Abstract

In this study, stabilization/solidification of electric arc furnace dust and Pb-refining dust was investigated. Stabilization of both wastes was performed by mixing each raw waste with MgO, Portland cement, MgO with MgCl2 (magnesium oxychloride cement), and MgO with phosphate salts (magnesium phosphate cement), at ratios between 5 and 25 wt%. Stabilization/solidification processes were evaluated using EN 12457-4 standard leaching test and stabilized wastes were classified according to the 2003/33/EC Decision. Leachates of stabilized electric arc furnace dust with magnesium oxychloride and magnesium phosphate cement at 10 wt% and 5 wt%, respectively, presented lower concentrations than the regulation limits for disposal in non-hazardous waste landfills; however, the stabilized electric arc furnace dust using MgO or Portland cement at 25 wt% cannot be disposed in hazardous waste landfills. Stabilized Pb-refining dust using MgO or Portland cement at 25 wt% can be disposed of in hazardous waste landfills, whereas stabilized Pb-refining dust with magnesium oxychloride and magnesium phosphate cement at 20 wt% is suitable for disposal in non-hazardous waste landfills. The efficiency of magnesia cements stabilization is attributed to regulation of pH at 10–11, where metal solubility is diminished and positive surface charge of hydrolyzed MgO products results in high adsorption of metalloids oxy-anions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Stabilization/Solidification (S/S) is an effective treatment method of large amounts of wastes that are difficult to be treated using other methods, such as recovery or reuse, or to be simply disposed of in controlled landfills [1]. S/S can limit the solubility or mobility of hazardous substances and maintain them in their least mobile or toxic form [2]. S/S does not remove the pollutants, but is rather used as source control method in order to modify the physical and/or chemical properties of wastes [3]. Stabilization refers to those techniques that reduce the hazardous behaviour of wastes by means of chemical reactions, whereas solidification refers to techniques that can generate a monolithic solid of high structural integrity [4]. As a result, the stabilized/solidified wastes can be safely disposed of in landfills with minimal risk of leaching toxic substances and polluting soil, surface and ground water [5]. Several materials, such as Portland cement, hydrated lime, phosphoric compounds, as well as pozzolanic materials, such as fly ash, have been commonly examined and used as stabilizing additives at S/S processes [5, 6]. The appropriate stabilizing additives are selected after understanding their properties and the interactions with polluted wastes [7].

Portland cement is commonly used in production of concrete and mortar, which are structural elements and can be used in various applications, such as roads, dams, beams, panels, walls and floors. Cement-based S/S is a widely used waste treatment process, especially for immobilizing metals. S/S using cement has been shown to be effective for the immobilisation of metals [7, 8]. The specific properties of high strength, reduced permeability, high durability and availability render cement a good binder for S/S processes [3].

Caustic calcined magnesia is used as a dietary supplement of magnesium for animal feedstuff, as well as for the production of fertilizers and soil amendment applications. It is also used in constructions, specifically for the manufacture of lightweight insulating panels, building boards and mortars for magnesia cements, which are suitable for industrial floors, grinding wheels and polishing stones [9]. Magnesia can be used in environmental technology for a variety of applications, such as soil decontamination, flue gas desulfurization, wastewater and waste treatment, as well as in hydrometallurgy for purification of acid leach solutions. Magnesium oxychloride cement (MOC), also known as Sorel cement, is based on MgO and MgCl2 and it is considered as non-hydraulic and rapid hardening cement. It can be used as an alternative cementitious agent in S/S processes [10]. Magnesium phosphate cement (MPC) is formed at room temperature by acid–base reaction between MgO and a phosphate source. It is worth noting that phosphate salts present very low solubility, which render MPC a promising S/S additive [11].

