Abstract

Accelerated carbonation of municipal solid waste incineration residues is effective for immobilizing heavy metals. In this study, the contribution of the physical containment by carbonation to immobilization of some heavy metals was examined by some leaching tests and SEM–EDS analysis of untreated, carbonated, and milled bottom ash after carbonation that was crushed with a mortar to a mean particle size of approximately 1 μm. The surface of carbonated bottom ash particles on SEM images seemed mostly coated, while there were uneven micro-spaces on the surface of the untreated bottom ash. Results of Japan Leaching Test No. 18 (JLT18) for soil pollution showed that milling carbonated bottom ash increased the pH and EC. The leaching concentration of each element tended to be high for untreated samples, and was decreased by carbonation. However, after the milling of carbonated samples, the leaching concentration became high again. The immobilization effect of each element was weakened by milling. The ratio of physical containment effect to immobilization effects by accelerated carbonation was calculated using the results of JLT18. The ratio for each element was as follows: Pb: 13.9–69.0 %, Cu: 12.0–49.1 %, Cr: 24.1–99.7 %, Zn: 20.0–33.3 %, and Ca: 28.9–63.4 %.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Municipal solid waste incineration (MSWI) treatment is effective for mineralization and reducing volume, and possibly for recovering energy [e.g., 1]. In Japan, approximately 80 % of MSW is incinerated [2]. Due to the lack of appropriate sites to construct landfills [3], especially in large cities, the role of incineration in Japan will become more important in the future. MSWI residues need to be treated using environmentally safe methods. MSWI residues that do not comply with the Japanese landfill standards, mainly fly ash, must be treated by one of five methods; that is, solidification with cement, chemical immobilization using a chelate agent, leaching by acid, calcination, or melting. On the other hand, the geomechanics of MSWI bottom ash are similar to those of sand or gravel [4, 5]. MSWI bottom ash can be recycled as construction material if an appropriate treatment that satisfies environmental safety requirements is performed, for example, carbonation, calcination, or washing with acid or water [e.g., 6–8].

Accelerated carbonation is a reaction involving CO2 and combustion residues. MSWI residues exhibit alkalinity and contain hazardous substances, such as heavy metals. Carbonation immobilizes many heavy metals. It is possible using stack gas, which contains approximately 5–10 % CO2 on average [9]. It is also expected as a possible CO2 capture and storage (CCS) system due to the high CO2 uptake potential of MSWI residues, especially fly ash, for controlling climate change [10–13]. Researchers have been studying accelerated carbonation by focusing on parameters, including the concentration and pressure of CO2, the temperature or time of the carbonation reaction, and the water content of MSWI residues. Various leaching test results of carbonated residues have been reported. Costa et al. [14] reviewed the modification of ash properties by carbonation in detail. Not only are carbonates formed with very low solubility or low pH up to the neutral range, but also some heavy metals are immobilized by interaction with minerals such as Calcite and Aragonite [e.g., 15, 16]. However, the carbonation reaction is not effective for immobilizing all heavy metals. It was reported to be effective in many cases for Pb, Zn, Cu, etc., but not for oxyanionic metals, such as Cr, Mo, and Sb. Although a level of immobilization of metals was achieved, it was not always. This suggests that there are some immobilization factors, such as the carbonation conditions, the type and content of elements, the spatial heterogeneity of the elements, and the non-uniformity of the original waste, that are responsible for the difference in the immobilization effects. It was also pointed co-existence organic matter like humic acid to form metal complexation [e.g., 17, 18]. As MSWI residues have properties similar to those of cement material, it is suggested that carbonation changes not only their chemical characteristics but also their physical microstructure because of the surface coating of the calcium carbonate [19–21]. However, few quantitative studies on the effects of physical containment by the change in the microstructure of MSWI bottom ash by carbonation have been performed.

In this study, the contribution of the physical containment with carbonates to immobilization of some heavy metals was examined by leaching tests and SEM–EDS analysis of carbonated MSWI bottom ash particles that were crushed with a mortar to change the physical microstructure of the surface of the particles.

