 mL/g VS (60th day) and 1:2 with a yield of 72.90 mL/g VS (6th day); both with the portion assigned to the negative banana leaf, since the cumulative yield of the control was 84.30 mL/g VS. The low production may be associated to the intrinsic characteristics of banana leaves, presenting a high C/N ratio, contributing to possible accumulation of organic acids or ammonia suppression during the anaerobic digestion process, resulting in low biogas productions [12, 95]; different from that found by Vats et al. [72] which concluded that the higher carbon concentration (due to the food waste fraction) significantly increased biodegradability in reactors. Despite the 1:1 and 1:2 proportions presented lower production profile during the 60 days of monitoring, even with slight temperature fluctuations; adapting to the two exposed temperature conditions (mesophilic and thermophilic).

The 1:9 proportion obtained the highest cumulative biogas yield with 113.00 mL/g VS; with the portion assigned to banana leaf 28.69 mL/g VS, corresponding to 25.39%. The results suggest that in low quantity of banana leaf in proportion (1:9); the proportion presents greater affinity of degradation between the wastes by the action of microorganisms, through access to the substrate (banana leaf) and subsequently, production of biogas [75, 96, 97] producing a synergistic effect (additional biogas volume when compared to the control). The synergistic effect is resulting from the contribution of nutritious ones, microorganisms or any other improvement that an organic waste, turning in an increase in the degradability of the wastes and increase in the biodegradability of waste and biogas yield [98]. It is verified that the higher concentration of animal manure in the proportion led to the higher biogas yield and consequently the lower C/N ratio; observation also reported by Achinas et al. [99], Sa'Diah and Putra [100], Zhao et al. [101] and Parralejo et al. [87]. The positive effect of a higher concentration of bovine manure may be due to nutrients carried from the inoculum to the substrate; a higher load of microorganisms [29], creating a favorable habitat for the accelerating of organic matter degradation in the anaerobic digestion process [102]. Another possibility that has been reported by Al-Zuhairi et al. [120] is that the higher concentration of bovine manure in relation to lignocellulosic wastes provides faster hydrolysis of more complex organic substrates that are reduced to simpler products; increasing biogas yield.

As well as the other proportions tested, the 1:9 proportion adapted well to the new conditions imposed on the system. Tietz et al. [103], confirms the theory, since when evaluating the influence of temperature on biogas production from bovine manure, biogas production was influenced by sudden temperature variations, affecting the activity of mesophilic microorganisms, resulting in the reduction of biogas production.

The optimal S/I ratio obtained for the banana leaf test with bovine manure was 0.1 based on the VS content of both wastes; providing stable operating conditions, because, in general, proportions, lower than 2.0 for the digestion of most wastes show greater efficiency in solids removal and biogas production than at higher rates [104]. In this study, it was observed that as the S/I ratio increased, the biogas yield and VS reduction decreased; this fact may be associated with the fact that banana leaves need a considerable population of microorganisms compared to easily degradable substrates (bovine manure) [29, 80]. Yang et al. [27] reported that the low S/I ratio is generally preferred to provide more methanogenic microorganisms for the rapid onset of AcoD. In addition, higher S/I rates generally reduce the alkalinity of the medium, which can lead to an inadequate system capacity to consume AGV produced in the early stage of AcoD, resulting in possible process failure [95, 105] with low biogas production yields [106, 107]. The results of this study do not agree with those reported by Pore et al. [108], even the authors using a different banana leaf substrate, reporting the optimum S/I ratio of 1.0 for AcoD of banana leave with bovine manure.

In this test, the 25:1 C/N ratio produced the highest biogas yield (1:9–113.00 mL/g VS). When the banana leaf proportion decreased, the C/N ratio showed a decreasing trend and remained in the recommended range, mainly for the 1:9 proportion (C/N 25) [121]. The results reported in the present study, support the data reported in the literature, where the reason the optimal C/N ratio is in the range 20–30 [31, 109, 110]. Biogas yield was reduced as the C/N ratio increased (C/N 39:1–1:1 and C/N 34:1–1:2) [15].

Statistical analysis

Table 4 presents the summary of the ANOVA test for the biogas production in the proportions.

Interpreting the results obtained through the ANOVA test and presented in Table 3, all the proportions presented statistically significant, since the values of F were greater than Fcritic (F > Fcritical). In addition, all proportions were statistically significant (p < 0.05). In this case, as the ANOVA statistically showed significant, the Tukey’s test was applied at the 5% significance level, to verify the statistical differences between the proportions. From the results obtained, it was verified that they differed statistically for the production biogas, corroborating with the results obtained in the laboratory, since the proportions produced biogas at higher levels than the control.

In relation the calculation of principal component analysis (PCA) (Fig. 4), the cumulative biogas yield and the variables: time and temperature were used. The main components that presented the highest self-value and that added up explain most of the total variation of the data were considered significant [111].

Component 1 has the highest percentage of the explanation of the variability of the results for the biogas yield of the proportions 1:1 and 1:2, both with 93% and, therefore, the highest weight, corroborating with the biogas yield, which for both proportions were similar. Among the variables, time presented the highest weight; therefore, the greatest influence on biogas yield [87, 112].

For the proportion 1:9, component 1 has the highest percentage of explanation of the results for the biogas yield, with 94% (higher weight). As for 1:1 and 1:2, time had the highest weight (greater influence on biogas yield, associated with proportion, composition) [113], indicating that microorganisms needed little adaptation to the environment [114].

For control, it was found that component 1 has the highest percentage of explanation of the results to produce biogas, with 93% (greater weight). The time variable presented the highest weight; being the greatest influence on biogas yield [28, 88]. It was verified with the PCA analysis that the statistical test confirms what was observed in the daily and cumulative biogas yield graphs, that is, that the temperature variable did not sign with the yield; the time (days) is presented as the primary variable so that the degradation of organic materials and biogas yield can efficiently.

Evaluation of biogas yield kinetics in batch reactors

Figure 5 illustrates the adjustments of the model to the experimental data of biogas yield in the proportions.

