Abstract

We show here that a new labyrinthulid strain, L72, isolated from a fallen leaf in the Seto Inland Sea of Japan, produced only docohexaenoic acid (DHA) among all the long-chain polyunsaturated fatty acids (LCPUFAs). The main fatty acid composition was 16:0 (28.9%), 18:0 (7.2%), 18:1 (5.7%), 18:2 (10.4%), and DHA (45.9%) without any other LCPUFA. The lipid content of the strain was 27.4%. The cells had many lipid bodies, which were densely located in all of the cells. On phylogenetic analysis using the 18S rDNA sequence, the strain was located in the labyrinthulids group, forming a monophyletic group with Labyrinthula sp. (strain s) and Labyrinthuila sp. (strain L59). We further tested the culture optimization of strain L72 to evaluate the ability of the strain to produce DHA. The optimum salt concentration and the temperature of the strain were 100% of artificial seawater and 20°C. Strain L72 could grow well on soybean oil (SBO) or soybean lecithin (SBL) as the carbon source. When 20 g/l of SBL was added to the medium, DHA production reached the maximum amount at 0.67 g/l for 14 d. The two important facts, that the strain can use SBL as the main nutrient and contains only DHA among the LCPUFAs, will be of great advantage for industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Docosahexaenoic acid (DHA) is a long-chain polyunsaturated fatty acid (LCPUFA) composed of 22 carbon atoms and 6 double bonds. It is one of the most attractive chemicals because of its various specific functions. It can lower the blood cholesterol level, thereby reducing the risk of arteriosclerosis (Bang and Dyerberg, 1972). LCPUFAs have also been found to be effective in retina and brain (Urquiza etal., 2000; San Giovanni and Chew, 2005). DHA is used in medicine, supplements, enriched milk, and enriched feed stock for domestic animals. At present, almost all DHA is purified from fish oil, although the source has some problems. It always occurs along with icosapentaenoic acid, which was contraindicated for inclusion in infant diets as it affects the uptake of DHA. Also, there were serious doubts about the use of fish oils because of environmental manmade pollutants, such as dioxins and heavy metals, being taken up by fish and concentrated in the organs (Ratledge, 2004). Microorganisms have sometimes replaced fish oil as the source of DHA. DHA is being produced from the marine dinoflagellate Crypthecodinium (Swaaf etal., 2003) and the thraustochytrid Schizochytrium (Ratledge, 2004).

Labyrinthulids are marine microorganisms comprising the single genus Labyrinthula. They belong to the phylum Labyrinthulomycota, which contains three distinct groups, labyrinthulids, thraustochytrids, and aplanochytrids (Honda et al., 1999; Leander and Porter, 2001). They are peculiar organisms with spindle-shaped cell bodies and a gliding movement within the ectoplasmic networks. The ectoplasmic network of labyrinthulids can digest bacteria, yeast, and other organisms (Porter, 1989). They have started to attract attention because of their ability to produce LCPUFAs. Since some isolation techniques of labyrinthulids were proposed (Watson and Ordal, 1957; Sakata and Iwamoto, 1995; Yokochi et al., 2001), not a few strains of thelabyrinthulids have been isolated. The active culture condition of the labyrinthulids had almost been limited on agar media, probably owing to the microbial requirement of food bacteria or yeasts. We then reported a new method of growth acceleration for labyrinthulids by dispersing soybean oil (SBO) or soybean lecithin (SBL) in agar medium (Kumon et al., 2002, 2005). These methods realized the three-dimensional growth of labyrinthulids and may enable high-quantity LCPUFA production.

We report here the isolation of a new labyrinthulid strain, which produces only DHA among all the LCPUFAs, and the trial of increasing DHA production by optimization of the culture conditions for the purpose of future industrialization.

Materials and Methods

Isolation of Labyrinthulid

Labyrinthulid strain L72 was isolated from a fallen leaf floating in the coastal area of Takehara (Hiroshima prefecture) in the Seto Inland Sea of Japan, in February 2002, using the isolation technique for Psychlobacter phenylpyruvicus (FERM P-16954) as previously reported (Yokochi et al., 2001). The plant samples were cut into square pieces of about 1 cm length and washed twice with sterilized 50% salt concentrationof artificial seawater (50% ASW) (Tropic Marine Aquarientechnik, Wartenberg, Germany) (approximately 1.5% NaCl). The cut samples were then aseptically placed on the GPYA medium on which P. phenylpyruvicus had grown. The plates were sealed with sealing films and incubated at 25°C. We observed the plates daily using an inverted microscope for the next 7 d. Owing to their specific spindle shape and gliding movement, the labyrinthulids were easily recognizable. The isolated strains were kept on PYA–SBO medium as a monoxenic culture with P. phenylpyruvicus.