Materials and methods

MSWI bottom ash

The three kinds of water-quenched bottom ashes generated in different stoker incinerator, BA-1, BA-2, and BA-3, were used in this study. Unburnt and incombustible parts were removed as much as possible. The contents of Pb, Zn, Cd, Cr, Cu, and Ca were analyzed by ICP-AES (SPS7800, Seiko Instruments Inc.) after digestion by nitric and perchloric acid. The results are shown in Table 1. The Ca content was the highest in each sample, at 7790–17,400 mg/kg.

Accelerated carbonation treatment

Each sample was mixed with pure water (30 % of initial water content) on the plastic tray, which was then placed in a constant temperature chamber at 20 °C. Humidified CO2 gas (99.999 %) was flowed from the bottom of the chamber at 500 mL-CO2/min for 2 h (rapid carbonation). The BA-3 sample underwent slow carbonation at 20 mL-CO2/min for 14 days (BA-3s). The top and bottom of the layers of each sample was regularly mixed.

To observe and examine the elemental mapping on the surface of the particles of each sample, SEM–EDS microanalysis and semi-quantitative analysis were performed [6510A, equipped with a Si(Li) probe with 138 eV resolution; JEOL Ltd.]. The objective elements were Cl, Ca, Cr, Cu, Zn, Cd, and Pb. EDS analysis of this device was able to detect fluorescent X-rays from the surface layer to 10 μm. The carbonate content of each sample was also measured as follows. Pure water (100 ml) and 25 ml of 1 M H2SO4 were added to 5 g of each sample, and heated on a hot plate at 200 °C. The CO2 generated was trapped by two stages of 0.047 M Ba(OH)2 solution. Unreacted Ba(OH)2 was titrated by 0.25 M H2SO4 with a phenolphthalein indicator.

After carbonation, a part of each sample was milled with an automatic mortar (ANM-150, As one Inc.) at 200 rpm for 6 h. The particle size distribution of BA-1 before and after milling is shown in Fig. 1. The samples after milling were measured with a dynamic light scattering particle size analyzer (LB-550, Horiba Ltd.). The mean particle sizes of the samples before and after milling were 2.1 mm and 0.95 μm, respectively; a difference of approximately three orders of magnitude. The results were similar for the other samples.

Leaching test

The leaching characteristics of each sample were analyzed following Japan Leaching Test No. 18 (JLT18), a standard leaching test for soil pollution. Briefly, 50 g of sample and 500 ml of pure water [liquid/solid ratio (L/S): 10] were added to 1000 ml polyvinyl bottles. The bottles were then closed and shaken at 200 rpm for 6 h. The leachate was filtered through a glass fiber filter with a pore size of 0.45 μm. pH, electrical conductivity (EC), P-alkalinity, and each concentration of Pb, Zn, Cd, Cr, Cu, and Ca in the leachate were analyzed. In addition, for untreated, carbonated, and milled-after-carbonation samples of BA-3 and BA-3s, pH dependency tests at pH 4, 7, 9, and 12 were performed, respectively, at an L/S ratio of 10 for 6 h to clarify the elution characteristics of each element.

Results and discussion

Cumulative CO2 absorption

The amount of cumulative CO2 absorption calculated using the results of carbonate content is shown in Fig. 2. There was sufficient carbonation because the amount of cumulative CO2 absorption for each sample was almost maximized after each treatment time. The cumulative CO2 absorption for BA-2 was 0.68 mmol-CO2/g-BA, which was almost half of that for BA-1 (1.05 mmol-CO2/g-BA) and BA-3 (1.06 mmol-CO2/g-BA). Comparing BA-3 (rapid carbonation) with BA-3s (slow carbonation), which were the same bottom ash, the amount of cumulative CO2 absorption for BA-3s was 2.22 mmol-CO2/g-BA, which was twice that of BA-3. The mean CO2 absorption rate for each sample after the treatment time was as follows: BA-1: 0.52 mmol-CO2/g-BA/h, BA-2: 0.34 mmol-CO2/g-BA/h, BA-3: 0.53 mmol-CO2/g-BA/h, and BA-3s: 0.01 mmol-CO2/g-BA/h. The rates for BA-1, BA-2, and BA-3 were about 30–50 times that of BA-3s.

