Abstract

Experiments were conducted using a bubbling reactor to investigate nitrogen oxide absorption in the calcium sulfite slurry. The effects of CaSO3 concentration, NO2/NO mole ratio and O2 concentrations on NO2 and SO2 absorption efficiencies were investigated. Five types of additives, including MgSO4, Na2SO4, FeSO4, MgSO4/Na2SO4 and FeSO4/Na2SO4, had been evaluated for enhancing NO2 absorption in CaSO3 slurry. Results showed that CaSO3 concentration had significant impact on NO2 and SO2 absorption efficiencies, and the highest absorption efficiencies of SO2 and NO2 could reach about 99.5 and 75.0 %, respectively. Furthermore, the NO2 absorption was closely related to the NO2/NO mole ratio, and the existence of NO2 in flue gas may promote NO absorption. The presence of O2 in simulated flue gas was disadvantage for NO x removal because it can oxidize sulfite to sulfate. It was worth pointing out that FeSO4/Na2SO4 was the best additive among those investigated additives, as the NO2 removal efficiency was significantly increased from 74.8 to 95.0 %. IC and in situ FTIR results suggest that the main products were NO3 − and NO2 − in liquid phase and N2O, N2O5 and HNO3 in gas phase during the CaSO3 absorption process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrogen oxides (NO x ) generated from fuel combustion and waste incineration in stationary sources are precursors of acid rain, photochemical smogs and fine aerosols, have received unprecedented public attention [1]. In China, a series of NO x emission standards for different industries, which are regarded as the strictest standards in history, have been successively issued by the Chinese government to limit NO x emissions. The emission limit value of NO x for waste incineration has changed from 400 to 250 mg m−3 [2]. Therefore, an urgent issue of air quality improvement is NO x emission control. Currently, various removal technologies for control of NO x have been widely used, including combustion modification technology, selective catalytic reduction (SCR) method, selective non-catalytic reduction (SNCR) method and wet absorption process [3]. However, most of these single-function unit operations suffer high operating costs. Emerging cost-effective technologies for multi-pollutants control are necessary. One promising candidate is the chemical absorption process for the co-capture of pollutants.

For the chemical absorption deNO x process, sufficient NO2 is the precondition. Accordingly, numerous aqueous oxidants such as KMnO4, H2O2, Fe(II)-EDTA and NaClO2 [4–6], some gas phase oxidations including ozone, ClO2, non-thermal plasma and transition metal oxides catalysts [7, 8] have been investigated to convert insoluble NO to soluble NO2. However, higher NO oxidation efficiency is limited by higher operating cost. If a certain amount of NO could be co-captured in absorption process, the overall treatment cost will be greatly slashed. Numerous aqueous absorbents, such as H2O, NaOH, Ca(OH)2, aqueous sulfite, ammoniacal cobalt(II) solutions, ferrate(VI), Fe(II)-EDTA and other complex component solutions, have been investigated in the removal of NO and NO2 [9–18]. Compared with other approaches, the aqueous sulfite absorption method is one of the promising processes due to its high removal efficiency, moreover sulfite is an abundant reaction intermediate in the typical wet flue gas desulfurization [19].

CaSO3 slurry can be a reasonable absorbent for the co-capture of multi-pollutants, as it is the leading byproduct in the limestone scrubbing solution and reacts with NO2 in preference to O2 [17]. Nevertheless, the low solubility of CaSO3 slurry limits the reaction of NO2 and SO3 2−, thus scientists are currently investigating alternative cost-effective additives for enhancing NO2 absorption through enriching the SO3 2− concentration. Tang et al. [13] indicated the MgSO4 as an effective additive could significantly increase the NO2 absorption efficiency from 70.8 to 86.0 %. Some metal and non-metal additives for enhancing NO2 absorption in insoluble calcium sulfite slurry were also investigated. Wang et al. [17] reported that the FeSO4 was the most effective additive with absorption efficiency of 95 %. In addition, with 0.5 mol L−1 ammonium sulfate added, the NO2 removal efficiency increased significantly from 67 to 90 %.

To the best of our knowledge, the chemical behavior of NO2 absorption process in CaSO3 slurry has not yet been systematically investigated. This study investigated the effects of CaSO3 concentration, NO2/NO mole ratio and SO2 and O2 concentrations on NO x absorption in CaSO3 slurry. The liquid and gas products formed in CaSO3 slurry were investigated, and the chemical behavior of NO2 absorption process in CaSO3 slurry was discussed. In addition, different additives employed to enhance the absorption process were also studied.