Electric arc furnace dust (EAFD) is classified as an environmentally hazardous waste worldwide. Hydrometallurgical and pyrometallurgical techniques have been developed, also at industrial scale, for metals recovery of EAFD, such as Zn, Pb and Fe. In Greece almost the entire quantity of EAFD is either transported abroad or temporarily deposited at industrial sites [12]. A common practice is followed for Pb-ReFining Dust (Pb-RFD) in Greece, as it is a by-product of pyrometallurgical and/or hydrometallurgical Pb recovery.

Extended research has been conducted in the literature in order to stabilize metals using magnesia and magnesia cements (MOC, MPC) [10, 13,14,15,16,17]. However, the stabilization of EAFD using magnesia or magnesia cements is limited. Specifically, it has been proposed the stabilization of EAFD using low-grade magnesia [13, 14]. Portland cement has been the most widely applied ingredient in metal S/S processes [1]. Portland cement, as well as Portland cement with lime, has been used in order to stabilize Pb and Zn in EAFD [18]. Additionally, Pb-RFD stabilization has not been studied yet using magnesia or various types of cements (magnesia or Portland cement).

In this study, an efficient S/S process, which can allow the safe disposal of EAFD and Pb-RFD in appropriate landfill sites, is proposed. An interesting approach, aiming to reduce the environmental and health impact of EAFD and Pb-RFD, is S/S using MOC and MPC. Low-grade MgO and Portland cement were also examined in this research for the stabilization of EAFD and Pb-RFD, to compare the respective results with those obtained using magnesia cements.

Materials and methods

Low-grade magnesia (MgO) is a product of Grecian Magnesite S.A. (caustic calcined microcrystalline magnesite) of 83.4% nominal purity, while Ordinary Portland Cement (OPC) is CEM II type with high resistance (42.5 MPa). MgCl2·6H2O (contains 47% MgCl2) and KH2PO4 are reagents of industrial grade.

Toxic elements could be fixed in the resulting hydrated compounds through the respective hydration reactions during cement-based S/S process [19]. The fixation effects are different for the various pollutants, as well as the mobility of metals in the final stabilized products after the S/S treatment. The mechanism of S/S can be written in a simplified way as [20]:

where A refers to Portland cement, B refers to solid waste containing metals, M refers to metal, H(M)OH2 refers to hydrated compound containing the M.

MOC is produced by mixing MgO with MgCl2 [10]. The bonding phase of MOC is formed according to the following chemical reactions:

Different variants of MPC can be formed, based on the phosphate source used, i.e., magnesium ammonium phosphate cement, using as raw material NH4H2PO4, and magnesium potassium phosphate cement, using as raw material KH2PO4. The reactions are summarized as follows [11, 17]:

EAFD is a by-product of steel production in scrap recycling facilities [12]. Pb-RFD is produced during the secondary lead (re-smelting) production [21]. The Iso-Electric Point (IEP) in a water dispersion of MgO was determined by the curve of zeta-potential at 20 ± 1 °C using a Rank Brothers Micro-electrophoresis Apparatus Mk II device. The crystalline structure of each produced powder was identified by X-Ray Diffractometry (XRD) using a water-cooled BRUKER D8 Advance with CuKa radiation, a step size of 0.05° and step time of 3 s, operating at 40 kV and 40 mA. Fourier Transformed Infrared (FTIR) spectra of materials were recorded in KBr media using a Perkin Elmer Spectrum 100 spectrophotometer. Scanning Electron Microscopy (SEM) images were obtained using a Quanta 200 ESEM FEG FEI microscope with a field-emission gun operating at 15–30 kV, supported by an Energy-Dispersive Spectroscopy (EDS) analyzer.