In Fig. 5, in general, the biogas yield curves (experimental data) fit well to the theoretical model (Gompertz equation). The arrangement of the observed points (cumulative yield) around the adjusted model characterized the model efficiency of the reactors with 60 days of operating time and thus it is observed that the estimate of biogas yield is good when using the modified Gompertz model.

Table 5 shows the parameters of the model: maximum biogas production potential (A); maximum biogas production speed (μmax) and the duration time of the lag phase (λ) with 95% confidence interval.

It was found that the highest cumulative biogas yield (A) was for the 1:9 proportion and was consistent with the maximum yield value obtained in the test. Thus, knowing that the coefficient of determination (R2) is a measure that represents the adjustment of a model in relation to the observed experimental values (varying between 0 and 1), the proportions were high (R2 > 0.90), indicating a good correlation between the experimental data and the adjustment of the model [114].

The values μmax modeled followed the trend observed in the laboratory (the higher μmax, the faster the process will stabilize). In this case, 1:2 and 1:9 were the first to stabilize. It is possible that the increase in speed occurred, due to the greater availability of animal manure [115, 116].

Regarding the duration of the lag phase (λ) (time required by the anaerobic microorganisms to adapt the proportions), the values found may have been according to the adaptation of the consortium among the wastes. It was found that the higher the proportion of lignocellulosic biomass (1:1 proportion), the longer was the duration of the lag phase; this was because the low value of λ indicated that the microorganisms needed bigger adaptation to the environment [78]. Thus, it is assumed that this factor contributed to the longer adaptation time of the biomass with the microorganisms to the consortium, due to the possible limitation of hydrolytic reactions, which may be incomplete and slow; making it difficult to hinder the availability of simple sugars in high concentrations of the cellulose component, limiting the growth of microorganisms in the medium [117]. Nielfa et al. [67] report that the higher the biodegradability of the wastes, the higher the biogas production rate, i.e., the closer to the Y-axis will be the curve (lower lag phase). It is also noted that the higher production of biogas refers to the proportion that presented the lowest lag phase (λ). For the 1:9 ratio, the delay phase was maximized by the AcoD of waste with high protein load, in this case, the bovine manure [118, 119].

In general, it can be concluded that the addition of banana leaf to bovine manure reduces the time needed for anaerobic codigestion due to the presence of sugar and digestible compounds, as long as their participation does not exceed the optimal C/N ratio of the process [132].

In general, the delay time (λ) varied due to different organic compositions (carbohydrates, proteins and lipids), presenting a synergistic influence on the total codigestion delay time. The shortest delay time was found in the 1:9 proportion, with a time of 1.07 days and the longest time was reported for the 1:1 proportion with 3.47 days.

Conclusions

The profiles of the cumulative biogas yield curves varied according to the test configurations proposed. The biodegradability tests of the different proportions showed better biogas production rates and achieved the highest cumulative biogas yield when compared to the control samples, mainly for the 1:9 proportion, due to the synergistic effect of bovine manure on agricultural fractions (providing nutrient balance and buffering capacity) promoting better biogas yields. In addition, the wastes showed good adaptability to temperature conditions (mesophilic and thermophilic), showing synergism.

The trend observed in biodegradability tests indicated that mixing substrates bring a better distribution of nutrients and availability of C/N in the processes; therefore, the substrate composition is important both for the volume of biogas yield and for the decomposition time of the waste. It was also found that VS reduction was directly correlated with biogas yield, recovering organic matter bringing several environmental benefits.

Modelling by the modified Gompertz equation showed that, depending on the proportion, the adaptation times of biomass (lag) to produce biogas varied significantly and were relatively high, even under the conditions in which the largest biogas yields were observed.

References

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass—an overview. Biores Technol 199:76–82. https://doi.org/10.1016/j.biortech.2015.08.030

Shen F, Li H, Wu X, Wang Y, Zhang Q (2018) Effect of organic loading rate on anaerobic co-digestion of rice straw and pig manure with or without biological pretreatment. Biores Technol 250:155–162. https://doi.org/10.1016/j.biortech.2017.11.037

Awe OW, Zhao Y, Nzihou A, Minh DP, Lyczko N (2017) Review of biogas utilisation, purification and upgrading technologies. Waste Biomass Valorization 8:267–283. https://doi.org/10.1007/s12649-016-9826-4

Chiumenti A, Borso FD, Limina S (2018) Dry anaerobic digestion of cow manure and agricultural products in a full-scale plant: efficiency and comparison with wet fermentation. Waste Manag 71:704–710. https://doi.org/10.1016/j.wasman.2017.03.046

Milani M, Montorsi L (2018) Energy recovery of the biomass from livestock farms in Italy: the case of Modena Province. J Sustain Dev Energy Water Environ Syst 6:464–480. https://doi.org/10.13044/j.sdewes.d6.0199

Xu F, Li Y, Ge X, Yang L, Li Y (2018) Anaerobic digestion of food waste—challenges and opportunities. Biores Technol 247:1047–1058. https://doi.org/10.1016/j.biortech.2017.09.020

Ren Y, Yu M, Wu C, Wang Q, Gao M, Huang Q, Liu Y (2018) A comprehensive review on food waste anaerobic digestion: research updates and tendencies. Biores Technol 247:1069–1076. https://doi.org/10.1016/j.biortech.2017.09.109

Valli L, Rossi L, Fabbri C, Sibilla F, Gattoni P, Dale BE, Kim S, Ong RG, Bozzetto S (2017) Greenhouse gas emissions of electricity and biomethane produced using the Biogasdoneright™ system: four case studies from Italy. Biofuels Bioprod Biorefin 11:847–860. https://doi.org/10.1002/bbb.1789

Parajuli R, Dalgaard T, Birkved M (2018) Can farmers mitigate environmental impacts through combined production of food, fuel and feed? A consequential life cycle assessment of integrated mixed crop-livestock system with a green biorefinery. Sci Total Environ 619–620:127–143. https://doi.org/10.1016/j.scitotenv.2017.11.082

