Abstract

With ever increase in the consumption of bottled beverages; waste polyethylene terephthalate (wPET) bottles are rapidly emerging as a major constituent of urban waste. Amongst the various chemical techniques in vogue for recycling of wPET, glycolysis shows distinct advantage due to its ability to synthesize value added products. The current work was carried with the aim of optimizing the reaction conditions for microwave-induced catalytic glycolysis of wPET. As a first step, the effect of various cations like Zn, Ti, Fe and Co ions is reported which showed that zinc ions exhibit higher efficiency. In the second step the effect of variation in the loading of ethylene glycol (EG) glycolyzing agent showed that above a certain limit, the yield of bis-hydroxyethyl terephthalate monomer (BHET) reduced. In order to find the optimum ratio of reactants (wPET: EG) and weight of catalyst, a Taguchi design of experiments was formulated and experiments were carried. Our results show that at an optimal condition of 1:3 wPET: EG with a 1 wt% of zinc acetate gives a 65% molar yield of BHET product within 30 min.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyethylene terephthalate (PET) is a versatile thermoplastic polymer resin possessing excellent thermal and mechanical properties, crystal clear transparency and non-toxic nature and is widely used in the manufacture of products such as food packaging material, water and soft-drink bottles, synthetic fiber, insulating plastic films, etc. The global annual consumption of PET has exceeded 50 million tons and is one of the major constituents of urban waste (8% by volume and 12% by weight). Though PET is not a direct hazard to the environment, its insensitivity to either hydrolytic or oxidative or microbial degradation in air and soil makes PET an obnoxious material [1, 2]. Most municipalities or large cities recycle plastics in an unsustainable manner by simply burning all combustible polymer wastes in incinerators and generating small amounts of electricity. Though this is an easy method, it is environmentally unsustainable since large amounts of green house gases like CO2 and CO are emitted into the atmosphere.

Recycling of PET can be broadly classified as mechanical and chemical techniques. In the mechanical technique, waste PET (wPET) is simply re-extruded as granules and fibers which usually end up as feed stock for low-cost polymer fiber and door mats. This simple technique has disadvantages such as discoloration of wPET from transparent to gray and partial reactivation of antimony catalyst thereby making physically recycled PET unsuitable for food and beverage packaging.

Chemical recycling processes involves either total depolymerizing or partially depolymerizing wPET into individual monomers. PET is commonly produced by poly-condensation reaction, though this reaction is completely reversible, but the entropy of reverse reaction is very high. Many types of chemical recycling of wPET are in vogue of which alcoholysis [3], glycolysis, [4], methanolysis, [5, 6] and hydrolysis [7] are the most common. Of these, glycolysis which involves insertion of glycols like ethylene glycol (EG) [8] or diethylene glycol (DEG) [9] or tri-ethylene glycol (TEG) [10] in PET chains to give bis (2-hydroxyethyl) terephthalate (BHET) is the most widely investigated. The BHET product of glycolysis reaction is very useful in synthesis of ‘value added’ secondary products such as poly- and vinyl esters, polyurethanes, epoxy resins, etc. Besides, the glycolysis reaction can be carried out at moderate temperatures (mostly in the vicinity of melting point of PET) and at normal pressures, whereas other processes like methanolysis [11] and hydrolysis [12] are carried out at much higher pressures and temperatures. Though glycolysis reaction is simple, the reaction is slow and necessitates use of metal catalysts like zinc, cobalt, manganese, etc. Furthermore, the reaction time is very long, spanning to at least 7–8 h [13], and the yield of product oligomers is in the range of 60–70%. Therefore, in order to fasten the rate of reaction, microwave synthesis has been used. Previous reports by Aguado et al. [14], Krzan et al. [15], and Karayannidis et al. [16] have studied the feasibility of microwave-induced glycolysis of wPET. Though these works have reported the feasibility of microwave in depolymerization of wPET, there are no systematic studies on optimization of reaction conditions in microwave glycolysis of wPET.