Experimental section

Experimental setup

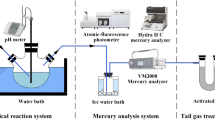

The schematic of the experimental system setup is illustrated in Fig. 1. It consists of a reaction gas supply unit, a cylindrical flue gas treatment reactor and a set of analytical instruments.

A cylinder with an inner diameter of 300 mm and a length of 600 mm (a volume of 5 L) was used as the bubbling reactor, redundant solution was stored in the overflow tank, and outer layer of the reactor was filled with water from water bath to control reaction temperature. The liquid stirring speed was controlled at 110 rpm. A cooling pipe was used to cool and dehydrate the outlet flue gas to protect the flue gas analyzer.

Experimental methods

The simulated flue gas was prepared with air, N2, CO2, SO2, NO, and NO2. A set of mass flow controllers was used to adjust the flow rate. All of the experiments were performed at atmospheric pressure and 325 K. The simulated gas consisted of 12 % CO2, 300 ppm SO2, 0–200 ppm NO, 0–200 ppm NO2, 0–10 % O2, using N2 as balance gas, with a total flow rate of 4 L min−1. While in the study of reaction products of NO2 absorption in CaSO3 slurry (see “Reaction products of NO2 absorption in CaSO3 slurry”), the simulated flue gas consisted of 5 % O2, 260 ppm NO2, and inert gas Ar, which is marked red in Fig. 1. The concentrations of NO x , O2 and SO2 were monitored by a flue gas analyzer (Testo 350, Germany). Sulfite ions (SO3 2−) in the liquid phase were measured by an iodometric titration method. The concentrations of NO3 − and NO2 − in the liquid phase were tested by ion chromatogram (Metrohm 792, Switzerland; column: Asupper5/250). The qualitative analysis of gaseous products after reactor was performed by a Fourier transform infrared spectrometer (In situ FTIR, Nicolet 6700, USA).

And the initial pH (5.5–6) was moderated by the additional HCl. The CaSO3 used in this study is CaSO3·2H2O (98 % purity) and deionized water, and the total CaSO3 slurry volume in reactor was 2 L. Additives tested in this study include MgSO4, Na2SO4, FeSO4, MgSO4/Na2SO4, FeSO4/Na2SO4, which were introduced to the slurry with a concentration ranging from 0 to 0.5 mol L−1. Meanwhile, the mole ratio of complex additives was 1/1.

The absorption efficiencies of SO2 and NO x were calculated as

here C in (ppm) is the concentrations of SO2 or NO x measured at inlet of the bubbling reactor; C out (ppm) is the outlet concentrations of SO2 and NO x .

Results and discussion

Effect of CaSO3 concentration on SO2 and NO2 absorption

Some experiments were carried out to investigate the effect of CaSO3 concentration on NO2 absorption rate, and the results were shown in Fig. 2. From Fig. 2a, b, it is obvious that the higher CaSO3 concentration is favorable to the absorption of NO2. It can be found from Fig. 2a that the absorption efficiency of NO2 increased with CaSO3 concentration from zero to 0.05 mol L−1, thereafter, remained stable with increasing CaSO3 concentration at above 0.05 mol L−1, and the highest absorption efficiency of NO2 about 75.2 % was obtained. This phenomenon is not only the cause of the existence of more SO3 2− ions, but also more likely attributed to the absorbent particles that were suspended in the CaSO3 slurry which could provide more reactive surface; the absorption rate would increase with solid content within a certain range, which is in accordance with the conclusion drawn by Dagaonkar et al. [20]. Also, when CaSO3 concentration was changed from zero to 0.1 mol L−1, the absorption efficiency of SO2 kept stable, different from NO2, the removal efficiency of SO2 is slightly affected by CaSO3 concentration and almost retains 99.0 %, and it indicates that SO2 is easier removed. Figure 2b shows the relation of the NO2 removal efficiency and CaSO3 concentration with reaction time at different CaSO3 concentrations. As shown in Fig. 2b, when CaSO3 concentration was above 0.05 mol L−1, the presence of more CaSO3 absorbent (0.05–0.2 mol L−1) resulted in a significant improvement in NO2 absorption performance. Although the variety trend of NO2 absorption was similar, a longer efficient time was kept. However, a sharply declining happened in a short time, and NO2 removal efficiency finally retained at around 50 %. This trend is due to the fact that the SO3 2− concentration decreases can lower chemical reaction rates. Moreover, the decreases of SO3 2− concentration influence the gas–liquid mass transfer.