Hosseini Koupaie E, Dahadha S, Lakeh Bazyar AA, Azizi A, Elbeshbishy E (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production—a review. J Environ Manag 233:774–784. https://doi.org/10.1016/j.jenvman.2018.09.106

Jang HM, Ha JH, Kim M-S, Kim J-O, Kim YM, Park JM (2016) Effect of increased load of high-strength food wastewater in thermophilic and mesophilic anaerobic co-digestion of waste activated sludge on bacterial community structure. Water Res 99:140–148. https://doi.org/10.1016/j.watres.2016.04.051

Nghiem LD, Koch K, Bolzonella D, Drewes JE (2017) Full scale co-digestion of wastewater sludge and food waste: bottlenecks and possibilities. Renew Sustain Energy Rev 72:354–362. https://doi.org/10.1016/j.rser.2017.01.062

Obulisamy PK, Chakraborty D, Selvam A, Wong JW (2016) Anaerobic co-digestion of food waste and chemically enhanced primary-treated sludge under mesophilic and thermophilic conditions. Environ Technol 37:3200–3207. https://doi.org/10.1080/09593330.2016.1181112

Chakraborty D, Karthikeyan OP, Selvam A, Wong JWC (2018) Co-digestion of food waste and chemically enhanced primary treated sludge in a continuous stirred tank reactor. Biomass Bioenergy 111:232–240. https://doi.org/10.1016/j.biombioe.2017.06.002

Mehariya S, Patel AK, Obulisamy PK, Punniyakotti E, Wong JWC (2018) Co-digestion of food waste and sewage sludge for methane production: current status and perspective. Bioresour Technol 265:519–531. https://doi.org/10.1016/j.biortech.2018.04.030

Da Ros C, Cavinatto C, Pavan P, Bolzonella D (2017) Mesophilic and thermophilic anaerobic co-digestion of winery wastewater sludge and wine lees: an integrated approach for sustainable wine production. J Environ Manag 203(Part 2, 1):745–752. https://doi.org/10.1016/j.jenvman.2016.03.029

Esposito G, Frunzo L, Giordano A, Liotta F, Pánico A, Pirozzi F (2012) Anaerobic co-digestion of organic wastes. Rev Environ Sci Bio/Technol 11:325–341. https://doi.org/10.1007/s11157-012-9277-8

Gou C, Yang Z, Huang J, Wang H, Xu H, Wang L (2014) Effects of temperature and organic loading rate on the performance and microbial community of anaerobic co-digestion of waste activated sludge and food waste. Chemosphere 105:146–151. https://doi.org/10.1016/j.chemosphere.2014.01.018

Serrano A, Siles JA, Martín MA, Chica AF, Estévez-Pastor FS, Toro-Baptista E (2016) Improvement of anaerobic digestion of sewage sludge through microwave pre-treatment. J Environ Manag 177:231–239. https://doi.org/10.1016/j.jenvman.2016.03.048

Wickham R, Galway B, Bustamante H, Nghiem LD (2016) Biomethane potential evaluation of co-digestion of sewage sludge and organic wastes. Int Biodeterioration Biodegrad 113:3–8. https://doi.org/10.1016/j.ibiod.2016.03.018

Negi S, Dhar H, Hussain A, Kumar S (2018) Biomethanation potential for co-digestion of municipal solid waste and rice straw: a batch study. Biores Technol 254:139–144. https://doi.org/10.1016/j.biortech.2018.01.070

Dahunsi SO, Oranusi S, Owolabi JB, Efeovbokhan VE (2017) Synergy of Siam weed (Chromolaena odorata) and poultry manure for energy generation: effects of pretreatment methods, modeling and process optimization. Biores Technol 225:409–417. https://doi.org/10.1016/j.biortech.2016.11.123

Matheri AN, Ndiweni SN, Belaid M, Muzenda E, Hubert R (2017) Optimising biogas production from anaerobic co-digestion of chicken manure and organic fraction of municipal solid waste. Renew Sustain Energy Rev 80:756–764. https://doi.org/10.1016/j.rser.2017.05.068

Bong CPC, Lim LY, Lee CT, Klemeš JJ, Ho CS, Ho WS (2018) The characterization and treatment of food waste for improvement of biogas production during anaerobic digestion—a review. J Clean Prod 172:1545–1558. https://doi.org/10.1016/j.jclepro.2017.10.199

Vasco-Correa J, Khanal S, Manandhar A, Shah A (2018) Anaerobic digestion for bioenergy production: global status, environmental and techno-economic implications, and government policies. Biores Technol 247:1015–1026. https://doi.org/10.1016/j.biortech.2017.09.004

Pecchi M, Baratieri M (2019) Coupling anaerobic digestion with gasification, pyrolysis or hydrothermal carbonization: a review. Renew Sustain Energy Rev 105:462–475. https://doi.org/10.1016/j.rser.2019.02.003

Yang L, Xu F, Ge X, Li Y (2015) Challenges and strategies for solid-state anaerobic digestion of lignocellulosic biomass. Renew Sustain Energy Rev 44:824–834. https://doi.org/10.1016/j.rser.2015.01.002

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555. https://doi.org/10.1016/j.rser.2015.02.032

Vrieze JDE, Smet D, Klok J, Colsen J, Angenent LT, Vlaeminck SE (2016) Thermophilic sludge digestion improves energy balance and nutrient recovery potential in full-scale municipal wastewater treatment plants. Biores Technol 218:1237–1245. https://doi.org/10.1016/j.biortech.2016.06.119

Zhang T, Mao C, Zhai N, Wang X, Yang G (2015) Influence of initial pH on thermophilic anaerobic co-digestion of swine manure and maize stalk. Waste Manag 35:119–126. https://doi.org/10.1016/j.wasman.2014.09.004

Sukhesh M, Rao P (2018) Anaerobic digestion of crop residues: technological developments and environmental impact in the Indian context. Biocatal Agric Biotechnol 16:513–528. https://doi.org/10.1016/j.bcab.2018.08.007

