Abstract

Bioenergy production from lignocellulosic biomass is challenging due to its complex structure. Therefore, a pretreatment is required before methane production. Studies investigating the pretreatment of lignocellulosic waste using rumen fluid are limited and focused only on a certain waste. In this study, pretreatment by rumen microorganisms was applied for different types of lignocellulosic wastes: wheat straw, cotton stalk, reeds and sunflower stalk. The reactors containing 1 g waste were pretreated for 2, 5, 10, 15 and 20 days to investigate optimum pretreatment time for methane production. After the pretreatment stages and gas measurements, reactors were separated into two phases as solid phase and liquid phase. The reactors were installed for the anaerobic digestion; gas measurements were made cumulatively. Modified Gompertz equation was used to estimate potential biogas production. The maximum biogas productions were obtained in 2 days pretreatment of wheat straw, reeds and sunflower stalk with 1.2 to 1.4-fold increase compared to non-pretreated wastes. Maximum increase in biogas amount of 1.3-fold was obtained in 5 and 10 days pretreated cotton stalk compared to non-pretreated cotton stalk. The highest methane yield was obtained in 5 days pretreated wheat straw with 101.7 ml methane. The maximum methane yield was followed by reeds waste pretreated for 20 days with 76.15 ml, sunflower stalk pretreated for 2 days with 52 ml, and cotton stalk pretreated for 2 days with 50 ml methane. Rumen pretreatment had positive effects in the production of methane from different lignocellulosic wastes, depending on the pretreatment time. It has been suggested to examine the effect of rumen on methane and other fuel productions from other wastes.

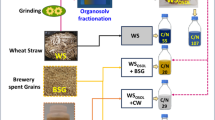

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid increase in population and industrialization brought about the need for alternative energy resources. Biomass energy is one of the most important resources to be used in order to provide energy in a sustainable way without causing environmental pollution. Biomass is a non-fossil organic matter of biological origin. Food industry residues and wastes, forest residues, agricultural wastes, animal wastes, municipal wastes and all plants are within the definition of biomass. The improper management of biomass origin wastes results in environmental pollution. Especially, the wastes caused by the processing of agricultural products occupy space in the facility sites due to storage problems and sometimes cause environmental problems by being given to surface waters (Baran et al. 1995). According to the U.S. Energy Information Administration (2020), biomass can be used to obtain energy directly by burning as well as converted into liquid biofuels or biogas; in turn, it contributes economically while reducing the environmental damage. Biomass is a renewable energy source and can reduce the demand for fossil fuels in energy. The energy produced from biomass is clean, so that it can improve the environment, economy and energy security (Gokcol et al. 2009). Lignocellulosic waste is mostly generated in agricultural and food industries, and is an abundant type of biomass (Oh et al. 2018). Lignocellulose is present on woody or herbaceous plant cell walls and consists of two complex carbohydrates, cellulose and hemicellulose, that are enclosed by a lignin matrix (Zhang et al. 2016a, b). Lignocellulosic biomass can be converted into biofuels by biological conversion, since cellulose and hemicellulose present in lignocellulose are fermentable sugars (Chuetor et al. 2019). However, the breakdown and hydrolysis of the lignocellulosic biomass become a rate limiting step during anaerobic digestion. The complex matrix structure of lignocellulose gives rise to need for pretreatment, where it is fractionated into lignin, hemicellulose and solid substrate (Islam et al. 2020). Fractionation of biomass ensures maximization of substrate accessibility and increases sugar and biogas yields (Van Fan et al. 2019; Leu and Zhu 2013; Zhao et al. 2017).

There are 4 main types of lignocellulosic pretreatment: physical, chemical, physico-chemical and biological pretreatment. Physical pretreatment methods include particle size reducing processes such as chipping-milling (Ramos 2003), microwave (Jackowiak et al. 2011), and freezing (Chang et al. 2011). Physical pretreatment methods increase cellulose digestion for hydrolysis. However, these technologies are not economically feasible for the use of a large-scale bio-refinery in terms of capital and energy costs (Kumari and Singh 2018). In chemical pretreatment methods; acids (Sen et al. 2016), oxidizing agents (Song et al. 2016), NaOH (Antonopoulou et al. 2016) and organic solvents (Zhao et al. 2009) are the most commonly used substances. Chemical pretreatment methods promote methane production, but cannot be applied to large-scale fermenters due high energy consumption, neutralization of wastewater, production of fermentation inhibitors, high reagent costs and low pretreatment rates (Hendriks and Zeeman 2008). Biological pretreatment methods include using enzymes (Romano et al. 2009), fungi (Song et al. 2013), and microbial consortium (Zhang et al. 2011) for dissociation of lignocellulosic biomass. These methods have important advantages compared to other pretreatment methods since they are environmentally friendly and safe. Biodegradation of lignocellulose is already taking place in a known natural cycle. The removal of lignin from lignocellulose occurs naturally by the microorganisms in the rumen of ruminant animals such as sheep and cows (Gullert et al. 2016).

Rumen bacteria found in the digestive system of ruminant animals are also used for the biological pretreatment of lignocellulosic biomass. Ruminant animals use cellulosic materials in plants as an energy source by converting them into volatile fatty acids (VFA) by fermentation as a result of the symbiotic relationship of the microbial population in their digestive systems (Forsberg et al. 1997). High cellulolytic activities of rumen bacteria constitute a significant advantage in the degradation of lignocellulosic wastes (Quintero et al. 2012).