a Effect of CaSO3 concentration on SO2 and NO2 absorption. b Variation of NO2 removal efficiency and CaSO3 concentration in absorption solution with reaction time. (The reaction temperature is 325 K, the CaSO3 slurry pH is 6.0, flue gas flow rate was 4.0 L min−1, and the concentrations of O2, CO2, SO2 and NO2 are 5, 12 %, 300 and 200 ppm, respectively)

The results indicate that compared with solubility SO3 2− absorbent, although the low solubility of CaSO3 will limit the NO2 absorption efficiency, the maximum removal efficiencies for NO2 reached 75.2 %, so CaSO3 slurry is a suitable absorbent, because CaSO3 can also be oxidized by NO2 prior to by O2, which is consistent with the conclusion drawn by Tang et al. [13].

The overall reaction of the NO2 absorption in CaSO3 slurry can be written as follows:

According to Eq. (2), when NO2 is absorbed by CaSO3 slurry, SO3 2− is oxidized to SO4 2−, and NO2 is reduced to NO3 − and NO2 −. Meanwhile, SO2 absorption in CaSO3 slurry will be complementary to SO3 2−, and then, desulfurization and denitrification processes will be combined reasonably.

Effect of O2 concentration on SO2 and NO2 absorption

The effect of O2 concentration on the SO2 and NO2 absorption were investigated, and the results are displayed in Fig. 3.

In Fig. 3, it is obvious that the presence of O2 resulted in a significant decrease of NO2 absorption performance in CaSO3 slurry, and it is partly due to the fact that SO3 2− can also be oxidized to SO4 2− by O2. The effective operating time in absence of O2 was obviously longer than that of 5 % O2 concentration, the result revealed that O2 concentration is an important parameter during the CaSO3 absorption process. In this study, there is almost no influence of the variation of O2 concentration on the SO2 absorption.

Figure 4 shows the effect of O2 concentrations on NO2 −, NO3 − and the DO concentrations in CaSO3 slurry. NO3 − concentration steadily increased with the increase of O2 concentration, while NO2 − concentration decreased. That is because the NO2 −could also be oxidized to NO3 − in the presence of O2. Also, the formation of more NO3 − is due to the reaction of NO2 and H2O. The reactions with the participation of oxygen in this study can be summarized by the following chemical equations.

NO2 absorption product compositions and DO in CaSO3 slurry. The reaction temperature is 325 K, the CaSO3 slurry pH is 6.0, the initial CaSO3 concentration is 0.1 mol L−1, flue gas flow rate was 4.0 L min−1, and the concentrations of O2, CO2, SO2 and NO2 are 5, 12 %, 300 and 200 ppm, respectively; the sampling time is 30 min

Figure 4 also showed that the DO concentration in CaSO3 slurry was almost invariable at about 0.46 mg L−1 as the O2 concentration increased from 0 to 10 %. The result indicates that the mass transfer resistance of O2 dissolving may lie on liquid phase.

Effect of NO2/NO ratio on SO2 and NO x absorption

Since the effect of NO2/NO ratio on the removal of SO2 and NO x is an important factor, NO2/NO ratios were investigated and the results are shown in Fig. 5.

Effect of NO2/NO ratio on SO2 and NO x absorption in CaSO3 slurry. The reaction temperature is 325 K, the CaSO3 slurry pH is 6.0, the initial CaSO3 concentration is 0.1 mol L−1, flue gas flow rate was 4.0 L min−1, and the concentrations of O2, CO2, SO2, NO and NO2 are 5, 12 %, 300, 0–200 and 0–200 ppm, respectively. The reaction time is 30 min