Media and Cultivation

The base medium for the isolation of the labyrinthulids is GPYA medium, which contained glucose (2 g/l), peptone (1 g/l), yeast extract (0.5 g/l), and agar (15 g/l) in 50% ASW.

In this study, the labyrinthulids were cultivated with bacteria (a monoxenic culture). The medium without agar from the GPYA medium was designated GPY medium. The bacterial suspension (100 μl) containing almost 50 μg dry cell weight, which had grown in GPY medium, was spread on the fresh agar medium. A square piece of inoculum (PYA-SBO medium about 5 mm length and width, on which labyrinthulids had already grown) was then placed in the center of the fresh medium. The culture was incubated under stationary conditions at 25°C.

We previously reported that the labyrinthulid strain S3-2 grew well on the agar medium that contained soybean oil (SBO) as the carbon source (Kumon et al., 2002). The PYA–SBO medium, which included SBO (5 g/l) instead of glucose in GPYA, was used for the morphological observation and maintenance of the isolated labyrinthulids. Tween-80 (Nacalai Tesque Inc.) was added to SBO at 25% (wt/wt oil) and the mixture was autoclaved separately from the PYA medium. The autoclaved SBO was aseptically mixed with the PYA medium before solidification and the oil emulsion was prepared by repeated charge/discharge using disposable syringes. Petri dishes (9-cm diameter) containing 10 ml of medium were used in all the experiments.

The base medium to determine the optimum culture conditions was the PYA–SBL medium which included 10 g/l of paste-forming SBL instead of glucose in GPYA. SBL contains mainly triacylglycerol and phospholipids (Kumon et al., 2005). The labyrinthulid strain L72 was cultivated on the medium at 25°C for 7 or 14 d. For the test of the optimum carbon source, 5 g/l of each SBL, SBO, linoleic acid, α-linolenic acid, glycerol, or glucose (Wako Pure Chemical Industries, Ltd., Tokyo, Japan) was added to PYA medium. The four lipids (SBL, SBO, linoleic acid, α-linolenic acid) were added to the medium by the same method with the SBO dispersed medium described above. To determine the optimum nitrogen source, a nitrogen-rich base containing organic nitrogen: 1.5 g/l of yeast extract, tryptone, peptone, or inorganic nitrogen: 1.5 g/l of urea, KNO3, or NH4Cl (Wako Pure Chemical Industries Ltd., Tokyo, Japan) was added to the base medium instead of 1.0 g/l of peptone and 0.5 g/l of yeast extract. Other experiments for the optimum conditions, that is, temperature and salt concentration, were performed with the PYA medium including 10 g/l of SBL.

Lipid Analysis

Square pieces of the agar medium (about 2 cm length) containing labyrinthulids and P. phenylpyruvicus were cut off, weighed, and dried at 105°C for 3 h. The oxidation of LCPUFAs did not occur during the drying procedure. The dried cultures were directly methyl-esterified with 10% HCl in methanol. The resultant methylesters were then injected into a gas chromatograph (GC) (GC-17-A Shimadzu, Kyoto, Japan), equipped with a TC-70 capillary column (GL Science, Tokyo, Japan) under temperature programming (180 to 220°C at4°C/min increments). Each fatty acid and total fatty acids were quantified using arachidic acid (20:0) as the internal standard. The produced DHA is expressed as “DHA production” (g-DHA/l of medium)using the average specific gravity (0.96 g/l) of the cultivated agar media and “DHA content” using percent of DHA peak area to the total peak area.

Separation of Strain L72 from the Monoxenic Culture

Labyrinthulid strain L72 and bacterium cultivated on the surface of GPYA were collected and suspended with 50% ASW, then filtered through a 1-μm-pore filter. The residue on the filter was resuspended with 50% ASW and filtered again. The residue on the filter was resuspended and centrifuged at 1,000 g for 5 min. Most of the bacteria were not precipitated but suspended in the 50% ASW, which was removed by decantation. The cell pellets were rinsed twice with 50% ASW. The sedimentary fraction was used for the analysis of the fatty acid composition of the purified labyrinthulid strain L72. The lipid content was estimated by the weight of the total fatty acid in the dry cell weight.