Chaikitkaew S, Kongjan P, O-Thong S (2015) Biogas production from biomass residues of palm oil mill by solid state anaerobic digestion. Energy Procedia 79:838–844. https://doi.org/10.1016/j.egypro.2015.11.575

Abdul Aziz NIH, Hanafiah MM, Mohamed Ali MY (2019) Sustainable biogas production from agrowaste and effluents—a promising step for small-scale industry income. Renew Energy 132:363–369. https://doi.org/10.1016/j.renene.2018.07.149

Klein M, Griess O, Pulidindi IN, Perkas N, Gedanken A (2016) Bioethanol production from Ficus religiosa leaves using microwave irradiation. J Environ Manag 177:20–25. https://doi.org/10.1016/j.jenvman.2016.03.050

Billota P, Steinmetz RLR, Kunz A, Mores R (2017) Swine effluent post-treatment by alkaline control and UV radiation combined for water reuse. J Clean Prod 140:1247–1254. https://doi.org/10.1016/j.jclepro.2016.10.033

Dollhofer V, Dandikas V, Dorn-In S, Bauer C, Lebuhn M, Bauer J (2018) Accelerated biogas production from lignocellulosic biomass after pre-treatment with Neocallimastix frontalis. Biores Technol 264:219–227. https://doi.org/10.1016/j.biortech.2018.05.068

Hillion M-L, Moscoviz R, Trably E, Leblanc Y, Bernet N, Torrijos M, Escudié R (2017) Co-ensiling as a new technique for long-term storage of agro-industrial waste with low sugar content prior to anaerobic digestion. Waste Manag 71:147–165. https://doi.org/10.1016/j.wasman.2017.10.024

Zahan Z, Othman M, Muster T (2016) Characterisation of agro-industrial wastes and their anaerobic digestion/co-digestion kinetic potential: a comparative batch study. In: Sixth international symposium on energy from biomass and waste 2016, Venice, Italy, 14–17 November 2016, pp 1–9

Rojas-Downing MM, Nejadhashemi P, Harrigan T, Woznicki SA (2017) Climate change and livestock: Impacts, adaptation, and mitigation. Clim Risk Manag 16:145–163. https://doi.org/10.1016/j.crm.2017.02.001

Schnürer A, Bohn I, Moestedt J (2016) Protocol for start-up and operation of CSTR biogas processes. In: McGenity TJ, Timmis KN, Nogales B (eds) Hydrocarbon and lipid microbiology protocols: bioproducts, biofuels, biocatalysts and facilitating tools. Springer, Berlin, pp 171–200

Janke L, Weinrich S, Leite AF, Schüch A, Nikolausz M, Nelles M, Stinner W (2017) Optimization of semi-continuous anaerobic digestion of sugarcane straw codigested with filter cake: effects of macronutrients supplementation on conversion kinetics. Bioresour Technol 245:35–43. https://doi.org/10.1016/j.biortech.2017.08.084

Awasthi SK, Joshi R, Dhar H, Verma S, Awasthi MK, Varjani S, Sarsaiya S, Zhang Z, Kumar S (2018) Improving methane yield and quality via co-digestion of cow dung mixed with food waste. Bioresour Technol 251:259–263. https://doi.org/10.1016/j.biortech.2017.12.063

Ormaechea P, Castrillón L, Suárez-Peña B, Megido L, Fernández-Nava Y, Negral L, Marañón E, Rodríguez-Iglesias J (2018) Enhancement of biogas production from cattle manure pretreated and/or co-digested at pilot-plant scale. Characterization by SEM. Renew Energy 126:897–904. https://doi.org/10.1016/j.renene.2018.04.022

Kamdem I, Hiligsmann S, Vanderghem C, Jacquet N, Tiappi FM, Richel A, Jacques P, Thonart P (2018) Enhanced biogas production during anaerobic digestion of steam-pretreated lignocellulosic biomass from Williams Cavendish Banana Plants. Waste Biomass Valor 9:175–185. https://doi.org/10.1007/s12649-016-9788-6

Ge X, Xu F, Li Y (2016) Solid-state anaerobic digestion of lignocellulosic biomass: recent progress and perspectives. Biores Technol 205:239–249. https://doi.org/10.1016/j.biortech.2016.01.050

Guerrero AB, Aguado PL, Sánchez J, Curt MD (2016) Gis-based assessment of banana residual biomass potential for ethanol production and power generation: a case study. Waste Biomass Valorization 7:405–415. https://doi.org/10.1007/s12649-015-9455-3

Fernandes ERK, Marangoni C, Souza O, Sellin N (2013) Thermochemical characterization of banana leaves as a potential energy source. Energy Convers Manage 75:603–608. https://doi.org/10.1016/j.enconman.2013.08.008

Awedem WF, Achu MBL, Happi ET (2016) Nutritive value of three varieties of banana and plan-tain blossoms from Cameroon. Greener J Agric Sci 5:52–61. https://doi.org/10.15580/GJAS.2015.2.012115009

Wobiwo FA, Alleluya VK, Emaga TH, Boda M, Fokou E, Gillet S, Deleu M, Gerin PA (2017) Recovery of fibers and biomethane from banana penducles biomass through anaerobic digestiON. Energy Sustain Dev 37:60–65. https://doi.org/10.1016/j.esd.2017.01.005

Burg V, Bowman G, Haubensak M, Baier U, Thess O (2018) Valorization of an untapped resource: energy and greenhouse gas emissions benefits of converting manure to biogas through anaerobic digestion. Resour Conserv Recycling 136:53–62. https://doi.org/10.1016/j.resconrec.2018.04.004

Tsapekos P, Kougias PG, Egelund H, Larsen U, Pedersen J, Trénel P, Angelidaki I (2017) Mechanical pretreatment at harvesting increases the bioenergy output from marginal land grasses. Renew Energy 111:914–921. https://doi.org/10.1016/j.renene.2017.04.061

