Abstract

Vermicomposting of organic fraction of compostable municipal waste solids (CMWS) spiked with cow dung at ratio 0, 20, 40, 60, 80 and 100 % was done using earthworm Eisenia fetida. Pre-composting for 3 weeks followed by vermicomposting caused decrease (fold) in pH (1.06–1.17), organic carbon (1.07–1.36) and C:N ratio (1.60–2.89) and substantial increase (fold) in total N (1.50–2.45), total phosphorous (1.37–1.96), total potassium (1.12–2.09) and trace elements—Ca, Fe, Mn and Zn (1.02–1.32) in waste mixtures. The wastes with 40–60 % fraction of CMWS showed high decomposition and mineralization rate than other treatments. The biomass gain and cocoon production in E. fetida were also monitored in all experimental vermibeds. The earthworm showed better growth rate and reproduction pattern in vermibeds with 40–60 % CMWS. The C:N ratio and chemical composition of end product suggested the suitability of vermicomposting technique to recover valuable plant nutrients from negligible community waste solids for sustainable soil fertility management programme.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The municipal solid waste (MSW) generated in Indian cities has increased from 6 million tons in 1947 to 300 million tons per annum in 2007 [1]. In India, the amount of waste generated per capita is estimated to increase at a rate of 1–1.33 % annually [2]. In such conditions, the total waste quantity generated in 2047 would be approximately above 260 million tons, more than five times the present level. This enormous increase in solid waste will have significant impacts in terms of the land required for disposing this waste as well as on methane emission. Moreover, 40–60 % solid wastes in India are of organic nature and open dumping of such garbage not only facilitates the breeding for the disease vectors, e.g., flies, mosquitoes, cockroaches, rats, and other pests [1], but at the same time also creates the issues of environmental pollutions. The safe disposal of solid waste has continued to be a big challenge in most of the urban centers in the country.

Reducing, reusing and recycling have been promoted as one of the sustainable tools for effective solid waste management programme [3]. In majority of the cases, the biodegradable organic fractions have been reported as major constituent of MSW, especially in developing countries. The biodegradable MSW contains a wide range of plant beneficial nutrients which can be recovered through appropriate biotechnologies. The organic waste recycling is an efficient and environmental-friendly technology to convert wastes into value-added products. The decomposition of complex organic waste resources into odor-free humus like substances through the action of worms is termed as vermicomposting. Dominguez and Edwards [4] and Dominguez [5] stated that “earthworm acts as mechanical blenders, and by comminuting the organic matter, they modify its biological, physical and chemical status, gradually reducing its C:N ratio, increasing the surface area exposed to microorganisms, and making it much more favorable for microbial activity and further decomposition”. In this process, inoculated earthworms maintain aerobic conditions, ingest solid, convert a portion of the organics into worm biomass and respiration products, and expel the remaining partially stabilized product, i.e., vermicompost [6]. The quality of end material in vermicomposting process is relatively better than composting in terms of chemical as well as microbial properties. In general, it would appear that composted material from vermicomposting can have “added-value” characteristics, mainly related to conservation of nutrients and moisture as well as particle size reduction [7].

Kaviraj and Sharma [8] investigated the potential of exotic and local species of earthworm for source-segregated municipal solid waste degradation. Results suggested that vermicomposting causes significant changes in chemical characteristics of MSW. Similarly, John Paul et al. [9] reported vermicomposting of municipal waste solids spiked with cow dung by employing earthworm species Perionyx ceylanensis for 50 days. Data showed that earthworm causes significant enrichment of microbial populations by providing suitable conditions for microbial propagations. Singh et al. [10] concluded that vermicomposting may be a suitable option for urban solid waste management. It is clear from the literature review that frequent reports on vermicomposting of municipal solid waste are available in literature, but comprehensive studies on some important issues like fate of trace elements in MSW during vermicomposting are not well addressed. Nonetheless, apart from NP & K, the trace elements are essentially required nutrients for plant production and, therefore, the changes in trace elements should be measured in composted materials. The issue of earthworm survival, growth and productivity of inoculated worms in MSW feedstock is not well unexplored by previous researchers who published work on vermicomposting of MSW organic fractions.