Morphological Observations

This strain was grown on PYA–SBO medium at 25°C. The living cells of the colony were observed using an Olympus BX50 light microscope fitted with Nomarski interference differential contrast objectives. For observation of the lipid bodies, a drop of the cell suspension was mixed with a drop of Nile red (1 μg/ml in acetone). The cells were then observed using an Olympus BX60 epifluorescence microscope under 520–550 nm excitation.

Phylogenetic Analysis

Cells were harvested after 3 d. The total genomic DNA was extracted using the suggested method of the Genomic Prep™ Cells and Tissue DNA Isolation Kit (Amersham Pharmacia Biotech, Inc.) and purified by a phenol and chloroform–isoamyl alcohol protocol. To obtain almost the complete 18 S rDNA, we used the polymerase chain reaction (PCR) protocol with amplification primers SR1 and SR12 (Nakayama et al., 1996). We cut out the amplified band of about 1,800 bases in 0.5% TBE–agarose gel, then extracted it using GENECLEAN® Turbo (Q-BIO gene). The nucleotide sequences were determined by the terminator method with 12 primers, 18S01-12, that are same as those of Nakayama et al. (1996) using an ABI PRISM™ 310NT Genetic Analyzer (Applied Biosystem). The data set included the determined sequence in this research, the aligned sequence data set (Honda et al., 1999), and the submitted sequences through a profile alignment process by Clustal W version 1.74 (Thompson et al., 1994) and manually aligned. The positions with gaps and undetermined and ambiguous bases were removed for subsequent phylogenetic analysis. Phylogenetic trees were generated using the neighbor-joining (NJ) method (Saitou and Nei, 1987). NJ analysis was performed using PAUP* version 4.0b10 (Swofford, 2002). Distances were used with the model of Hasegawa et al. (1985).

Results

Microscopic Morphology of Strain L72

The cells grew on the surface as well as within PYA–SBO medium. All cells were surrounded by the ectoplasmic net elements (Figure 1, arrowheads), and glided over along the element. The spindle-shaped cells were 12.2 ± 1.8 μm long and 3.3 ± 0.4 μm wide (n = 20). The aggregated cells were colorless. The cell had many oil bodies, large and small, that were stained by Nile red, and observed under the 520–550 nm excitation fluorescence. These lipid bodies were densely located in all of the cells (Figure 2). These observations supported the cell has typical characterof labyrinthulids. The heterokont biflagellate zoospore was not clearly recognized on the agar medium.

Phylogenetic Classification of Strain L72

The almost complete length of the 18 S rDNA sequence (1,730 bases) was sequenced and deposited in the DNA Data Bank of Japan (DDBJ) as accession no. AB220158. The NJ tree includes the four following groups: Thraustochytrid Group 1, Thraustochytrid Group 2, the genus Aplanochytrium, and the genus Labyrinthula (Figure 3). The monophyly of the four groups was well supported by the bootstrap probabilities (93% to 100%). Our strain (L72), located in the Labyrinthulids Group, formed a monophyletic group with Labyrinthula sp. (strain s) and Labyrinthuila sp. (strain L59) (Kumon et al., 2003), supported by 99% bootstrap probabilities.

Neighbor-joining (NJ) tree of labyrinthulids and thraustochytrids based on 18 S rDNA with Ochromonas danica as an outgroup (47 OTUs, 2147 nucleotide sites). Accession numbers in the database are shown in parentheses. Distance was used with the Hasegawa et al. (1985) (HKY85) model. Bold characteristics indicate the strain for which the 18 S rDNA sequences were determined in the present study. The numbers at each internal branch show the bootstrap values (%, 1,000 replicates).

Fatty Acid Composition of L72 Separated from Associated Bacteria

The fatty acid composition of the separated L72 strain is shown in Figure 4. The main fatty acid compositions of L72 were 16:0 (28.9%), 18:0 (7.2%), 18:1 (5.7%), 18:2 (10.4%), and DHA (45.9%). The other small peaks in Figure 4 were less than 0.5%. A very small peak of n-6 DPA was detected. Other LCPUFAs, such as arachidonic acid, icosapentaenoic acid, n-6 22:4, and n-3 DPA, were not detected. The peak of DHA showed the same retention time and mass spectrum pattern asthe standard methylesterified DHA (data not shown). The lipid content (total fatty acids in dry cell weight) was 27.4%.

