Abstract

In vitro culture is one possible method for supplying sponge metabolites for pharmaceutical applications, but appropriate feeding regimens that maximize both growth and metabolite biosynthesis are largely unknown. According to the natural concentration (NC) of cells 1 to 50 µm in size that are available to wild Axinella corrugata, we fed explants a multispecific diet of bacteria, microalgae, and yeast at 4 different concentrations: 1NC, 3NC, 5NC, and 5+1NC (the last consisted of 5 NC of bacteria and 1 NC of microalgae and yeast). Explants fed a 3NC diet had the best culture response, growing on average from 8.5 g to 10.3 g in 8 weeks, and showing a 110% increase in concentration (milligrams per gram of dry weight) of the antitumor compound stevensine. Stevensine production in 3NC explants, representing the total milligrams of metabolite per explant, increased by 157% over the study. Explants fed at 1NC had relatively stable weights, indicating that the diet met metabolic costs only. Explants fed at the two highest concentrations lost weight after 4 weeks, possibly because long-term high cell concentration blocked their aquiferous system, reducing their ability to feed efficiently. Stevensine production in explants fed the 1NC, 5NC, or 5+1NC diets were similar, and varied little from the initial amount. A separate experiment showed that the clearance rate for A. corrugata is similar between the examined food types and cell concentrations over 5 hours, averaging 766 ml h−1 g DW−1.Overall, this study demonstrates that relatively small changes in food abundance can greatly affect both sponge growth and metabolite biosynthesis. The good growth and increased production of the target metabolite stevensine for A. corrugata explants fed a 3NC diet suggests that in vitro culture is a viable method of supplying some sponge metabolites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Of the entire marine fauna, sponges are the best sources of metabolites with biomedical potential (Ireland et al., 1993). Unfortunately, many sponges contain only trace amounts of bioactive metabolites (Schmitz et al., 1993), and the need for large quantities for drug development and production has at times resulted in the near extinction of a population or a species (Anderson, 1995). It is therefore useful to develop methods to guarantee the supply of metabolites selected for development as pharmaceuticals. One supply method currently being developed is in vitro sponge culture, whereby sponges are grown under controlled environmental and nutritional conditions (Osinga et al., 1999b).

The nutritional and environmental conditions that promote sponge growth and metabolite biosynthesis are largely unknown (Osinga et al., 1999b); consequently, most studies examining in vitro sponge culture have had poor results (Osinga et al., 1997, 2001; Nickel et al., 2001). In their review of sponge culture, Osinga and colleagues (1999b) stated that determining suitable feeding regimens is the key to successful in vitro sponge culture. Sponges feed unselectively on bacteria and microalgae less than 50 µm in size (Reiswig, 1971; Pile et al., 1996). Growth of sponges generally increases as food concentration increases, but this relationship is not always linear (Poirrier et al., 1981; Huysecom et al., 1988). The effect of food concentration on the biosynthesis of sponge metabolites is unknown. However, considering that environmental conditions can greatly influence metabolite biosynthesis in cultured sponges (Thompson et al., 1987; Kreuter et al., 1992), it is likely that the diet will also affect production of the target metabolite.

In this study, we cultured the Caribbean Demospongiae Axinella corrugata (=Teichaxinella morchella), with explants being fed a multispecific diet at different cell concentrations. Axinella corrugata produces stevensine, an alkaloid metabolite with antitumor properties (Wright et al., 1991). Stevensine is a major secondary metabolite in A. corrugata and probably serves multiple defensive roles, having strong antipredatory properties (Wilson et al., 1999) and weak antimicrobial activity (Newbold et al., 1999). Studies have determined that A. corrugata retains the ability to produce stevensine in cell culture (Pomponi et al., 1997; Andrade et al., 1999), suggesting that stevensine is biosynthesized by A. corrugata and not a microbial symbiont.

MATERIALS AND METHODS

Sponge Collection and Cutting

Twenty individuals of A. corrugata were collected from a depth of 15 m off Long Key, Florida. To minimize harvesting impact, one third of each sponge was left intact and attached to rock. The collected sponges were placed in 20-L buckets containing aerated seawater and transported to Harbor Branch Oceanographic Institution (HBOI), Fort Pierce, Florida. In aerated seawater, the sponges were cut using sharp scalpels into approximately 60 cube-shaped explants. All explants had at least one side covered in pinacoderm and were, on average, 8.5 g (SE, 0.3 g) in weight. After cutting, explants were placed into three 80-L aquaria for 2 weeks to allow time for them to heal their cut surfaces and reorganize their canal system before being used. Each aquarium contained a mechanical and biological filter to maintain high water quality.