Due to its environmental friendly and inexpensive properties, several studies have focused on biological pretreatment methods such as using fungal consortiums on hydrolysis of corn stover (Song et al. 2013) and straw (Taha et al. 2015). Satisfactory increase in hydrolysis rates was obtained in these studies. In the study conducted by Baba et al. (2013), the degradation of cellulose, hemicellulose and lignin was carried out with rumen microorganisms before the methane production phase. At the end of the study, it was observed that 2–6 times more methane was produced from waste paper pretreated with rumen compared to that without pretreatment. Zhang et al. (2016a, b) reported a feasibility study for rice straw waste with rumen fluid pretreatment to produce methane. They reached 66.5% more biogas formation and 82.6% methane yield with the pretreatment time of 24 h, compared to non-pretreated rice straw. However, the study remained limited with only one type of waste. Therefore, further studies are required in the literature on the use of rumen microorganisms in pretreatment of different types of lignocellulosic wastes.

In this study, the effect of biological pretreatment on biomethane production from lignocellulosic wastes was examined. Four different wastes, which are cotton stalk, wheat straw, reeds, and sunflower stalk, were pretreated with rumen microorganisms for 2, 5, 10, 15, and 20 days to determine the optimum retention period of pretreatment. Pretreated samples were fed to an anaerobic bioreactor to produce biomethane and obtained results were modeled with the modified Gompertz equation to compare the effect of pretreatment time. It was aimed to produce bioenergy by using various lignocellulosic wastes that are satisfactory in terms of energy potential, thus providing both waste management and valuable product recovery. We focused on determining the methane production capacity of different lignocellulosic wastes by applying pretreatment with rumen microorganisms for different durations.

Materials and methods

Sample collection and characterization

Four different agricultural wastes, which are cotton stalks, sunflower stalks, wheat straw, and reeds, were used for biological methane potential analysis. Cotton and sunflower stalk wastes were provided from Sanliurfa and Kayseri, which are cities located in the southeast and central of Anatolia, respectively. Wheat straw and reed wastes were obtained from Istanbul.

The samples were carried to the laboratory within plastic bags and were dried at a constant temperature of 60ºC overnight. Dried wastes were ground with a grinder to 1–2 cm and stored in plastic bags at room temperature until the experiment.

Elemental carbon, nitrogen, and sulfur analysis of dried samples were carried out following TS ISO 10694, TS ISO 13878, and ASTM E 775–15, respectively. The characterization of agricultural wastes is given in Table 1. The carbon content of wastes was quite high and nitrogen content was low, which promises a high biogas production potential. Cotton stalk waste had the highest carbon content among all wastes.

Rumen and methanogenic seed

Rumen fluid was obtained from a healthy, non-medicated sheep that was kept at a veterinary faculty of a university. Rumen fluid was obtained 2 h after morning feeding by the orogastric collection method and fresh samples brought to the laboratory immediately. Rumen culture was used directly for reactor setup without any enrichment process.

Granular anaerobic sludge inoculum was supplied from a gum factory treating its wastewater via anaerobic digestion under mesophilic conditions. The granular anaerobic sludge was added to each reactor in equal amounts as 0.5 g to the reactors.

Pretreatment of wastes

The effect of pretreatment on biomethane production of agricultural wastes was examined by the setup of a two-stage reactor. The first stage was pretreatment and second biomethane production reactors. In the first stage, 1 g of ground agricultural waste, 1.5 mL of rumen fluid, and 45 mL nutrient solution were added to a glass reactor which had 100 mL total volume.

One liter of nutrient medium required for microbial activity was prepared as follows: 8 g/L NaHCO3; 1 g/L KH2PO4; 3 g/L K2HPO4; 0.03 g/L CaCl2.2H2O; 0.08 g/L MgCl2.6H2O; 0.18 g/L NH4Cl; 0.173 g/L L-cysteine.

One liter of metal solution was prepared as follows: 0.1 g/L ZnSO4.7H2O; 0.03 g/L MnCl2.4H2O; 0.3 g/L H3BO3; 0.2 g/L CoCl2.H2O; 0.01 g/L CuCl2.2H2O; 0.02 g/L NiCl2.6H2O; 0.03 g/L NaMoO4.2H2O and 1.5 g/L FeCl2.4H2O (Hu and Yu 2006). 0.2 g/L 2-bromoethanesulfonic acid (BESA) was also added to prevent methanogenic activity in the pretreatment stage.

Different reactors were conducted to observe the effect of pretreatment time on biomethane production from lignocellulosic wastes. Therefore, different reactors were prepared for 2, 5, 10, 15, and 20 days incubation times for 4 different agricultural wastes. Each reactor was studied in duplicate to observe the consistency of the experiment data. 40 pretreatment reactors were flushed with N2 gas to remove dissolved oxygen and provide the anaerobic condition. Reactors were incubated under mesophilic conditions in a shaker at 145 rpm. Gas production was followed with the help of syringes. After the pretreatment period complements, the reactors were opened.

Reactor setup for pretreated samples

The reactors whose pretreatment times completed were opened. Reactors were centrifuged to separate the solid and liquid phases. The biomethane potential of solid and liquid phases was investigated separately. Each pretreated solid and liquid sample was fed into reactors with 100 ml volume, containing nutrient medium and granular anaerobic seed sludge to support methanogenic activity.

