Abstract

The advent of Industry 4.0 where humans and intelligent machines coexist, allows machines to assist humans on production lines. During such processes, humans work with other humans and/or machines to produce the required products, forming human-related collaborations. Therefore, Industry 4.0 goes beyond a digital ecosystem by being considered as a System of Information Systems which matches heterogeneous systems. This heterogeneity causes poor information interoperability, weakening the effectiveness of collaboration. This poses an issue: how to facilitate human-related collaborations on production lines into Industry 4.0? Addressing it requires better information interoperability and the definition of indicators that can be used to generate recommendations during collaborations. In this article, we focus on indicators of collaboration context and integrate them into a collaboration context ontology to enhance human-related collaborations into Industry 4.0. We then show how to use it in generating context-aware collaborator recommendations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Industrial revolutions upgrade production by providing new supports in the manufacturing process. The first three industrial revolutions have brought steam, electronic and automated machines to humans (Tay et al. 2018), empowering humans to respectively work with these supports on production lines. With the fourth revolution—Industry 4.0, intelligent machines become available (Schumacher et al. 2016). Humans are allowed to produce in a more flexible and efficient manner by working with other humans and/or intelligent machines on production lines. During such processes, both humans and machines aim to achieve a common goal: manufacturing the required products. Thus, human-related collaborations are formed, including human-to-human and human-to-machine collaboration.

As a group work pattern, a collaboration involves at least two collaborators (Li et al. 2018), which can be either humans and/or intelligent machines in Industry 4.0. While collaborating, they adjust their own activities to attain common goals (Patel et al. 2012) that would be difficult or costly to reach when compared to working individually. Thus, collaboration is an indispensable and efficient way of working (Mattessich and Monsey 1992), which is thus critical for greater productivity in manufacturing (Schuh et al. 2014). Particularly in Industry 4.0, human-related collaborations on production lines belong to the vertical system integration (Saucedo-Martínez et al. 2018; Alcácer and Cruz-Machado 2019) which combines systems related to production lines. Thus, a digital ecosystem (Nayyar and Kumar 2020) is formed in Industry 4.0, where humans and machines collaborate in digital production.

Given that a digital ecosystem is a System of Information Systems (Saleh and Abel 2016), Industry 4.0 can also be seen as a System of Information Systems. Accordingly, humans and machines are heterogeneous information systems, which lead to poor information interoperability between them. Besides, these systems also need to process relevant information for achieving transparency in their collaborations on production lines. However, the massive quantity of such information (Weyer et al. 2015) leads to information overload, weakening the effectiveness of their collaborations and decreasing productivity. Therefore, one of the current issues is how to facilitate these human-related collaborations into Industry 4.0.

To solve this issue, it is necessary not only to improve information interoperability between heterogeneous systems, but also to generate recommendations for humans by filtering out irrelevant information. These recommendations are expected to assist humans in analyzing and facilitating their collaborations in Industry 4.0. To this end, various indicators that may impact collaborations must be considered, such as collaborators (Mattessich and Monsey 1992; Patel et al. 2012), resources (Mattessich and Monsey 1992; San Martín-Rodríguez et al. 2005), and goals (Mattessich and Monsey 1992; Patel et al. 2012; Oliveira et al. 2011). However, it is insufficient to just deal with these impacting indicators. As a special indicator, the context of the collaboration also has an impact on other indicators (e.g., activity, resources). Here, context indicates any characteristic information that can be used to describe the situation of an entity (e.g., human, object, event) (Li et al. 2018, 2019). In our research, the entity is the collaboration, a macro entity composed of certain indicators. Thus, in addition to concentrating only on the indicators, considering them within the context is necessary to assess and therefore facilitate collaborations (Taylor-Powell and Rossing 2009). As part of our research, we propose to integrate these indicators into a collaboration context model and employ this model in generating context-aware collaborator recommendations to enhance human-related collaborations into Industry 4.0.

While constructing the collaboration context model, we are interested in adopting ontology. On the one hand, one method to improve information interoperability is applying a common language to describe information so that it can be interpreted by different systems (Bowen and Sahin 2010). The establishment of a common knowledge base using ontology in a System of Information Systems (Saleh and Abel 2016) proves that ontology is a such language. On the other hand, ontology is also a machine-interpretable (Obrst 2003) and reasonable (Heflin 2004) knowledge representation. This enables both humans and machines in Industry 4.0 to interpret the context of collaboration.

Therefore, we intend to construct a collaboration context ontology. This ontology can improve information interoperability and define the indicators that are used to generate context-aware collaborator recommendations for humans to enhance human-related collaboration into Industry 4.0.

The remainder of this paper is organized as follows. Section 2 introduces Industry 4.0 and System of Information Systems. Besides, we also analyze impacting indicators of collaboration, make a survey of approaches to model context and investigate context-aware recommendations (cf. Sect. 2). We then present the collaboration context ontology and how to use it in generating context-aware collaborator recommendations (cf. Sect. 3). Section 4 discusses the advantages and disadvantages of the collaboration context ontology. Finally, some conclusions and future work are put forward (cf. Sect. 5).

2 Related work

Section 2.1 introduces Industry 4.0 and its relation with collaborations. Then the notion of System of Information Systems is studied from the perspectives of its origins and features (cf. Sect. 2.2). After, we analyze impacting indicators of collaboration and discuss the collaboration context (cf. Sect. 2.3). Section 2.4 investigates different approaches of context modeling. Finally, context-aware recommendations are presented (cf. Sect. 2.5).

2.1 Industry 4.0 and collaborations

Industry 4.0 describes the future of global manufacturing with intelligent and digital production (Nayyar and Kumar 2020; Brettel et al. 2014). It seeks to produce more efficiently and less costly through nine key pillars (see Fig. 1), including (1) big data and analytics; (2) autonomous robots; (3) simulation; (4) horizontal and vertical system integration; (5) the industrial internet of things; (6) cyber-security; (7) additive manufacturing; (8) augmented reality; (9) cloud computing (Tay et al. 2018; Saucedo-Martínez et al. 2018; Alcácer and Cruz-Machado 2019).

These nine key pillars connect with each other to integrate intelligent machines and humans into production lines (Schumacher et al. 2016). For example, the industrial Internet of Things enables production sectors (i.e., production lines, products, and machines) to be digitized with sensitive devices and connected with human (Tay et al. 2018; Alcácer and Cruz-Machado 2019). It can also help to gather relevant information on entire production lines (Tay et al. 2018). Such information is too enormous so that its processing and storing require the use of Cloud Computing and Big data. This makes the producing process transparent (Weyer et al. 2015; Salkin et al. 2018). Besides, Cyber-security is used to protect the information on production lines.

In addition, while the horizontal system integration builds a network of enterprises along the whole value chain from suppliers to customers, the vertical system integration organizes and controls processes from the production to the distribution of products or services (Tay et al. 2018; Alcácer and Cruz-Machado 2019; Salkin et al. 2018; Schuh et al. 2014; Camarinha-Matos et al. 2017). Particularly, the vertical integration creates a combination of hierarchical subsystems relevant to production lines (Tay et al. 2018; Alcácer and Cruz-Machado 2019; Salkin et al. 2018; Schuh et al. 2014; Camarinha-Matos et al. 2017), where the subsystems (e.g. management systems and logistic system) are digitized and connected through using the other eight pillars. Through such integration, all production lines within a factory can be controlled and organized intelligently (Suri et al. 2017; Camarinha-Matos et al. 2017; Salkin et al. 2018). In doing so, smart factories (Salkin et al. 2018) are achievable with flexible production lines (Tay et al. 2018), which can be reconfigured to cope with different types of products (Nayyar and Kumar 2020), such as small-lot sizes and customized products (Salkin et al. 2018). This signifies that within vertical integration, humans and intelligent machines can work together on production lines to manufacture products based on customers’ orders.