Feeding Experiment Setup

Twelve aquaria (25 × 29 × 41 cm) were used in this study, each containing 15 L of natural seawater. The seawater was first passed through a series of UV lights and filters (down to 1 µm pore size) to remove or kill any particles. Clean aerated water dripped at a rate of 2 (SE, 0.4) L h−1 into each aquarium from large holding tanks situated above. Water flowed out from an outlet pipe on each aquarium so that volume was constant (15 L). In addition, the water in each aquarium was totally replaced with clean aerated seawater twice weekly. These procedures removed any uneaten food cells and detritus, and prevented ammonia levels from reaching high and possibly damaging levels. Dissolved ammonia was monitored using the salicylate-cyanurate method and a spectrophotometer (Hach 41800-02) and was, on average, 0.02 (SE, 0.003) mg L−1 throughout the experiment. Ammonia levels were not significantly different between the feeding regimens (Kruskal-Wallis 1-way analysis of variance [ANOVA] on ranks: H df(3) = 4.47, P = 0.21). Water temperature, salinity, and pH were kept constant throughout the experiment at 25°C, 35‰, and 8.1, respectively. Most days the explants were cultured on an 8-hour light, 16-hour dark regimen. Because silicon is an essential skeletal component for Demospongiae such as A. corrugata and may affect sponge growth, 125 µl of 227 mol L−1 sodium metasilicate (SIGMA, S-4392) was added to each aquarium twice a week. No antibiotics were used at any stage during this study.

Into each aquarium, 3 explants were randomly chosen and placed onto a horizontal mesh support, more than 5 cm apart to prevent possible inter-explant interference. Explants remained in the same place throughout the experiment so their progress could be monitored individually. The mesh support in each aquarium was wedged 8 cm off the bottom, promoting water circulation around each explant and preventing possible smothering from detritus.

The seawater was aerated constantly from 2 air-stones located in opposite corners of each aquarium, and away from all explants to prevent direct exposure to the air bubbles. The seawater in each aquarium was aerated at a rate of 2 × 20 ml s−1 to provide sufficient O2 for explant respiration and to promote good water circulation, keeping the added food particles in suspension.

Food Types and Concentrations

To determine appropriate cell concentrations to feed to A. corrugata, the natural concentration (NC) available to wild sponges was examined. Water samples were first collected next to sponges and then analyzed using a hemacytometer and a phase-contrast microscope. To better represent the sponges’ natural diet, we divided cells into 3 size classes: 1–4 µm, concentration = 2 × 105 cells ml−1; 4–10 µm, 2 × 104 cells ml−1 and 10–50 µm, 3 × 103 cells ml−1. Bacteria dominated the smallest size class, while microalgae dominated the 2 larger size classes. These cell concentrations determined for the Florida Keys are comparable to concentrations reported elsewhere in similar habitats (e.g., Jamaica [Reiswig, 1971] and Bahamas [Pile, 1999]). Particles less than 1 µm could not be counted accurately using a hemacytometer.

Explants were fed a multispecific diet, with food types grouped into the 3 size classes. Cells 1–4 µm in size consisted of 5 bacterial strains: Marinococcus halophilus, Vibrio alginolyticus, Escherichia coli, Bacillus subtilis, and G365 (gram-negative motile rod isolated from A. corrugata by the Division of Biomedical Marine Research, HBOI). Cells 4–10 µm in size included the microalga Isochrysis galbana and the yeast Saccharomyces cerevisiae. Finally, the large cell size of 10–50 µm consisted solely of the diatom Thallasiosira weissflogii. The average size of each food type was 3 µm for the 5 bacterial strains, 5 µm for I. galbana and S. cerevisiae and, 12 µm for T. weissflogii.