SEM–EDS analysis

SEM images and EDS elemental mapping for untreated and carbonated samples of BA-1 are shown in Fig. 3. The surface of carbonated bottom ash particle seemed mostly coated, while there were uneven micro-spaces in the untreated samples. Moreover, EDS semi-quantitative analysis of some surfaces of untreated bottom ash for target elements (Cl, Ca, Cr, Cu, Zn, Cd, and Pb) revealed that Ca was the highest, with an existence ratio of approximately 81 % (w/w %). Though X-ray diffraction analysis was not performed in this study, it was guessed that mainly Ca hydroxides changed into carbonates like Calcite and Aragonite [22–24]. Cl, Pb, and Cd were distributed similarly to Ca, but Cu, Zn, and Cr had low existence ratios, and were almost uniformly present regardless of Ca. Much time was likely required to infiltrate rain water inside the particle by carbonation. Water passing between the particle surface and internal micro-pores thought to be intercepted due to the surface coating with the carbonates. This reason increases the retention time of the contaminant-like cement mortar [25], and it was suggested to be one of the factors that affects immobilization.

Leaching results of JLT18

JLT18 results of untreated, carbonated, and milled-after-carbonation bottom ash for each sample are shown in Table 2. For targeted elements, Cd was not detected in any samples (less than 0.005 mg/L). pH ranged from 11.2 to 11.4 for untreated ashes, and decreased to 8.6–9.4 by carbonation. After milling, however, pH of each sample increased to 9.5–10.8. The EC of milled-after-carbonation samples were all bigger than those of untreated samples. This suggested that soluble substances like many Cl compounds were affected by milling. The leaching concentration of each element tended to be high for untreated samples, and was decreased by carbonation. After milling of carbonated samples, however, the concentrations were high again. Therefore, the immobilization effect of each element was likely weakened by the milling, which destroyed the physical microstructure of the surface of bottom ash particles. Comparing BA-3 with BA-3s, concentrations of both Pb and Zn were almost the same, but Cu and Cr of BA-3 were lower than those of BA-3s.

Leaching results of pH dependency test

The results of the pH dependency test for BA-3 and BA-3s are shown in Fig. 4. In both samples, the concentrations of each element after carbonation and milling were higher than those after only carbonation. Cu and Ca were immobilized by the physical containment due to carbonation because the differences of their concentrations were large before and after the milling. However, the concentrations of Pb, Zn, and Cr before and after the milling did not change so much. Especially, Cr concentration before and after the milling was considerably lower than that of untreated ash. It was suggested that Cr was immobilized by the physical containment due to carbonation.

To examine the influence of milling on elution concentration by milling, a ratio of the elemental concentration of carbonated ash for that of carbonation and milling (carbonation/carbonation and milling ratio) at each pH was calculated using Eq. (1):

where C i,c is the elemental concentration after carbonation (mg/L), and C i,cm is the one after carbonation and milling (mg/L). The subscript i indicates each element.

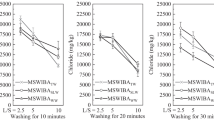

The carbonation/carbonation & milling ratio is shown in Fig. 5. The physical containment effect increases as the ratio approaches 0. Conversely, the effect decreases as the ratio approaches 1. For BA-3, the ratio was small at pH 7 and 9, which indicated that the effect of physical containment exceeded that at other pH. At pH 4 or 12, the ratio for each element was big. The effect of containment may have been lost due to the strong acid or alkaline condition while the surface was coated by carbonation (see Fig. 3). For BA-3s, the ratio was small at pH 9, so the containment effect exceeded that at other pH, while the apparent trend was only seen at pH 9.

Comparing Ca with other elements, the graph patterns were similar for BA-3 rather than for BA-3s. This suggested that Ca carbonates on the surface mainly controlled leaching of other elements by accelerated carbonation of BA-3, i.e., rapid carbonation. However, in BA-3s, which was slowly carbonated, Ca on the surface reacted slower than in BA-3. The chemical and/or mineralogical immobilization effect in BA-3s seemed to exceed that of physical containment.