Specifically, the manufacturing processes on production lines are considered as collaborations between humans and/or intelligent machines, instead of other similar concepts, such as cooperation and teamwork. In a collaboration, its members must have one or more common goals. They are willing to adjust their own activities and share their responsibilities to achieve these goals, such as coordinating (Li et al. 2018; Patel et al. 2012; San Martín-Rodríguez et al. 2005; Camarihna-Matos and Afsarmanesh 2008). However, the members of a cooperation do not share responsibilities or necessarily have a common goal (Hoc 2001; Piaget 1977). Cooperation emphasizes the interference between members’ goals and makes use of such interference to facilitate members’ activities (Hoc 2001; Millot and Hoc 1997). Particularly, this interference can be positive (e.g., compatible or common goals) or negative (e.g., conflicts between goals) (Millot 2007; Camarihna-Matos and Afsarmanesh 2008). On production lines, both humans and intelligent machines aim to manufacture certain products required in orders, which are their common goals. To achieve such goals, they interact with each other to jointly plan, implement, and evaluate their activities, such as making decisions. This implies that such manufacturing processes involve sharing risks, resources, and responsibilities, which are therefore more than cooperation. Besides, teamwork emphasizes its members and their various activities, including collaborative activities and individual activities (Salas et al. 1995). In our research, we focus on analyzing activities during the manufacturing process of an order, not including individual activities that are irrelevant to manufacturing. Therefore, we consider the manufacturing process of an order within vertical integration as a collaboration where at least two collaborators carry out activities to achieve a common goal (Li et al. 2018). Notably, three types of collaborations are available: human-to-human, human-to-machine and machine-to-machine collaborations (Hermann et al. 2016). In our research, we focus on human-to-human and human-to-machine collaboration on production lines, which can be summarized as human-related collaboration within vertical integration.

However, achieving vertical integration requires replacing or upgrading all machines on production lines, until a digital ecosystem is attained (Nayyar and Kumar 2020; Salkin et al. 2018). Such a digital ecosystem includes all intelligent machines and humans involved in the production lines. This implies that Industry 4.0 is a digital ecosystem where humans and/or machines collaborate at a high level of digitization to accomplish production. Therefore, for better production, we need to facilitate these human-related collaborations on production lines into Industry 4.0. For this purpose, effective transfer and communication of information between humans and/or machines are indispensable (Qin et al. 2016). This signifies that humans and machines can be regarded as independent systems handling information. Together, they can form a System of Information Systems (SoIS) (Saleh and Abel 2016). With the aim to have a high-level understanding of the relationship between Industry 4.0 and SoIS, SoIS should also be explored.

2.2 System of information systems (SoIS)

A SoIS is a special type of system of systems (SoS). A SoS is an integrated network of systems that are heterogeneous and independently operable on their own, but are networked together for a common goal (Jamshidi 2008). In other words, a SoS can be separated into two parts: component systems (which are those independent and heterogeneous systems) and a global system (which is the result of gathering the component systems) (Assaad et al. 2016). Particularly, if each component system in a SoS is an information system, such a SoS is a SoIS (Saleh and Abel 2016).

Hence, the specificity of SoIS lies in the difference between the information system and other systems. An information system contains a set of interrelated components that perform activities for collecting, processing, storing and distributing information, while a system is a set of elements dynamically interrelated to perform activities aiming at achieving a specific goal (Neto et al. 2017). In comparison, the unique character of the information system lies in its high relevance to the information. Thus, the characteristics of SoIS are also relevant to the information. A SoIS uses information from separated systems to aggregate existing services and produce new ones. For example, the Internet is a SoIS that contains different information systems providing various services to users (see Fig. 2).

Particularly, Saleh and Abel (2016) pointed out that a SoIS can be considered as a digital ecosystem by treating the component systems as digital species. This relationship between SoIS and the digital ecosystem signals that, as a digital ecosystem, Industry 4.0 is also a SoIS. Thus, intelligent machines and humans are autonomous component systems in a SoIS. They collaborate on production lines to manufacture certain products following customers’ orders. Based on the requirements in orders (i.e., goals of their collaborations), these component systems can be identified for adding and/or removing in such a SoIS by the human managers that are responsible for the corresponding orders. These identified component systems are heterogeneous because of the huge disparity between humans and machines, which create barriers to information exchange. This leads to poor information interoperability between heterogeneous systems in Industry 4.0, and thus has a negative impact on production efficiency.

To solve this issue, one method is to create a common language for describing data, where each information system can represent its data such that other systems may interpret (Bowen and Sahin 2010). Hence, it is necessary to apply a language into Industry 4.0, which can be interpreted by both humans and machines.

However, it is not enough to only consider interpretations of humans and machines. This language should also be able to define and represent indicators (e.g., goals) for analyzing and facilitating collaborations, which is crucial to enable the adjustment of humans and machines on production lines, thus enhancing human-related collaborations within vertical integration (Camarinha-Matos et al. 2017). Without such indicators, humans need to make decisions on their own during collaborations from unfiltered and overloaded information about collaborations. Therefore, we need to explore and identify these impacting indicators in the context of collaboration.

2.3 Impacting indicators of collaboration and collaboration context

With a common goal to achieve (Mattessich and Monsey 1992; Patel et al. 2012; Oliveira et al. 2011; Li et al. 2018), a collaboration involves two or more collaborators and comprises a set of their activities (Li et al. 2018). To investigate indicators that can influence collaboration, a literature review of previous studies, including Hara et al. (2003), Bruneel et al. (2010), San Martín-Rodríguez et al. (2005), Patel et al. (2012) and Mattessich and Monsey (1992), was performed in one of our previous papers: Li et al. (2019). A summary of the results is reported in this section.

These previous studies (Hara et al. 2003; Bruneel et al. 2010; San Martín-Rodríguez et al. 2005; Patel et al. 2012; Mattessich and Monsey 1992) seek to analyze and facilitate collaborations through several indicators. Each concerns on the indicators in its own field of research, which is why these indicators are so diverse. Sometimes, certain indicators are not universal and cannot qualify collaborations in other fields. For example, research work connections (Hara et al. 2003) is only suitable for scientific collaborations. In commercial collaborations, this indicator is no longer adoptable. Other similar indicators include inter-organizational trust (Bruneel et al. 2010) and business climate (Patel et al. 2012).

Moreover, all research methods in these previous studies (Hara et al. 2003; Bruneel et al. 2010; San Martín-Rodríguez et al. 2005; Patel et al. 2012; Mattessich and Monsey 1992) can be divided into two main classes: (1) directly explore indicators, e.g., (Hara et al. 2003; Bruneel et al. 2010); (2) integrate indicators into different levels by grouping/categorizing, e.g., (Mattessich and Monsey 1992; San Martín-Rodríguez et al. 2005; Patel et al. 2012). Such a difference indicates that each indicator has a specific impact on collaboration. And its impact depends on the domain of collaboration.

Besides, many shared indicators are identified and summarized as below, based on (Patel et al. 2012; Mattessich and Monsey 1992; San Martín-Rodríguez et al. 2005; Hara et al. 2003; Bruneel et al. 2010):

-

Goal: This is essential for collaborations and is mentioned by the definitions of collaboration in Liu et al. (2018). A goal can refer to desired outcomes, products, or states but must be shared by collaborators.

-

Collaborators: This is also basic for collaboration, which signifies members of a collaboration. In some cases, it can be represented by a group of indicators that are used to describe a collaborator, including relationships and compatibility with other collaborators, individual activities/experiences, individual abilities/skills, and trust. Particularly in Industry 4.0, a collaborator refers to either a human or an intelligent machine.

-

Activity: This indicates the actions that collaborators take to progress towards the goals of collaboration. This consists of collaborators’ individual actions and interactions with other collaborators, such as coordination for sub-tasks and decision-making. Specifically, collaborators’ individual actions that are not directly related to collaboration are not considered here, but in collaborators above.

-

Resources: This covers various forms of assets used to support collaborations, such as documents, tools, technologies.

-

Context: This involves the surroundings of collaboration that do not define the collaboration but are closely tied to and influence it. It can be a cultural, organizational, or environmental indicator. For example, if humans collaborate with intelligent machines on a production line, then the location and surroundings of the production line belong to this kind of indicator when belonging to environments of collaborations. And they have an effect on humans’ activities and effectiveness of their collaboration in Industry 4.0.

While these indicators have some similarities and differences, they complement each other to some extent. For example, collaborators can achieve shared control during collaborations using their abilities/skills and activities (Flemisch et al. 2019). In other words, jointly considering collaborator and activity helps describe another feature of collaboration (i.e., shared control). Thus, the collaboration is not determined by a single indicator, but by the integration of all these indicators. In turn, such indicators can assist in the assessment of collaboration and suggest adjustments accordingly. That is, refining these indicators can directly or indirectly facilitate collaboration. For instance, Liu et al. (2018) tried to encourage scientific collaborations by recommending collaborators.