The nutrient medium for biological methane production included synthetic media and micronutrients, as in the study conducted by Yoruklu et al. (2018). The components of the synthetic media were as follows: 9.3 g/L NaH2PO4·H2O; 3.2 g/L Na2HPO4; 0.6 g/L NH4Cl; 0.125 g/L KH2PO4; 0.11 g/L CaCl2·2H2O; 0.1 g/L MgCl2·6H2O; and 0.2 g/L NaHCO3.

The micronutrients in the media were FeCl2·4H2O; H3BO3; ZnCl2; CuCl2·2H2O; MnCl2·2H2O; (NH4)6Mo7O24·4H2O; AlCl3; CoCl2·6H2O; NiCl2·6H2O; and EDTA along with Pyridoxamine (C8H12N2O2·2H2O); Nicotinic acid (C6H5NO2); Nicotinamide (C6H5N2O); dl-pantothenic acid (C9H16NO5·1/2 Ca); Vitamin B12, p-aminobenzoic acid (C7H7NO2); Pyridoxine HCl (B6; C8H11NO3·HCl); D Biotin; Thioctic acid; Folic acid (C19H19N7O6); Riboflavin; Thiamine HCl; vitamins; Na2SeO3·5H2O; NaWO4·2H2O; 2 g/L yeast extract; and 0.5 g/L-cysteine-HCl.

For the solid phases, the following were added to the reactors: the solid phase resulting from the pretreatment, 22.5 ml of medium, 25 ml of distilled water and 0.5 g of anaerobic seed sludge. For the liquid phases, 20 ml supernatant resulted from centrifuge, 22.5 ml medium and 0.5 g anaerobic seed sludge were added to the reactors. Thus, 80 biomethane reactors composed of 40 liquid phases and 40 solid phases were prepared in total. Control reactors were also prepared for each non-pretreated agricultural waste by adding raw waste, media, and inoculum in the same amounts. All reactors were flushed with N2 gas for 5 min to provide the anaerobic condition and sealed with rubber stoppers. After the anaerobic conditions were provided, the reactors were continuously stirred at 120 rpm under mesophilic conditions.

Biogas production was followed and the biomethane content in the total biogas of all reactors was analyzed by gas chromatography (GC) (GC-2014, SHIMADZU Gas Chromatograph, SHIMADZU Corporation, Japan) to determine methane and carbon dioxide composition.

Modeling

Modified Gompertz equation was used to determine the kinetic constants of biogas production curves. Kinetic parameters were calculated through the nonlinear regression method by using the MS Excel tool developed by Demir et al. (2018). The kinetic coefficients obtained from the model played an important role in analyzing the effect of biological pretreatment on biogas production efficiency from agricultural wastes. The modified Gompertz equation given in Eq. (1) can be used in a wide range of study from microbial activity to biogas production and given as follows:

where B is the cumulative biogas yield in ‘t’ days (ml/g waste); P is the maximum biogas yield potential (ml/g waste); Rm is the maximum specific biogas yield (ml/g waste/day); λ is lag phase period (days) and t is the time for biogas production (days).

Results and discussion

Pretreatment stage

The wastes were pretreated with rumen microorganisms for 2, 5, 10, 15, and 20 days, and at the end of this period, the wastes were fed to anaerobic batch reactors for biomethane production. Since a part of biomass can be consumed by mixed culture for biogas production during pretreatment, the biogas formation was also monitored in this step. The data obtained from the pretreatment were examined based on the type of lignocellulosic waste.

Since BESA was added to the pretreatment bioreactors in the reactor setup, the biogas contains only CO2. Although the gas generated during the pretreatment was valueless, monitoring biogas production was important in terms of controlling the biodegradation of biomass. The graphs showing the amount of biogas produced in pretreatment stages are given in Fig. 1.

According to the biogas amounts generated during the pretreatment given in Fig. 1 were examined, the amount of biogas production during the pretreatment increases as the pretreatment time increases.

The highest biogas formation for wheat straw was observed in the 20 days pretreatment with 65.75 ml CO2 formation. This result was followed by 58 and 32.1 ml in 15 and 10 days pretreatments, respectively. A gradual increase in biogas production was observed for wheat straw waste as the pretreatment time increased. The highest rise was observed between 10 and 15 days. The effect of persistent action of cow rumen pretreatment on degradation of wheat straw has been studied by Xing et al. (2020). At the end of 33 days pretreatment, approximately 240 ml of biogas was obtained with the volatile fatty acids (VFAs) yield of 0.453 g COD g−1 VS. The highest biogas amount for cotton stalk was obtained in 20 days pretreatment period with 24.5 ml CO2. Biogas formation in 15 and 10 days pretreatments of cotton stalk was 10.5 and 4.75 ml, respectively. The pretreatment for 2 days did not produce biogas. The highest rise was observed between 15 and 20 days. The effect of a thermophilic microbial consortium (MC1) pretreatment on degradation of cotton stalk has been studied by Yuan et al. (2016). The substrate with 4.0% load pretreated for 8 days resulted in the largest amounts of soluble chemical oxygen demand (COD). The highest biogas formation for reed was observed in the pretreatment period of 20 days with 43.25 ml CO2. 19 ml and 13.55 ml CO2 was obtained in 15 and 10 days pretreatments. Biogas output was not observed in the reactors pretreated for 2 and 5 days. The highest rise was observed between 15 and 20 days. The highest amount of biogas in pretreatments of sunflower stalk was obtained from the 20 days pretreated reactor with 28.25 ml CO2. It is followed by 15, 10 and 5 days pretreatments with 28, 27.8 and 26.5 ml CO2 formations, respectively. 2 days pretreatment was observed as the pretreatment time that has the least effect on the structure of the sunflower stalk waste with 7.25 ml. Nevertheless, the highest rise was observed between 2 and 5 days, and then increased very slowly. Biological pretreatment of sunflower stalk with a type of fungus T. reesei has been studied and compared with alkali pretreatment for bioethanol production by Manmai et al. (2019). However, the biological pretreatment was below the alkali treatment in terms of sugar yields. It was estimated that the carbon amount required for anaerobic digestion in the next stage was decreased as the pretreatment period increased, since more carbon is converted to carbon dioxide (Zhang et al. 2016a, b).