The 5 bacterial strains were cultured individually in 200-ml Pyrex flasks containing 50 ml of marine broth (DIFCO, 0791-01-2) or nutrient broth (DIFCO, 0003-01-6). The first cultures were inoculated by adding 2 ml of cryopreserved stock culture. The subsequent cultures were inoculated using 2 ml from the previous culture. To reduce microbial contamination, new cultures were started from cryopreserved stock every 2 weeks. The yeast S. cerevisiae was cultured in a separate 200-ml flask containing 50 ml of sugar-water; each culture was inoculated with 0.5 g of active dry yeast (Red Star) and 2 g of white sugar. All bacterial strains and S. cerevisiae were incubated in an environmental shaker (Innova 4900) at 210 rpm and 25°C before being used (final culture concentration of approx. 109 cells ml−1 for the bacterial strains and 107 cells ml−1 for the yeast). Because the microbial culture medium might also have interfered with sponge growth, it was removed by centrifugation prior to feeding the sponge explants. The bacteria and yeast cultures were poured into 2 separate vials and centrifuged at 1400 g for 20 minutes. The culture broth was removed, and the cell pellets of either bacteria or yeast were resuspended in large flasks containing 1000 ml and 100 ml of seawater, respectively.

Each week, I. galbana and T. weissflogii were cultured in separate 20-L vessels containing F/2-enriched seawater (Hoff and Snell, 1987). Silica was added to the diatom T. weissflogii culture to promote population growth. The microalgae were cultured for more than 5 days at 24°C on 24 hours of light before being used, thus allowing sufficient time for cell concentration to reach a high level (I. galbana, approx. 7 × 106 cells ml−1; T. weissflogii, approx. 4 × 105 cells ml−1). Each algal culture was used for 1 week before being replaced. Each feeding day, 400 ml of I. galbana was added to the yeast suspension, and 4 L of T. weissflogii was poured into a separate container. For each food solution, 4 subsamples were counted using a hemacytometer to determine their average cell concentrations.

Feeding Regimens

Four feeding regimens were examined: (1) 1NC (1–4 µm, 2 × 105 cell ml−1, 4–10 µm, 2 × 104 cells ml−1; and 10–50 µm, 3 × 103 cells ml−1); (2) 3NC; (3) 5NC; and (4) 5+1NC (5NC of 1–4 µm cells and 1NC of 4–10 and 10–50 µm cells). Feeding regimen 1, 1NC, acted as a feeding control. Feeding regimen 4, 5+1NC, was used to examine the response to high food concentration of small cells of 1 to 4 µm, while eliminating the possible smothering effect from larger food cells. The volume of each food solution required was calculated by dividing seawater volume (15 L) by the measured cell concentration of each solution. Explants of A. corrugata were fed in the morning, 5 times each week, for a total of 8 weeks. There were 3 aquaria, randomly distributed, for each feeding regimen. Thus, each regimen had 9 explants.

Examining Culture Response

Growth was examined weekly by measuring the weight of each explant (to 0.1 g) in a container of water resting on a scale. There was no significant difference in initial explant weight between the 4 feeding regimens (1-way ANOVA: F df(3, 32) = 0.53, P = 0.66).

At the end of the experiment, 3 randomly chosen explants from each feeding regimen (1 explant per aquarium replicate) were chemically analyzed for stevensine content. Three explants frozen at the start of the experiment were also chemically analyzed to get an initial baseline of stevensine concentration. Explants were extracted by maceration in 100% ethanol. After steeping overnight, the extracts were filtered to remove tissue and the filtrate was dried by distillation under reduced pressure. The total weight of extract was measured, and 100 mg of each extract was subsampled and chromatographed on a Waters C-18 Sep-pak column (900 mg sorbent size). The column was eluted with a step gradient of CH3CN in H2O containing 0.1% trifluroacetic acid (TFA). The fractions that eluted with H2O-CH3CN-TFA (60:40:0.1 and 20:80:0.1) were dried and analyzed by HPLC using UV detection at 230 nm. The HPLC method utilized a Vydac C-18 Large Pore Protein and Peptide Column (10 µ, 4.6 mm × 250 mm) eluted with H2O-CH3CN-TFA (90:10:0.1) at a flow rate of 1 ml min−1. Stevensine was quantified by comparison to a standard curve (run each day of the analysis).

Clearance Rates

In a series of experiments, we examined the clearance rate of the 3 food sizes by A. corrugata. Each food size was examined separately, with each cell concentration (1NC, 3NC, and 5NC) using 3 replicate aquaria with 1 explant each and 3 aquaria with no sponges (controls). The 18 aquaria used in this experiment were each filled with 2 L of seawater, with temperature, salinity, and pH constant at 25°C, 35‰, and 8.1, respectively. Each experiment was done in the dark, and all treatments and replicates were distributed randomly.