Besides, goals, collaborators, activities, resources, and context are five key indicators, which implies common features of collaboration from the above analysis. Particularly, the indicator context is so complex that it may influence other indicators by influencing collaborators’ behaviors, such as activity (collaborators’ actions) and resources (their used tools). It also has an impact on both the actual process and the effectiveness of collaboration (Patel et al. 2012). This necessitates taking these indicators into account within the context rather than merely integrating them together.

Therefore, we focus on collaboration context, which is identified by the definition of context (Dey 2001): context is any information that can be used to characterize the situation of an entity. An entity is a person, place, or object that is considered relevant to the interaction between a user and an application, including the user and applications themselves. Particularly in Industry 4.0, we consider the entity as a human-related collaboration on production lines. Any information that can be used to characterize the situation of a human-related collaboration on production lines belongs to the collaboration context, whether it concerns all or part of the production lines. Defining a collaboration context model can deepen the comprehension of collaboration and facilitate it (Li et al. 2019). However, in Industry 4.0, heterogeneous information from diverse systems on production lines places higher demands on context modeling, requiring us to investigate different approaches of developing the collaboration context model.

2.4 Context modeling

A large number of context modeling approaches were proposed. Based on the scheme of data structures, Strang and Linnhoff-Popien (2004) classified six approaches of context modeling, as follows: key-value model, markup model, graphical model, object-oriented model, logic-based model, and ontology-based model. Moreover, Bettini et al. (2010) added a spatial model that concentrates on the location information.

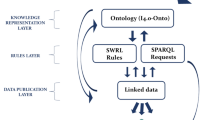

Particularly, ontology provides a formal and explicit structure for manipulating domain-specific knowledge or, more broadly, knowledge bases. An ontology-based model specifies a shared, agreed, and detailed conceptualization of information (Gruber 1993; Du et al. 2019; Munir and Anjum 2018). Based on Du et al. (2019), Negre (2017) and Strang et al. (2003), an ontology-based model includes two components (see Fig. 3):

-

1.

T-Box defines the nature of concepts (classes of subjects) and their interrelationships that constitute model.

-

2.

A-Box explains the relationships between instances of the concepts and relations that are defined in T-Box.

By splitting into two components, ontology-based models are able to reuse the T-Box component in existing ontologies. Specifically, ontologies that are fully documentedFootnote 1 can provide useful input for ontology reuse.

Ontology-based models also offer flexibility and extensibility in distributed systems by supporting distributed storage and multi-author creation (Strang et al. 2003). The available reasoning tools of ontology can check both consistency and completeness (Bettini et al. 2010; Strang and Linnhoff-Popien 2004). This implies that such a model is machine-interpretable, which signifies that ontology is a common language for both humans and intelligent machines in Industry 4.0. Therefore, applying ontology in the SoIS, Industry 4.0, can ease information communications between heterogeneous systems (humans and machines) and thus achieves better information interoperability. This viability is evidenced by the fact that ontology was implemented in a SoIS to interpret the information gathered from various information systems (Saleh and Abel 2016).

Besides, ontology has already been used to conceptualize and formalize context. Gu et al. (2004) developed an ontology-based context model in intelligent environments. Moreover, Yu et al. (2007) modeled user context ontology for e-learning. Strang et al. (2003) proposed Context Ontology Language (CoOL) to enable context-awareness and contextual interoperability in a distributed system. However, to the best of our knowledge, there is no existing ontology about collaboration context.

Regarding context as a specific type of knowledge (Bettini et al. 2010), ontology-based modeling approach is favored among all mentioned approaches, because of its reusability, flexibility, extensibility, and interpretability. Thus, we decide to build a collaboration context ontology and employ it in generating context-aware recommendations to enhance human-related collaborations into Industry 4.0.

2.5 Context-aware recommendation

Recommendations are generated through recommender systems (RS) that are designed and applied to find the information most relevant to users’ needs and transfer it to users (Nunes and Jannach 2017). Typically, RSs deal with two dimensions of data: users and items (Adomavicius et al. 2005). Here, items is the general term to indicate the objects that RS recommends to users, while users indicates people who will receive these recommended items (Ricci et al. 2011). For example, in Industry 4.0, intelligent machines can be recommended to humans for manufacturing certain products. An item refers to a machine, a user as a human.

To provide recommendations, RSs need to identify and sort items by their utilities (ratings) (Ricci et al. 2011) that indicate how a particular user preferred a specific item (Adomavicius and Tuzhilin 2005). Thus, the core task of RS is: given an initial set of ratings that users explicitly or implicitly give for items, RSs try to calculate/compare items’ unknown/missing ratings and decide which items to recommend, by storing and applying known ratings of items (Ricci et al. 2011; Adomavicius and Tuzhilin 2011).

Adomavicius and Tuzhilin (2005) modeled utility (rating) function of the RSs with two dimensions of data (written as 2D RS in the following part of this paper) as follows:

where Rating is a totally ordered set (e.g., non-negative integers or real numbers within a certain range).

Recently, a new branch of RS, Context-Aware Recommender System (CARS), was proposed by Adomavicius et al. (2005). A CARS is constructed by incorporating context into recommendation generating processes, which can result in more accurate recommendations (Palmisano et al. 2008), namely context-aware recommendations.

CARS aims to recommend items to users (Ricci et al. 2011) based on contexts. Here, context is any information that can be used to characterize the situation of users, items, or interaction between users and items (Dey 2001). In the above example, context refers to the fact that certain products need to be manufactured by humans and/or machines on production lines. Based on the three dimensions of data: user, item, and context, utilities (ratings) of items in CARS indicate how a particular user preferred a specific item (Adomavicius and Tuzhilin 2005) in a certain context. Therefore, the rating function of a CARS is (Adomavicius et al. 2005):

As part of our research, context in Eq. (2) indicates the collaboration context. In other words, the collaboration context is implemented and applied in a CARS to recommend items for a particular human in Industry 4.0. Here, an item is a collaborator, either an intelligent machine or another human. Accordingly, a rating of collaborators signifies how a particular human preferred to collaborate with a specific collaborator in a certain context of collaboration. Through humans’ known ratings of collaborators, it is possible to predict those unknown ratings and thus recommend collaborators with higher ratings to humans. These context-aware collaborator recommendations are intended to suggest collaborators for humans, with the aim of enhancing human-related collaborations on production lines and thus leading to more efficient production in industry 4.0.

3 Contributions

We consider Industry 4.0 as a System of Information Systems (SoIS) (cf. Sect. 2). In such a SoIS, component systems are heterogeneous information systems, which can be humans and/or intelligent machines. These systems collaborate on production lines to manufacture products based on customers’ orders. From their collaborations, massive and heterogeneous information can be collected, thus resulting in poor information interoperability and information overload. This affects the efficiency of their collaborations and leads to less production. To enhance such collaborations into Industry 4.0, we make the choice to construct a collaboration context ontology that can improve information interoperability and define specific indicators for generating context-aware collaborator recommendations.

Therefore, Sect. 3.1 identifies the indicators of collaboration context. We then explain the modeling of these indicators in the collaboration context ontology, MEMORAe-Collaboration-Context (MCC) (cf. Sect. 3.2). Finally, Sect. 3.3 presents and demonstrates how MCC can be employed to describe the collaboration and generate context-aware collaborator recommendations, thus facilitating human-related collaborations into Industry 4.0.

3.1 Indicators of collaboration context

As analyzed in Sect. 2.3, five key indicators that signify common characteristics of collaboration are identified: goal, collaborator, activity, resource, and context. Particularly, the special impact of context demands to consider the other four indicators within the collaboration context. In other words, the other four indicators (goal, collaborator, activity, and resource) also serve as indicators of collaboration context.

Furthermore, considering the complexities of the indicators and their impacts on collaboration, they can be categorized in two different levels: indicator and indicator group (group of indicators). Due to the critical impact of the four indicators (Goal, Collaborator, Activity, and Resource), we handle them as four indicator groups in the collaboration context ontology. Each indicator group consists of several relevant indicators. For example, the indicator group Activity may include indicators like activity type and actor.