Therefore, the aim of this study was to recycle the nutrients from biodegradable fractions of MSW using potential of a composting earthworm Eisenia fetida (Savigny), under laboratory conditions. The compostable municipal waste solids (CMWS) was spiked with a bulky agent cow dung (CD) into different proportions to produce different combinations of the waste for vermicomposting operation. MSW is a heterogeneous mixture of urban waste solids of different physical and chemical nature. The microbial activation is essentially required for starting any biological degradation of waste stuff. For that cow dung is appeared as suitable bulky material for preparing a microbially active substrate for composting and vermicomposting operation [4, 8–10]. Therefore, CD was used to prepare waste mixtures of CMWS for the current experiment. The second object, i.e., biology of composting earthworms (worm biomass, numbers and cocoon production) in vermicomposting system was also monitored in all waste feedstock during the vermicomposting process.

Materials and methods

Background: urban solid waste collection and disposal system

Solid waste used in this study was collected from primary and secondary waste deposition sites in commercial centres of the city. The secondary waste collection system is composed of open, masonry, concrete and metallic containers. The waste collection is mainly composed of fixed-point communal containers. The metallic communal containers are placed at fixed position near to the commercial centre where they could be as accessible as possible to local store/shop holders/residents. The waste is then further collected and transported to land dumping sites by municipality. A variety of shops/stores (food, fruit/vegetable shop, sweets shops, cloths, stationary, furniture, electronic/electrical items, restaurants, cafeteria, etc.) are located in major commercial centres of the city. The waste produced from these centers includes: polythene bags, plastic scraps, food waste, food packing waste, soiled papers, fresh papers, cardboards, husk and straw, vegetable wastes (discarded vegetables/fruits, fresh or dried skins of vegetables/fruits, fresh/dried leaves, peel off material, paper packing, etc.), metal containers, plastic containers, plastic utensils, clothes, leather, sanitary napkins, glass scrape, etc. The daily waste production in main (2–3) commercial centre of the city is about 4–7 tons/day. About 46–62 % of total solid waste is of biodegradable nature which can be utilized for further composting operation. The vegetable/fruit trading is one of the major economical ventures in these commercial centres. The daily trading of vegetables and fruits in this city is ~150–200 tons/day. Such huge quantities of vegetables and fruit trading produce a great quantity of solid wastes (~2.5–5.0 tons/day).

Earthworms, bulking agent and compostable urban solid waste collection

Juvenile and adult specimens of the earthworm species Eisenia fetida were collected from a stock culture maintained in our laboratory and fed with partially decomposed cow dung. In majority of the previous studies, E. fetida was used as a candidate species for vermicomposting operation, because it can tolerate wide pH range, temperature, moisture and a wide range of putrescible substances and biotoxic compounds [4].

The cow dung was used as bulk agent to prepare different waste mixtures for vermicomposting operation. Fresh cow dung was procured from a local cattle shed.

Freshly deposited solid waste sample (~10–15 kg) was collected from 2 to 3 secondary deposition points of the commercial centre. All collected samples of solid waste were mixed together to produce a homogenous sample of solid waste. The waste was then collected in large polythene bags and immediately brought the laboratory. The waste sample contained about 45–60 % moisture. In laboratory, the waste was screened out to separate waste into different waste fractions (food/vegetable waste, leaf litter, paper waste, polythene/plastic, metals, glass, cardboards, textiles, leather, etc.). The waste composition (% of total weight) was as follows: vegetable/food = 51–68 %, soiled/fresh paper waste = 8–12 %, leaf litter = 2–2.5 %, polythene/plastic bags and bottles = 5–9.5 %, cardboards = 9–11 %, metal/plastic containers = 3–4.7 %, glass 1.2–3 %, and miscellaneous = 2–6.9 % (dirt and silt, textile, leather, battery, electrical wire, wood, husk, etc.). For vermicomposting operation, biodegradable fractions (food/vegetable waste, soiled papers and leaf litter) were used in this study. The biodegradable fraction was sorted manually and dried under shed for a week. Then, waste fraction was kept for pre-composting or thermal decomposition process for 3 weeks in large-sized cement containers (30 L capacity). Appropriate moisture was maintained during this period by sprinkling water over composting beds after each week’s interval. The waste was turned after each 3–4 days interval to maintain aeration in composting pile. After 3 weeks, partially composted waste was then used for further vermicomposting operation.

The physico-chemical characteristics of processed homogenized compostable urban waste solids (CUWS) and CD are presented in Table 1.

Preparation of waste mixtures for vermicomposting trial and observation recorded

For vermicomposting trials, a total of six bedding materials were used in this study. The detail of experimental bedding is described in Table 2.