Krause MJ, Chickering GW, Townsend TG, Pullammanappallil P (2018) Effects of temperature and particle size on the biochemical methane potential of municipal solid waste components. Waste Manag 71:25–30. https://doi.org/10.1016/j.wasman.2017.11.015

Brasileiro Institute of Geography and Statistics-IBGE (2018) Agricultural Census 2017, preliminary results. https://censos.ibge.gov.br/agro/2017/templates/censo_agro/resultadosagro/index.html. Accessed 16 Nov 2018 (in Portuguese)

APHA (2012) Standard methods for the examination of water and wastewater, 22nd edn. American Public Health Association, American Water Works Association, Water Environmental Federation, Washington

Koch K, Lippert T, Drewes JE (2017) The role of inoculum’s origin on the methane yield of different substrates in Biochemical Methane Potential (BMP) tests. Bioresour Technol 243:457–463. https://doi.org/10.1016/j.biortech.2017.06.142

Xin L, Guo Z, Xiao X, Xu W, Geng R, Wang W (2018) Feasibility of anaerobic digestion for contaminated rice straw inoculated with waste activated sludge. Biores Technol 266:45–50. https://doi.org/10.1016/j.biortech.2018.06.048

Yan Y, Zhang L, Feng L, Sun D, Dang Y (2018) Comparison of varying operating parameters on heavy metals ecological risk during anaerobic co-digestion of chicken manure and corn stover. Bioresour Technol 247:660–668. https://doi.org/10.1016/j.biortech.2017.09.146

Li D, Liu S, Mi L, Yuan Y, Yan Z, Liu X (2015) Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and cow manure. Biores Technol 189:319–326. https://doi.org/10.1016/j.biortech.2015.04.033

Barua VB, Rathore V, Kalamdhad AS (2018) Comparative evaluation of anaerobic co-digestion of water hyacinth and cooked food waste with and without pretreatment. Bioresour Technol Rep 4:202–208. https://doi.org/10.1016/j.biteb.2018.11.002

Xu L, Peng S, Dong D, Wang C, Fan W, Cao Y, Huang F, Wang J, Yue Z (2019) Performance and microbial community analysis of dry anaerobic codigestion of rice straw and cow manure with added limonite. Biomass Bioenerg 126:41–46. https://doi.org/10.1016/j.biombioe.2019.04.026

Schnurer A, Jarvis A (2018) Microbiology of the biogas process. In: Handbook. SLU (Swedish University of Agricultural Sciences). ISBN: 978-91-576-9546-8

Tapadia-Maheshwari S, Pore S, Engineer A, Shetty D, Dagar SS, Dhakephalkar PK (2019) Illustration of the microbial community selected by optimized process and nutritional parameters resulting in enhanced biomethanation of rice straw without thermo-chemical pretreatment. Bioresour Technol 289:121639. https://doi.org/10.1016/j.biortech.2019.121639

Hidalgo D, Martín-Marroquín JM (2015) Biochemical methane potential of livestock and agri-food waste streams in the Castilla y León Region (Spain). Food Res Int 73:226–233. https://doi.org/10.1016/j.foodres.2014.12.044

Wang B, Björn A, Strömberg S, Nges IA, Nistor M, Liu J (2017) Evaluating the influences of mixing strategies on the Biochemical Methane Potential test. J Environ Manag 185:54–59. https://doi.org/10.1016/j.jenvman.2016.10.044

Labatut RA, Angenent LT, Scott NR (2011) Biochemical methane potential and biodegradability of complex organic substrates. Biores Technol 10:2255–2264. https://doi.org/10.1016/j.biortech.2010.10.035

Holliger C, Alves M, Andrade D, Angel I, Astals S, Baier U, Bougrier C, Buffere P, Carballa M, de Wilde V, Ebertsder F, Fernández B, Ficara E, Fotidis I, Frigon JC, De Laclos HF, Ghasimi DS, Hack G, Hartel M, Heerenklage J, Horvath IS, Jenicek P, Koch K, Krautwald J, Lizasoain J, Liu J, Mosberger L, Nistor M, Oechsner H, Oliveira JV, Paterson M, Pauss A, Pommier S, Porqueddu I, Raposo F, Ribeiro T, Rusch Pfund F, Stromberg S, Torrijos M, Van Eekert M, Van Lier J, Wedwitschka H, Wierinck I (2016) Towards a standardization of biomethane potential tests. Water Sci Technol 74:2515–2522. https://doi.org/10.2166/wst.2016.336

Athanasoulia E, Melidis P, Aivasidis A (2014) Co-digestion of sewage sludge and crude glycerol from biodiesel production. Renew Energy 62:73–78. https://doi.org/10.1016/j.renene.2013.06.040

Li Y, Zhang R, Chen C, Liu G, He Y, Liu X (2013) Biogas production from codigestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Biores Technol 149:406–412. https://doi.org/10.1016/j.biortech.2013.09.091

Baêta BEL, Lima DRS, Balena JGF, Adarme OFH, Gurgel LVA, Aquino SF (2016) Evaluation of hydrogen and methane production from sugarcane bagasse hemicellulose hydrolysates by two-stage anaerobic digestion process. Bioresour Technol 218:436–446. https://doi.org/10.1016/j.biortech.2016.06.113

Baêta BEL, Lima DRS, Balena Filho JG, Adarme OFH, Gurgel LVA, Aquino SF (2016) Optimization of sugarcane bagasse autohydrolysis for methane production from hemicellulose hydrolyzates in a biorefinery concept. Bioresour Technol 200:137–146. https://doi.org/10.1016/j.biortech.2015.10.003

Abdelgadir A, Chen X, Liu J, Xie X, Zhang J, Zhang K, Wang H, Liu N (2014) Characteristics, process parameters, and inner components of anaerobic bioreactors. Biomed Res Int 2014:1–10. https://doi.org/10.1155/2014/841573

Vats N, Khan AA, Ahmad K (2019) Observation of biogas production by sugarcane bagasse and food waste in different composition combinations. Energy 185:1100–1105. https://doi.org/10.1016/j.energy.2019.07.080