Air was bubbled into each aquarium to provide O2 for the sponges and to keep the food cells in suspension. At intervals of 0 (initial), 1, 2, 3, 4, and 5 hours after cell addition, a 1-ml water sample was taken from each flask and counted using a Coulter Multisizer 3 (Beckman Coulter). At the end of each experiment, the 9 explants were placed in an oven set at 150°C until their dry weights had stabilized (approx. 12 hours). Using the average cell concentration per treatment, cell clearance was monitored over time. Clearance rate (c) of food cells per gram dry weight of sponge was determined by the formula:

where V w represents the volume of water in the flasks (200 ml), and C 0 and C t are the food cell concentrations at time 0 and time t respectively (Riisgård et al., 1993). Two-sample T tests determined that for the control treatments there was little difference between initial and final cell concentrations, and therefore any changes in concentration in the sponge treatments would result from filtration.

RESULTS

Growth and Survival

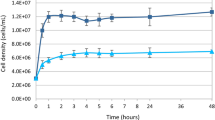

Final percentage of weight differed significantly between the 4 diets (1-way ANOVA: F df(3, 32) = 9.88, P = 0.0001), being greatest overall for A. corrugata explants fed a 3NC diet (Figure 1). On average, 3NC explants grew from 8.5 g to 10.3 g, representing a 22% increase in weight. Growth of 3NC explants was not constant, however, as explants grew quickest during the first half of the study (Figure 1). The percentage weight of 1NC explants varied little during the experiment (Figure 1), with the mean final weight being 101.3% of initial weight. Growth of A. corrugata fed the 2 highest cell concentrations was poorest overall. The mean final weights of 5NC and 5+1NC explants were 81% and 87% of initial weights, respectively. Axinella corrugata explants fed 5NC and 5+1NC diets had relatively stable weight for the first few weeks of the study (Figure 1). Final percentage weight varied greatly between explants in the same treatment. At the end of the experiment, for example, the percentage weight of explants fed a 3NC diet ranged from 90% to 164%.

Percentage growth over time of A. corrugata explants fed a multispecific diet at different cell concentrations. NC, natural concentration. 1NC is 1–4 µm, 2 × 105 cells ml−1; 4–10 µm, 2 × 104 cells ml−1; and 10–50 µm, 3 × 103 cells ml−1. 5+1NC is 5NC of 1–4 µm cells and 1NC of 4–10 and 10–50 µm cells. Error bars represent variation between explants.

All 36 explants cultured in this study survived to the end of the experiment. Explants healed their cut surfaces in less than 2 weeks, and none attached to the horizontal mesh support.

Stevensine Concentration and Production

Stevensine concentration (mg g DW−1 of explant) was highest for 3NC explants (Figure 2) and represented a 110% increase from the initial amount. The large variation in concentration between explants within each treatment (Figure 2), however, meant that there was no significant difference between treatments (1-way ANOVA: F df(4, 10) = 0.2.29, P = 0.13). The average concentration of stevensine in the 3 wild sponges (initial treatment) was 193 (1 SE, 58) mg g DW−1.

Concentration of stevensine (mg g DW−1) in A. corrugata explants fed a multispecific diet at different cell concentrations. The initial or wild stevensine concentration is also shown. See Figure 1 for explanation of codes. Error bars represent variation between explants.

Stevensine production (total milligrams of stevensine per explant) differed significantly between the treatments (1-way ANOVA: F df(3, 8) = 6.07, P = 0.02), greatest for the 3NC diet with explants containing an average 59 (SE, 8) mg of stevensine (Figure 3). This represented a 157% increase in stevensine weight per explant from the start of the experiment. Stevensine productions for explants fed the 1NC, 5NC, and 5+1NC diets were similar and varied little from the initial weight (Figure 3).

Production of stevensine (total milligrams) per A. corrugata explant fed a multispecific diet at different cell concentrations. The horizontal dashed line represents the initial amount of stevensine in explants. See Figure 1 for explanation of codes. Error bars represent variation between explants.

Clearance Rates

A 2-way ANOVA determined that clearance rates of A. corrugata were similar for the examined food types (F df(2, 18) = 2.63, P = 0.1) and concentrations (F df(2, 18) = 1.38, P = 0.28) The overall clearance rate of A. corrugata, averaged over 27 explants, was 766 ml h−1 g DW−1. However, individual explants showed great variation in pumping activity, ranging from 171 to 2353 ml h−1 g DW−1. Regression analysis determined that for A. corrugata, wet weight equaled 6.08 dry weight plus 1.03 (r 2 = 0.662, n = 27).