As shown in Fig. 5, the SO2 and NO x absorption in CaSO3 slurry is closely related to NO2/NO ratio, because the SO2 removal efficiency in the absence of NO2, which is much lower than that in the presence of NO2 (99.5 %), was 94.2 %. This result reveals that the existence of NO2 can facilitate SO2 absorption. It could be ascribed to that the dissolved NO2 reacted with CaSO3 slurry, which leads to decrease of the SO3 2− concentration. On the other hand, the increasing of SO3 2−concentration, due to the products of SO2 dissolution into CaSO3 slurry, may promote the reaction Eq. (2) moving to the right. However, the SO2 removal efficiency had a slight increase with the NO2 concentration from 50 to 200 ppm. Also, with the increase of the NO2/NO ratio, the concentration of NO2 had a slight decrease, which indicates that NO2 absorption reaches equilibrium and further NO2 absorption is inhibited. Figure 5 also shows that the NO removal efficiency kept low range without NO2 in CaSO3 absorbent system, which is decided by the insoluble property of NO. Moreover, NO removal rate increased firstly and then decreased, according to reaction (6), the NO2 is advantageous to the absorption of effect on the absorption of NO at lower concentration of NO2; then when the NO2 concentration is large enough, the NO absorption rate shows decreasing trend. This change is consistent with the study of Gao et al. [11]. They investigated the effect of the presence of NO2 on NO absorption and indicated that the existence of NO2 may promote NO absorption in (NH4)2SO3 absorbent; this result was also similar with the case of NO x absorption into CaSO3 slurry. When NO and NO2 coexist in inlet flue gas, the reaction between NO, H2O and NO2 occurred in the liquid phase.

Effect of additive agents on SO2 and NO2 absorption

To improve the dissolution of CaSO3 slurry, the additives, including individual FeSO4, MgSO4, Na2SO4, and complex MgSO4/Na2SO4, FeSO4/Na2SO4 had been selected to enhance the deNO x performance (Fig. 6).

Effects of individual and complex additives on NO2 absorption in CaSO3 slurry. The reaction temperature is 325 K, the CaSO3 slurry pH is 6.0, the initial CaSO3 concentration is 0.1 mol L−1, flue gas flow rate was 4.0 L min−1, and the concentrations of O2, CO2, SO2 and NO2 are 5, 12 %, 300 and 200 ppm, respectively; the reaction time is 30 min

According to the preceding results, about 75 % of NO2 was removed in the CaSO3 system without additives. As shown in Fig. 6, with the concentration of additives varied from 0 to 0.5 mol L−1, all individual and complex additives had contributed to NO2 absorption at different levels, and the bubble was finer and smoother when additives were added into absorption system. Meanwhile, complex additives were more effective additives with absorption efficiency reaching about 95 %. While for individual additives, the maximum absorption efficiency reached around 87 %. The performance of additives varies typically as the following order MgSO4 < Na2SO4 < FeSO4 < MgSO4/Na2SO4 < FeSO4/Na2SO4. It is possible that SO4 2− could preferentially react with Ca2+ in CaSO3 slurry to form CaSO4, and the existence of SO4 2− increases the concentration of dissociated SO3 2−, The related reactions appear as following [17]. On the other hand, another reason of enhancing the deNO x performance by additives is that the metal ions Mg2+ might react with SO3 2− to form other soluble sulfite species, and Na+ might improve the gas–liquid mass transfer of absorption system. Fe2+ has catalytic effects on the oxidation of aqueous sulfur dioxide solutions, which may also benefit the contribution of soluble SO3 2−, all individual and complex additives had contributed to shift the reaction (2) to the right, and the SO3 2− ions in the system are enriched.

Reaction products of NO2 absorption in CaSO3 slurry

The potential reaction products of NO2 absorption in CaSO3 slurry were NO3 − and NO2 −; using IC analysis, SO4 2−, NO3 − and NO2 − were detected. NO3 − and NO2 − were formed in solution because of the reactions between NO2 and H2O and between NO2 and SO3 2−, respectively.