The standard leaching test EN 12457-4 was performed by using deionized water as a solvent at liquid per solid ratio (L/S) 10 L/kg and selected to characterize the initial raw wastes, as well as the stabilized EAFD and Pb-RFD structures. An easily applicable method was followed, specifically each waste was mixed with MgO, OPC, MOC, and MPC at ratios 5–25 wt% in a mixing machine and deionized water was accordingly added. MgCl2 was added on a stoichiometric ratio with MgO following the above reaction (phase 5), while KH2PO4 was added between 1.5 and 5% based on MgO. The stabilized structures were subjected to the ΕΝ 12457-4 leaching test after aging of the structures for 15 days and sieving or crushing at a particle size of less than 10 mm. The classification of the initial wastes, as well as of the stabilized structures, was based on the 2003/33/EC Council Decision, regarding the acceptance of wastes in appropriate landfills [22]. Metal concentrations of the leachates were determined using Atomic Absorption Spectrophotometry (AAS), either with flame (Perkin Elmer Analyst 400), or with graphite furnace (Perkin Elmer Analyst 800).

Results and discussion

MgO characteristics related to solid wastes stabilization

FTIR spectrum and IEP of MgO is shown in Fig. 1. The characteristic broad band at 450 cm−1 is attributed to the vibration of Mg–O, while the medium peaks at 870 and 1050 cm−1 confirm the Mg–O bending vibrations. Peaks at 3700 and 3400 cm−1 correspond to the O–H stretching vibration of the adsorbed H2O on the surface of MgO (moisture of MgO) (Fig. 1a). The strong band at 1450 cm−1 can be attributed to the C=O stretching vibration of carbonate anions of caustic calcined MgO [23]. The IEP of MgO was identified by plotting the zeta-potential curve at the pH range 9–14 (Fig. 1b). The surface becomes practically neutral at approximately 12. Such high IEP value indicates that the surface charge of hydrolyzed MgO-compounds is positive at pH range lower than 12, favoring thus the adsorption of metals hydroxyl-anions forms as well as metalloid oxy-anions.

EAFD and Pb-RFD leaching characteristics

The leaching characteristics of raw EAFD and Pb-RFD samples are presented in Table 1. As shown in Table 1, the leached Hg (1.5 mg Hg/kg) and Se (1.2 mg Se/kg) concentrations from EAFD exceed the respective regulation limits of 0.2 mg Hg/kg and 0.5 mg Se/kg for disposal in non-hazardous waste landfills. Furthermore, the leached concentration of Pb, i.e., 650 mg Pb/kg, exceeds the limit value of 50 mg Pb/kg for disposal even in hazardous waste landfills, which is attributed to high pH value (Table 1). Therefore, EAFD cannot be accepted for disposal even in hazardous waste landfills. The high [OH−] concentration at pH greater than 12 favor the transformation of Pb in the extremely soluble form of Pb(OH)42− according to the following reaction, resulting in soluble concentration greater than 100 mg Pb/kg [24].

In contrast, at a pH range lower than 11.5 Pb(OH)2 becomes the predominant Pb species, resulting in soluble concentrations significantly lower than 100 mg Pb/kg (Fig. 1). Generally, the high [OH−] concentration favors the leachability of metals through the formation of metal hydroxyl-anions (reaction 1) and metalloid oxy-anions. According to the literature, EAFD contains considerable quantities of Zn, Fe, Pb, Ca and Mg, as well as significant amounts of Cd, Cr, Cu, Mn and Sb [24, 25]. However, the results revealed that Zn leaching is limited at pH range 11 ± 1, which is reassured by Mitrakas et al. [24] and Kavouras et al. [26].

The leached As, Cd, Hg, Pb and Se concentrations from Pb-RFD, which are 4.5 mg As/kg, 2.2 mg Cd/kg, 1.5 mg Hg/kg, 11 mg Pb/kg and 4.3 mg Se/kg, exceed the respective limit concentration values for disposal in non-hazardous waste landfills, while fulfill the regulation limits for disposal in hazardous waste landfills (Table 1). The significant solubility of Cd, Hg and Pb [27], as well as of As, Sb and Se oxy-anions, is attributed to high alkaline pH value of Pb-RFD. The leached Sb concentration (12 mg/kg) exceeds the limit value for disposal even in hazardous waste landfills, which is 5 mg Sb/kg. Consequently, Pb-RFD cannot be accepted for disposal even in hazardous waste landfills without any treatment.