Immobilization ratio due to containment by carbonation

Among immobilization effect by carbonation, the ratio (%) of physical containment effect to all immobilization effects by carbonation, P i, was calculated by the Eq. (2). In Fig. 4, as the elution concentration of each element was influenced by pH, the result of JLT18, when using pure water as the solvent and pH were determined by sample’s own contents (see Table 2), was used. The pH of the pure water was 7.1.

where P i is the ratio of the physical containment effect to all immobilization by carbonation, C i is the concentration of untreated ash (mg/L), C i,c is the concentration after carbonation (mg/L), and C i,cm is the concentration after carbonation and milling (mg/L). The subscript i indicates each element.

P i is shown in Table 3. Note that P i may change according to the extent of milling. In this study, the mean particle size of each sample after milling was approximately 1 μm. The P i for each element was as follows: Pb: 13.9–69.0 %, Cu: 12.0–49.1 %, Cr: 24.1–99.7 %, Zn: 20.0–33.3 %, and Ca: 28.9–63.4 %. Comparing the ratios for BA-3 and BA-3s, which were the same bottom ash but with different carbonation rates, the ratio for BA-3 was bigger than that for BA-3s for all elements. This suggests that physical containment is achieved more easily with rapid carbonation (BA-3) than slow carbonation (BA-3s), as indicated by the results shown in Fig. 5. However, immobilization of heavy metals by rapid carbonation was conversely suggested to be more unstable than the slow one due to Ca carbonates such as CaCO3 on the surface.

For BA-1, BA-2, and BA-3, which underwent rapid carbonation, the ratio of Zn was comparatively low. On the other hand, the ratio of Cr was high. The leaching characteristics of Cr, an oxyanionic metal, are more complex [14], so the effect of immobilization by carbonation is not apparent. As in the present study, Rendek et al. [26] showed that Cr leaching was decreased by accelerated carbonation of bottom ash, while Arickx et al. [27] reported that Cr immobilization hardly occurred. Oppositely, Bone et al. [28] indicated that carbonation enhanced Cr leaching by approximately one order of magnitude. Gerven et al. [6] reported experimental results of bottom ash under changing conditions of carbonation, CO2 concentration, temperature, and humidity. They showed that Cr leaching concentration was maximized after 6 h, but it decreased after a longer treatment. The effect of carbonation is affected by the heterogeneity of the combustible waste, condition of carbonation, reaction pathway and rate of content elements, L/S ratio, pH, oxidation–reduction condition, particle size, etc. [e.g., 29–31]. The leaching characteristics of content elements likely differed according to the predominant condition. This study indicated a possibility of physical containment as one of the immobilization effects of content elements by carbonation.

Conclusions

In this study, physical containment by carbonation as an immobilization mechanism of heavy metal in MSWI bottom ash was examined using untreated, carbonated, and milled bottom ash after carbonation that was crushed with a mortar to change the physical microstructure of the surface of the particles.

The cumulative CO2 absorption amount by carbonation was 0.68–2.22 mmol-CO2/g-BA. Comparing BA-3 and BA-3s, which were the same bottom ash but with different carbonation rates, the cumulative CO2 absorption amount of BA-3s (slow carbonation) was twice that of BA-3 (rapid carbonation).

On SEM images, the surface of carbonated bottom ash particles seemed mostly coated, while there were abundant, uneven micro-spaces on the surface of the untreated bottom ash. EDS semi-quantitative analysis of some surfaces of untreated bottom ash for target elements (Cl, Ca, Cr, Cu, Zn, Cd, Pb) revealed that Ca was the highest, with an existence ratio of approximately 81 % (w/w %), which likely changed into carbonates.

From the results of the Japan Leaching Test No. 18 (JLT18), a standard leaching test for soil pollution, milling increased the pH and EC of carbonated bottom ash. Especially, the ECs were all bigger than those of untreated samples. This suggested that soluble substances, like many Cl compounds, are affected by milling. The leaching concentration of each element tended to be high for untreated samples, and was decreased by carbonation. After milling of carbonated samples, however, the concentration became high again. Therefore, the immobilization effect of each element was likely weakened by milling, which destroyed the physical microstructure of the surface of bottom ash particles.

The ratio of carbonation/carbonation & milling was calculated using the pH dependency test results of BA-3 and BA-3s. For BA-3, the ratio for each element was small at pH 7 and 9 while at pH 4 and 12, the ratio was big. This indicated that the effect of containment at pH 7 and 9 exceeded that at pH 4 and 12. This suggested that Ca carbonates generated on the surface mainly controlled the leaching of other elements in BA-3. However, in BA-3s, which was slowly carbonated, Ca carbonation on the surface reacted slower than that on BA-3. The chemical and/or mineralogical immobilization effect in BA-3s likely exceeded that of physical containment.