To further investigate the products of NO2 absorption and nitrogen species fate in reaction system, a typical measurement of NO2 absorption in CaSO3 solution was carried out (Fig. 7).

a Typical experiment of NO2 absorption in CaSO3 solution; b ion chromatogram of NO2 absorption in CaSO3 solution; c nitrogen equilibrium of NO2 absorption in CaSO3 slurry; d in situ FTIR spectra of all nitrogen individuals of outlet flue gas. The reaction temperature is 325 K, the CaSO3 slurry pH is 6.0, the initial CaSO3 concentration is 0.06 mol L−1, flue gas flow rate was 4.0 L min−1, and the concentrations of O2 and NO2 are 5 % and 260 ppm, respectively, Ar as the balance gas, the reaction time is 70 min

As shown in Fig. 7a, the absorption efficiency of NO2 remained stable at around 70 % before 20 min, however, a sharp decline occurred from 20 to 30 min; thereafter, the NO2 removal efficiency was originally stabilized. Also, when the reaction time was 15, 30 and 60 min, respectively, the obtained samples of the absorption liquid were tested by the ion chromatograph. The ion chromatogram of absorption solution (reaction time is 30 min) is presented in Fig. 7b. Figure 7c points out that the amount of nitrate and nitrite concentrations showed an increasing trend as time went on; nevertheless, the experimental sum of total nitrate and nitrite concentrations were not equivalent to the calculated values, about 10 % other nitrogen species existed in this system. This is mostly due to the fact that N–S compound and N–S compound decomposed [15, 21]. Figure 7d shows the in situ FTIR spectra of all chemical individuals of outlet flue gas, especially for nitrogen species. It can be found that the absorbance peaks at 2930, 2287, 1720, 1600, 1326, and 887 cm−1 were presented; the bands were assigned to NO2, N2O, N2O5, NO2, HNO3, HNO3, respectively [22]. According to the IC and in situ FTIR results, the main NO2 absorption products in CaSO3 absorption system are nitrate and nitrite in liquid phase; meanwhile, the consideration of gaseous products, including N2O, N2O5, HNO3 and so on, is indispensable.

Conclusions

A series of experiments were carried out to study the absorption of SO2 and NO x in CaSO3 slurry with or without additives and the formation of liquid and gas products. The experimental results can be summarized as follows:

-

1.

NO2 removal efficiency increases with CaSO3 concentration at the range from 0 to 0.2 mol L−1, and the highest NO2 absorption efficiency is about 75 %, while SO2 removal efficiency will not be affected.

-

2.

The existence of O2 in flue gas is disadvantage to the sulfite concentration in solution in the system. NO3 − is the major absorption product in the presence of O2, while NO3 −and NO2 − concentrations are almost equilibrium in the absence of O2.

-

3.

SO2 and NO x absorption in CaSO3 slurry is strongly related to NO2/NO ratio. When NO and NO2 coexist in inlet flue gas, the existence of NO2 may promote NO absorption in CaSO3 absorbent, the best NO2/NO ratio for NO and NO2 co-absorption is 1/1.

-

4.

The individual and complex additives have contributed to NO2 absorption at different levels, complex additives are more effective additives, and the performance of additives varies typically in the following order MgSO4 < Na2SO4 < FeSO4 < MgSO4/Na2SO4 < FeSO4/Na2SO4.

-

5.

In addition to the liquid phase products, gaseous N2O5, N2O and HNO3 products in outlet flue gas can be obviously detected. The new reaction of NO x absorption and conversion in CaSO3 slurry could be explained.

References

Zhang SH, Cai LL, Mi XH et al (2008) NO x removal from simulated flue gas by chemical absorption-biological reduction integrated approach in a biofilter. Environ Sci Technol 42(10):3814–3820. doi:10.1021/es800200g

MEPPRC China Environment Statistical Annual Report (2013). http://zls.mep.gov.cn/hjtj/nb/2013tjnb/201411/t20141124_291867.htm. Accessed 24 Nov 2014

Zhao Y, Hao R, Qi M (2015) Integrative process of preoxidation and absorption for simultaneous removal of SO2, NO and Hg0. Chem Eng J 269:159–167. doi:10.1016/j.cej.2015.01.064

Fang P, Cen CP, Wang XM et al (2013) Simultaneous removal of SO2, NO and Hg0 by wet scrubbing using urea + KMnO4 solution. Fuel Process Technol 106(2):645–653. doi:10.1016/j.fuproc.2012.09.060

Liu Y, Zhang J, Sheng C et al (2010) Simultaneous removal of NO and SO2, from coal-fired flue gas by UV/H2O2, advanced oxidation process. Chem Eng J 162(3):1006–1011. doi:10.1016/j.cej.2010.07.009

Zhao Y, Guo TX, Chen ZY et al (2010) Simultaneous removal of SO2 and NO using M/NaClO2 complex absorbent. Chem Eng J 160(1):42–47. doi:10.1016/j.cej.2010.02.060