EAFD stabilization/solidification

The leachates’ pH values of stabilized EAFD with MOC, MPC, MgO or OPC are given in Table 2, since pH is a decisive parameter of metals and metalloids solubility. The leachates’ pH range 9.8–10.3 of stabilized EAFD samples using MOC and MPC are expected to show satisfactory leaching characteristics.

The concentrations of Hg in the leachates, produced from the stabilized EAFD structures with different additives, are presented in Table 3. Hg concentrations were below the respective limit values for disposal in inert waste landfills (0.01 mg Hg/kg) after incorporation of more than 10 wt% of additive for all the examined S/S processes.

Figure 2a shows the Pb leached concentrations and Fig. 2b shows the Se leached concentrations of the stabilized EAFD structures after 15 days aging time, using different ratios of the examined additives. Pb and Se concentrations were found below the respective regulation limits for disposal in non-hazardous waste landfills (10 mg Pb/kg and 0.5 mg Se/kg), when MOC and MPC S/S processes were used. MgO or OPC addition to EAFD did not decrease the pH of the leachates, as MgO and OPC are highly alkaline additives; therefore Pb and Se leaching was not limited satisfactorily. However, EAFD treatment using MOC and MPC mixtures was found capable to reduce significantly the leaching behavior of metals, as pH values of the leachates of the stabilized structures were reduced at around 10. The reduction of metals leaching can be partly attributed to the pH buffering activity of magnesia cements and partly to their encapsulation properties [9]. The pH buffers around 10, where Pb and most heavy metals reach their lowest solubility.

The positive contribution of magnesium based cements in diminishing metals and metalloids solubility is attributed to magnesium hydrolysis to Mg(OH)2, which regulates the pH in the range 10–11.

Metals As previously mentioned at pH values lower than 11 the formation of metal hydroxides [M(OH)x] predominates, the solubility of which diminishes due to high concentration of [OH−]. For instance, the solubility of Pb (Ksp·Pb(OH)2 = 4.2 × 10–15) at pH 10 is 87 μg/L.

Metalloids They are dissolved in oxy-anions forms, e.g., AsO43−/AsO33−, Sb(OH)4−/Sb(OH)6−, SeO32−/SeO42−. The IEP of hydrolyzed MgO is 12 (Fig. 1b), which means that its surface charge in pH range 10–11 is strongly positive resulting in turn in high adsorption capacity of oxy-anions, as verified by Tresintsi et al. [28].

MOC and MPC S/S processes managed to reduce pH values of the stabilized EAFD structures. The leachates’ pH values were ranged at 9.8–10.3, where solubility of metals is minimized; hence, this alkalinity aids in their immobilization [9, 11, 23]. The solubility of metals and metalloids, which is favored at high alkaline pH values, was decreased by using the alkaline additives of MgO and OPC (Table 2). Using MgO and OPC did not significantly modify the leaching pH values (pH > 11.5), since EAFD presents similar alkaline behaviour, resulting in high metal leaching concentrations [18]. Conclusively, mixing EAFD with MOC in proportions greater than 10 wt%, as well as with MPC at 5 wt%, resulted in the production of stabilized wastes acceptable in non-hazardous waste landfills, according to the 2003/33/EC Council Decision.