The partially decomposed CMWS was mixed with bulky material CD to produce different waste mixtures. For laboratory trial, 750 g (on dry weight basis) waste mixture was filled in plastic circular containers of 3 L size, with pierced lid for aeration. The experimental beddings were kept in triplicate for each treatment and the experimental container with pure cow dung acted as an experimental control. Twenty-five (4 to 5-week-old) earthworms (individual live weight ≈ 279–286 mg) were released into each experimental container. The moisture level of all substrates in vermibeds was maintained around 60–65 % throughout the study period by sprinkling of adequate quantity of water after each week interval. The experimental containers were placed in a humid and dark room at a temperature of 27.3 °C (SD = 0.06). The earthworm mortality was observed for initial critical periods (for initial 3 weeks of experimental starting) and data of mortality were recorded for different experimental vermibeds. The experiment was run for a total of 8 weeks and to measure the physico-chemical changes in waste mixture, homogenized samples of the substrate material were drawn after each week interval. The samples were oven dried (48 h at 60 °C), ground in stainless steal blender and stored in sterilized plastic airtight containers for further physico-chemical analysis.

The biological parameters of inoculated earthworms in vermibeds were also measured weekly during vermicomposting operation. To measure the changes in individual biomass, earthworms were separated from the substrate material by hand sorting, after which worms were washed in tap water to remove adhering material from their body, and subsequently weighed on a live weight basis. Then, all measured earthworms were returned to the original containers. The newly produced cocoons were also separated from the containers and counted for each test container. Separated cocoons and new hatchlings (if observed) were introduced into a separate bedding container just to avoid overlapping in total cocoon counting. On the basis of obtained data of biomass and cocoon numbers, other parameters of earthworm, i.e., maximum biomass achieved, net biomass gain, maximum growth rate (mg wt worm−1 day−1), and reproduction rate (cocoon worm−1 day−1) were produced for different waste mixtures.

Chemical analysis

The pH was measured using a digital pH meter (Metrohm, Swiss-made) in 1:10 (w/v) aqueous solution (deionized water). Total organic carbon (TOC) was measured after igniting the sample in a Muffle furnace at 550 °C for 60 min by the method of Nelson and Sommers [11]. Total Kjeldahl nitrogen (TKN) was measured using the method described by Jackson [12]. Total phosphorous (TP) was measured using the method described by Anderson and Ingram [13]. Exchangeable potassium was determined after extracting the sample using ammonium acetate [14]. Trace elements (Ca, Mn, Fe and Zn) were determined using the following acid mixture (10-mL HNO3 + 5-mL HCLO4) and analyzed by atom absorption spectrophotometer [15]. Biodegradability coefficient indicates the organic matter (OM) contents: OM % = (100 − Ash content %). Biodegradability coefficient (Kb) was calculated using the following equation [16]:

where OMf is the organic matter content at the end of the process and OMi is the organic matter content at the beginning of the process.

Statistical analysis

Two-way ANOVA was used to analyze the differences between treatments by considering time and waste composition (treatment) as factors in physico-chemical changes during vermicomposting process. A Tukey’s t test was also performed to identify the homogeneous type of the data sets. SPSS® statistical package (Window Version 13.0) was used for data analysis. All statements reported in this study are at the p < 0.05 levels.

Results and discussion

Changes in physico-chemical quality of waste mixtures during vermicomposting

The physico-chemical quality of the worm-processed material was analyzed during this study. Vermicomposted waste mixtures were more stabilized odor-free and nutrient-rich material than initial waste mixtures (Table 3).

As described in Table 4, the major chemical characteristics of bedding materials changed drastically after vermicomposting. The pH of the substrate material was lower in all treatments than their initial values (Table 4).

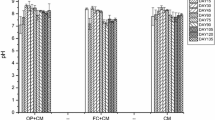

The pH of the vermicomposted material was in the ranges of 7.16 (T 5)–7.57 (T 2). A trend of gradual reduction in pH was observed in all treatments (Fig. 1). In few waste set-ups, the decline in pH was moderate up to 5–6 weeks and then it becomes very steady.

The change in pH could be due to the production of metabolites and intermediate compounds (e.g., CO2, ammonia, NO3 − and organic acids, Ndegwa et al. [17]). The decrease in pH helps to conserve the nitrogen in vermicompost, as this element is lost as volatile ammonia at high pH values [18]. TOC decreased significantly in all vermibeds during vermicomposting process. The rate of TOC loss in vermibeds was in the ranges of 6.47 (T 1)–26.3 (T 5) %. The TOC loss in treatment mixture was in the order: T 1 > T 6 > T 2 > T 3 > T 4 > T 5. The trend of TOC changes is presented in Fig. 1. As results suggest, there was similar trend of TOC loss in all waste mixtures except in T 1 and T 5. TOC showed gradual decrease during vermicomposting in all waste mixtures (Fig. 1). It is clear that increasing proportion of urban solid waste in vermibeds enhances the carbon mineralization but at higher concentration urban waste solids caused drastic effect on C mineralization. This suggests that urban waste solids appear as good feedstock for earthworm culture up to 60 % concentration spiked with bulky agent (CD). The loss in TOC may be attributed to the microbial respiration during vermicomposting process. Moreover, digestion and assimilation of some carbon sources in feedstuff (carbohydrates and other polysaccharides) by earthworms could cause C loss from the substrates. The fragments homogenize the ingested material through muscular action of their foregut and subsequently enhance the surface areas for microbial degradations of wastes. The functional mutualism between gut-microbes and earthworms accelerates the carbon mineralization if the waste mixes during vermicomposting operation [5].