Besides, the collaboration context involves any information that can be used to characterize the situation of collaboration over a given period (Li et al. 2018, 2019). As two basic characteristics, the temporal and spatial information of the collaboration can also be expressed by two indicator groups: Time and Location. Since collaborations are connected, we also define an indicator group Relation to encompass the indicators that are relevant to these relationships between collaborations. Finally, the indicator group Satisfaction allows collaborators to give their personal views about the collaboration.

Therefore, eight indicator groups are proposed to facilitate collaboration: goal, collaborator, activity, resource, time, location, relation, and satisfaction. The indicators associated with each indicator group are summarized as follows. Particularly in Industry 4.0, the indicator group Collaborator can support the representation of humans and intelligent machines in human-related collaborations.

-

1.

Goal includes desired products from the collaboration.

-

2.

Collaborator is represented by collaborator’s abilities and demographic information.

-

3.

Activity specifies type, actors, resources involved, time, and location in activities.

-

4.

Resource covers resources’ types, and identifications.

-

5.

Time contains start time and end time of the collaboration.

-

6.

Location holds all places involved during the collaboration with their identifications, types and corresponding geographical information, such as longitude and latitude.

-

7.

Relation has other related collaborations and their relationships with the collaboration.

-

8.

Satisfaction provides collaborator’s degrees of satisfaction and comments about the collaboration.

To define and represent these indicator groups and associated indicators in the collaboration context ontology, it is necessary to explore how to deploy them in an architecture of context model. Based on an architecture structured by three interdependent concepts (contextual information, factor and dimension) (Li et al. 2018) (see the left side of Fig. 4), a contextual dimension of collaboration can be transformed as an indicator group. Thus, a contextual factor equals an indicator whose value is represented by the corresponding contextual information (Adomavicius and Tuzhilin 2011). For example, for the indicator start time in the indicator group Time, its value is 01/02/2020. Hence, with such a transformation, the collaboration context ontology should be developed following the architecture presented on the right side of Fig. 4.

From an architecture of context models to the architecture of the collaboration context ontology (Li et al. 2019)

3.2 Modeling indicators in the collaboration context ontology

To model the eight indicator groups (goal, collaborator, activity, resource, time, location, relation, and satisfaction) in the collaboration context ontology, we first need to describe the entity (i.e., collaboration) based on the architecture shown on the right side of Fig. 4. Given that a collaboration consists of a common goal and at least two collaborators, the collaboration context ontology MEMORAe-Collaboration-Context (MCC) employs user groups to represent collaborations: a user group has a goal and at least two members that hold their accounts to access different information systems in a SoIS.

Then, it is necessary to link the user group with the eight indicator groups. While modeling them in MCC, the reusability of ontology greatly simplifies this process and saves effort by extending other existing ontologies. This implies that these existing ontologies can be integrated into MCC. Thus, we explore two existing ontologies of collaboration: MEMORAe-Core2 (MC2) (Abel 2008, 2015; Wang et al. 2016) and MEMORAe-SoIS (MS) (Saleh and Abel 2017).

-

MC2 aims to support the collaborations between users in a web-based collaborative platform (Abel 2008, 2015; Wang et al. 2016). These collaborations occur in organizations that are considered as collections of humans belonging to groups. Thus, MC2 concentrates on three main modules (Deparis et al. 2014; Wang et al. 2016): individuals and groups of individuals, resource, and activity.

-

Extended from MC2, MS provides assistance for collaborations happening in a SoIS (Saleh and Abel 2017). Within MS, users can interact with different resources coming from separated information systems. Thus, MS concerns about two main modules: resource and activity.

Specifically, MC2 establishes the fundamental modules for collaborations between users in organizations. MS deals with users’ collaborations in a SoIS by accounting for the complexity and diversity of resource systems. Both MC2 and MS are close to our focus: human-related collaborations in Industry 4.0 considered as a SoIS. Such proximity signifies that MC2 and MS are worth reusing to construct MCC. Plus, they have been validated and proved by developing web platforms (Abel 2015; Wang et al. 2016; Saleh and Abel 2017).

Besides, the mains modules of MC2 and MS already cover three indicator groups. Particularly, Individuals and groups of individuals module corresponds to the indicator group Collaborator by specifying users and groups. The other two modules match the two indicator groups with same names: resource and activity. Note that these three indicator groups are not fully represented in MC2 and MS, suggesting they need extra modifications in MCC.

Therefore, MC2 and MS are indispensable to MCC. This necessitates that four other ontologies reused by MC2 and MS should also be integrated into MCC, including: FOAF,Footnote 2 PROV,Footnote 3 SIOC,Footnote 4 and VCard.Footnote 5

Within these existing ontologies (MC2, MS, FOAF, PROV, SIOC, and VCard), MCC defines collaboration using a concept of user group, mcc:UserGroup (see Fig. 5). Surrounding mcc:UserGroup (marked with a circle), the eight indicator groups (goal, collaborator, activity, resource, time, location, relation, and satisfaction) are represented by different concepts and/or their interrelationships in MCC, as specified with rectangles in Fig. 5.

3.3 Use in industry 4.0

To demonstrate the usage of MCC, a scenario of human-related collaboration on production lines in Industry 4.0 is provided. We then explain how MCC can be applied to represent the collaboration in the scenario and enhance it by generating context-aware collaborator recommendations to humans.

A scenario of collaboration in Industry 4.0 As a smart beverage factory, CokeX focuses mainly on the beverages production. Meantime, It also accepts customized orders from its clients. Particularly, CokeX produces three different beverages: CoKe1, CoKe2, and CoKe3. Each beverage may contain different amounts of sugar: no sugar, normal sugar, and double sugar. However, CokeX does not offer different flavors of the three beverages, such as cherry CoKe1. If such beverages are required by clients’ orders, then the product development department needs to work with the production department for creating special flavors of beverages.

CokeX owns five production lines in the production department. Specifically, three lines serve to manufacture no-sugar beverages and two lines control amounts of sugar in beverages. When operating, each production line requires one employee to supervise it and check product quality. Moreover, the ingredients on all production lines are controlled by an ingredient management software. A summary of these lines is presented in Table 1. Particularly, the three lines (A, B, and C) occupy the second floor, while the other two lines (S and T) are situated on the first floor.

Besides, there are seven employees working in CokeX. A summary of these employees is presented in Table 2.

Recently, CokeX received two orders from a client, UniLAB. UniLAB purchased 150 bottles of CoKe1 (normal sugar), CoKe2 (normal sugar), and CoKe3 (normal sugar) on December 16, which was already completed by Antoine, Claude, Dominique, and Emilie with production line A, B, C, and S on December 30. On January 19, UniLAB placed a customized order, including: 70 bottles of CoKe1 (no sugar), 70 bottles of CoKe1 (double sugar), 100 bottles of CoKe2 (no sugar), and 40 bottles of CoKe3 (double sugar). Once the customized order was received, Antoine, Claude, Emilie and Guillaume immediately collaborated on production line A, B, and S to produce the required beverages. However, on January 24, the customized order was updated by adding: 60 bottles of CoKe1 (normal sugar) and 30 bottles of cherry CoKe2 (normal sugar).

MEMORAe-Collaboration-Context (MCC)

As shown in Fig. 5, collaboration is defined through mcc:UserGroup in MCC. Thus, the human-related collaboration of the customized order in the scenario can be represented by an instance of mcc:UserGroup. Such a user group provides a group space for four humans (i.e., Antoine, Claude, Emilie, Guillaume) and three intelligent machines (i.e., production line A, B, and S) in CokeX to interact with each other and access to the available resources (e.g., ingredients). Every user group is held by a mc2:Group, equivalent to foaf:Group. A mc2:Group represents a group of agents in real world. Here, an agent indicate a thing that do stuff, such as person and intelligent machine. Members of an mc2:Group can collaborate multiple times, while members of a mcc:UserGroup are limited to a single collaboration. Hence, an mc2:Group can create multiple instances of mcc:UserGroup to stand for different collaborations.