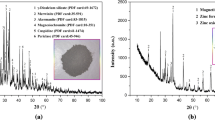

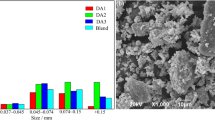

The XRD data of EAFD, along with the stabilized one using MPC at 5 wt% are presented in Fig. 3a, while the FTIR spectrum of stabilized EAFD with MPC 5 wt% is presented in Fig. 3b and SEM micrograph in Fig. 3c. The main crystal phases of EAFD were franklinite (ZnO·Fe2O3), zinc oxide (ZnO) and sylvine (KCl), which were not significantly modified by the addition of MPC. The stabilized EAFD shows high homogeneity both in morphology and composition, while its grains are spherical in shape. The dominant elements were Zn and Fe, while large percentages of Na, K, Pb and Ca were also detected. The characteristic peak of Mg–O at 450 cm−1 is distinguished, while the strong band at 560 cm−1 is ascribed to Pb–O of EAFD. The broad band at 3100 cm−1 is characteristic of the O–H stretching vibration of water, while the band at 1500 cm−1 is due to the O–H bending vibration of water. The medium band at 1450 cm−1 is attributed to the stretching vibration of C=O of calcite impurity of MgO. The wide band at 1050 cm−1 reveals the formation of MPC, as it is characteristic of asymmetric stretching vibration of PO43− [23, 29, 30]. Conclusively, FTIR spectrum did not reveal new structures, as well as the corresponding XRD data, since metals are stabilized as amorphous oxy-hydroxides [M(OH)x].

Pb-RFD stabilization/solidification

The leachates’ pH values of the stabilized Pb-RFD with MOC, MPC, MgO and OPC are given in Table 4, as pH is a crucial parameter of metals and metalloids solubility as previously mentioned. Figure 4 shows the respective Se (Fig. 4a) and Sb (Fig. 4b) leached concentrations of the stabilized Pb-RFD structures after 15 days aging time, using different proportions of the examined additives. The leachates of stabilized Pb-RFD with:

MOC at percentage up to 20 wt% showed Se concentrations below the limit values for disposal in non-hazardous waste landfills (0.5 mg Se/kg), while at 25 wt% Se concentration was below the limit value for disposal in inert waste landfills (0.1 mg Se/kg). In contrast, Sb concentration was below the limit value for disposal in non-hazardous waste landfills (0.7 mg Sb/kg) only at MOC percentage 20 wt%.

MPC at percentage 20 wt% revealed Se and Sb concentrations below the limit values for disposal in non-hazardous waste landfills.

MgO at percentage up to 20 wt% revealed Se and Sb concentrations below the limit values for disposal in hazardous waste landfills, while at 25 wt% were below the limit values for disposal in inert and non-hazardous waste landfills respectively.

OPC at percentage up to 25 wt% showed Se and Sb concentrations below the limit values for disposal in hazardous waste landfills.

Table 5 presents the concentrations of As, Cd, Hg and Pb in the leachates. MOC diminished the concentrations of all elements in leachates below the respective limit concentration values for disposal in inert waste landfills. MPC diminished also the concentrations of As, Cd, Hg and Pb in the leachates below the respective limit concentration values for disposal in non-hazardous waste landfills. Magnesia cements managed to adjust pH values in the range of 7.5–11, where most heavy metals exhibit low solubility [31]. MgO and OPC S/S processes resulted in leachate concentrations of As, Cd and Hg within the inert wastes range, while Pb concentrations were below the respective limit concentration values for disposal in non-hazardous waste landfills. The lower metals’ solubility is related to the lower pH value of Pb-RFD than EAFD. MgO and OPC S/S process can better fix metals at Pb-RFD [13, 15, 20] than at EAFD, due to pH variation in the range of 10.3 ± 0.3 (Table 4). Conclusively, the stabilized wastes can be accepted for disposal in hazardous waste landfills, while the addition of 20 wt% MOC, 20 wt% MPC and 25 wt% MgO resulted in stabilized wastes acceptable in non-hazardous waste landfills, according to the 2003/33/EC Decision.

The XRD data of Pb-RFD, along with the stabilized one using MPC at 20 wt% are presented in Fig. 5a, while the FTIR spectrum of stabilized Pb-RFD with MPC 20 wt% is presented in Fig. 5b and SEM micrograph in Fig. 5c. The main crystalline phases of Pb-RFD were thenardite (Na2SO4), magnetite (Fe3O4), quartz (SiO2) and lead oxide sulphate (PbO·PbSO4), which similarly to EAFD were not significantly modified by the addition of MPC. The stabilized Pb-RFD is consisted of sharp grains with wide size distribution. Corresponding EDS analysis indicated the presence of various compounds with Fe, Pb, K, S and Na appearing as the major elements.