DISCUSSION

Explants of A. corrugata were fed a multispecific diet at 4 different concentrations based on the natural concentration of cells 1 to 50 µm in size available to wild A. corrugata in the Florida Keys. Food concentration greatly influenced the culture response of A. corrugata, with explants fed a 3NC diet growing on average from 8.5 to 10.3 g in 8 weeks. In comparison, explants fed the 2 highest concentrations (5NC and 5+1NC) lost weight, while explants fed a 1NC diet had relatively constant weight over the study. This indicates that a 1NC diet supplied sufficient energy to meet metabolic costs only. Overall, these results suggest that growth of A. corrugata increases as food abundance increases until a threshold is reached at which high cell concentration has a negative impact. A similar response to increasing food concentration has been found for freshwater sponges (Poirrier et al., 1981; Huysecom et al., 1988), although high concentrations in these studies merely arrested sponge growth. High particle concentration can block the aquiferous system of sponges (Gerrodtte and Flechsig, 1979; Huysecom et al., 1988), which may reduce their ability to feed efficiently. In this study, similar clearance rates between cell concentrations and relatively stable weights for explants fed 5NC and 5+1NC diets for the first few weeks indicate that A. corrugata can withstand high cell concentrations for a short duration. This may be an ecologic adaptation of A. corrugata to withstand short-term peaks in particle concentration resulting from plankton blooms or suspension of sediments following storms. The decrease in growth at high particle concentration was observed to be slightly less for 5+1NC explants than for 5NC explants. The 5+1NC diet consists of 5NC of bacteria but only 1NC of larger microalgae and yeasts and may therefore have slightly less of a blocking effect.

Sponges cultured in the laboratory often grow poorly or not at all (Osinga et al., 1997, 2001; Nickel et al., 2001). Considering that poor growth is one factor restricting the commercial development of in vitro sponge culture for the production of pharmaceuticals (Osinga et al., 1999b), the good growth rate of A. corrugata in one treatment is a promising result. A multispecific diet generally promotes the highest growth rates in cultured marine invertebrates (Mercer et al., 1993; Brown et al., 1998) because it provides essential vitamins and nutrients that may be deficient in a monospecific diet. Growth of the sponge Halichondria melanadocia is greater on a mixed diet of bacteria and microalgae than on a diet consisting solely of bacteria (A.R. Duckworth and S.A. Pomponi, unpublished data). The multispecific diet consisting of 5 bacterial strains, 2 microalgae species, and yeast fed to A. corrugata likely promoted growth of explants in the 3NC treatment. Although 3NC explants grew reasonably well in this study, sponges farmed in the sea generally grow faster. For example, Latrunculia wellingtonensis and Polymastia croceus farmed in the sea grew by an average of 960% and 730% of their initial volume, respectively, in 6 months (Duckworth, 2001). In comparison, the estimated final weight of 3NC explants, if cultured for 6 months, would be approximately 180% of their initial weight. These differences probably result from interspecific variation in growth rates or indicate environmental or nutritional deficiencies with in vitro culture.

Explants in the same feeding regimen and thus experiencing similar culture conditions varied greatly in final weight. Variable growth among sponges grown in similar conditions is common to many species (Thompson et al., 1987; Duckworth et al., 1997), and it may result from differences in initial explant health (Thompson et al., 1987) or filtration rates. Explants fed at 3NC also showed variable growth over time, with growth rates greater in the first half than in the second half of the study. Osinga and colleagues (1999a) observed a similar growth pattern for the cultured Demospongiae Pseudosuberites aff. andrewsi and suggested that it may result from food limitation as the explants grew. Many sponges respond to tissue damage by growing rapidly (Ayling, 1981, 1983), and this may also explain the fast growth of some A. corrugata shortly after being cut into explants.

The increase in the concentration of stevensine, like growth, was highest for A. corrugata explants fed a 3NC diet. Increased production of both sponge biomass and target metabolite is a promising result for commercial in vitro sponge culture because it would lead to maximum metabolite yield. Because growth and metabolite biosynthesis both require energy, marine organisms may allocate energy to one process at a cost to the other (reviewed by Cronin, 2001). This study shows that under good conditions marine organisms can invest in both growth and metabolite biosynthesis. Stevensine concentrations in A. corrugata fed the other diets remained relatively unchanged after 8 weeks. Considering the 5NC and 5+1NC diets, this indicates that biosynthesis of stevensine was largely unaffected by the explants’ losing weight. Many factors can effect the biosynthesis of metabolites in marine invertebrates, including light intensity (Thompson et al., 1987), individual size (Becerro et al., 1997), and season (Turon et al., 1996). This study shows that food concentration can also influence metabolite biosynthesis.