There was increase in total nitrogen (TKN) contents in all vermibeds at the end of the experiment. The TKN in ready vermicompost was in the ranges of 11.49 ± 0.53–20.53 ± 0.55 g kg−1. The maximum increase in TKN content was in T 4 (145 % more than initial level) followed by T 5 (129.2 %), T 3 (106.2 %), T 2 (81.9 %), T 1 (67.7 %) and T 6 (49.9 %). A trend of rapid increase in TKN content was recorded in all waste mixtures except in T 1 and T 6 (Fig. 1). TKN increased sharply in all waste mixtures during vermicomposting (Fig. 1).The nitrogen mineralization was directly related to the content of urban waste solids in vermibeds. Data clearly suggested that nitrogen increase in vermicomposted material was directly related to the physical and chemical nature of the substrate material used for earthworm feed. Earthworm also alters the microclimatic conditions of vermibeds which consequently promote microbial populations responsible for N enrichment. Also, mucus, a polysaccharide, is secreted by earthworm to moisten the body surface and also importantly to enrich vermibeds with nitrogen fixers. The study by Kevian and Ghatnekar [19] suggested the enhanced population of N fixers (Azotobacter and Rhizobium) in vermibeds, while working on vermicomposting of paper mill sludge. In addition to releasing N from compost material, earthworms also enhance nitrogen levels by adding their excretory products, mucus, body fluid, enzymes, etc. to the substrate. Results thus indicate that N enrichment was better in vermibeds with 40–60 % proportion of urban waste solids. This indicates the suitability of urban waste solids for such vermicomposting operation for quality compost production if it is mixed with an appropriate bulky agent.

The total phosphorous content in vermibeds was high in vermicomposted waste mixtures than initial materials. The level of TP in end material was in the ranges of 12.78 ± 0.23 (T 1)–18.60 ± 0.62 g kg−1 (T 5) for different waste mixtures. The changes of TP in all waste mixtures over the composting duration are illustrated in Fig. 1. TP showed similar trend of increase except to T 5 which showed swift increase after 4th week of vermicomposting (Fig. 1). TP is an essential nutrient required for better plant growth. The high level of TP in ready vermicompost suggests its potential as plant growth media for sustainable agronomic production. There was significant difference among different vermibeds for nitrogen mineralization rate. The observed differences could be due to the feedstock compositions. The P-mineralization is performed partly by earthworm gut phosphatases, and further release of P is facilitated by microbial communities associated with deposited casts [20]. Few author suggested the role of P-solubilizing bacteria in phosphorous enhancements in deposited casts of earthworms [21, 22].

TK was high in vermicomposted materials than in initial waste mixtures. In vermicomposted material, TK content was in the ranges of 15.89–28.81 g kg−1. TK changes in waste mixture were relatively slow during experimentation except to T 5 (Fig. 1). In T 5 an abnormal increase in TK content was recorded after 3rd week (Fig. 1). K is an essential component for plant growth and high level of TK in ready materials indicates the suitability of vermicomposted material for land applications. The earthworm plays an important role in potassium mineralization during vermicomposting process. In general, when organic waste passes through the gut of worm, some fraction of organic minerals is then converted into more available species of nutrients (i.e., exchangeable forms) due to the action of endogenic and/or exogenic enzymes [23]. This result agrees with previous reports that the vermicomposting accelerates the waste mineralization rate by facilitating the microbial communities in decomposing waste sub-systems [8, 22–24] concluding that earthworm plays an important role in microbial-mediated nutrient mineralization in waste decomposition process.