Optimum Culture Conditions for DHA Production

The effects of the various cultural conditions (carbon source, nitrogen source, temperature, and salt concentration of ASW) on cell growth were tested. The culture of P. phenylpyruvicus without the labyrinthulid was maintained as the control for all experiments. In no case were LCPUFAs noticed in the control, confirming that the DHA was produced by the labyrinthulids. When the bacterium was cultivated in PYA–SBL at 14 d, the fatty acid composition was as follows: 16:0 (20.5%), 18:0 (4.6%), 18:1 (23.6%), 18:2 (42.1%), and 18:3 (3.6%).

Carbon and Nitrogen Source

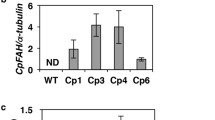

The effect of the carbon source is shown in Table 1. With SBO and SBL, the strain grew more than with the other four carbon sources. DHA production with SBO and SBL reached 0.32 g/l and 0.17 g/l at 14 d. Although the growth of L72 was observed only on the surface of the agar plate with glucose and glycerol, few DHAs were detected. In the case of the free fatty acids, DHA production also resulted in a small amount. In particular, the growth of L72 with linoleic acid appeared to be inhibited by the acid. For the optimum concentration of SBO and SBL, each oil was added to the medium in the range of 0 to 30 g/l (Figure 5). SBO showed a higher DHA production than SBL at an oil concentration lower than 5 g/l. On the contrary, when these oils were added at more than 10 g/l, DHA production with SBL was higher than that with SBO. The maximum amount of DHA production reached 0.67 g/l for the 20 g/l SBL condition. Each LCPUFA showed the highest amounts with SBO and SBL, 46.1% (5 g/l of SBO) and 34.2% (10 g/l of SBL).

The effect of the nitrogen source is shown in Table 2. For the inorganic nitrogen source, urea, KNO3, or NH4Cl, DHA production was low. For peptone, tryptone, and yeast extract, strain L72 grew well, and DHA production using peptone was the highest.

Temperature and Salt Concentration

The effect of temperature on the cell growth was tested in the range of 10°C to 30°C (Table 3). The labyrinthulid accumulated higher amounts of DHA at 14 d than 7 d except at a temperature of 10°C. At 7 d at 10°C, DHA production was very low although a little growth was observed, and at 14 d, growth had already stopped. The culture cultivated at 20°C resulted in the highest DHA production (0.54 g/l), at 14 d. Increase in LCPUFA production from 7 d to 14 d was also highest at 20°C.

The effect of the ASW salt concentration on growth was examined in the range of 0 to 150% ASW (Table 4). At 0%, no labyrinthulid growth was observed. In the range of 25% to 150%, the labyrinthulids grew, but very little growth was observed at 150%. The culture at 100% resulted in the highest DHA production (0.44 g/l).

Discussion

A high content of a single LCPUFA in microbial lipid is universally rare but is an important factor for the production of single cell oils including the LCPUFAs. For example, Crypthecodinium cohnii, frequently utilized for DHA production, contains only DHA among all the LCPUFAs (Ratledge, 2004). C. cohnii is one of the Dinophyta group, and phylogenetically distant from the Labyrinthulids Group. We show here that the new labyrinthulid strain, L72, produced only DHA among all the LCPUFAs (45.9% DHA composition). Sakata et al. (2000) found a labyrinthulid, L95-2, that mainly produced DHA. The L95-2 contained not only DHA but also a few n-3 DPA and icosapentaenoic acid among LCPUFAs. Strain L72 contained mainly DHA and palmitic acid (16:0). It contained also very few n-6 DPA among the LCPUFAs, but did not contain n-3 DPA and icosapentaenoic acid, which is different from strain L95-2. In all the experiments for the culture optimization of the strain L72 (Tables 1 to 4 and Figure 5), the content of n-6 DPA did not go beyond 0.5%. The strain may well become a promising DHA producer without other LCPUFAs.