Orrico ACA, Sunada NDAS, Lucas Junior JDE, Orrico Junior MAP, Schwingel ALW (2015) Codigestão anaeróbia de dejetos de suínos e níveis de inclusão de óleo de descartes. J Braz Assoc Agric Eng 25:657–664. https://doi.org/10.1590/1809-4430-Eng.Agric.v35n4p657-664/2015(in Portuguese)

McVoitte WPA, Clark G (2019) The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 5:e02140. https://doi.org/10.1016/j.heliyon.2019.e02140

Wang H, Zhang Y, Angelidaki I (2016) Ammonia inhibition on hydrogen enriched Anaerobic digestion of manure under mesophilic and thermophilic conditions. Water Res 105:314–319. https://doi.org/10.1016/j.watres.2016.09.006

Liu CM, Wachemo A, Yuan HR, Zou DX, Liu YP, Zhang L, Pang YZ, Li XJ (2018) Evaluation of methane yield using acidogenic effluent of NaOH pretreated corn stover in anaerobic digestion. Renew Energy 116(PartA):224–233. https://doi.org/10.1016/j.renene.2017.07.001

Schwantes D, Gonçalves JRAC, Richart A, Castro GMDE, Trespach FW, Scwantes N, Manfrin J (2017) Alternative biodigesters for organic waste treatment. Sci Agraria Paranaensis 16:475–484 10.18188/1983-1471/sap.v16n4p475-484

Vivan M, Kunz A, Stolberg J, Perdomo C, Techio VH (2010) Eficiência da interação biodigestor e lagoas de estabilização na remoção de poluentes em dejetos de suínos. Revista Brasileira de Engenharia Agrícola e Ambiental 14:320–325 (in Portuguese)

Costa MSSM, Lucas JRJDE, Costa LADEM, Orrico ACA (2016) Highly concentrated diet increases biogas production and the agronomic value of young bull's manure. Waste Manag 48:521–527. https://doi.org/10.1016/j.wasman.2015.09.038

Schwingel AW, Orrico ACA, Orrico Junior MAP, Sunada NDAS, Centurion SR (2016) Performance of the anaerobic co-digestion of pig manure with the inclusion of crude glycerine. Revista Ciência Agronômica 47:778–783. https://doi.org/10.5935/1806-6690.20160093

Veroneze ML, Schwantes D, Gonçalves JRAC, Richart A, Manfrin J, Schiller ADAP, Schuba TB (2019) Production of biogas and biofertilizer using anaerobic reactors with swine manure and glycerin doses. J Clean Prod 213:176–184. https://doi.org/10.1016/j.jclepro.2018.12.181

Wang K, Yin J, Shen D, Li N (2014) Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: effect of pH. Biores Technol 161:395–401. https://doi.org/10.1016/j.biortech.2014.03.088

Jaffar M, Pang Y, Yuan H, Zou D, Liu Y, Zhu B, Korai RM, Li X (2016) Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chin J Chem Eng 24:404–409. https://doi.org/10.1016/j.cjche.2015.11.005

Karlsson T et al (2014) Manual Básico de Biogás, 1st edn. Editora da Univates Rio Grande do Sul, Lajeado (in Portuguese)

Chandra R, Vijay VK, Subbarao PMV, Khura TK (2012) Production of methane from anaerobic digestion of jatropha and pongamia oil cakes. Appl Energy 93:148–159. https://doi.org/10.1016/j.apenergy.2010.10.049

Patinvoh R, Osadolor OA, Horváth IS, Taherzadeh MJ (2017) Cost effective dry anaerobic digestion in textile bioreactors: experimental and economic evaluation. Bioresour Technol 245(Part A):549–559. https://doi.org/10.1016/j.biortech.2017.08.081

Parralejo AI, Royano L, González J, González JF (2019) Small scale biogas production with animal excrement and agricultural residues. Ind Crops Prod 131:307–314. https://doi.org/10.1016/j.indcrop.2019.01.059

Song Z, Zhang C (2015) Anaerobic codigestion of pretreated wheat straw with cattle manure and analysis of the microbial community. Biores Technol 186:128–135. https://doi.org/10.1016/j.biortech.2015.03.028

Kenasa G, Kena E (2019) Optimization of biogas production from avocado fruit peel wastes codigestion with animal manure collected from juice vending house in Gimbi Town, Ethiopia. J Ferment Technol 8:1–6

Işik EHB, Polat F (2018) Effects of pretreatments on the production of biogas from cow manure. Int Adv Res Eng J 2:48–52

Yao Y, Luo Y, Yang Y, Sheng H, Li X, Li T, Song Y, Zhang H, Chen S, He W, Ren Y, Gao J, Wei Y, An L (2014) Water free anaerobic co-digestion of vegetable processing waste with cattle slurry for methane production at high total solid content. Energy 74:309–313. https://doi.org/10.1016/j.energy.2014.06.014

Tumutegyereize P, Muranga FI, Kawangolo J, Nabugoomu F (2011) Optimization of biogas production from banana peels: effect of particle size on methane yield. Afr J Biotechnol 10:18243–18251. https://doi.org/10.5897/AJB11.2442

Lima DRS, Adarme OFH, Baêta BEL, Gurgel LVA, Aquino SFDE (2018) Influence of different thermal pretreatments and inoculum selection on the biomethanation of sugarcane bagasse by solid-state anaerobic digestion: a kinetic analysis. Ind Crops Prod 111:684–693. https://doi.org/10.1016/j.indcrop.2017.11.048

Hansen TL, Schmidt JE, Angelidaki I, Marca E, Jansen JLAC, Mosbaek H, Christensen TH (2004) Method for determination of methane potentials of solid organic waste. Waste Manag 24:393–400. https://doi.org/10.1016/j.wasman.2003.09.009

Xu F, Wang F, Lin Y, Li Y (2016) Comparison of digestate from solid anaerobic digesters and dewatered effluent from liquid anaerobic digesters as inocula for solid state anaerobic digestion of yard trimmings. Biores Technol 200:753–760. https://doi.org/10.1016/j.biortech.2015.10.103