The group collaborator in MCC (T-Box component) (Li et al. 2019)

By using the eight indicator groups (Goal, Collaborator, Activity, Resource, Time, Location, Relation, and Satisfaction), a mcc:UserGroup in MCC is established for a time period, has a goal and at least two collaborators with their accounts. These collaborators are agents that are members of a collaboration, such as humans, groups, organizations (Li et al. 2018), and intelligent machines, which is detailed in Fig. 6. In the scenario, the instance of mcc:UserGroup created for the customized order includes accounts of Antoine, Claude, Emilie, Guillaume, production line A, B, and S, rather than themselves. These accounts are managed in the global system of a SoIS. Through their accounts, collaborators can access to different information systems in the SoIS. In the scenario, Claude can login to his account to remotely and/or manually check the status of production line A that is also considered as an information system in Industry 4.0. Besides, collaborators can carry out different activities using various resources and provide their degree of satisfaction with the user group.

Associated with mcc:UserGroup, mcc:Goal represents the goal of collaboration. It can be composed of anything, expressed as owl:Thing in MCC. In the scenario, the goal of the customized order on January 19 is to produce 70 bottles of CoKe1 (no sugar), 70 bottles of CoKe1 (double sugar), 100 bottles of CoKe2 (no sugar), and 40 bottles of CoKe3 (double sugar). To represent this goal in MCC, an instance of mcc:Goal is built, containing the four required beverages and held by the user group of the corresponding collaboration (Fig. 7).

Besides, MCC applies MC2, MS, FOAF, SIOC, and VCard to model the indicator group—Collaborator (see Fig. 6). Especially, MC2 and VCard aim to construct profiles for humans, including their demographic information and abilities. In the scenario, to arrange production lines A, B and S between Antoine, Claude, Emilie and Guillaume, the profiles of these employees can be consulted. Figure 8 illustrates Emilie’s profile, indicating that she can operate and supervise production lines B and C. This suggests that production line B should be assigned to Emilie.

Regarding resources, MC2 defines them as vectors of information and classifies them into simple and composite resource Saleh and Abel (2017). In MCC, resources are still divided into the two categories based on their complexity levels. Particularly, information systems are composite resources. This is because information systems can not only be manipulated by collaborators during some activities, but also store other resources in a SoIS. For example, production lines need to store some ingredients and/or products while waiting for product transportation. Notably, these resources are digitally contained in the information system where they were originally stocked, whether it is the global system or a component system in the SoIS. Thus, we apply reference keys to bind these resources with the global system. Each reference key is included in the global system and has an index key that is visible to certain group spaces. This ties resources to user groups. Through mc2:IndexKey and ms:ReferenceKey, the global system of SoIS can access and manage heterogeneous resources originating from different systems. In the scenario, the ingredients on production lines are considered as resources, which are organized by the ingredient management software via mc2:IndexKey and ms:ReferenceKey.

As for activities, MCC combines the two activity modules (in MC2 and MS) together to collect collaborators’ traces. An activity can utilize and/or generate anything, such as resources and goals. In the scenario, when UniLAB updates the customized order, the goal of the corresponding user group in MCC is therefore modified (see Fig. 9). By reusing PROV, location information can be specified and attached to activities. This enables MCC to track which resources are used in which activity at which location. In the scenario, ingredients water and phosphoric acid are used by Claude and production line A to produce CoKe1 (no sugar) on the second floor (see Fig. 10).

For the other three indicator groups (time, relation and satisfaction), they are all related directly to mcc:UserGroup. With them, MCC can register collaborators’ feedback and analyze relationships between different collaborations. In the scenario, the collaboration of the customized order on January 19 is linked to the previous order on December 16. Thus, the two user groups are connected with each other (see Fig. 11). Besides, Fig. 11 also demonstrates the common collaborators, their satisfactions and start time of the two user groups.

Using MCC, human-related collaborations on production lines in Industry 4.0 can be presented around the concept, mcc:UserGroup. Such a concept is linked to the eight indicator groups (Goal, Collaborator, Activity, Resource, Time, Location, Relation, and Satisfaction) in MCC. Specifically, Time, Relation and Satisfaction are directly related to mcc:UserGroup (see Fig. 5), others indirectly.Footnote 6 Besides, as an ontological model, MCC can specify all information by the semantic 3-uple <Subject, Predicate, Object>, such as <mcc:customized_ order_UniLAB, mcc:startedAtTime, “19/01/2020”> representing the start time of the customized order. Considering mcc:UserGroup as the subject and values of the eight indicator groups as objects, both direct and indirect relations between mcc:UserGroup and the eight indicator groups are therefore predicates. Specifically, for direct relations, a predicate is the relation itself (e.g., mcc:startedAtTime). Whereas for indirect relations, a predicate is a succession of relations and associated concepts. For example, the set of mcc:hasGoal, mcc:Goal, and mcc:isComposedOf is the predicate between mcc:UserGroup and the indicator group Goal. Concerning such indirect relations, a distribution of concepts and interrelations according to their role in the semantic 3-uple is illustrated in Fig. 12. Therefore, a mcc:UserGroup can be formulated as a set of such semantic 3-uples.

An instance of mcc:UserGroup c can be represented as a collection of 3-uple \(C=\left\{ <c, p_{g}^{k}, o_{g}^{c}>| g \le G_{c}, k \le 8, g,k \in \mathbb {N}^{+}\right\}\). Here, \(P^{k} =\left\{ p_{g}^{k}| g \le G_{c}, g \in \mathbb {N}^{+}\right\}\) \((k=1, 2, \ldots 8)\) is the set of predicates between the user group c and values of one indicator group; \(p_{g}^{k} (g \le G_{c}, k \le 8, g, k \in \mathbb {N}^{+})\) is a predicate between the user group c and values of indicator groups; \(O^{c} = \left\{ o_{g}^{c}| g \le G_{c}, g \in \mathbb {N}^{+}\right\}\) is the set of all values of the indicator groups that the user group c has; \(o_{g}^{c} ( \in O^{c})\) is the corresponding value of the predicate \(p_{g}^{k}\); \(G_{c}\) represents the number of predicates that the user group c relates; k represents the 8 types of predicates between the user group c and values of the eight indicator groups (Goal, Collaborator, Activity, Resource, Time, Location, Relation, and Satisfaction).

Based on the semantic 3-uple, the context-aware collaborator recommendation problem in Industry 4.0 is formulated as:

Given a human u in a user group c (\(u \in O^{c}\)) containing a collection of 3-uple \(C=\left\{ <c, p_{g}^{k}, o_{g}^{c}>| g \le G_{c}, k \le 8, g,k \in \mathbb {N}^{+}\right\}\), the top K collaborators that can facilitate u’s collaboration in the user group c with the highest probabilities will be recommended to u, either intelligent machines \(i_m (i_m \notin O^{c})\) or humans \(i_h (i_h \ne u,i_h\notin O^{c})\). Here, based on MCC, \(i_m\) and \(i_h\) are values of the indicator group Collaborator.

The main steps in generating context-aware collaborator recommendationsFootnote 7 are as follows:

-

1.

Calculate similarity \(S(c_{i},c) (i=1, 2, \ldots , N-1)\) between the user group c and other user groups \(c_{i} (c_{i} \ne c)\). Here, N is the number of all user groups.

-

2.

Rank user groups \(c_{i} (i=1, 2, \ldots , N-1)\) based on \(S(c_{i},c)\) in decreasing order.

-

3.

Filter out irrelevant intelligent machines \(i_m (i_m \notin O^{c})\) and humans \(i_h (i_h \ne u,i_h\notin O^{c})\) that are not involved in \(c_{i}\) with the K highest values of \(S(c_{i},c)\), then get relevant intelligent machines \(i'_m\) and humans \(i'_h\).

-

4.

Find the intelligent machine and/or humans with the \(M (M\le K, M\in \mathbb {N})\) highest rating\((u, i'_m)\).

-

5.

Find the human with the \(K-M\) highest rating\((u, i'_h)\).

-

6.

Recommend/return the intelligent machines with the M highest rating\((u, i'_m)\) and the humans with the \(K-M\) highest rating\((u, i'_h)\) to the human u for facilitating u’s human-related collaboration in the user group c.