To examine the immobilization effects by accelerated carbonation, the ratio due to physical containment was calculated using the results of JLT18. Comparing BA-3 and BA-3s, the ratio for BA-3 was bigger than that for BA-3s. This suggested that physical containment was achieved more easily with rapid carbonation than the slow one.

References

Autret E, Berthier F, Luszezanec A, Nicolas F (2007) Incineration of municipal and assimilated wastes in France: assessment of latest energy and material recovery performances. J Hazard Mater 139(3):569–574. doi:10.1016/j.jhazmat.2006.02.065

Japan Ministry of the Environment (2012) Annual Report on Waste management in Japan (in Japanese)

Tanaka N, Tojo Y, Matsuto T (2005) Past, present, and future of MSW landfills in Japan. J Mater Cycles Waste Manag 7(2):104–111. doi:10.1007/s10163-005-0133-6

Kayabal K, Buluş G (2000) The usability of bottom ash as an engineering material when amended with different matrices. Eng Geol 56(3–4):293–303. doi:10.1016/S0013-7952(99)00097-6

Kim YT, Do TH (2012) Effect of bottom ash particle size on strength development in composite geomaterial. Eng Geol 139–140:85–91. doi:10.1016/j.enggeo.2012.04.012

Gerven TV, Keer EV, Arickx S, Jaspers M, Wauters G, Vandecasteele C (2005) Carbonation of MSWI-bottom ash to decrease heavy metal leaching, in view of recycling. Waste Manag 25(3):291–300. doi:10.1016/j.wasman.2004.07.008

Lin CF, Wu CH, Ho HM (2006) Recovery of municipal waste incineration bottom ash and water treatment sludge to water permeable pavement materials. Waste Manag 26(9):970–978. doi:10.1016/j.wasman.2005.09.014

Izquierdo M, Querol X, Josa A, Vazquez E, López-Soler A (2008) Comparison between laboratory and field leachability of MSWI bottom ash as a road material. Sci Total Environ 389(1):10–19. doi:10.1016/j.scitotenv.2007.08.020

Sakita S., Shimaoka T., Nishigaki M., Tanaka T. (2006) Carbonation treatment of lead in municipal solid waste incineration bottom ash for beneficial use. Cement and Concrete Science (Ed.), Extended abstracts of the First Int. Conf. on Accelerated Carbonation for Environ and Mater Eng., London, UK

Lackner KS, Wendt CH, Butt DP, Joyce EL Jr, Sharp DH (1995) Carbon dioxide disposal in carbonate minerals. Energy 20(11):1153–1170. doi:10.1016/0360-5442(95)00071-N

Fernandez-Bertos M, Simons SJR, Hills CD, Carey PJ (2004) A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2. J Hazard Mater 112(3):193–205. doi:10.1016/j.jhazmat.2004.04.019

Baciocchi R, Costa G, Bartolomeo DE, Polettini A, Pomi R (2009) The effects of accelerated carbonation on CO2 uptake and metal release from incineration APC residues. Waste Manag 29(12):2994–3003. doi:10.1016/j.wasman.2009.07.012

Muriithi GN, Petrik LF, Fatoba O, Gitari WM, Doucet FJ, Nel J, Nyale SM, Chuks PE (2013) Comparison of CO2 capture by ex-situ accelerated carbonation and in in-situ naturally weathered coal fly ash. J Environ Manag 127:212–220. doi:10.1016/j.jenvman.2013.05.027

Costa G, Baciocchi R, Polettini A, Pomi R, Hills CD, Carey PJ (2007) Current status and perspectives of accelerated carbonation processes on municipal waste combustion residues. Environ Monit Assess 135(1–3):55–75. doi:10.1007/s10661-007-9704-4

Meima JA, Van der Weijden RD, Eighmy TT, Comans RNJ (2002) Carbonation processes in municipal solid waste incinerator bottom ash and their effect on the leaching of copper and molybdenum. Appl Geochem 17(12):1503–1513. doi:10.1016/S0883-2927(02)00015-X