Shen FLH, Wu X, Wang Y, Zhang Q (2018) Effect of organic loading rate on anaerobic co-digestion of rice straw and pig manure with or without biological pretreatment. Bioresour Technol 250:155–162. https://doi.org/10.1016/j.biortech.2017.11.037

Cerrillo M, Viñas M, Bonmatí A (2017) Unravelling the active microbial community in a thermophilic anaerobic digester-microbial electrolysis cell coupled system under different conditions. Water Res 110:192–201. https://doi.org/10.1016/j.watres.2016.12.019

Nielfa A, Cano R, Fdz-Polanco M (2015) Theoretical methane production generated by the co-digestion of organic fraction municipal solid waste and biological sludge. Biotechnol Rep 5:14–21. https://doi.org/10.1016/j.btre.2014.10.005

Achinas S, Li Y, Achinas V, Euverink GJW (2018) Influence of sheep manure addition on biogas potential and methanogenic communities during cow dung digestion under mesophilic conditions. Sustain Environ Res 28:240–246. https://doi.org/10.1016/j.serj.2018.03.003

Sa’diah S, Putra MD (2018) Biogas production from wastes of tofu industry with effects of water hyacinth and cow manure additions. IOP Conf Series Mater Sci Eng 543:1–7. https://doi.org/10.1088/1757-899X/543/1/012097

Zhao Y, Sun F, Yu J, Cai Y, Luo X, Cui Z, Hu Y, Wang X (2018) Co-digestion of oat straw and cow manure during anaerobic digestion: stimulative and inhibitory effects on fermentation. Biores Technol 269:143–152. https://doi.org/10.1016/j.biortech.2018.08.040

Amirta R, Herawati E, Suwinarti W, Watanabe T (2016) Two-steps utilization of shorea wood waste biomass for the production of oyster mushroom and biogas—a zero waste approach. Agric Agric Sci Procedia 9:202–208. https://doi.org/10.1016/j.aaspro.2016.02.127

Tietz CM, Soares PRH, dos Santos KG (2013) Produção de energia pela biodigestão anaeróbia de efluentes: o caso da bovinocultura. Acta Iguazu 2:15–29

Cremonez PA, Sampaio SC, Teleken JG, Meier TW, Dieter J, Teleken J (2019) Influence of inoculum to substrate ratio on the anaerobic digestion of a cassava starch polymer. Ind Crops Prod 141:111709. https://doi.org/10.1016/j.indcrop.2019.111709

Shi J, Xu F, Wang Z, Stiverson JA, Yu Z, Li Y (2014) Effects of microbial and nonmicrobial factors of liquid anaerobic digestion effluent as inoculum on solidstate anaerobic digestion of corn stover. Bioresour Technol 57:188–196. https://doi.org/10.1016/j.biortech.2014.01.089

Kawai M, Nagao N, Tajima N, Niwa C, Matsuyama T, Toda T (2014) The effect of the labile organic fraction in food waste and the substrate/inoculum ratio on anaerobic digestion for a reliable methane yield. Biores Technol 157:174–180. https://doi.org/10.1016/j.biortech.2014.01.018

Zhang W, Li L, Xing W, Chen B, Zhang L, Li A, Li R, Yang R (2019) Dynamic behaviors of batch anaerobic systems of food waste for methane production under different organic loads, substrate to inoculum ratios and initial pH. J Biosci Bioeng 128:733–743. https://doi.org/10.1016/j.jbiosc.2019.05.013

Pore SD, Engineer A, Dagar SS, Dhakephalkar PK (2019) Meta-omics based analyses of microbiome involved in biomethanation of rice straw in a thermophilic anaerobic bioreactor under optimized conditions. Biores Technol 279:25–33. https://doi.org/10.1016/j.biortech.2019.01.099

Náthia-Neves G, Berni M, Dragone G, Mussatto SI, Forster-Carneiro T (2018) Anaerobic digestion process: technological aspects and recent developments. Int J Environ Sci Technol 15:2033–2046. https://doi.org/10.1007/s13762-018-1682-2

Riya S, Suzuki K, Terada A, Hosomi M (2016) Influence of C/N ratio on performance and microbial community structure of dry-thermophilic anaerobic co-digestion of swine manure and rice straw. J Med Biol Eng 5:11–14. https://doi.org/10.12720/jomb.5.1.11-14

Mardia KV, Kent JT, Bibby JM (1978) Multivariate analysis. Academic Press, New York

Wei S, Zhang H, Cai X, Xu J, Fang J, Liu H (2014) Psychrophilic anaerobic co-digestion of highland barley straw with two animal manures at high altitude for enhancing biogas production. Energy Convers Manage 88:40–48. https://doi.org/10.1016/j.enconman.2014.08.018

de Vrieze J, Gildemyn S, Vilchez-Vargas R, Jáuregui R, Pieper DH, Verstraete W, Boon N (2015) Inoculum selection is crucial to ensure operational stability in anaerobic digestion. Appl Microbiol Biotechnol 99:189–199. https://doi.org/10.1007/s00253-014-6046-3

Syaichurrozi I, Suhirman S, Hidayat T (2018) Effect of initial pH on anaerobic co-digestion of Salvinia molesta and rice straw for biogas production and kinetics. Biocatal Agric Biotechnol 16:594–603. https://doi.org/10.1016/j.bcab.2018.10.007

Bundhoo MAZ, Mohee R (2016) Inhibition of dark fermentative bio-dydrogen production: a review. Int J Hydrogen Energy 41:6713–6733. https://doi.org/10.1016/j.ijhydene.2016.03.057

Shitophyta LM, Maryudi M, Budiyono BNR (2017) Comparison of kinetic models for biogas production from rice straw. J Bahan Alam Terbarukan 6:107–111. https://doi.org/10.15294/jbat.v6i2.9325

Battista F, Fino D, Mancini G (2016) Optimization of biogas production from coffee production waste. Biores Technol 200:884–890. https://doi.org/10.1016/j.biortech.2015.11.020