Ever since the introduction of Design of Experiments (DOE) in early 1920s by Fisher in agricultural sciences [17] aimed to study the effects of interaction between the variables, many DOE experimental designs like full factorial design, central composite design (CCD) [18], response surface methodology (RSM) [19, 20], etc. have been widely used in optimization of compounding ingredients in formulations. Though these designs will identify all the possible combinations for a given set of factors, the number of experiments that needs to be carried out will grow exponentially when there are more factors. In 1940s, Dr. Genichi Taguchi has developed a new experimental strategy: Taguchi method which utilizes a modified and standardized form of DOE. The Taguchi method utilizes orthogonal arrays to study a large number of variables using a minimal number of experiments. By using orthogonal arrays, the number of experimental parameters can be reduced significantly. Moreover, the conclusions drawn from small set of experiments are valid over the entire experimental region thereby reducing the research and development costs by simultaneously studying the influence of large number of experimental variables. Here in this manuscript we report the utility of Taguchi method to optimize the operating variables such as reaction time, temperature, type of catalyst etc. on the yield of BHET by glycolysis of wPET.

Experimental

Materials and methods

Waste PET was obtained from discarded PET soft drink bottles cut manually into small pieces of approximately 10 × 10 mm2 and cleaned thoroughly with soap solution and subsequently with deionized water and dried. Energy Dispersive X-ray Fluorescence (ED-XRF) was used to analyze the elemental composition of waste PET using a Epsilon 4 Spectrometer manufactured by Malvern Panalytical and the elemental composition was found to be carbon: 76.3725, oxygen: 23.558, sodium: 0.0304; antimony: 0.018; silica: 0.0143, phosphorus: 0.0027; potassium: 0.0023 and iron: 0.0017 weight %. Zinc stearate, tetrabutyl ortho titanate, ammonium iron citrate and cobalt stearate were purchased from Daejung chemicals, TCI Chemicals, Sigma-Aldrich and Alfa-Aesar, respectively, and ethylene glycol, purchased from Daejung chemicals was used as received. Microwave synthesis was carried out in Masterwave BTR oven manufactured by Anton-Paar operating at 600 W and pressure of 4 bar. Fourier transform infrared spectra, FTIR were recorded by a Thermo Scientific Nicolet iS10 Spectrometer with and attenuated total reflection (ATR) accessory, in the wave band range from 4000 to 400 cm−1. The spectra were acquired with a resolution of 8 cm−1 and a total of 32 scans. 1H-NMR spectra were recorded on a Bruker DRX-400 spectrometer at 400 MHz in CDCl3 solution. The chemical shifts were reported in parts per million (ppm) and with Tetra methyl silane (TMS) as an internal standard. Minitab software package was used to analyze Taguchi data.

Calculation of BHET yield

After glycolysis reaction, hot distilled water (100 g) was added in excess to the glycolyzed product (5 g) and stirred for 30 min under vigorous agitation. The reason for using hot water is that it is known that BHET and catalyst are dissolved well in hot water. While still hot, the suspension was filtered under vacuum using a sintered glass filter (Whatman glass microfiber binder free, grade GF/C 1.2 µm). The filtrate contained ethylene glycol, BHET, and small quantities of few water-soluble oligomers. This was heated until a clear mixture was obtained. When the filtrate became transparent, it was filtered under vacuum using a sintered glass filter (Whatman glass microfiber binder free, grade GF/F 0.7 µm). The filtrate was stored in a refrigerator at 5 ℃ for 16 h and filtered once more (Whatman glass microfiber binder free, grade GF/F 0.7 µm). After the final filtration, the obtained BHET was dried at 60 ℃ for 30 h and the BHET yield was calculated using the following equation after weighting:

where WPET,O and WBHET,f refer to the initial weight of PET and the weight of BHET at a specific reaction time, respectively. MWBHET and MWPET are the molecular weights of BHET (254 g/mol) and the PET (192 g/mol) repeating unit, respectively.

Results and discussion

It is postulated that during microwave glycolysis reaction of wPET and glycol the following three reactions occur concurrently [21]:

- 1.

In the first step, microwave induced addition of hydroxyl groups into the wPET chains causing chain scission and yielding oligomers terminated with −OH group.