Chaspoul FR, Le Droguene MF, Barban G, Rose JC, Gallice PM (2008) A role for adsorption in lead leachability from MSWI bottom ash. Waste Manag 28(8):1324–1330. doi:10.1016/j.wasman.2007.07.005

Zomeren AV, Comans RNJ (2004) Contribution of natural organic matter to copper leaching from municipal solid waste incinerator bottom ash. Environ Sci Technol 38(14):3927–3932. doi:10.1021/es035266v

Su L, Guo G, Shi X, Zuo M, Niu D, Zhao A, Zhao Y (2013) Copper leaching of MSWI bottom ash co-disposed with refuse: effect of short-term accelerated weathering. Waste Manag 33(6):1411–1417. doi:10.1016/j.wasman.2013.02.011

Maries A (1985) The activation of Portland cement by carbon dioxide. In: Proceedings of Conference in Cement and Concrete Sci Oxford, UK

Reijnders L (2005) Disposal, uses and treatments of combustion ashes: a review. Resour Conserv Recycl 43(3):313–336. doi:10.1016/j.resconrec.2004.06.007

García-González CA, Hidalgo A, Fraile J, López-Periago AM, Andrade C, Domingo C (2007) Porosity and water permeability study of supercritically carbonated cement pastes involving mineral additions. Ind Eng Chem Res 46(8):2488–2496. doi:10.1021/ie061571o

Speiser C, Baumann T, Niessner R (2000) Morphological and chemical characterization of calcium-hydrate phases formed in alteration processes of deposited municipal solid waste incinerator bottom ash. Environ Sci Technol 34(23):5030–5037. doi:10.1021/es990739c

Freyssinet P, Piantone P, Azaroual M, Itard Y, Clozel-Leloup B, Guyonnet D, Baubron JC (2002) Chemical changes and leachate mass balance of municipal solid waste bottom ash submitted to weathering. Waste Manag 22(2):159–172. doi:10.1016/S0956-053X(01)00065-4

Gunning PJ, Colin D, Hills CD, Carey PJ (2010) Accelerated carbonation treatment of industrial wastes. Waste Manag 30(6):1081–1090. doi:10.1016/j.wasman.2010.01.005

Johannesson B, Utgenannt P (2001) Microstructural changes caused by carbonation of cement mortar. Cement Concrete Res 31(6):925–931. doi:10.1016/S0008-8846(01)00498-7

Rendek E, Ducom G, Germain P (2006) Carbon dioxide sequestration in municipal solid waste incinerator (MSWI) bottom ash. J Hazard Mater 128(1):73–79. doi:10.1016/j.jhazmat.2005.07.033

Arickx S, Van Gerven T, Vandecasteele C (2006) Accelerated carbonation for treatment of MSWI bottom ash. J Hazard Mater 137(1):235–243. doi:10.1016/j.jhazmat.2006.01.059

Bone BD, Knox K, Picken A, Robinson HD (2003) The effect of carbonation on leachate quality from landfilled municipal solid waste (MSW) incinerator residues. In: Proceedings of Sardinia 2003, Ninth International Waste Management Landfill Symposium (on CD-ROM)

Chimenos JM, Fernández AI, Miralles L, Segarra M, Espiell F (2003) Short-term natural weathering of MSWI bottom ash as a function of particle size. Waste Manag 23(10):887–895. doi:10.1016/S0956-053X(03)00074-6

Todorovic J, Ecke H (2006) Demobilisation of critical contaminants in four typical waste-to-energy ashes by carbonation. Waste Manag 26(4):430–441. doi:10.1016/j.wasman.2005.11.011

Rendek E, Ducom G, Germain P (2007) Influence of waste input and combustion technology on MSWI bottom ash quality. Waste Manag 27(10):1403–1407. doi:10.1016/j.wasman.2007.03.016

Acknowledgments

This study was supported by the Japan Society for the Promotion of Science (JSPS), Grant Number 21760420.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakita, S., Nishimura, K. Physical containment of municipal solid waste incineration bottom ash by accelerated carbonation. J Mater Cycles Waste Manag 18, 687–694 (2016). https://doi.org/10.1007/s10163-015-0369-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-015-0369-8