Biological methane production stage

The upper and lower phases of the reactors whose pretreatment period has been completed were separated, and methanation reactors were installed for each of them. Gas measurements were made at regular intervals with the help of syringes; the values were recorded and plotted. The gas measurement data were compared with nonlinear regression using the modified Gompertz equation to estimate the kinetic parameters. The kinetic parameters are shown in Table 2.

The correlation coefficient (R2) of the modified Gompertz equation was generally higher than 0.95, suggesting that the modified Gompertz equation fits the biomethane production profile and the final biomethane yield (Table 2). But it was insufficient to model biogas production curves completed in two-stage, such as pretreated sunflower and cotton stalks for 10 days.

The pretreatment of lignocellulosic wastes allowed faster hydrolysis and a shorter acclimation time for microorganisms (Mao et al. 2017; Bianco et al. 2020), as approved by the reduction of λ value. Even so, the optimum pretreatment time changed with the type of the waste. Based on lag phase reduction of wastes, the optimum pretreatment time was 2, 5, 5, and 15 days for sunflower stalks, wheat straws, cotton stalks, and reeds, respectively.

The bottom phase of the wheat straw pretreated for 2 days reached 150 ml of biogas in 60 days of anaerobic digestion. The biogas formation in the upper phase started to rise on the 10th and 40th days. It is understood that the lignocellulosic material in the upper phase breaks down in 2 stages. A total of 160 ml biogas was obtained from the combination of the upper and lower phases of straw waste after 60 days.

146 ml of biogas was obtained after 80 days when the bottom phase of 5 days pretreated wheat straw was examined. An increase in production is observed as of the 36th day. In the upper phase, 17 ml of biogas was produced in 43 days. This value is 3 times more efficient than the upper phase of the straw, which was pretreated for 2 days. This shows that more substances dissolved in the upper phase in 5 days pretreatment. The total biogas yield from straw is 162 ml in 80 days.

The anaerobic digestion stage of wheat straw lower phase after 10 days of pretreatment resulted in 90 ml of biogas in 72 days. Production started after the 4th day. A fluctuation occurred after the 33rd day. The production is completed in 45 days in the upper phase, resulting in 49 ml of biogas. As in the lower phase, fluctuation occurred in the upper phase on the 33rd day. The yield from straw in total is 139 ml.

Continuous biogas production was observed during anaerobic digestion of 15 days pretreated straw bottom phase and 69 ml of biogas is obtained after 40 days. In the upper phase, 22 ml of biogas was produced in 68 days. A decrease was observed according to the 10-day pretreatment straw upper phase. In total, the yield from the straw is 91 ml of biogas. A low yield was obtained for 10 days compared to pretreatment.

Considering the lower phase of 20 days pretreated wheat straw values, approximately 73 ml of biogas production was obtained in 74 days. The straw bottom phase production did not reach equilibrium for the first time in the biogas measurement process. Production continued with the fluctuation on the 60th day. Nevertheless, 2 and 5 days pretreatments are more advantageous for straw than 20 days pretreatment. According to the straw waste upper phase values, approximately 44 ml of biogas was produced in 60 days. There was an increase in the yield compared to the upper phase of the straw pretreated for 15 days. The total yield from the straw is 116 ml of biogas. 20 days pretreatment time for straw is more advantageous than 15 days pretreatment.

Comparison of biogas generated in anaerobic digestions of raw and pretreated wheat straw reactors and model results was given in Fig. 2. Pretreatments for 2, 5 and 10 days had an increasing effect on biogas production. This shows the biological pretreatment induced the degradation of wheat straw waste with lignocellulosic structure (Ferraro et al. 2018). However, lower biogas production was observed in the reactors pretreated for 15 and 20 days when they are compared with biogas generated in the anaerobic digestion of raw wheat straw waste.

The biogas production continued up to 80 days by the lower phase of cotton stalk during the anaerobic process after 2 days of pretreatment. 75 ml of biogas was produced in 60 days, and 86 ml of biogas was produced at the end of 80 days. After reaching the 40th day, an increase was observed after stabilization. Finally, the biogas production stopped completely when incubation time was reached up to 80 days. The biogas production in the upper phase of cotton stalk started on the 7th day and ended on the 14th day. However, the amount produced was approximately 1 ml and it was neglected.

The amount of biogas produced by anaerobic digestion of the bottom phase of cotton stalk pretreated for 5 days reached 53 ml of biogas in 50 days and then production stopped. There was an increase in biogas production after the first two days. In the upper phase of cotton waste, there was a fluctuation following a delayed production on 7th, 14th and 35th days. In 49 days, 12 ml of biogas was measured and production ended. After combining the lower and upper phase of the cotton stalk values after 5 days of pretreatment, 65 ml of biogas yield was obtained from the cotton stalk in 49 days.