To calculate the similarity between the two collaborations among members in two user groups, we need to measure the common values in two sets with different user groups but the same predicate. Based on Tversky (1977) and Carrer-Neto et al. (2012), the semantic similarity between the user group c and another user group x is:

where \(G_{k} (G_{k} \le G_{c}, G_{k} \in \mathbb {N}^{+})\) represents the number of predicates that the user group c relates of type k; \(O^{c}_{p^{k}_{a}}\) indicates a set of objects of predicate \(p^{k}_{a}\) that the user group c relates; \(O^{x}_{p^{k}_{a}} - O^{c}_{p^{k}_{a}}\) denotes the relative complement of \(O^{c}_{p^{k}_{a}}\) in \(O^{x}_{p^{k}_{a}}\); \(|O^{x}_{p^{k}_{a}} \cap O^{c}_{p^{k}_{a}}|\) represents the number of common objects associated to x and c through the predicate \(p^{k}_{a}\); Weight\((P^{k})\) expresses the significance of the type of predicate \(P^{k}\) in the formula \((k={1, 2, \ldots , 8})\); \(\alpha , \beta \ge 0\).

Besides, the values of K and M in the steps above are specified according to the needs of the human u. In our scenario, we consider \(K=2\) and \(M=1\) to illustrate how to recommend an intelligent machine and a human to a given human u. Specifically, after updating the customized order on January 24, an employee and a production line can be recommended to Antoine for producing the required beverages: 60 bottles of CoKe1 (normal sugar) and 30 bottles of cherry CoKe2 (normal sugar). Therefore, the human u above indicates Antoine, while c refers to the user group of the customized order.

Besides, UniLAB purchased 100 bottles of CoKe1 (normal sugar), 70 bottles of grape CoKe2 (normal sugar), and 60 bottles of CoKe3 (normal sugar) on January 1, which was already completed by Antoine, Benoit, Claude, and Dominique with production line A, B and S on January 15. The user group for this order is represented by \(c_1\). And \(c_2\) indicates the other user group for the order on December 19 in the scenario.

Following the steps listed above, we need to calculate \(S (c_1,c)\) and \(S (c_2,c)\) for ranking \(c_1\) and \(c_2\). Suppose that \(\mathrm{{Weight}}(P^\mathrm{{goal}})\) = \(\mathrm{{Weight}}(P^\mathrm{{collaborator}})\) = \(\mathrm{{Weight}}(P^\mathrm{{resource}})=\frac{1}{3}\), \(\alpha =\beta =1\), and there is not any common objects of other five predicates, so the range of the similarities S(x, c) is [0, 1]. We can also summarize the objects of the three types of predicate (\(P^\mathrm{{goal}}\), \(P^\mathrm{{collaborator}}\), and \(P^\mathrm{{resource}}\)) as shown in Table 3. Each of the three types has only one predicate. Besides, with the given ratings in [0, 5], we know rating\((u, \mathrm{{Benoit}}) = 4.7\) and rating\((u, \mathrm{{Dominique}}) = 3.8\).

Then we can get \(S (c_1, c) = \frac{2}{2+1+4}\times \frac{1}{3} +\frac{5}{5+2+2}\times \frac{1}{3} +\frac{4}{4+0+0}\times \frac{1}{3} +0=\frac{137}{189}\approx 0.725\) and \(S (c_2, c) = \frac{1}{1+2+5}\times \frac{1}{3}+\frac{6}{6+1+2}\times \frac{1}{3}+\frac{4}{4+0+0}\times \frac{1}{3}+0=\frac{43}{72}\approx 0.597\). \(S (c_1, c) > S (c_2, c)\) indicates that \(c_1\) is more similar to c than \(c_2\). Particularly, \(c_1\) has more common objects in the indicator groups Goal and Collaborator, including: non-regular beverage required by clients, the same production lines and employees.

Next, the production lines that we can recommend to Antoine are C and T. Because production lines A, B and S are already employed in c. Besides, production line T is filtered out since it does not exist in \(c_1\) or \(c_2\). Finally, production line C will be recommended to Antoine.

As for the humans, Claude, Dominique and Guillaume are not candidates because they already participated in c. Then, Julien is excluded because he does not appear in \(c_1\) nor in \(c_2\). Finally, between Benoit and Dominique, a higher value of rating\((u, \mathrm{{Benoit}})\) implies that Benoit becomes the most appropriate employee to help Antoine.

Within MCC, the collaboration context can be integrated into recommendation generating processes to filter out irrelevant collaborators. And the eight indicator groups can be used to examine the semantic similarity between collaborations, and thus propose context-aware collaborator recommendations to facilitate human-related collaborations into Industry 4.0.

4 Discussion

The collaboration context ontology MCC is an ontology-based model that can manage heterogeneous information in a System of Information Systems (SoIS) from a semantic perspective. This is mainly approached through two parts: T-Box and A-Box.

Specifically, the T-Box enables us to define a uniform semantic structure of the information in a SoIS. Such a structure is unconnected to the representation manner or the language of the information, but is only concerned with its meaning. In such a structure, different levels of information representation can be specified in ontologies, e.g., a factory ontology for describing the responsibilities and functions of factory departments. Based on this structure of T-Box, ontology, as a common language in the SoIS (Saleh and Abel 2016), can interpret heterogeneous information from different information systems. Then, the A-Box instantiates the matching information into the corresponding instances. Also, these instances are expressed using ontology, making them interpretable by the information systems of a SoIS. Thus, the information contained in a SoIS can be represented in a unified and standardized way, through which useful knowledge can be reasoned and extracted.

By considering Industry 4.0 as a SoIS, useful knowledge from MCC can support and improve the capacity and adaptability of the manufacturing process on production lines (Sokolov and Ivanov 2015), thus resulting in more efficient production. This signifies that MCC serves as a common knowledge base in Industry 4.0 to interpret heterogeneous information and improve information interoperability. Without MCC or without regarding Industry 4.0 as a SoIS, humans cannot access knowledge obtained from heterogeneous information and must make decisions on their own without any external help during their collaborations. In our research, MCC is used to represent human-related collaborations (i.e., human-to-human and human-to-machine collaborations) and generate context-aware collaborator recommendations to humans in Industry 4.0. Meantime, MCC is also implemented into a SoIS web platform (Saleh and Abel 2017) which is tested by the students at the University of Technology of Compiègne (UTC) while collaborating in their courses. This signifies that MCC supports not only human-related collaborations in Industry 4.0, but also collaborations nowadays. However, machine-to-machine collaborations are not concerned in this article, which is also involved in Industry 4.0. Mainly because intelligent machines are less in need of recommendations than humans. Considering recommendations as information-filtering suggestions, machines have better capability than humans in filtering irrelevant information and in processing a huge amount of information.

Besides, defining the eight indicator groups of collaboration context (Goal, Collaborator, Activity, Resource, Time, Location, Relation, and Satisfaction) and their associated indicators in MCC permits to clarify the characteristics of collaboration and its context in different phases: (1) to prepare a collaboration, with a well-determined goal, suitable collaborators can be found according to their past activities and abilities presented in MCC; (2) during a collaboration, the progress of the collaboration can be assessed by comparing the distance between the goal and the achievement to date, which allows collaborators to determine appropriate adaptations; (3) after collaboration, it is possible to analyze and understand the collaboration from eight different perspectives. These characteristics assist humans to deepen their comprehension of human-related collaborations in Industry 4.0, ultimately making it possible to facilitate human-related collaborations.

Particularly, the assessment of the respective significance of the eight indicator groups to collaboration is also available with MCC. Using the semantic 3-uple <Subject, Predicate, Object>, the occurrence frequencies of the eight indicator groups in collaboration can be calculated. These frequencies reflect the significance that indicator groups have in collaboration. Besides, through comparing these significations in collaboration, the different impacts that these indicator groups have on various collaborations can be shown and explained. Then, by adjusting the most influential indicator group(s), collaboration can be improved. This type of work is never included or discussed in previous studies on collaboration (Hara et al. 2003; Bruneel et al. 2010; San Martín-Rodríguez et al. 2005; Patel et al. 2012; Mattessich and Monsey 1992).

In addition, MCC can also be broadened by defining other concepts that are relevant to collaboration. For instance, competitive activities (Vanderhaegen et al. 2006) and learning process (Vanderhaegen 2012) are linked with collaborations, which can therefore serve to extend MCC and provide a fuller coverage of the manufacturing process on production lines in Industry 4.0.