Deepanraj B, Sivasubramanian V, Jayaraj S (2015) Experimental and kinetic study on anaerobic digestion of food waste: the effect of total solids and pH. J Renew Sustain Energy 7:1–13. https://doi.org/10.1063/1.4935559

Seswoya RA, Karim ATA, Darnak NA, Rahman MFA (2018) Methane potential from the digestion of food waste in a batch reactor. Int J Eng Technol 7:36–39. https://doi.org/10.14419/ijet.v7i3.23.17255

Al-Zuhairi F, Micoli L, Florio C, Ausiello A, Turco M, Pirozzi D, Toscano G (2019) Anaerobic co-digestion of municipal solid wastes with giant reed under mesophilic conditions. J Mater Cycles Waste Manage 21:1332–1340. https://doi.org/10.1007/s10163-019-00886-6

Zhang H, Luo L, Li W, Wang X, Sun Y, Sun Y, Gong W (2018) Optimization of mixing ratio of ammoniated rice straw and food waste co-digestion and impact of trace element supplementation on biogas production. J Mater Cycles Waste Manag 20:745–753. https://doi.org/10.1007/s10163-017-0634-0

Bardi MJ, Rad HA (2019) Simultaneous synergistic effects of addition of agro-based adsorbent on anaerobic co-digestion of food waste and sewage sludge. J Mater Cycles Waste Manage 22:65–79. https://doi.org/10.1007/s10163-019-00911-8

Ohuchi Y, Ying C, Lateef SA, Ihara I, Iwasaki M, Inoue R, Umetsu K (2014) Anaerobic co-digestion of sugar beet tops silage and dairy cow manure under thermophilic condition. J Mater Cycles Waste Manag 17:540–546. https://doi.org/10.1007/s10163-014-0284-4

Chaiyapong P, Chavalparit O (2016) Enhancement of biogas production potential from Acacia leaf waste using alkaline pre-treatment and co-digestion. J Mater Cycles Waste Manage 18:427–436. https://doi.org/10.1007/s10163-016-0469-0

Franqueto F, da Silva JD, Konig M (2019) Effect of temperature variation on codigestion of animal waste and agricultural residue for biogas production. BioEnergy Res. https://doi.org/10.1007/s12155-019-10049-y

Santos TN, Dutra ED, Prado AG, Leite FCB, Souza RFR, Santos DC, Abreu CAM, Simões DA, Morais JRMA, Menezes RSC (2016) Potencial for biofuels from the biomass of prickly pear cladodes: challenges for bioethanol and biogas production in dry areas. Biomass Bioenergy 85:215–222. https://doi.org/10.1016/j.biombioe.2015.12.005

CIBIOGÁS (2019) Nota Técnica: No. 03/2019—Produção de biogás a partir de dejetos da bovinocultura de leite e corte. Foz do Iguaçu, março de (in Portuguese)

Orrico ACA, Lopes WRT, Manarelli DM, Orrico Junior MAP, Sunada NDAS (2016) Codigestão anaeróbia dos dejetos de bovinos leiteiros e óleo de descartes. J Braz Assoc Agric Eng 36:537–545. https://doi.org/10.1590/1809-4430-Eng.Agric.v36n3p537-545/2016(in Portuguese)

Luo H, Liu X, Anderson B, Zhang K, Li X, Huang B, Li M, Mo Y, Fan L, Shen Q, Chen F, Jiang M (2015) Carbon sequestration potential of green roofs using mixed-sewage-sludge substrate in Chengdu World Modern Garden City. Ecol Ind 49:247–259. https://doi.org/10.1016/j.ecolind.2014.10.016

Pavlík Z, Fǒrt J, Záleská M, Pavlíková M, Tmík A, Medved I, Keppert M, Koutsoukos P, Černý R (2016) Energy-efficient termal treatment of sewage sludge for its application in blended cements. J Clean Prod 112:409–419. https://doi.org/10.1016/j.jclepro.2015.09.072

Kothari R, Pandey AK, Kumar S, Tyagi VV, Tyagi SK (2014) Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew Sustain Energy Rev 39:174–195. https://doi.org/10.1016/j.rser.2014.07.011

Salehiyoun AR, Sharifi M, di Maria F, Zilouei H, Aghbashlo M (2019) Efect of substituting organic fraction of municipal solid waste with fruit and vegetable wastes on anaerobic digestion. J Mater Cycles Waste Manage 21:1321–1331. https://doi.org/10.1007/s10163-019-00887-5

Company of Agricultural Research and Rural Extension of Santa Catarina*EPAGRI (2017) Annual synthesis of the agriculture of Santa Catarina 2014–2015. https://docweb.epagri.sc.gov.br/website_cepa/. Accessed 16 Mar 2017 (in Portuguese)

Company of Agricultural Research and Rural Extension of Santa Catarina-EPAGRI (2018) Santa Catarina Annual Agricultural Summary 2017–2018. https://docweb.epagri.sc.gov.br/website_cepa/publicacoes/Sintese_2017_18.pdf. Accessed 09 May 2019 (in Portuguese)

Saghouri M, Mansoori Y, Rohani A, Khodaparast MHH, Sheikhdavoodi MJ (2017) Modelling and evaluation of anaerobic digestion process of tomato processing wastes for biogas generation. J Mater Cycles Waste Manag 20:561–567. https://doi.org/10.1007/s10163-017-0622-4

Sawatdeenarunat C, Nguyen D, Surendra KC, Shrestha S, Rajendran K, Oechsner H, Xie L, Khanal SK (2016) Anaerobic biorefinery: current status, challenges, and opportunities. Bioresour Technol 215:304–313. https://doi.org/10.1016/j.biortech.2016.03.074

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Brazil (CAPES)—Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Franqueto, R., da Silva, J.D., Starick, E.K. et al. Anaerobic codigestion of bovine manure and banana tree leaf: the effect of temperature variability on biogas yield in different proportions of waste. J Mater Cycles Waste Manag 22, 1444–1458 (2020). https://doi.org/10.1007/s10163-020-01033-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01033-2