Some labyrinthulid strains can accumulate LCPUFAs at almost 50% of the total fatty acids; L59 contains 48.1% LCPUFAs (only n-6 DPA) (Kumon et al., 2003), and strain S3-2 contains 59.1% LCPUFAs (25.4% n-6 DPA and 33.7% DHA) (Kumon et al., 2002). Strain L72 also contained 45.9% LCPUFAs (only DHA). While they differed between DHA and n-6 DPA, these strains have in common a high LCPUFA content at almost 50%. The results suggested that the high LCPUFA content may have originated from an evolutional process or have some role in survival in the marine biosphere.

Strain L72 contains many oil bodies in the cell, like other labyrinthulid strains (Figure 2b). The significance of the lipid and LCPUFA accumulation in the microbes is to be determined. The presence of dense lipid bodies in L72 suggested higher lipid contents than in L59 (26.6% (Kumon et al., 2003)), but actually amounted to only 27.4%. The cell size of labyrinthulid L72 was very similar to that of strain L59 (10.5 × 3.5) and L. coenocystis (10−15 × 3−6) (Porter, 1989). L72 was colorless, similar to strain L59 (Kumon et al., 2003). The phylogenetic relationship of strains L72 and L59 also resulted in their near close proximity in the genus Labyrinthula group (Figure 3). The fatty acid composition was often used for grouping of the microorganisms. Huang etal. (2001) used fatty acid compositions for grouping thraustochytrids. It is interesting that L72 as the DHA producer and L59 as the n-6 DPA producerwere in close proximity based on phylogenetic analysis.

The strain could grow well on SBO or SBL as the carbon source (Table 1 and Figure 5). The paste-forming SBL is produced as a coproduct of degumming SBO. At present, a large part of SBL has not been effectively utilized. The utility of SBL as carbon source may be one of the advantages for DHA production by the strain. Although we expected that strain L72 can produce a high content of DHA of with α-linolenic acid, one of the same n-3 LCPUFAs as DHA, it did not use the carbon source as a DHA precursor. The culture with less than 5 g/l of SBO resulted in a high DHA content at 46.1% (Figure 5). This value is almost the same as the DHA content of the purified L72 (Figure 4). This means that almost all the oil in medium was effectively used by strain L72. The culture at 10 g/l or more of SBO, however, resulted in extremely decreased DHA content owing to the unused lipid of increased SBO in the medium. When strain L72 grew at 10 g/l or more of SBL, a higher DHA content and DHA production were obtained than with SBO. In the culture with peptone, strain L72 could accumulate the highest DHA production, which was the same as for L59 (Kumon et al., 2003). The test of thesalt concentration and temperature showed thehighest DHA production in 100% ASW and at 20°C, respectively. We previously reported that thedifference in the optimum temperature in each labyrinthulid might be attributed to the isolated environment of these strains (Kumon et al., 2003). The optimum temperature of L72 (20°C) was the same as that of L59 that was isolated from the environment at a seawater temperature of 15°C. In the present study, strain L72 was also isolated from cold seawater at 11°C.

When 20 g/l of SBL was added to the medium, DHA production reached the maximum amount at0.67 g/l in 14 d. Compared with other DHA producers such as Crypthecodinium and Schizochytrium sp. SR21 (Sijtsma and Swaaf, 2004), the present production rate by labyrinthulid strain L72 was still lower. However, two important facts, that the strain can use SBL as the main nutrient and contains only DHA among the LCPUFA compositions, will be of great advantage for industry.

References

HO Bang J Dyerberg (1972) ArticleTitlePlasma and lipoproteins in Greenlandic West Coast Eskimos Acta Med Scand 192 85–94

M Hasegawa H Kishino T Yano (1985) ArticleTitleDating of the human-ape splitting by a molecular clock of mitochondrial J Mol Evol 22 160–174

D Honda T Yokochi T Nakahara S Raghukumar A Nakagiri K Schaumann T Higashihara (1999) ArticleTitleMolecular phylogeny of labyrinthulids and thraustochytrids based on the sequencing of 18 S ribosomal RNA gene J Eukaryot Microbiol 46 637–647

J Huang T Aki K Hachida T Yokochi S Kawamoto S Shigeta K Ono O Suzuki (2001) ArticleTitleProfile of polyunsaturated fatty acids produced by Thraustochytrium sp. KK17-3 J Am Oil Chem Soc 78 605–610