Total calcium content in vermicomposted material was significantly higher than initial level in waste mixtures. Total calcium level in vermicomposted material was in the ranges of 241.0 ± 1.15–278.0 ± 1.15 g kg−1 in different vermibeds. The trend of calcium mineralization during experiment is described in Fig. 1. The calcium mineralization rate showed drastic variations among different waste mixtures. The Ca-mineralization in vermicomposting sub-system is the result of earthworm activities in waste mixtures. Further mineralization is facilitated by the fugal hyphae or other microbial communities after cast’s deposition in vermibeds [24]. Calcium is also added in worm casts through secretions of calcium glands of few earthworms. But in E. fetida, such evidences are not clear. The difference among different vermibeds for calcium mineralization rate attributed to the quality of the substrate mixture.

Vermicomposting also caused significant changes in level of trace elements (Fe, Mn and Zn). The concentration of total Fe, total Mn and total Zn in vermicomposted material was in the ranges of 1368.0 (T1)–1603.3 (T 2) mg kg−1, 569.3 (T 1)–1043.3 (T 2) mg kg−1 and 154.0 (T 3)–236.7 (T 2) mg kg−1, respectively. The changes in Fe, Mn and Zn level in waste mixture during vermicomposting are described in Fig. 1. There was about 2.20–15 % increase in total Fe contents in waste mixtures after vermicomposting operation. Total Mn increase during vermicomposting was in the order: T 1 (32.3 %) > T 2 (17.6 %) > T 3 (16.2 %), T 4 (12.5 %), T 5 (12.0 %) > T 6 (7.04 %). Trace elements are important components of soil chemistry and require essentially for normal plant growth and metabolism. Its deficiency in soil may lead to several physiological disorders in commercial crops. The considerable content of such elements in ready vermicompost indicates its agronomical potential for land applications. Results thus indicate that vermicomposting may be a sound method to recover precious plant nutrients from discarded organic wastes for sustainable soil fertility program. The mineralization of trace elements may be due to enzymatic activities by earthworms and gut-associated microflora. Moreover, mineralization and biological activation of freshly deposited casts in few week old vermicomposting substrates may be accelerated by colonization on microbial communities [8].The semi-digested substances with easy available nutrients in freshly deposited earthworm casts attract detritus communities (fungal and micro-algal hyphae, bacteria, protozoan, nematodes, actinomycetes, etc.) which directly or indirectly enhance the quality of vermicompost in terms of trace elements, vitamins and plant growth-promoting substance, etc. [22].

The C:N ratios of waste mixtures showed significant changes after vermicomposting process in all vermibeds. The vermicomposted material showed C:N ratio in the range of 17.4 (T 5)–37.3 (T 1) (Table 5).

The parameter traditionally considered to determine the degree of maturity of compost and to define its agronomic quality is the C:N ratio Nair et al. [25]. According to a standard the C:N ratio below 20 is indicative of acceptable maturity, while a ratio of 15 or lower was preferable for agronomic used of composts. Results thus indicate that C:N ratios of vermicomposted urban waste solids were slightly higher than standard described by Morais and Queda [26] except in T 4 (18.5) and T 5 (17.4). The difference in vermibeds for carbon mineralization and nitrogen enrichment rate leads to drastic alternation in C:N ratio of the end materials during vermicomposting process. The greater shift in C:N scale in T 3, T 4 and T 5 vermibeds indicates the fast mineralization in the presence of earthworms. The shifting in C:N ratio is directly related to the quality of feedstock used for composting/vermicomposting operation. The waste high palatability and decomposing efficiency result in composts with low C:N ratios. In general, the loss of carbon as carbon dioxide due to respiratory activities of earthworms and associated microflora, and simultaneous addition of nitrogen in the substrate material by inoculated earthworms (through production of mucus, enzymes and nitrogenous excrements) lower the C:N ratio of the substrate [22, 27]. The C:P ratio was also calculated for ready materials in all vermibeds. The range of C:P ratio in vermicomposted material was: 18.0 (T 5)–29.9 (T 2). The loss or stabilization of carbon during vermicomposting process and enhancement of phosphorous in decaying substrate result in reduced C:P ratio of vermicomposted materials. C:P ratio is an important indicator of quality of vermicompost as phosphorous plays an important role in plant metabolism. The C:P ratio of vermicomposted material was higher than the acceptable limit (15:1) as suggested by Edwards and Bohlen [28].

The statistical analysis suggested the impact of vermicomposting period and composition of waste mixture on mineralization rate of different physico-chemical parameters (Table 6), except in total zinc. Treatment (waste mixture type T) and time (composting period t) showed the direct impact on changes of pH and TKN level during vermicomposting, but factors’ interaction (T × t) was not statistically significant (two-factor ANOVA). The results of statistical analysis showed the role of waste mixture type and experiment during waste mineralization mechanism.