- 2.

With further increase in reaction time, this chain scission continues due to the catalytic action of metal moieties and also due to thermal pockets caused by localized heating of metal moieties by microwaves.

- 3.

These generated short-chained wPET are rapidly attacked by the hydroxyl moieties of EG yielding oligomers of shorter chain lengths until the total consumption of ethylene glycol. So based on above steps, the three rate controlling steps are amount of ethylene glycol and type of catalyst and the irradiation time. We investigated the effects of these variables in two separate sets of experiments.

Effect of type of catalyst

In the first step, the effect of various types of catalysts on the BHET yield was studied using ethylene glycol as the glycolysing agent and at a constant ratio of 1:9.29; wPET: EG at 250 °C, and with irradiation time of 30 min was carried out. Four catalysts, namely Zinc stearate, Tetrabutyl ortho titanate, ammonium iron citrate, cobalt stearate and a control experiment with no catalyst were investigated and the results are tabulated in Table 1 below. The choice of catalysts was based on the previous reports on utility of zinc salts [22]; iron moieties [23]; titania [24] and cobalt [25] on the glycolysis of wPET.

Amongst all the investigated catalysts, zinc stearate showed the highest yield of BHET which is more than six times the yield of un-catalyzed reaction. Apicella et al. [26] have postulated that the rate of glycolysis reaction proceeds by the nucleophilic attack of the hydroxyl group of ethylene glycol on the carbonyl ester of wPET. Since this ester carbonyl group in wPET is in the state of inter-linking in wPET, these bonds must be first activated and broken by the catalyst cations (Zn or Fe or Co or Ti). In our case, due to the polar nature of PET and also due to thermal effects, microwave irradiation also has the capability of activating carbonyl esters. In the presence of metal catalysts, whilst breaking these carbonyl esters, coordination compounds of ester carbonyls with metal cations are formed which facilitates the hydroxyl groups of EG to nucleophilically attack on the positively polarized carbon atom, resulting in the cleavage of the polymer chain to yield BHET. For a catalyst to be effective, the metal cation must easily form an intermediate complex with the wPET wherein the strength of the metal–oxygen bond formed will be a key factor in governing the activity of the catalyst [27]. So based on these studies, zinc stearate was chosen as the catalyst for further experiments.

Chemical analysis of the obtained product was done using FTIR spectrometry. Figure 1 shows the FTIR plots of wPET, EG and products obtained from catalytic glycolysis recorded in the range of 400–4000 cm−1. FTIR spectra of wPET show the characteristic dominant absorption peaks at 1720 cm−1 and 730 cm−1 denoting the existence of aromatic carboxylic esters as well as its corresponding minor peaks at 1272, 1018, and 730 cm−1. However, after microwave glycolysis reaction the intensity of 1720 cm−1 peak is greatly reduced and in case of ECAT1–3, the one catalyzed by zinc stearate, the peak appears only as small hump reinforcing our argument that amongst the investigated metal catalysts, zinc stearate is the most efficient.

In order to further study the purity of BHET obtained, DSC studies were carried out and representative DSC spectra of BHET obtained by glycolysis of wPET using ECAT1–3, 2–3 and 3–3 corresponding to zinc stearate, tetrabutyl ortho titanate and ammonium iron citrate are shown in Fig. 2. Irrespective of the catalyst used, in all the DSC curves a sharp endothermic peak at 111 °C is observed which is related to the melting point of BHET. However, a closer inspection of the peaks (insert in Fig. 2) shows that in case of titanate and iron catalysts, there is a split in the peak. Though a proper explanation for this observation is elusive, this can be attributed to the formation of BHET dimers. So, based on yield and DSC data, we concluded that zinc-based salts are optimal for wPET glycolysis and zinc catalysts have been chosen for further studies and optimization.