The broad band in the region of 2450 and 3650 cm−1 with peak centered at 3050 cm−1, as well as the medium band at 2350 cm−1 can be assigned to the O–H stretching vibrations of water. Additionally, the medium intense band at 1670 cm-1 indicates the O–H bending vibration of water. The strong peaks at 1000 and 1100 cm−1 belongs to the asymmetric and symmetric stretching vibrations of PO43− due to MPC, whereas the double intense peak at 650 cm−1 is characteristic of metal–oxygen bonds (M–O) and can be attributed to Pb–O of Pb-RFD [23, 29, 30]. Conclusively, the addition of MPC did not modify the structure of Pb-RFD, while its buffer capacity at pH range 10–10.5 diminished the metals’ solubility, while its positive surface charge density favored the adsorption of metalloid (As, Sb, Se) oxy-anions, resulting in optimum leaching characteristics of S/S process.

Conclusion

Several additives, i.e., low-grade magnesia (MgO), Sorel cement (MOC), magnesium phosphate cement (MPC) and Portland cement (OPC) were examined, aiming to stabilize metals and metalloids content of two hazardous industrial solid wastes (EAFD and Pb-RFD), in order to be safely disposed either in non-hazardous or hazardous waste landfills according to the Council Decision 2003/33/EC.

Stabilized EAFD either with MOC 10 wt% or 5 wt% MPC can be disposed of in non-hazardous waste landfills, according to the EC regulation. The dependence of heavy metals leaching by pH was observed at this study, as well as at similar studies [14, 15]. Solubility of most metal and metalloid hydroxides/oxides, such as Pb and Cd was minimal within pH range 9–11. MPC was a very effective stabilizing agent for metals and metalloids, which was also observed by Buj et al. especially regarding Ni, Pb, Cu and Zn [17]. No mineralogical transformation was undergone because of the use of MgO, which was confirmed by past studies [14]. In contrast, OPC and MgO additives manage to limit metals and metalloids concentration in the leachates within the range of hazardous wastes. OPC and MgO provided better results in metal stabilization at high percentages addition of these binding materials [14, 18]. The stabilized Pb-RFD can be disposed of in hazardous waste landfills, while the addition of 20 wt% MOC or MPC resulted in stabilized wastes acceptable in non-hazardous waste landfills, according to the 2003/33/EC Decision.

In conclusion, caustic calcined magnesia in magnesia cements is proposed for the stabilization of dusts, such as EAFD and Pb-RFD. Specifically, MPC showed promising results. Additionally, MPC as a chloride-free cement seems to be the object for future studies. Optimization of the used additives during the production of MPC can further improve the performance of magnesia cement as S/S additive.

Abbreviations

- AAS:

-

Atomic absorption spectrophotometry

- EAFD:

-

Electric arc furnace dust

- EDS:

-

Energy-dispersive spectroscopy

- FTIR:

-

Fourier transformed infrared

- IEP:

-

Iso-electric point

- L/S:

-

Liquid per solid

- MOC:

-

Magnesium oxychloride cement/Sorel cement

- MPC:

-

Magnesium phosphate cement

- OPC:

-

Ordinary Portland cement

- Pb-RFD:

-

Pb-Refining dust

- SEM:

-

Scanning electron microscopy

- S/S:

-

Stabilization/solidification

- XRD:

-

X-Ray diffractometry

References

Conner JR, Hoeffner SL (1998) The history of stabilization/solidification technology. Crit Rev Environ Sci Technol 28:325–396. https://doi.org/10.1080/10643389891254241

US EPA (1986) Handbook for stabilization/solidification of hazardous wastes. https://clu-in.org/download/contaminantfocus/dnapl/Treatment_Technologies/SS-Handbook.pdf. Accessed 3 Nov 2016