Lastly, generating context-aware collaborator recommendations to enhance collaboration becomes possible because of the collaboration context defined in MCC. Such recommendations were already produced by other studies. For instance, Liu et al. (2018) concentrated on context-aware academic collaborator recommendations to support scientific collaborations. However, these previous studies usually focus on either user context or item context. None of them takes into account users and items together. With the collaboration context represented in MCC, users and items are considered jointly in collaboration. This deepens the comprehension of both users and items in context-aware collaborator recommendation problems. Particularly, through comparing the similarity between two collaborations, the recommended items must have involved in similar collaboration(s) in terms of the eight indicator groups. This explains the context-aware recommendations based on MCC, such as “human X is recommended because X has collaborated with others for a similar goal and applied some similar resources”. However, these recommendations have a serendipity problem (De Gemmis et al. 2015): the recommended items are not ‘surprising’ to users. This leads to insufficient diversity of recommendations: it is often the same items that are recommended to users. Based on the recommendation generating process, each item recommended to the user must have involved in collaborations with high similarities. Such items are obvious to facilitate users’ collaborations, but not the good ones. The items that have not involved in the same collaborations with the user should also be included in the recommendation generating process, which may result in surprising and diverse recommendations. Besides, the collaboration context in MCC also offers the opportunity to generate multi-context recommendations by applying it with user context and/or item context.

5 Conclusion and future work

Considering Industry 4.0 as a System of Information Systems, humans and intelligent machines face problems while collaborating on production lines: poor information interoperability and information overload. To facilitate these human-related collaborations into Industry 4.0, we propose to develop a collaboration context ontology and employ it for generating context-aware collaborator recommendations to humans. This collaboration context ontology not only enables better information interoperability between heterogeneous information systems (whether humans or intelligent machines), but also defines eight indicator groups of the collaboration context that can support generating context-aware collaborator recommendations. Particularly, these indicator groups are Goal, Collaborator, Activity, Resource, Time, Location, Relation, and Satisfactions, each of which has a significant impact on collaboration. Accordingly, adopting the collaboration context ontology into Industry 4.0 can help humans deepen their comprehension of collaboration from the eight perspectives of indicator groups, thereby improving their efficiency in human-related collaborations.

The generated context-aware collaborator recommendations are directly related to the indicator groups of the collaboration context. These indicator groups can be extended by broadening the scope of collecting information in Industry 4.0, such as specifying the role of humans in activities. It is also possible to enrich the collaboration context by defining some particular indicators and/or indicator groups only suitable for Industry 4.0. More information we have about the collaboration context, more accurate the context-aware recommendation will be.

Besides, when calculating the similarity between collaborations, we concentrate exclusively on the common elements that both collaborations share. This applies to qualitative elements but not to others. For those quantitative elements, their distances matter in computing similarities. Hence, an improvement of the similarity between collaborations can be reached by distinguishing qualitative and quantitative elements in the calculation.

Based on the potential improvements above, our future work focuses on refining the context-aware collaborator recommendations. Thus, we will further optimize the calculation method for the similarity between collaborations and test it through databases on collaborations. Meanwhile, the performance of this similarity can be evaluated by implementing it in different context-aware collaborator recommendation algorithms. Particularly, these recommendation algorithms apply the similarity in the different phases of the recommendation generating process to preserve ’surprising’ and diverse items, solving the serendipity problem. Finally, we can also apply the collaboration context with the user context and/or the item context for generating multi-context recommendations to enhance collaborations.

Notes

A summary of the indirect relations between mcc:UserGroup and the five indicator groups (Goal, Collaborator, Activity, and Resource) is available in Fig. 12.

Notably, the two different ratings, rating\((u, i'_m)\) and rating\((u, i'_h)\), are the given data. We do not discuss how to obtain them in this paper.

References

Abel MH (2008) Competencies management and learning organizational memory. J Knowl Manag 12(6):15–30

Abel MH (2015) Knowledge map-based web platform to facilitate organizational learning return of experiences. Comput Hum Behav 51:960–966

Adomavicius G, Tuzhilin A (2005) Toward the next generation of recommender systems: a survey of the state-of-the-art and possible extensions. IEEE Trans Knowl Data Eng 17(6):734–749

Adomavicius G, Tuzhilin A (2011) Context-aware recommender systems. In: Ricci F, Rokach L, Shapira B, Kantor P (eds) Recommender systems handbook. Springer, Boston, pp 217–253

Adomavicius G, Sankaranarayanan R, Sen S, Tuzhilin A (2005) Incorporating contextual information in recommender systems using a multidimensional approach. ACM Trans Inf Syst (TOIS) 23(1):103–145

Alcácer V, Cruz-Machado V (2019) Scanning the industry 4.0: a literature review on technologies for manufacturing systems. Eng Sci Technol Int J 22(3):899–919

Assaad MA, Talj R, Charara A (2016) A view on systems of systems (sos). In: 20th world congress of the international federation of automatic control (IFAC WC 2017)—special session, Toulouse, France

Bettini C, Brdiczka O, Henricksen K, Indulska J, Nicklas D, Ranganathan A, Riboni D (2010) A survey of context modelling and reasoning techniques. Pervasive Mob Comput 6(2):161–180

Bowen RM, Sahin F (2010) A net-centric xml based system of systems architecture for human tracking. In: 2010 5th international conference on system of systems engineering, Loughborough, UK. IEEE, pp 1–6. https://doi.org/10.1109/SYSOSE.2010.5543992

Brettel M, Friederichsen N, Keller M, Rosenberg M (2014) How virtualization, decentralization and network building change the manufacturing landscape an industry 40 perspective. Int J Mech Ind Sci Eng 8(1):37–44

Bruneel J, d’Este P, Salter A (2010) Investigating the factors that diminish the barriers to university-industry collaboration. Res Policy 39(7):858–868

Camarihna-Matos LM, Afsarmanesh H (2008) Concept of collaboration. In: Putnik GD, Cruz-Cunha MM (eds) Encyclopedia of networked and virtual organizations. IGI Global, pp 311–315. https://doi.org/10.4018/978-1-59904-885-7

Camarinha-Matos LM, Fornasiero R, Afsarmanesh H (2017) Collaborative networks as a core enabler of industry 4.0. In: Camarinha-Matos L, Afsarmanesh H, Fornasiero R (eds) Collaboration in a Data-Rich World. PRO-VE 2017. IFIP Advances in information and communication technology, vol 506. Springer, Cham. https://doi.org/10.1007/978-3-319-65151-4_1

Carrer-Neto W, Hernández-Alcaraz ML, Valencia-García R, García-Sánchez F (2012) Social knowledge-based recommender system application to the movies domain. Expert Syst Appl 39(12):10990–11000

De Gemmis M, Lops P, Semeraro G, Musto C (2015) An investigation on the serendipity problem in recommender systems. Inf Process Manag 51(5):695–717

Deparis É, Abel MH, Lortal G, Mattioli J (2014) Information management from social and documentary sources in organizations. Comput Hum Behav 30:753–759

Dey AK (2001) Understanding and using context. Pers Ubiquitous Comput 5(1):4–7

Du Y, Ranwez S, Sutton-Charani N, Ranwez V (2019) Apports des ontologies aux systèmes de recommandation : état de l’art et perspectives. 30es Journées Francophones d’Ingénierie des Connaissances. IC 2019. Toulouse, France, pp 64–77

Flemisch F, Abbink DA, Itoh M, Pacaux-Lemoine MP, Weßel G (2019) Joining the blunt and the pointy end of the spear: towards a common framework of joint action, human–machine cooperation, cooperative guidance and control, shared, traded and supervisory control. Cognit Technol Work 21(4):555–568

Gruber TR (1993) A translation approach to portable ontology specifications. Knowl Acquis 5(2):199–220

Gu T, Wang XH, Pung HK, Zhang DQ (2004) An ontology-based context model in intelligent environments. In: Proceedings of communication networks and distributed systems modeling and simulation conference, San Diego, pp 270–275

Hara N, Solomon P, Kim SL, Sonnenwald DH (2003) An emerging view of scientific collaboration: Scientists’ perspectives on collaboration and factors that impact collaboration. J Am Soc Inf Sci Technol 54(10):952–965

Heflin J (2004) Owl web ontology language-use cases and requirements. W3C Recomm 10(10):1–12