Growth and cocoon production by E. fetida in different waste mixtures

The biological productivity of inoculated earthworms in waste mixtures is considered as the key indicator of potential of wastes for vermicomposting operation. The earthworms showed growth and cocoon production in all vermibeds, but rate of growth and productivity was directly related to the composition of the waste feedstock. There was statistically significant difference (ANOVA) among waste mixtures for observed parameters of earthworms: the maximum individual live weight (F = 130.54, p < 0.001), total individual biomass gain (F = 92.45, p = 0.001), the maximum individual growth rate (mg wt worm−1 day−1) (F = 116.85, p < 0.001), total cocoon production (F = 48.0, p < 0.001), reproduction rate (cocoon worm−1) (F = 38.97, p < 0.001). The changes in individual live weight of inoculated earthworms in all waste mixtures are illustrated in Fig. 2.

E. fetida showed rapid growth (biomass gain) in all waste mixtures during initial 4–5 weeks thereafter; a trend of stabilization or declined was recorded in all vermibeds. The earthworm achieved peak biomass after 6–7 weeks in different waste mixtures. The peak biomass was recorded: 521.0 ± 1.53 mg in T 1, 529.7 ± 2.60 mg in T 2, 593.3 ± 3.84 mg in T 3, 623.3 ± 7.26 mg in T 4, 696.3 ± 6.83 mg in T 5 and 549.3 ± 9.06 mg in T 6 ( Table 7).

The maximum individual biomass in earthworm was recorded in T 5. The observed difference among different treatments for the peak biomass may be due to quality of feed stock which directly affects the feed palatability and assimilation rates [29]. The individual weight in earthworms, at the end, was relatively lower than peak biomass. It could be attributed to the degradability of waste feedstock. E. fetida exhibited the maximum individual live weight after 11–14 weeks of vermicomposting (Fig. 1). Suthar [29] and Neuhauser et al. [30] have reported similar trend in weight loss in E. fetida on allowing these earthworms for longer duration in the treated sludge. It is suggested that weight loss was due to conversion of most of the used substrate to vermicompost, which further does not support the growth of earthworms [22]. The maximum net biomass gain in individual earthworm was recorded as 410.7 ± 5.81 mg in T 5, while T 2 showed the minimum range of biomass gain, i.e., 240.7 ± 2.40 mg (Table 5). Net biomass gain in inoculated earthworms was in the order: T 5 > T 4 > T 3 > T 6 > T 1 > T 2. The earthworm biomass gain is directly related to the quality of feedstock and feeding rate. The maximum growth rate is an important indicator of earthworm growth patterns in waste mixtures. In this study, the maximum earthworm growth rate was 8.38 ± 0.12 mg wt worm−1 day−1 in T 5 and it was significantly higher than T 1 (4.94 ± 0.02 mg wt worm−1 day−1), T 2 (4.91 ± 0.21 mg wt worm−1 day−1), T 3 (7.51 ± 0.21 mg wt worm−1 day−1), T 4 (8.12 ± 0.13 mg wt worm−1 day−1) and T 6 (5.46 ± 0.24 mg wt worm−1 day−1). The difference among T 1, T 2 and T 6 for the maximum individual growth rate was not significantly different (ANOVA/Tukey’s t test; p = 0.181). The better growth patterns of earthworms in T 4 and T 5 waste mixtures could be due to the high-feeding rate in earthworms. The urban solid waste contained several components which constitute favorable feeding stuff for earthworms. The major faction in urban waste solid was food waste and vegetable waste which are included as one of the best culture substrates for composting earthworms [29]. Moreover, vegetable wastes have different palatability, particle size, protein and crude fiber contents that can influence the earthworm growth trends in waste mixtures during vermicomposting. The biomass gain per unit of waste mixture is an important indicator of earthworm productivity in vermicomposting sub-system. As described in Table 6, the maximum value of biomass gain per unit waste mg g−1 was in T 5 (2.05 ± 0.029) followed by T 4, T 3, T 6, T 1 and T 2.

There was significant difference among waste mixtures for total cocoon numbers during vermicomposting process. The maximum cocoon numbers were recorded in T 4 (167.0 ± 6.35), while T 6 showed the minimum cocoon production, i.e., 58.0 ± 5.86. The cocoon production trend in waste mixtures was in the order: T 4 > T 5 > T 3 > T 2 > T 1 > T 6 (Table 7).