John UE, Jefferson I, Boardman DI, Ghataora GS, Hills CD (2011) Leaching evaluation of cement stabilisation/solidification treated kaolin clay. Eng Geol 123:315–323. https://doi.org/10.1016/j.enggeo.2011.09.004

Coz A, Andres A, Soriano S, Irabien A (2004) Environmental behaviour of stabilised foundry sludge. J Hazard Mater B109:95–104. https://doi.org/10.1016/j.jhazmat.2004.03.002

Moon DH, Dermatas D (2007) Arsenic and lead release from fly ash stabilised/solidified soils under modified semi-dynamic leaching conditions. J Hazard Mater 141:388–394. https://doi.org/10.1016/j.jhazmat.2006.05.085

Jing C, Liu S, Korfiatis G, Meng X (2006) Leaching behavior of Cr(III) in stabilized/solidified soil. Chemosphere 64:379–385. https://doi.org/10.1016/j.chemosphere.2005.12.039

Chen QY, Tyrer M, Hills CD, Yang XM, Carey P (2009) Immobilisation of heavy metal in cement-based solidification/stabilisation: a review. Waste Manag 29:390–403. https://doi.org/10.1016/j.wasman.2008.01.019

Ballesteros F, Manila AA, Choi AES, Lu MC (2019) Electroplating sludge handling by solidification/stabilization process: a comprehensive assessment using kaolinite clay, waste latex paint and calcium chloride cement additives. J Mater Cycles Waste Manag 21:1505–1517. https://doi.org/10.1007/s10163-019-00903-8

Zampetakis Th, Yiannoulakis H, Meidani A, Zouboulis AI, Zebiliadou O, Pantazopoulou E (2014) Use of magnesia cement in industrial waste cementation. In: 34th cement and concrete science conference, Sheffield

Jianli M, Youcai Z, Jinmei W, Li W (2010) Effect of magnesium oxychloride cement on stabilization/solidification of sewage sludge. Constr Build Mater 24(1):79–83. https://doi.org/10.1109/ICBBE.2009.5162700

Iyengar SR, Al-Tabbaa A (2007) Developmental study of a low-pH magnesium phosphate cement for environmental applications. Environ Technol 28:1387–1401. https://doi.org/10.1080/09593332808618899

Pantazopoulou E, Zebiliadou O, Bartzas G, Xenidis A, Zouboulis A, Komnitsas K (2015) Industrial solid waste management in Greece: the current situation and prospects for valorization. In: The 30th international conference on solid waste technology and management, Philadelphia (USA). J Solid Waste Technol Manag 383–394

Cubukcuoglu B, Ouki SK (2012) Solidification/stabilization of electric arc furnace waste using low grade MgO. Chemosphere 86:789–796. https://doi.org/10.1016/j.chemosphere.2011.11.007

Fernandez AI, Chimenos JM, Raventos N, Miralles L, Espiell F (2003) Stabilization of electrical arc furnace dust with low-grade MgO prior to landfill. J Environ Eng 129:275–279. https://doi.org/10.1061/(asce)0733-9372(2003)129:3(275)

Garcia MA, Chimenos JM, Fernandez AI, Miralles L, Segarra M, Espiell F (2004) Low-grade MgO used to stabilize heavy metals in highly contaminated soils. Chemosphere 56:481–491. https://doi.org/10.1016/j.chemosphere.2004.04.005

Torras J, Buj I, Rovira M, Rablo J (2011) Semi-dynamic leaching tests of nickel containing wastes stabilized/solidified with magnesium potassium phosphate cements. J Hazard Mater 186:1954–1960. https://doi.org/10.1016/j.jhazmat.2010.12.093

Buj I, Torras J, Rovira M, De Pablo J (2010) Leaching behaviour of magnesium phosphate cements containing high quantities of heavy metals. J Hazard Mater 175:789–794. https://doi.org/10.1016/j.jhazmat.2009.10.077