The biogas performance of the cotton stalk lower phase after 10 days of pretreatment resulted in 69.5 ml of biogas in 60 days. A significant fluctuation was observed on day 33. Production started after the 4th day in the upper phase. Biogas production was not taken into account for the cotton upper phase, since the amount obtained in more than 40 days was limited to about 6 ml of biogas. A total of 75 ml of biogas was obtained in 60 days from 10 days pretreated cotton stalk phases.

Fifty-six milliliter of biogas was obtained from the anaerobic digestion of 15 days pretreated cotton stalk lower phase in 50 days, and the production was completed. 15 ml of biogas was formed in 50 days in the upper phase. Fluctuations occurred on the 21st and 41st days in the lower and upper phases. This indicates that the lignocellulosic biomass was gradually breaking down. Upper phase cotton stalk yield increased compared to the upper phase which was pretreated for 10 days. The total yield obtained from cotton stalk with 15 days of pretreatment is 71 ml of biogas in 50 days. A yield close to the total yield of cotton stalk that was pretreated for 10 days was obtained.

When the lower phase values of 20 days pretreated cotton stalks are examined, approximately 29 ml of biogas was produced in 6 days and the production stopped. In the upper phase, a biogas yield of 5 ml was obtained in 24 days and the production was completed. The total yield from cotton stalk is approximately 34 ml of biogas in 40 days. 20 days were the most inefficient pretreatment time for pretreatment cotton stalks. Comparison of biogas generated in anaerobic digestion of raw and pretreated cotton stalk wastes and model results was given in Fig. 3. Biogas production was observed to be increased significantly when cotton stalk waste was pretreated until 15 days.

After 2 days of pretreatment and anaerobic digestion, 27.75 and 46.9 ml biogas was produced in 30 and 60 days, respectively, in the bottom phase of reed waste. Production increased between the 40th and 50th days. Lignocellulosic biomass was fragmented in two stages and a peak was observed in the biogas production after the 80th day. It is assumed that the reason for this may be internal breathing. In the upper phase, the fragmentation started on the 7th day and ended on the 14th day. A low yield of 3.8 ml was obtained. This result shows that almost all of the lignocellulosic biomass that had dissociated in the pretreatment stage remained in the lower phase.

Fluctuations in the biogas production were observed on the 7th, 14th, 35th and 85th days of the 5 days pretreated reed bottom phase. 86 ml of biogas was obtained on the 90th day. These results are similar with the 2 days pretreated bottom phase. In the upper phase, there are fluctuations on the same days. However, due to the lack of lignocellulosic biomass in the upper phase, the amount reached in 42 days is only 7.5 ml of biogas. The total yield from the combination of biogas produced in 5 days pretreatment of lower and upper phase reed waste is 93 ml in 91 days.

67.55 ml biogas was obtained from the anaerobic digestion of the bottom phase of reed in 84 days after 10 days pretreatment. Fluctuations were observed on 33rd, 55th and 77th days. The upper phase completed production in 45 days and 25 ml of biogas was produced. A total of 93 ml of biogas was produced in 84 days from both phases of reed waste that was pretreated for 10 days.

Approximately 82 ml biogas was produced in 78 days, during anaerobic digestion of 15 days pretreated reeds bottom phase. During the biogas measurement process, the continuous production was observed as in the previous reeds phases. However, when the pretreatment time increases, an increase was observed in biogas production performance for reeds. Approximately 23 ml of biogas was measured in 40 days in the upper phase. Total yield obtained from reed waste that was pretreated for 15 days is approximately 105 ml of biogas in 78 days. According to the total yield of the reed that was pretreated for 10 days, the yield was increased in 15 days pretreatment.

Considering the lower phase of 20 days pretreated reeds data, approximately 84 ml of biogas was produced during the 60 day incubation period and the production was completed. The reeds lower phase has reached the equilibrium at the end of the measurement for the first time. Considering the upper phase values, approximately 20 ml of biogas was produced in 40 days. Production started to increase on the 14th and 30th days. The total yield obtained from the reeds waste is 104 ml of biogas in 60 days. 15 and 20 days of pretreatments are the best methods for reeds, in terms of biogas volume. Comparison of biogas generated in anaerobic digestion of reactors which contain pretreated reeds wastes and model results is given in Fig. 4.

Biogas production reached 40 ml on the 10th day, 61 ml on the 30th day and 72 ml on the 60th day when the lower phase of sunflower stalk was examined after 2 days of pretreatment. 16.25 ml of biogas was obtained and production no longer continued as of the 45th day in the reactor of upper phase sunflower stalk waste. It is seen that a total of 88 ml of biogas was obtained from the sunflower stalk in 60 days.

The amount of biogas produced by anaerobic digestion of the bottom phase of sunflower stalk pretreated for 5 days was obtained as 45.6 ml in 49 days with continuous production. In the upper phase, 26 ml of biogas production was observed in 49 days. Fluctuations were observed on the 7th and 42nd days, as a result of the increase in production. The total yield from the sunflower stalk with 5 days pretreatment was 72 ml in 49 days.

Thirty-three milliliter biogas were produced from anaerobic digestion of 10 days pretreated lower phase of sunflower waste in 46 days, and production was completed. There was a fluctuation on the 33rd day. In the upper phase, 28 ml of biogas was produced in 46 days. Again, the fluctuation occurred on the 33rd day. The lower phase and upper phase values for 10 days pretreated sunflower stalks are quite close to each other.