Y Kumon T Yokochi T Nakahara M Yamaoka K Mito (2002) ArticleTitleProduction of long chain polyunsaturated fatty acids by monoxenic growth of labyrinthulids on oil-dispersed agar medium Appl Microbiol Biotechnol 60 275–280

Y Kumon R Yokoyama T Yokochi D Honda T Nakahara (2003) ArticleTitleA new labyrinthulid isolate, which solely produces n-6 docosapentaenoic acid Appl Microbiol Biotechnol 63 22–28 Occurrence Handle10.1007/s00253-003-1333-4

Kumon Y, Yokochi T, Nakahara T (2005) High yield of long-chain polyunsaturated fatty acids by labyrinthulids on soybean lecithin-dispersed agar medium. Appl Microbiol Biotechnol (in press). DOI: 10.1007/s00253-005-1978-2

C Leander D Porter (2001) ArticleTitleThe Labyrinthulomycota is comprised of three distinct lineages Mycologica 93 459–464

T Nakayama S Watanabe K Mitsui H Uchida I Inouye (1996) ArticleTitleThe phylogenetic relationship between the Chlamydomonadales and Chlorococcales inferred from 18 S rDNA sequence data Phycol Res 44 47–55

D Porter (1989) Phylum Labyrinthulomycota L Margulis JO Corliss M Melkonian DJ Chapman (Eds) Handbook of Protoctista Jones and Bartlett Boston 388–398

C Ratledge (2004) ArticleTitleFatty acid biosynthesis in microorganisms being used for Single cell oil production Biochimie 86 807–815 Occurrence Handle10.1016/j.biochi.2004.09.017

N Saitou M Nei (1987) ArticleTitleThe neighbor-joining method: a new method for reconstructing phylogenetic trees Mol Biol Evol 4 406–425

T Sakata K Iwamoto (1995) ArticleTitleIsolation of marine algicidal microorganisms on diatom double layer agar plates Fish Sci 61 173–174

T Sakata T Fujisawa T Yoshikawa (2000) ArticleTitleColony formation and fatty acid composition of marine labyrinthulid isolates grown on agar media Fish Sci 66 84–90 Occurrence Handle10.1046/j.1444-2906.2000.00012.x

JP Giovanni ParticleSan EY Chew (2005) ArticleTitleThe role of omega-3 long-chain polyunsaturated fatty acids in health and disease of the retina Prog Retin Eye Res 24 87–138

L Sijtsma ME Swaaf (2004) ArticleTitleBiological production and applications of the omega-3 polyunsaturated fatty acid docosahexaenoic acid Appl Microbiol Biotechnol 64 146–153 Occurrence Handle10.1007/s00253-003-1525-y

ME Swaaf JT Pronk L Sijtsma (2003) ArticleTitleFed-batch cultivation of the docosahexaenoic-acid-producing marine alga Crypthecodinium cohnii on ethanol Appl Microbiol Biotechnol 61 40–43

Swofford DL (2002) PAUP*. Phylogenetic Analysis Using Parsimony (*and Other Methods). Version 4.0 beta 10. Sinauer Associates, Sunderland, M.A.

JD Thompson DG Higgins TJ Gibson (1994) ArticleTitleCLUSTAL W: improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice Nucleic Acids Res 22 4673–4680

AM Urquiza S Liu M Sjoberg RH Zetterstrom W Giffiths J Sjovall T Perlmann (2000) ArticleTitleDocosahexaenoic acid, a ligand for the retinoid receptor in mouse brain Science 290 2140–2144 Occurrence Handle10.1126/science.290.5499.2140

SW Watson EJ Ordal (1957) ArticleTitleTechniques for the isolation of Labyrinthula and Thraustochytrium in pure culture J Bacteriol 73 589–590

T Yokochi T Nakahara T Higashihara M Yamaoka R Kurane (2001) ArticleTitleA new isolation method for Labyrinthulids using a bacterium, Psychrobacter phenylpyruvicus Mar Biotechnol 3 68–73 Occurrence Handle10.1007/s101260000054

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumon, Y., Yokoyama, R., Haque, Z. et al. A New Labyrinthulid Isolate That Produces Only Docosahexaenoic Acid. Mar Biotechnol 8, 170–177 (2006). https://doi.org/10.1007/s10126-005-5098-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10126-005-5098-x