Salihoglu G, Pinarli V (2008) Steel foundry electric arc furnace dust management: stabilization by using lime and Portland cement. J Hazard Mater 153:1110–1116. https://doi.org/10.1016/j.jhazmat.2007.09.066

Malviya R, Chaudhary R (2004) Study of the treatment effectiveness of a solidification/stabilization process for waste bearing heavy metals. J Mater Cycles Waste Manag 6:147–152. https://doi.org/10.1007/s10163-004-0113-2

Zhang J, Liu J, Li C, Jin Y, Nie Y, Li J (2009) Comparison of the fixation effects of heavy metals by cement rotary kiln co-processing and cement based solidification/stabilization. J Hazard Mater 165:1179–1185. https://doi.org/10.1016/j.jhazmat.2008.10.109

Zabaniotou A, Kouskoumvekaki E, Sanopoulos D (1999) Recycling of spent lead: acid batteries: the case of Greece. Resour Conserv Recycl 25:301–317. https://doi.org/10.1016/s0921-3449(98)00071-8

Council of the European Union (2003) 2003/33/EC: Council decision of 19 December 2002 establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Official Journal of the European Communities, Brussels. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32003D0033&from=EL. Accessed 29 Dec 2019

Socrates G (2000) Infrared and Raman characteristic group frequencies: tables and charts. Wiley, London

Mitrakas M, Sikalidis C, Karamanli Th (2007) Immobilization of EAFD heavy metals using acidic materials. J Environ Sci Health Part A-A 42(4):535–541. https://doi.org/10.1080/10934520701189794

De Souza CAC, Machado AT, De Andrade Lima LRP, Cardoso RJC (2010) Stabilization of electric-arc furnace dust in concrete. Mater Res 13:513–519. https://doi.org/10.1590/S1516-14392010000400014

Kavouras P, Ioannidis ThA, Kehagias Th, Tsilika I, Chrissafis K, Kokkou S, Zouboulis A, Karakostas Th (2007) EAFD-loaded vitreous and glass-ceramic materials. J Eur Ceram Soc 27:2317–2323. https://doi.org/10.1016/j.jeurceramsoc.2006.07.021

Lassin A, Piantone P, Burnol A, Bodenan F, Chateau L, Lerouge C, Crouzet C, Guyonnet D, Bailly L (2007) Reactivity of waste generated during lead recycling: an integrated study. J Hazard Mater A139:430–437. https://doi.org/10.1016/j.jhazmat.2006.02.055

Tresintsi S, Simeonidis K, Katsikini M, Paloura EC, Bantsis G, Mitrakas M (2014) A novel approach for arsenic adsorbents regeneration using MgO. J Hazard Mater 265:217–225. https://doi.org/10.1016/j.jhazmat.2013.12.003

Suryawanshi VB, Chaudhari RT (2014) Synthesis and characterization of struvite-k crystals by agar gel. J Cryst Process Technol 4:212–224. https://doi.org/10.4236/jcpt.2014.44026

Xu B, Lothenbach B, Leemann A, Winnefeld F (2018) Reaction mechanism of magnesium potassium phosphate cement with high magnesium-to-phosphate ratio. Cem Concr Res 108:140–151. https://doi.org/10.1016/j.cemconres.2018.03.013

Conner JR, Hoeffner SL (1998) A critical review of stabilization/solidification technology. Crit Rev Environ Sci Technol 28(4):397–462. https://doi.org/10.1080/10643389891254250

Acknowledgements

This research has been co-financed by the European Union (European Social Fund—ESF) and Greek national funds through the Program “PAVET”—Project: Environmental applications of magnesia and utilization of produced by-products. Authors would like to thank Anna Esther Carrillo for the technical assistance during SEM observations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pantazopoulou, E., Ntinoudi, E., Zouboulis, A.I. et al. Heavy metal stabilization of industrial solid wastes using low-grade magnesia, Portland and magnesia cements. J Mater Cycles Waste Manag 22, 975–985 (2020). https://doi.org/10.1007/s10163-020-00985-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-00985-9