Effect of type of anions of zinc salt

From the above step we deduced that zinc is the most effective catalyst for depolymerization of wPET. In order to test the effect of anion of zinc salt on depolymerization of wPET we investigated utility of zinc stearate, zinc acetate, zinc naphthenate and metallic zinc powder at constant loading of 1 wt% of catalyst in 1: 5 wt% of wPET and EG and microwave irradiation time of 30 min. The molar yield of BHET was 66.13, 64.10, 43.61 and 62.75% for stearate, acetate, metal powder and naphthenate, respectively. The FTIR spectra of final product plotted in Fig. 3 shows that the type of anion associated with zinc has no influence on the final product with all the FTIR showing almost exactly the same type of spectra and peak locations, except for the peat at 1261 cm−1 which is more pronounced in metallic zinc powder samples when compared to other organo-zinc salts. The 1261 cm−1 peak is usually associated with Zn-CH3 bending vibration in zinc coordination compounds having ZIF (Zeolitic imidazolate framework) type of structures. The mechanism of glycolysis reaction of wPET by glycols involves the nucleophilic reaction between the ester carbonyl groups of wPET and hydroxyl groups of glycols. In order to initiate this reaction, the ester carbonyl groups of wPET must be activated by metal cations. This activation reaction usually involves the formation of metal cation-ester carbonyl coordination intermediates. So for a catalyst to be effective, the metal ion must be highly reactive and mist easily form an intermediate. Of the three organic zinc metal salts used in this study, zinc stearate even though having a complex polymeric structure has lower boiling point when compared to its naphthenate and acetate counter parts, thereby forming carbonyl ester–zinc reaction intermediates more quickly and expedites the depolymerization reaction. Another interesting observation is that in case of zinc metal powder the yield is low which can be attributed to the formation of inactive ZIF type of compounds by reacting with wPET, thereby inhibiting the catalytic activity of zinc cation.

Effect of temperature on glycolysis of wPET

Till date, most of the reported works on glycolysis of wPET have been carried out at relatively low temperatures in the range of 190–200 °C. But in most cases, wPET was used as flakes and reports by Goje and Mishra have shown that particle size above 100 µm size has profound effect on the glycolyzation reaction. But, in our case, we used wPET flakes of 10 × 10 mm2. So in order to minimize the size effects we used high temperatures ranging from 220 (the softening point of PET) to 250 °C (melting point of PET). From the data tabulated in Table 2, it can be observed that the yield of BHET at softening point temperatures is almost constant at 69%, but, whereas at 250 °C which is the melting point of PET, the yield is markedly higher at 73.44%.

Effect of reaction time on microwave glycolysis of wPET

In order to study the effect of reaction time on the yield of BHET, we carried out glycolysis of wPET using EG as the glycolyzing agent at the ratio of 1: 5 and 1 wt% of zinc stearate catalyst at 250 °C and the resulting yield is presented in Table 3.

From the above data it can be observed at all measured reaction times the BHET yield is 63%, whereas for reaction time of 30 min the yield is higher at 66%. The surprising result of lower yield at higher reaction times can be attributed to poly-condensation reaction of BHET [6]. It is generally known that at favorable conditions, BHET undergoes polycondensation reaction to form PET and EG as the byproduct of the following reaction:

Effect of increasing amount of EG on glycolysis

In the second step, the effect of wPET: EG ratio on the BHET yield, constant catalyst ratio of 1 wt% with respect to wPET was studied and reported in Table 4. From the table, it can be observed that the highest amount of BHET is obtained at a mole ratio of 1: 9.29 corresponding to 72.82% conversion reaction.

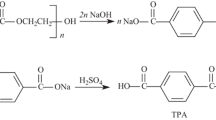

Glycolysis of wPET is a complex reaction and seldom reaches 100% conversion to a pure BHET due to the occurrence of multiple reversible glycolysis reactions. Pardal and Tersac [28] have classified the various occurring reactions to three simple classes: undesirable interchange and poly-condensation reactions (Scheme 1) and the desirable glycolysis reaction (Scheme 2) as shown below (Scheme 3).