Zhang J, Zhang R, Chen X et al (2014) Simultaneous removal of NO and SO2 from flue gas by ozone oxidation and NaOH absorption. Ind Eng Chem Res 53(15):6450–6456. doi:10.1021/ie403423p

Fei XU, Luo Z, Wei C et al (2009) Simultaneous oxidation of NO, SO2 and Hg0 from flue gas by pulsed corona discharge. J Environ Sci 21(3):328–332. doi:10.1016/S1001-0742(08)62272-X

Yu H, Tan Z (2014) On the kinetics of the absorption of nitric oxide into ammoniacal Cobalt(II) solutions. Environ Sci Technol 48(4):2453–2463. doi:10.1021/es403901r

Zheng C, Xu C, Zhang Y et al (2014) Nitrogen oxide absorption and nitrite/nitrate formation in limestone slurry for WFGD system. Appl Energy 129:187–194. doi:10.1016/j.apenergy.2014.05.006

Gao X, Du Z, Ding HL et al (2011) Effect of gas-liquid phase compositions on NO2 and NO absorption into ammonium-sulfite and bisulfite solutions. Fuel Process Technol 92(8):1506–1512. doi:10.1016/j.fuproc.2011.03.012

Chen L, Lin KF, Yang CL (2011) Pilot study of absorption of NO2 with Na2S aqueous solutions. Environ Prog Sustain Energy 30(4):632–639. doi:10.1002/ep.10551

Tang N, Liu Y, Wang H et al (2010) Enhanced absorption process of NO2 in CaSO3 slurry by the addition of MgSO4. Chem Eng J 160(1):145–149. doi:10.1016/j.cej.2010.03.022

Shibukawa T, Ohira Y, Obata E (2008) Absorption of nitrogen dioxide by sodium sulfite solution. Kagaku Kogaku Ronbunshu 34(4):438–443

Siddiqi MA, Petersen J, Lucas K (2001) A study of the effect of nitrogen dioxide on the absorption of sulfur dioxide in wet flue gas cleaning processes. Ind Eng Chem Res 40(9):2116–2127. doi:10.1021/ie000815g

Thomas D, Vanderschuren J (1999) Analysis and prediction of the liquid phase composition for the absorption of nitrogen oxides into aqueous solutions. Sep Purif Technol 18(1):37–45. doi:10.1016/S1383-5866(99)00049-0

Wang Z, Zhang X, Zhou Z et al (2012) Effect of additive agents on the simultaneous absorption of NO2 and SO2 in the calcium sulfite slurry. Energy Fuel 26(9):5583–5589. doi:10.1021/ef3007504

Hu G, Sun Z, Gao H (2010) Novel process of simultaneous removal of SO2 and NO2 by sodium humate solution. Environ Sci Technol 44(17):6712–6717. doi:10.1021/es101892r

Gao X, Du Z, Ding HL et al (2010) Kinetics of NO x absorption into (NH4)2SO3 solution in an ammonia-based wet flue gas desulfurization process. Energy Fuel 24:5876–5882. doi:10.1021/ef101137k

Dagaonkar MV, Beenackers AACM, Pangarkar VG (2001) Gas absorption into aqueous reactive slurries of calcium and magnesium hydroxide in a multiphase reactor. Catal Today 66(2):495–501. doi:10.1016/S0920-5861(01)00258-9

Wang M, Sun Y, Zhu T (2013) Removal of NO x , SO2, and Hg from simulated flue gas by plasma-absorption hybrid system. IEEE Trans Plasma Sci 41(2):312–318. doi:10.1109/TPS.2012.2234483

Sun C, Zhao N, Zhuang Z et al (2014) Mechanisms and reaction pathways for simultaneous oxidation of NO x and SO2 by ozone determined by in situ IR measurements. J Hazard Mater 274:376–383. doi:10.1016/j.jhazmat.2014.04.027

Acknowledgments

This work was supported by the National High Technology Research and Development Program (863) of China (No. 2012AA062503) and the Environmental Nonprofit Industry Research Project of China (No. 201209005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Meng, Y., Guo, X. et al. Study of nitrogen oxide absorption in the calcium sulfite slurry. J Mater Cycles Waste Manag 18, 618–624 (2016). https://doi.org/10.1007/s10163-016-0526-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-016-0526-8