Stevensine concentration in 3NC explants increased by 110% after 2 months. Pomponi and colleagues (1997) also recorded a doubling in stevensine concentration in archaeocytes of A. corrugata (Teichaxinella morchella) after 8 days in cell culture, showing that A. corrugata can quickly increase production of stevensine. It is unknown whether stevensine concentration in 3NC explants in this study peaked within a few days and then stabilized, or increased gradually over the experiment. The average concentration of stevensine in wild A. corrugata was determined to be 193 mg g DW−1 which equates to 32 mg g wet weight−1. If we assume that 1 g wet weight equals 1 ml of sponge, then the natural concentration of stevensine found here is comparable to a study by Wilson and colleagues in 1991 (average, 19 mg ml−1).

All of the 36 explants cultured in this study survived, and none showed signs of microbial infection problematic in some in vitro sponge studies (Ilan et al., 1996; Osinga et al., 1997; Nickel et al., 2001). Explants of A. corrugata were on average 8.5 g in size and generally larger than explants used in other studies (e.g., 1–3 ml, Barthel and Theede, 1986; 50 mm3, Nickel et al., 2001). Large explants would have greater energy reserves than small explants and thus possibly more ability to fight microbial infection, leading to higher survival. The greater energy reserves in large explants can also promote healing of the cut surfaces and a more rapid reorganization of their aquiferous system (Duckworth et al., 1997).

The clearance rate of A. corrugata, averaging 766 ml h−1 g DW−1, is comparatively low but still within the range found for other sponge species (Ribes et al., 1999: Table 5). Differences in clearance rates between species may result from differences in retention rates, sponge size, water temperature, and habitat (Reiswig, 1974; Frost, 1980; Riisgård et al., 1993; Ribes et al., 1999). The clearance rates of A. corrugata were similar among the different cell sizes and concentrations. These results agree with other studies that have found that clearance rates of sponges are largely unaffected by cell size or concentration, within the ranges examined here (Reiswig, 1971; Frost, 1980; Francis and Poirrier, 1986; Ribes et al., 1999).

Determining suitable feeding regimens is one factor vital for the development of in vitro sponge culture to supply bioactive metabolites. This study shows clearly that relatively small changes in food concentration can greatly influence sponge growth and metabolite biosynthesis. The nutritional requirements to maximize production will undoubtedly vary between sponge species. Determining the natural cell concentration for each species, however, will provide important information when selecting appropriate cell concentrations. The good growth and increased production of the target metabolite stevensine for A. corrugata explants fed a 3NC diet suggests that in vitro culture is a viable method of supplying some sponge metabolites.

References

I. Anderson (1999) ArticleTitleOceans plundered in the name of medicine. New Scientist 2002 5

P. Andrade R. Willoughby S.A. Pomponi R.G. Kerr (1999) ArticleTitleBiosynthetic studies of the alkaloid, stevensine, in a cell culture of the marine sponge Teichaxinella morchella. Tetrahedron Lett 40 4775–4778

A.M. Ayling (1981) ArticleTitleThe role of biological disturbance in temperate subtidal encrusting communities. Ecology 62 830–847

A.L. Ayling (1983) ArticleTitleGrowth and regeneration rates in thinly encrusting Demospongiae from temperate waters. Biol Bull 165 343–352

D. Barthel H. Theede (1986) ArticleTitleA new method for the culture of marine sponges and its application for experimental studies. Ophelia 25 75–82

M.A. Becerro M.J. Uriz X. Turon (1997) ArticleTitleChemically-mediated interactions in benthic organisms: the chemical ecology of Crambe crambe (Porifera, Poecilosclerida). Hydrobiologia 356 77–89 Occurrence Handle10.1023/A:1003019221354

M.R. Brown M.A. McCausland K. Kowalski (1998) ArticleTitleThe nutritional value of four Australian microalgal strains fed to Pacific oyster Crassostrea gigas spat. Aquaculture 165 281–293 Occurrence Handle10.1016/S0044-8486(98)00256-7

G. Cronin (2001) Resource allocation in seaweeds and marine invertebrates: chemical defense patterns in relation to defense theories. J.B. McClintock B.J. Baker (Eds) Marine Chemical Ecology. CRC Press Boca Raton, Fla. 325–353

A.R. Duckworth (2001) ArticleTitleFarming sponges for chemicals with pharmaceutical potential. World Aquaculture June 2001 14–18