As can be observed from the three schemes, glycolysis reaction is complex and there are different competing reactions with varying reaction rates. From experimental data it seems that increasing concentration of EG will lead to undesirable side reactions like poly-condensation and interchange, thereby yielding lower amounts of BHET. Based on above two studies: influence of catalyst type and effect of variation in reactant mixtures, we concluded that depolymerization of BHET is complex and needs more pragmatic approach to optimize the reactant mixtures. When compared to classic systematic trial and error methods, Taguchi experiments have two main advantages [29]: Simultaneous examination of influence of multiple factors on the experimental outcomes, study of synergy between two factors and finally identification of noise factors which cause invariable effect on the results.

Taguchi design for optimization of reaction conditions

The aim of using Taguchi design in this work is twofold: optimize the wPET: EG ratio and optimize the amount of required catalyst. As previously discussed in above section, amongst all catalysts zinc stearate was identified as the best catalyst but there are many contrasting reports on the exact amount of catalyst required. Campanelli et al. [30] reported that zinc compounds were found to catalyze the hydrolytic depolymerization of PET only at temperatures lower than melting point of PET. Above 265 °C, they reported that zinc salts are ineffective. Whereas in a recent report by Chaudhary et al. [31] under microwave irradiation, increasing amounts of catalyst will cause increased depolymerization of wPET. So, in light of above findings by choosing wPET: EG ratio and weight of catalyst as the two operating variables, a Taguchi experimental matrix was designed and shown in Table 5.

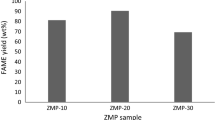

From the table above it can be observed that five different sets wPET: EG ranging from 1:1 to 1:5 and at zinc acetate catalyst weights of 1–4 wt% have been examined in a microwave reactor operating at 250 °C and operated at 30 min. The molar yields ranged from only 3% in case of 1:1/1 to 66.13% in case of 1:5/1. The progress of depolymerization was monitored by FTIR spectrometry and plots of some representative recipes are shown in Fig. 4. From the plot it can be observed that there is a progressive decrease in the characteristic absorption peaks at 1720 cm−1 and 730 cm−1 of wPET which denotes insertion of ethylene glycol moieties into the wPET chains leading to the formation of BHET. This observation is also reinforced by the yields calculated.

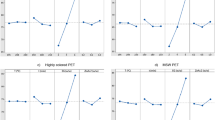

Another interesting observation is that irrespective of the ratio of wPET to EG, the maximum yield is obtained at a catalyst loading of 1 wt% and further increase in catalyst will not help in improving the yields. This result indicates that the yield and quality of the product are not only strongly influenced by the kinetics and equilibria, but also on the extent of catalytic activity. From our data we can conclude that on increasing amounts of zinc stearate, it will react with molten wPET forming coordination complexes thereby reducing the catalytic activity. When comparing the yield at a constant catalyst loading, there is marginal increase in the yield; however, this extent of yield is not uniform and tends to stabilize around 1:3 wPET: EG and further increase in the concentration the extent of improvement in yield is marginal. This observation is also reiterated from the signal-to-noise ratio values tabulated in the last column and plotted below.

Signal-to-noise (S/N) ratio analysis was used to analyze the effect of the ratio of wPET to EG and weight of catalyst on the yield of BHET. S/N ratios were calculated based on the “larger-the-better” analysis by using the equation (S/N = − 10 *log(Σ(1/Y2)/n)) wherein Y is the factor level and n is the number of variables [32]. S/N ratios make interesting reading wherein increase in weight ratio of wPET: EG reaches a maximum around 1:3 (Fig. 5a) and remains almost constant with further increase in concentration of EG, whereas a totally different scenario is given by the S/N ratio of catalyst (Fig. 5b). Increase in the amount of catalyst causes a slight and gradual fall in S/N ratio indicating that the presence of excess amount of catalyst leads to the occurrence of more undesirable reactions like poly-condensation and interchange. So, based on observed data the optimum operating conditions are deduced as 1:3 wt% of wPET: EG and a catalyst loading of 1 wt%. Based on this observation additional experiment was carried out and a representative NMR spectrum of product obtained is shown in Fig. 6. The signal at δ 8.15 ppm indicates the presence of the four aromatic protons of terephthalic residue. The two triplets between δ 4.4 and 3.9 ppm (8H) are characteristic of the methylene protons COO–CH2 and CH2–OH of ethylene glycol [33].