As the pretreatment time increases, the amount of biogas production in the lower phase decreases, while the increase in upper phase production is observed. This shows that as the pretreatment time increases, the amount of lignocellulosic biomass dissolved in the liquid supernatant increases. The total amount of biogas produced from the lower and upper phases for the sunflower stalk pretreated for 10 days is 62 ml in 41 days.

28.3 ml of biogas was produced from the anaerobic digestion of 15 days pretreated sunflower stalk lower phase in 50 days, and the production was completed. The upper phase produced 21 ml of biogas in 50 days. The total yield from 15 days pretreated sunflower stalks was 49 ml of biogas in 50 days. A decreased amount of biogas was obtained compared to the biogas production of the sunflower stalk that was pretreated for 10 days.

Considering the lower phase of 20 days pretreated sunflower stalk values, it is seen that approximately 44 ml of biogas was produced in 40 days. An increase in yield was observed compared to the lower phase of sunflower stalk pretreated for 15 days. Approximately 5 ml of biogas was produced in 24 days in the upper phase. There was a decrease in yield compared to the upper phase of sunflower stalk waste that was pretreated for 15 days. When looking at the total sunflower stalk yield, it is approximately 49 ml of biogas in 60 days. This shows that 20 days pretreatment does not cause an increase in yield compared to 15 days pretreatment. Comparison of biogas generated in anaerobic digestion of reactors which contain pretreated reeds wastes and model results was given in Fig. 5.

It was observed that a great majority of the biogas was obtained from the bottom phase, which is the solid phase, for all waste types. In addition to that more biogas production was observed in the earlier stages of pretreatment for all of the wastes, except reeds. The reason for the higher biogas yield in the earlier stages of pretreatment is the presence of higher soluble organics to be used for the anaerobic digestion at the beginning of the pretreatment process (Yuan et al. 2016).

Biogas content

The steady-state conditions were provided as from the 60th day of anaerobic digestion. The cumulative methane and carbon dioxide content of biogas until the 60th day were examined. Methane content was above 45% in almost all reactors, similar to typical biogas content (Asadollahzadeh et al. 2020; Markou et al. 2017) and was an indication that lignocellulosic wastes can be used in biomethanation with high efficiency (Mathew et al. 2015). Also, there was no clear relationship between the amount of methane formation and pretreatment time (Table 3).

The most appropriate pretreatment times for each type of waste have been observed with the best biogas and methane yields they have reached. According to Fig. 6, the highest amount of biogas obtained in the anaerobic digestion of pretreated wheat straw was observed for 5 and 2 days pretreatments with 162.8 and 161.8 ml, respectively. In terms of methane content, 5 days pretreatment reached the highest results with 101.7 ml methane. In addition, these values represent the highest efficiency among all wastes and pretreatments. The highest amount of biogas yield and methane produced in the anaerobic digestion of pretreated cotton stalk wastes was observed for 2 days pretreatment with 87.2 ml biogas and 50 ml methane. As the pretreatment time of reeds waste increased, the efficiency continued to increase. The highest biogas yield with 104.8 ml was observed for 15 days, and highest methane content with 76.15 ml was observed for 20 days pretreated reeds waste. The highest amount of biogas and methane produced in the anaerobic digestion of pretreated sunflower stalk was observed for 2 days pretreatment with 87.8 biogas and 52 ml methane. It was observed that the highest methane yields were obtained predominantly from the wastes pretreated for relatively shorter periods (Fig. 7).

Various studies that have carried out pretreatment with the use of microorganisms in order to increase the production of biomethane from lignocellulosic wastes are listed in Table 4 with methane yields. A comparison between the methane increases compared to untreated wastes in these studies and the four wastes in this study was made. It was observed that the methane amount of rumen pretreated waste paper (Baba et al. 2013), rice straw (Zhang et al. 2016a, b) and rapeseed (Baba et al. 2017) increased greatly. They have reached higher methane yields with short periods of pretreatments. This is because, as Zhang et al. (2016a, b) explained, the carbon content of the lignocellulosic waste to be converted to methane is not converted to carbon dioxide over long pretreatment periods.

Conclusion

Lignocellulosic wastes are important sources since they can be utilized as renewable bioenergy. However, the difficulties in anaerobic digestion process due to the structural complexity of lignocellulosic biomass lead to the requirement of pretreatment. In this study, biological pretreatment was preferred because of its cost-effectiveness and sustainability. This paper has analyzed the optimum pretreatment times for various lignocellulosic wastes required to obtain maximum biomethane amount. Pretreatment with rumen liquid taken from a sheep was applied to the wheat straw, cotton stalk, reeds and sunflower stalk wastes for 2, 5, 10, 15 and 20 days. The structural degradation of each type of wastes by rumen pretreatment was examined by measuring biogas production. It was observed that as the pretreatment time increased, the degradation of all the wastes also increased. The highest gas formation, 65.75 ml, in the pretreatment stage was observed in the wheat straw waste. In the following, the anaerobic digestions process was performed after separating the pretreated reactors as solid and liquid phases. The biogas productions were observed and compared with the model results. Majority of the biogas was obtained from the solid phases of all types of wastes. Biogas amounts produced from pretreated and non-pretreated wastes were compared. At the end of the anaerobic digestions, the biogas productions were increased 1.4-fold in 2 days pretreated wheat straw, 1.3-fold in 5 and 10 days pretreated cotton stalk, 1.2-fold in 2 days pretreated reeds, and 1.2-fold in 2 days pretreated sunflower waste, compared to non-pretreated wastes. The cumulative methane productions until the 60th day of anaerobic digestion were measured, since the wastes reached the steady-state conditions in the 60 day period. 101.7 ml methane was obtained in wheat straw with 5 days pretreatment, and this was the highest yield among all wastes and pretreatments. 50 ml methane was obtained in cotton stalk with 2 days pretreatment. 76.15 ml methane was obtained in reeds with 20 days pretreatment. Finally, 52 ml methane was produced in sunflower stalk with 2 days pretreatment.