Hermann M, Pentek T, Otto B (2016) Design principles for industrie 4.0 scenarios. In: 2016 49th Hawaii international conference on system sciences (HICSS), Koloa, HI, USA. IEEE, pp 3928–3937. https://doi.org/10.1109/HICSS.2016.488

Hoc JM (2001) Towards a cognitive approach to human–machine cooperation in dynamic situations. Int J Hum Comput Stud 54(4):509–540

Jamshidi M (2008) Systems of systems engineering: principles and applications. CRC Press, Boca Raton

Li S, Abel MH, Negre E (2018) Contact and collaboration context model. In: 2018 IEEE 4th international forum on research and technology for society and industry (RTSI), Palermo, Italy. IEEE, pp 1–6. https://doi.org/10.1109/RTSI.2018.8548381

Li S, Abel MH, Negre E (2019) Towards a collaboration context ontology. In: 2019 IEEE 23rd international conference on computer supported cooperative work in design (CSCWD), Porto, Portugal. IEEE, pp 93–98. https://doi.org/10.1109/CSCWD.2019.8791845

Liu Z, Xie X, Chen L (2018) Context-aware academic collaborator recommendation. In: Proceedings of the 24th ACM SIGKDD international conference on knowledge discovery and data mining (KDD '18). ACM, New York, NY, USA, pp 1870–1879. https://doi.org/10.1145/3219819.3220050

Mattessich PW, Monsey BR (1992) Collaboration: what makes it work. A review of research literature on factors influencing successful collaboration, ERIC

Millot P (2007) Toward human–machine cooperation. Springer, Berlin, pp 3–4. https://doi.org/10.1007/978-3-540-85640-5_1

Millot P, Hoc J (1997) Human-machine cooperation: metaphor or possible reality. In: European conference on cognitive sciences (ECCS 97), Manchester

Munir K, Anjum MS (2018) The use of ontologies for effective knowledge modelling and information retrieval. Appl Comput Inform 14(2):116–126

Nayyar A, Kumar A (2020) A roadmap to industry 4.0: smart production, sharp business and sustainable development. Springer, Berlin

Negre E (2017) Prise en compte du contexte dans les systèmes de recommandations de requetes olap. In: EDA 2017: BI & big data

Neto VVG, Araujo R, dos Santos RP (2017) New challenges in the social web: Towards systems-of-information systems ecosystems. In: Anais do VIII Workshop sobre Aspectos da Interação Humano-Computador para a Web Social. SBC, pp 1–12

Nunes I, Jannach D (2017) A systematic review and taxonomy of explanations in decision support and recommender systems. User Model User Adapt Interact 27(3–5):393–444

Obrst L (2003) Ontologies for semantically interoperable systems. In: Proceedings of the twelfth international conference on information and knowledge management (CIKM '03). ACM, New York, NY, USA, pp 366–369. https://doi.org/10.1145/956863.956932

Oliveira I, Tinoca L, Pereira A (2011) Online group work patterns: how to promote a successful collaboration. Comput Educ 57(1):1348–1357

Palmisano C, Tuzhilin A, Gorgoglione M (2008) Using context to improve predictive modeling of customers in personalization applications. IEEE Trans Knowl Data Eng 20(11):1535–1549

Patel H, Pettitt M, Wilson JR (2012) Factors of collaborative working: a framework for a collaboration model. Appl Ergon 43(1):1–26

Piaget J (1977) The development of thought: Equilibration of cognitive structures. (Trans A. Rosin). Viking

Qin J, Liu Y, Grosvenor R (2016) A categorical framework of manufacturing for industry 4.0 and beyond. Procedia Cirp 52:173–178

Ricci F, Rokach L, Shapira B (2011) Introduction to recommender systems handbook. In: Ricci F, Rokach L, Shapira B, Kantor P (eds) Recommender systems handbook. Springer, Boston, pp 1–35

Salas E, Prince C, Baker DP, Shrestha L (1995) Situation awareness in team performance: implications for measurement and training. Hum Factors 37(1):123–136

Saleh M, Abel MH (2016) Moving from digital ecosystem to system of information systems. In: 2016 IEEE 20th international conference on computer supported cooperative work in design (CSCWD), Nanchang, China. IEEE, pp 91–96. https://doi.org/10.1109/CSCWD.2016.7565969

Saleh M, Abel MH (2017) Modeling and developing a system of information systems for managing heterogeneous resources. In: 2017 IEEE international conference on systems, man, and cybernetics (SMC), Banff, AB, Canada. IEEE, pp 2672–2677. https://doi.org/10.1109/SMC.2017.8123029

Salkin C, Oner M, Ustundag A, Cevikcan E (2018) A conceptual framework for industry 4.0. In: Industry 4.0: managing the digital transformation. Springer, pp 3–23

San Martín-Rodríguez L, Beaulieu MD, D’Amour D, Ferrada-Videla M (2005) The determinants of successful collaboration: a review of theoretical and empirical studies. J Interprof Care 19(sup1):132–147

Saucedo-Martínez JA, Pérez-Lara M, Marmolejo-Saucedo JA, Salais-Fierro TE, Vasant P (2018) Industry 4.0 framework for management and operations: a review. J Ambient Intell Humaniz Comput 9(3):789–801

Schuh G, Potente T, Wesch-Potente C, Weber AR, Prote JP (2014) Collaboration mechanisms to increase productivity in the context of industrie 4.0. Procedia Cirp 19:51–56

Schumacher A, Erol S, Sihn W (2016) A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 52(1):161–166

Sokolov B, Ivanov D (2015) Integrated scheduling of material flows and information services in industry 4.0 supply networks. IFAC Papers OnLine 48(3):1533–1538

Strang T, Linnhoff-Popien C (2004) A context modeling survey. In: First international workshop on advanced context modelling, reasoning and management at UbiComp 2004, Nottingham, England

Strang T, Linnhoff-Popien C, Frank K (2003) Cool: a context ontology language to enable contextual interoperability. In: Stefani JB, Demeure I, Hagimont D (eds) Distributed Applications and Interoperable Systems. DAIS 2003, vol 2893. Lecture notes in computer science. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-40010-3_21

Suri K, Cuccuru A, Cadavid J, Gerard S, Gaaloul W, Tata S (2017) Model-based development of modular complex systems for accomplishing system integration for industry 4.0. In: MODELSWARD, pp 487–495

Tay S, Lee T, Hamid N, Ahmad A (2018) An overview of industry 4.0: definition, components, and government initiatives. J Adv Res Dyn Control Syst 10(Special Issue):1379

Taylor-Powell E, Rossing B (1998) Evaluating collaborations: challenges and methods, Report published online by University of Wisconsin-Extension

Tversky A (1977) Features of similarity. Psychol Rev 84(4):327

Vanderhaegen F (2012) Cooperation and learning to increase the autonomy of adas. Cognit Technol Work 14(1):61–69

Vanderhaegen F, Chalmé S, Anceaux F, Millot P (2006) Principles of cooperation and competition: application to car driver behavior analysis. Cognit Technol Work 8(3):183–192

Wang N, Abel MH, Barthès JP, Negre E (2016) Recommending competent person in a digital ecosystem. In: 2016 international conference on industrial informatics and computer systems (CIICS). Sharjah, United Arab Emirates, pp 1–6. https://doi.org/10.1109/ICCSII.2016.7462436

Weyer S, Schmitt M, Ohmer M, Gorecky D (2015) Towards industry 4.0-standardization as the crucial challenge for highly modular, multi-vendor production systems. Ifac Papers online 48(3):579–584

Yu Z, Nakamura Y, Jang S, Kajita S, Mase K (2007) Ontology-based semantic recommendation for context-aware e-learning. In: Indulska J, Ma J, Yang LT, Ungerer T, Cao J (eds) Ubiquitous Intelligence and Computing. UIC 2007, vol 4611. Lecture notes in computer science. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-73549-6_88

Acknowledgements

The first author is funded by the China Scholarship Council (CSC) from the Ministry of Education of P. R. China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, S., Abel, MH. & Negre, E. A collaboration context ontology to enhance human-related collaboration into Industry 4.0. Cogn Tech Work 24, 75–91 (2022). https://doi.org/10.1007/s10111-021-00677-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10111-021-00677-w