A.R. Duckworth C.N. Battershill P.R. Bergquist (1997) ArticleTitleInfluence of explant procedures and environmental factors on culture success of three sponges. Aquaculture 165 251–267 Occurrence Handle10.1016/S0044-8486(97)00131-2

J.C. Francis M.A. Poirrier (1986) ArticleTitleParticle uptake in two fresh-water sponge species, Ephydatia fluviatilis and Spongilla alba (Porifera: Spongillidae). Trans Am Microsc Soc 105 11–20

T.M. Frost (1980) ArticleTitleClearance rate determination for the freshwater sponge Spongilla lacustris: effects of temperature, particle type and concentration, and sponge size. Arch Hydrobiol 90 330–356

T. Gerrodette A.O. Flechsig (1979) ArticleTitleSediment-induced reduction in the pumping rate of the tropical sponge Verongia lacunosa. Mar Biol 55 103–110

F.H. Hoff T.W. Snell (1987) Plankton Culture Manual. Florida Aqua Farms Inc. Dade City, Fla.

J. Huysecom E. Richelle-Maurer G. van de Vyver B. Vray (1988) ArticleTitleEffect of bacterial concentration on retention and growth rate of the freshwater sponge Ephydatia fluviatilis. Physiol Zool 61 535–542 Occurrence Handle1:CAS:528:DyaL2sXitFyrs7k%3D

M. Ilan H. Contini S. Carmeli B. Rinkevich (1996) ArticleTitleProgress towards cell cultures from a marine sponge that produces bioactive compounds. J Mar Biotechnol 4 145–149

C.M. Ireland B.R. Copp M.P. Foster L.A. McDonald D.C. Radisky J.C. Swersey (1993) Biomedical potential of marine natural products. D.H. Attaway O.R. Zaborsky (Eds) Marine Biotechnology, Volume 1: Pharmaceutical and Bioactive Natural Products. Plenum Press New York, N.Y. 1–43

M.H. Kreuter A.R. Robitzki S. Chang R. Steffen M. Michaelis Z. Kljajic M. Bachmann H.C. Schröder W.E.G. Müller (1992) ArticleTitleProduction of the cytostatic agent aeroplysinin by the sponge Verongia aerophoba in in vitro culture. Comp Biochem Physiol 101 183–187 Occurrence Handle10.1016/0742-8413(92)90217-U Occurrence Handle1:STN:280:By2B1cbit1A%3D

J.P. Mercer K.S. Mai J. Donlon (1993) ArticleTitleComparative studies on the nutrition of two species of abalone, Haliotis tuberculata Linnaeus and Haliotis discus hannai Ino 1: effects of alga diets on growth and biochemical composition. Invert Reprod Dev 23 75–88 Occurrence Handle1:CAS:528:DyaK2cXhs1anurw%3D

R.W. Newbold P.R. Jensen W. Fenical J.R. Pawlik (1999) ArticleTitleAntimicrobial activity of Caribbean sponge extracts. Aquatic Micro Ecol 19 279–284

M. Nickel S. Leininger G. Proll F. Brümmer (2001) ArticleTitleComparative studies on two potential methods for the biotechnological production of sponge biomass. J Biotechnol 92 169–178 Occurrence Handle10.1016/S0168-1656(01)00357-1 Occurrence Handle1:CAS:528:DC%2BD3MXnsF2hs7Y%3D Occurrence Handle11640986

R. Osinga E. Planas Muela J. Tramper R.H. Wijffels (1997) In vitro cultivation of four marine sponge species: determination of the nutritional demands. Y. Le Gal A. Muller-Feuga (Eds) Marine Microorganisms for Industry. Issy-les-Moulineaux France: Ifremer 121–127

R. Osinga P.B. de Beukelaer E.M. Meijer J. Tramper R.H. Wijffels (1999a) ArticleTitleGrowth of the sponge Pseudosuberites (aff.) andrewsi in a closed system. J Biotechnol 70 155–161 Occurrence Handle1:CAS:528:DyaK1MXjs1Shs7Y%3D

R. Osinga J. Tramper R.H. Wijffels (1999b) ArticleTitleCultivation of marine sponges. Mar Biotechnol 1 509–532 Occurrence Handle1:CAS:528:DC%2BD3cXktFCjuw%3D%3D