A waste management scenario in which lignocellulosic wastes, which are mostly generated in the agricultural sector, are converted into biogas, as in our study, can facilitate achievement of environmental policy goals. In this way, these wastes will be prevented from being stored in landfills and creating storage problems. In addition, the use of methane, which is a greenhouse gas, to produce energy will create a reduction in greenhouse gas emissions and have a positive effect on the use of renewable energy. In this manner, biomethane production from lignocellulosic wastes should be promoted. Pretreatment with rumen microorganisms is recommended as a method that should be studied for efficient methane production from lignocellulosic biomass. This method has the advantage of being cost-effective and renewable. Therefore, pretreatment studies with rumen should be increased. Detailed research is recommended on the effect of rumen in the production of different types of bioenergy.

References

Antonopoulou G, Vayenas D, Lyberatos G (2016) Ethanol and hydrogen production from sunflower straw: The effect of pretreatment on the whole slurry fermentation. Biochem Eng J 116:65–74. https://doi.org/10.1016/j.bej.2016.06.014

Asadollahzadeh P, Hamedi MH, Jazayeri SA (2020) A comprehensive study of a reactivity-controlled compression ignition engine fueled with biogas and diesel oil. Clean Technol Environ Policy, pp 1–14

Baba Y, Tada C, Fukuda Y, Nakai Y (2013) Improvement of methane production from waste paper by pretreatment with rumen fluid. Bioresour Technol 128:94–99

Baba Y, Matsuki Y, Mori Y et al (2017) Pretreatment of lignocellulosic biomass by cattle rumen fluid for methane production: bacterial flora and enzyme activity analysis. J Biosci Bioeng 123(4):489–496

Baran A, Cayci G, Inal A (1995) Farklı tarımsal atıkların bazı fiziksel ve kimyasal özellikleri (in Turkish) Pamukkale University Journal of Engineering Sciences 1(2–3):169–172

Bianco F, Şenol H, Papirio S (2020) Enhanced lignocellulosic component removal and biomethane potential from chestnut shell by a combined hydrothermal–alkaline pretreatment. Sci Total Environ 144178.

Chang KL, Thitikorn-amorn J, Hsieh JF et al (2011) Enhanced enzymatic conversion with freeze pretreatment of rice straw. Biomass Bioenergy 35(1):90–95. https://doi.org/10.1016/j.biombioe.2010.08.027

Chuetor S, Champreda V, Laosiripojana N (2019) Evaluation of combined semi-humid chemo-mechanical pretreatment of lignocellulosic biomass in energy efficiency and waste generation. Bioresour Technol 292:121966. https://doi.org/10.1016/j.biortech.2019.121966

EIA (2020) Biomass explained. U.S. Energy Information Administration. https://www.eia.gov/energyexplained/biomass/. Accessed 26 January 2021

Ferraro A, Dottorini G, Massini G, Miritana VM, Signorini A, Lembo G, Fabbricino M (2018) Combined bioaugmentation with anaerobic ruminal fungi and fermentative bacteria to enhance biogas production from wheat straw and mushroom spent straw. Bioresour Technol 260:364–373. https://doi.org/10.1016/j.biortech.2018.03.128

Forsberg CW, Cheng KJ, White BA (1997) Polysaccharide Degradation in the Rumen and Large Intestine. In: Mackie RI, White BA (eds) Gastrointestinal microbiology. Chapman & Hall Microbiology Series. Springer, Boston MA, pp 319–379 https://doi.org/10.1007/978-1-4615-4111-0_10

Gokcol C, Dursun B, Alboyaci B, Sunan E (2009) Importance of biomass energy as alternative to other sources in Turkey. Energy Policy 37(2):424–431. https://doi.org/10.1016/j.enpol.2008.09.057

Gullert S, Fischer MA, Turaev D et al (2016) Deep metagenome and metatranscriptome analyses of microbial communities affiliated with an industrial biogas fermenter, a cow rumen, and elephant feces reveal major differences in carbohydrate hydrolysis strategies. Biotechnol Biofuels 9(1):1–20. https://doi.org/10.1186/s13068-016-0534-x

Hendriks ATWM, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100(1):10–18. https://doi.org/10.1016/j.biortech.2008.05.027

Hu ZH, Yu HQ (2006) Anaerobic digestion of cattail by rumen cultures. Waste Manage (oxford) 26(11):1222–1228. https://doi.org/10.1016/j.wasman.2005.08.003

Islam MK, Wang H, Rehman S, Dong C, Hsu HY, Lin CSK, Leu SY (2020) Sustainability metrics of pretreatment processes in a waste derived lignocellulosic biomass biorefinery. Bioresour Technol 298:122558. https://doi.org/10.1016/j.biortech.2019.122558

Jackowiak D, Bassard D, Pauss A, Ribeiro T (2011) Optimisation of a microwave pretreatment of wheat straw for methane production. Bioresour Technol 102(12):6750–6756. https://doi.org/10.1016/j.biortech.2011.03.107