Statistically, the variation among T 3, T 4 and T 5 was not significant (ANOVA/Tukeys t test; p = 0.060). The maximum reproduction rate was recorded in T 4 (8.35 ± 0.32 cocoons worm−1) followed by T 3, T 5, T 2, T 1 and T 6 (Table 8). The cocoons laying frequency (cocoons week−1) in waste mixture was also measured during this study. The maximum cocoon production frequency was 20.88 ± 0.79 in T 4 vermibed, while in T 6 the minimum cocoons production rate was recorded (i.e., 7.25 ± 0.73). The waste mixtures can be arranged in the following order for cocoon production frequencies in waste mixtures: T 4 > T 3 > T 5 > T 2 > T 1 > T 6 (Table 8). It is clear from results that cocoon production in waste mixtures was directly related to the feedstock quality. E. fetida showed better cocoon production rate in waste mixtures with 40–60 % proportion of urban waste solids. Edwards et al. [31] concluded that the important difference between the rates of cocoon production in the two organic wastes must be related to the quality of the wastes (Table 8). The proportion of waste in feedstock directly affects the earthworm growth patterns in vermibeds. However, microbes, which play an important role in earthworm’s diet, are directly interrelated to the quantity of the hazardous materials in earthworm feed. Kaur et al. [32] while studying vermicomposting of paper mill sludge reported better results of earthworm performance, evident from better population build-up in mixtures over 100 % paper mill sludge. It is clear that high content of urban waste solids in vermibeds alters the reproduction performance.

There was population mortality in waste mixtures during initial critical period of establishment in vermicomposting process. The earthworm mortality rate did not show statistically significant difference among different waste mixtures (ANOVA: F = 2.613, p = 0.080). The maximum earthworm mortality rate was recorded in T 6 followed by T 5, T 2, T 1, T 3 and T 4. The physical as well as chemical composition of waste mixture affects the earthworm survival in waste mixtures during vermicomposting operations. The rapid mineralization by bacterial and other microflora in decaying waste produces a great quantity of ammonia, which causes earthworm mortality by shifting pH and by direct toxic effect in earthworms. Suthar [23] concluded that the food consumption rate in earthworm during initial critical period (period of acclimatization of earthworms in waste system) also determines the survival rate of earthworms in vermibed. However, C:N ratio of initial feedstuff may be a limiting factor for earthworms in wastes by directly influencing their feed consumption rate. Comparatively, a high earthworm mortality rate in T 6 waste mixture could be due to the presence of some toxic substances in pure urban waste solids.

Conclusions

The worm-worked MSW (manure) was a stabilized and soil nutrient-rich stuff to be used for added-value product for land farming practices. The vermicomposting caused many-fold increases in the level of some important plant nutrients (e.g., total N, available P and exchangeable K). In majority of waste mixtures, the C:N ratio of manure was within acceptable limit (1:20). The ratio of CMSW in waste mixture was very important in terms of waste mineralization, and beddings with 40–60 % CMWS contents showed the high rate of decomposition/mineralization rate. Two-factor ANOVA suggested that composting duration and ratio of CMWS in waste mixture both affect the waste mineralization rate in vermicomposting system, except for a few parameters. The study provides a sound basis that vermicomposting can be a potential technology to convert the noxious community wastes into value-added material to achieve sustainable urban solid waste management goal.

References

Central Pollution Control Board (CPCB) (2000) Management of municipal solid waste. Central Pollution Control Boards, New Delhi

Shekdar AV (1999) Municipal solid waste management—the Indian perspective. J Indian Assoc Environ Manag 26(2):100–108

UNEP (2009) Developing integrated solid waste management plan—training manual. UNEP DTIE International Environmental Technology Centre, Osaka, p 176

Dominguez J, Edwards CA (2010) Relationships between composting and vermicomposting: relative values of the products. In: Edwards CA (ed) Vermiculture technology, 1st edn. CRC Press, USA, pp 11–25

Dominguez J (2004) State-of-the art and new perspectives on vermicomposting research. In: Edwards CA (ed) Earthworm ecology, 2nd edn. CRC Press, USA, pp 401–424

Loehr RC, Neuhauser EF, Malecki MR (1985) Factors affecting the vermistabilization process. Water Res 19(10):1311–1317

Gomez-Brandon M, Lazcano C, Lores M, Dominguez J (2011) Short-term stabilization of grape marc through earthworms. J Hazard Mater 187:291–295

Kaviraj Sharma S (2003) Municipal solid waste management through vermicomposting employing exotic and local species of earthworms. Bioresour Technol 90:169–173

John Paul JA, Karmegum N, Daniel T (2011) Municipal solid waste (MSW) vermicomposting with an epigeic earthworm, Perionyx ceylanensis Mich. Bioresour Technol 102:6769–6773