Conclusions

In conclusion, Taguchi method for optimization of reaction conditions for solvent less, microwave-induced glycolysis of waste PET (wPET) was studied. Preliminary tests showed that amongst the metal cations of Zn, Ti, Fe and Co, zinc ion is found to be more effective due to its ability to form highly active coordination complexes with molten wPET. Depolymerization of wPET by glycolysis in the absence of catalyst was insignificant. A control sample without use of catalyst also showed conversion of wPET to BHET. Study of influence of the concentration of ethylene glycol on the reaction time showed that the efficiency of PET glycolysis depends enormously on the synergetic combination of appropriate amount of catalyst and wPET: EG ratio. Based on Taguchi design, we have optimized an ideal reaction combination of 1:3 wPET: EG with a 1 wt% of zinc acetate will give 65% molar yield of BHET in 30 min.

References

George N, Kurian T (2014) Recent developments in the chemical recycling of postconsumer poly(ethylene terephthalate) waste. Ind Eng Chem Res 53(37):14185–14198

Shukla SR, Harad AM, Jawale LS (2009) Chemical recycling of PET waste into hydrophobic textile dyestuffs. Polym Degrad Stab 94(4):604–609

Zahedi AR, Rafizadeh M, Taromi FA (2012) Recycling of off-grade pet via partial alcoholysis to synthesize functionalized pet oligomer nanocomposites. Polym Compos 33(10):1832–1839

Colomines G, Rivas F, Lacoste ML, Robin JJ (2005) Study of polyurethane formulations containing diols obtained via glycolysis of poly(ethylene terephthalate) (PET) by Oligoesters Diols through a reactive extrusion process. Macromol Mater Eng 290(7):710–720

Mishra S, Goje A (2003) Kinetic and thermodynamic study of methanolysis of poly(ethylene terephthalate) waste powder. Polym Int 52(3):337–342

Kurokawa H, Ohshima M, Sugiyama K, Miura H (2003) Methanolysis of polyethylene terephthalate (PET) in the presence of aluminium tiisopropoxide catalyst to form dimethyl terephthalate and ethylene glycol. Polym Degrad Stab 79(3):529–533

Davies T, Goldsmith PL, Ravens DAS, Ward IM (1962) The kinetics of the hydrolysis of polyethylene terephthalate film. J Phys Chem 66(1):175–176

Spychaj T, Fabrycy E, Spychaj S, Kacperski M (2001) Aminolysis and aminoglycolysis of waste poly(ethylene terephthalate). J Mater Cycles Waste Manag 3(1):24–31

Vaidya UR, Nadkarni VM (1989) Polyester polyols from glycolyzed PET waste: effect of glycol type on kinetics of polyesterification. J Appl Polym Sci 38(6):1179–1190

Öztürk Y, Güçlü G (2005) Unsaturated polyester resins obtained from glycolysis products of waste PET. Polym Plast Technol Eng 43(5):1539–1552

Siddiqui MN, Redhwi HH, Achilias DS (2012) Recycling of poly(ethylene terephthalate) waste through methanolic pyrolysis in a microwave reactor. J Anal Appl Pyrolysis 98:214–220

Kumagai S, Hirahashi S, Grause G, Kameda T, Toyoda H, Yoshioka T (2018) Alkaline hydrolysis of PVC-coated PET fibers for simultaneous recycling of PET and PVC. J Mater Cycles Waste Manag 20(1):439–449

Carta D, Cao G, D’Angeli C (2003) Chemical recycling of poly(ethylene terephthalate) (pet) by hydrolysis and glycolysis. Environ Sci Pollut Res 10(6):390–394

Aguado A, Martínez L, Becerra L, Arieta-araunabeña M, Arnaiz S, Asueta A et al (2014) Chemical depolymerisation of PET complex waste: hydrolysis vs. glycolysis. J Mater Cycles Waste Manag 16(2):201–210