R. Osinga R. Kleijn E. Groenendijk . Niesink J. Tramper R.H. Wijffels (2001) ArticleTitleDevelopment of in vivo sponge cultures: particle feeding by the tropical sponge Pseudosuberites aff. andrewsi. Mar Biotechnol 3 544–554 Occurrence Handle10.1007/s1012601-0078-2 Occurrence Handle1:CAS:528:DC%2BD38XotVWhtw%3D%3D

A.J. Pile (1999) ArticleTitleResource partitioning by Caribbean coral reef sponges: is there enough food for everyone? Memoirs Queensland Museum 44 457–461

A.J. Pile M.R. Patterson J.D. Witman (1996) ArticleTitle In situ grazing on plankton >10µm by the boreal sponge Mycale lingua. Mar Ecol Prog Ser 141 95–102

M.A. Poirrier J.C. Francis R.A. LaBiche (1981) ArticleTitleA continuous-flow system for growing fresh-water sponges in the laboratory. Hydrobiologia 79 255–259

S.A. Pomponi R. Willoughby M.E. Kaighn A.E. Wright (1997) Development of techniques for in vitro production of bioactive natural products from marine sponges. K. Maramorosch J. Mitsuhashi (Eds) Invertebrate Cell Culture: Novel Directions and Biotechnology Applications. Science Publishers Enfield, N.H. 231–237

H.M. Reiswig (1971) ArticleTitleParticle feeding in natural populations of three marine demosponges. Biol Bull 141 568–591

H.M. Reiswig (1974) ArticleTitleWater transport, respiration and energetics of three tropical marine sponges. J Exp Mar Biol Ecol 14 231–249 Occurrence Handle10.1016/0022-0981(74)90005-7

M. Ribes R. Coma J.M. Gili (1999) ArticleTitleNatural diet and grazing rate of the temperate sponge Dysidea avara (Demospongiae, Dendroceratida) throughout an annual cycle. Mar Ecol Prog Ser 176 179–190

H.U. Riisgård S. Thomassen H. Jakobsen J.M. Weeks P.S. Larsen (1993) ArticleTitleSuspension feeding in marine sponges Halichondria panicea and Haliclona urceolus: effects of temperature on filtration rate and energy cost of pumping. Mar Ecol Prog Ser 96 177–188

F.J. Schmitz B.F. Bowden S.I. Toth (1993) Antitumor and cytotoxic compounds from marine organisms. D.H. Attaway O.R. Zaborsky (Eds) Marine Biotechnology, Volume 1: Pharmaceutical and Bioactive Natural Products. Plenum Press New York, N.Y. 197–308

J.E. Thompson P.T. Murphy P.R. Bergquist E.A. Evans (1987) ArticleTitleEnvironmentally induced variation in diterpene composition of the marine sponge Rhopaloeides odorabile. Biochem Syst Ecol 15 595–606 Occurrence Handle1:CAS:528:DyaL2sXmtlenurY%3D

X. Turon M.A. Becerro M.J. Uriz (1996) ArticleTitleSeasonal patterns of toxicity in benthic invertebrates: the encrusting sponge Crambe crambe (Poeciloslerida). Oikos 75 33–40

D.M. Wilson M. Puyana W. Fenical J.R. Pawlik (1999) ArticleTitleChemical defense of the Caribbean Reef sponge Axinella corrugata against predatory fishes. J Chem Ecol 25 2811–2823 Occurrence Handle10.1023/A:1020811810223 Occurrence Handle1:CAS:528:DyaK1MXnvFyitro%3D

A.E. Wright S.A. Chiles S.S. Cross (1991) ArticleTitle3-Amino-1-(2-aminoimidazoyl)-prop-1-ene from the marine sponges Teichaxinella morchella and Ptilocaulis walpersi. J Nat Prod 54 1684–1686 Occurrence Handle1:CAS:528:DyaK38XisFant7Y%3D

Acknowledgements

We thank Dr. Peter McCarthy and the HBOI fermentation group for media supplies, and Deborah Pierce and the two anonymous referees for helpful comments on the manuscript. The research was funded through a postdoctoral fellowship from the Harbor Branch Institution and the Gertrude E. Skelly Charitable Foundation. The experiments performed in this study comply with the current laws of the United States. This is HBOI contribution number 1503.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duckworth, A.R., Samples, G.A., Wright, A.E. et al. In Vitro CuIture of the Tropical Sponge Axinella corrugata (Demospongiae): Effect of Food Cell Concentration on Growth, Clearance Rate, and Biosynthesis of Stevensine . Mar. Biotechnol. 5, 519–527 (2003). https://doi.org/10.1007/s10126-002-0111-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10126-002-0111-0