Singh RP, Singh P, Araujo ASF, Ibrahim MH, Sulaiman O (2011) Management of urban solid waste: vermicomposting a sustainable option. Resour Conserv Recycl 55:719–729

Nelson DW, Sommers LE (1996) Total carbon and organic carbon and organic matter. In: Page AL, Miller RH, Keeney DR (eds) Method of soil analysis. American Society of Agronomy, Madison, pp 539–579

Jackson ML (1975) Soil chemical analysis. Prentice Hall of India, New Delhi

Anderson JM, Ingram JS (1993) Tropical soil biology and fertility. A handbook of methods. Commonwealth Agriculture Bureau, Oxon

Simard RR (1993) Ammonium acetate extractable elements. In: Martin R, Carter S (eds) Soil sampling and methods of analysis. Lewis Publisher, Florida, pp 39–43

APHA–AWWA–WPCF (1994) Standard methods for the examination of water and wastewater, 15th edn. American Public Health Association, Washington, DC

Diaz LF, Savage GM, Eggerth LL, Golueke CG (1996) Solid waste management for economically developing countries. International Solid Waste Association, Copenhagen

Ndegwa PM, Thompson SA, Das KC (2000) Effects of stocking density and feeding rate on vermicomposting of biosolids. Bioresour Technol 71:5–12

Hartensein R, Hartenstein F (1981) Chemical changes affected in activated sludge by the earthworm Eisenia fetida. J Environ Qual 10:377–382

Kavian MF, Ghatneker SD (1991) Bio-management of dairy effluents using culture of red earthworms (Lumbricus rubellus). Indian J Environ Prot 11:680–682

Vinotha SP, Parthasarthi K, Rangnathan LS (2000) Enhanced phosphatase activity in earthworm casts is more of microbial origin. Curr Sci 79(9):1158–1159

Pramanik P, Ghosh GK, Ghosal PK, Banik P (2007) Changes in organic—C, N, P and K and enzymatic activities in vermicompost of biodegradable organic wastes under liming and microbial inoculants. Bioresour Technol 98:2485–2495

Hanc A, Pliva P (2013) Vermicomposting technology as a tool for nutrient recovery from kitchen bio-waste. J Mater Cycles Waste Manag. doi:10.1007/s10163-013-0127-8

Suthar S (2010) Recycling of agro-industrial sludge through vermitechnology. Ecol Eng 36:1028–1036

Pramanik P, Chung YR (2011) Changes in fungal population of fly ash and vinasse mixture during vermicomposting by Eudrilus eugeniae and Eisenia fetida: documentation of cellulose isozymes in vermicompost. Waste Manag 31:1169–1175

Nair J, Sekiozoic V, Anda M (2006) Effect of pre-composting on vermicomposting of kitchen waste. Bioresour Technol 97:2091–2095

Morais FMC, Queda CAC (2003) Study of storage influence on evolution of stability and maturity properties of MSW composts. In: Proceeding of the fourth international conference of orbit association on biological processing of organics: advances for a sustainable society part II, Perth, 2003

Tripathi G, Bhardwaj P (2004) Decomposition of kitchen waste amended with cow manure using epigeic species (Eisenia fetida) and an anecic species (Lampito mauritii). Bioresour Technol 92:215–218

Edwards CA, Bohlen PJ (1996) The biology and ecology of earthworms, 3rd edn. Publ. Chapman & Hall, London

Suthar S (2007) Vermicomposting potential of Perionyx sansibaricus (Perrier) in different waste materials. Bioresour Technol 97:2474–2477

Neuhauser EF, Loehr RC, Makecki MR (1988) The potential of earthworms for managing sewage sludge. In: Edwards CA, Neuhauser EF (eds) Earthworm in waste and environmental management. SPB Academic Publishing, The Hague, pp 9–20

Edwards CA, Dominguez J, Neuhauser EF (1998) Growth and reproduction of Perionyx excavatus (Perr.) (Megascolecidae) as factors in organic waste management. Biol Fertil Soils 27:155–161

Kaur A, Singh J, Vig AP, Dhaliwal SS, Rup PJ (2010) Cocomposting with and without Eisenia fetida for conversion of toxic paper mill sludge to a soil conditioner. Bioresour Technol 101:8192–8198

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suthar, S., Kumar, K. & Mutiyar, P.K. Nutrient recovery from compostable fractions of municipal solid wastes using vermitechnology. J Mater Cycles Waste Manag 17, 174–184 (2015). https://doi.org/10.1007/s10163-014-0238-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-014-0238-x