Krzan A (1999) Poly(ethylene terephthalate) glycolysis under microwave irradiation. Polym Adv Technol 10(10):603–606

Karayannidis GP, Chatziavgoustis AP, Achilias DS (2002) Poly(ethylene terephthalate) recycling and recovery of pure terephthalic acid by alkaline hydrolysis. Adv Polym Tech 21(4):250–259

Fisher RA (1936) Design of experiments. Br Med J 1(3923):554

Liu Q, Li R, Fang T (2015) Investigating and modeling PET methanolysis under supercritical conditions by response surface methodology approach. Chem Eng J 270:535–541

Sridhar V, Shanmugharaj AM, Kim JK, Tripathy DK (2009) Optimization of carbon black and nanoclay filler loading in chlorobutyl vulcanizates using response surface methodology. Polym Compos 30(6):691–701

Li Z, Wang K, Song J, Xu Q, Kobayashi N (2014) Preparation of activated carbons from polycarbonate with chemical activation using response surface methodology. J Mater Cycles Waste Manag 16(2):359–366

Pingale ND, Shukla SR (2008) Microwave assisted ecofriendly recycling of poly (ethylene terephthalate) bottle waste. Eur Polym J 44(12):4151–4156

Chen JW, Chen LW, Cheng WH (1999) Kinetics of glycolysis of polyethylene terephthalate with zinc catalyst. Polym Int 48(9):885–888

Duque-Ingunza I, López-Fonseca R, de Rivas B, Gutiérrez-Ortiz JI (2013) Synthesis of unsaturated polyester resin from glycolysed postconsumer PET wastes. J Mater Cycles Waste Manage 15(3):256–263

Troev K, Grancharov G, Tsevi R, Gitsov I (2003) A novel catalyst for the glycolysis of poly(ethylene terephthalate). J Appl Polym Sci 90(8):148–1152

Geng Y, Dong T, Fang P, Zhou Q, Lu X, Zhang S (2015) Fast and effective glycolysis of poly(ethylene terephthalate) catalyzed by polyoxometalate. Polym Degrad Stab 117:30–36

Apicella B, Di Serio M, Fiocca L, Po R, Santacesaria E (1998) Kinetic and catalytic aspects of the formation of poly(ethylene terephthalate) (PET) investigated with model molecules. J Appl Polym Sci 69(12):2423–2433

López-Fonseca R, Duque-Ingunza I, de Rivas B, Arnaiz S, Gutiérrez-Ortiz JI (2010) Chemical recycling of post-consumer PET wastes by glycolysis in the presence of metal salts. Polym Degrad Stab 95(6):1022–1028

Pardal F, Tersac G (2006) Comparative reactivity of glycols in PET glycolysis. Polym Degrad Stab 91(11):2567–2578

Roy RK (2001) Design of experiments using the taguchi approach: 16 steps to product and process improvement. Wiley, Toronto (ISBN-10: 9780471361015)

Campanelli JR, Kamal MR, Cooper DG (1994) Kinetics of glycolysis of poly(ethylene terephthalate) melts. J Appl Polym Sci 54(11):1731–2174

Chaudhary S, Surekha P, Kumar D, Rajagopal C, Roy PK (2013) Microwave assisted glycolysis of poly(ethylene terepthalate) for preparation of polyester polyols. J Appl Polym Sci 129(5):2779–2788

Yue QF, Wang CX, Zhang LN, Ni Y, Jin YX (2011) Glycolysis of poly(ethylene terephthalate) (PET) using basic ionic liquids as catalysts. Polym Degrad Stab 96(4):399–403

Acknowledgements

This work was supported by the Industrial Strategic Technology Development Program (No. 10076439) funded by the Ministry of Trade, Industry and Energy (MOTIE, Korea) and by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2011-0030013, No. 2016R1A2B1013276).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, R., Sridhar, V. & Park, H. Taguchi method for optimization of reaction conditions in microwave glycolysis of waste PET. J Mater Cycles Waste Manag 22, 664–672 (2020). https://doi.org/10.1007/s10163-019-00958-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-019-00958-7