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renewable Sustainable Energy Rev 90:877–891. https://doi.org/10.1016/j.rser.2018.03.111

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Res 6(2):405–415. https://doi.org/10.1007/s12155-012-9276-1

Manmai N, Unpaprom Y, Mariano APB, Ramaraj R (2019) Bioethanol production from sunflower stalk: comparison between the impact of optimal chemical and biological pretreatments. The 1st Thailand Biorefinery Conference, 3(8): 9

Mao C, Wang X, Xi J, Feng Y, Ren G (2017) Linkage of kinetic parameters with process parameters and operational conditions during anaerobic digestion. Energy 135:352–360

Markou G, Brulé M, Balafoutis A, Kornaros M, Georgakakis D, Papadakis G (2017) Biogas production from energy crops in northern Greece: Economics of electricity generation associated with heat recovery in a greenhouse. Clean Technol Environ Policy 19(4):1147–1167

Mathew AK, Bhui I, Banerjee SN, Goswami R, Chakraborty AK, Shome A, Balachandran S, Chaudhury S (2015) Biogas production from locally available aquatic weeds of Santiniketan through anaerobic digestion. Clean Technol Environ Policy 17(6):1681–1688. https://doi.org/10.1007/s10098-014-0877-6

Oh WD, Lisak G, Webster RD et al (2018) Insights into the thermolytic transformation of lignocellulosic biomass waste to redox-active carbocatalyst: Durability of surface active sites. Appl Catal B 233:120–129. https://doi.org/10.1016/j.apcatb.2018.03.106

Quintero M, Castro L, Ortiz C, Guzmán C, Escalante H (2012) Enhancement of starting up anaerobic digestion of lignocellulosic substrate: fique’s bagasse as an example. Bioresour Technol 108:8–13. https://doi.org/10.1016/j.biortech.2011.12.052

Ramos LP (2003) The chemistry involved in the steam treatment of lignocellulosic materials. Quim Nova 26(6):863–871. https://doi.org/10.1590/S0100-40422003000600015

Romano RT, Zhang R, Teter S, McGarvey JA (2009) The effect of enzyme addition on anaerobic digestion of Jose Tall Wheat Grass. Bioresour Technol 100(20):4564–4571. https://doi.org/10.1016/j.biortech.2008.12.065

Seesatat A, Rattanasuk S, Bunnakit K et al (2021) Biological degradation of rice straw with thermophilic lignocellulolytic bacterial isolates and biogas production from total broth by rumen microorganisms. J Environ Chem Eng 9(1):104499.

Sen B, Chou YP, Wu SY, Liu CM (2016) Pretreatment conditions of rice straw for simultaneous hydrogen and ethanol fermentation by mixed culture. Int J Hydrogen Energy 41(7):4421–4428. https://doi.org/10.1016/j.ijhydene.2015.10.147

Song L, Yu H, Ma F, Zhang X (2013) Biological pretreatment under non-sterile conditions for enzymatic hydrolysis of corn stover. BioResources 8(3):3802–3816

Song Y, Wi SG, Kim HM, Bae HJ (2016) Cellulosic bioethanol production from Jerusalem artichoke (Helianthus tuberosus L.) using hydrogen peroxide-acetic acid (HPAC) pretreatment. Bioresour Technol 214:30–36. https://doi.org/10.1016/j.biortech.2016.04.065

Taha M, Shahsavari E, Al-Hothaly K, Mouradov A, Smith AT, Ball AS, Adetutu EM (2015) Enhanced biological straw saccharification through coculturing of lignocellulose-degrading microorganisms. Appl Biochem Biotechnol 175(8):3709–3728. https://doi.org/10.1007/s12010-015-1539-9

Van Fan Y, Klemeš JJ, Perry S, Lee CT (2019) Anaerobic digestion of lignocellulosic waste: Environmental impact and economic assessment. J Environ Manage 231:352–363. https://doi.org/10.1016/j.jenvman.2018.10.020

Xing BS, Han Y, Wang XC et al (2020) Persistent action of cow rumen microorganisms in enhancing biodegradation of wheat straw by rumen fermentation. Sci Total Environ 715:136529. https://doi.org/10.1016/j.scitotenv.2020.136529

Xu H, Li Y, Hua D, Zhao Y et al (2021) Effect of microaerobic microbial pretreatment on anaerobic digestion of a lignocellulosic substrate under controlled pH conditions. Bioresour Technol 328:124852.

Yoruklu HC, Korkmaz E, Demir NM, Ozkaya B, Demir A (2018) The impact of pretreatment and inoculum to substrate ratio on methane potential of organic wastes from various origins. J Mater Cycles Waste Manage 20(2):800–809

Yuan X, Ma L, Wen B, Zhou D, Kuang M, Yang W, Cui Z (2016) Enhancing anaerobic digestion of cotton stalk by pretreatment with a microbial consortium (MC1). Bioresour Technol 207:293–301. https://doi.org/10.1016/j.biortech.2016.02.037

Zhang Q, He J, Tian M, Mao Z, Tang L, Zhang J, Zhang H (2011) Enhancement of methane production from cassava residues by biological pretreatment using a constructed microbial consortium. Bioresour Technol 102(19):8899–8906. https://doi.org/10.1016/j.biortech.2011.06.061

Zhang X, Wilson K, Lee AF (2016a) Heterogeneously catalyzed hydrothermal processing of C5–C6 sugars. Chem Rev 116(19):12328–12368. https://doi.org/10.1021/acs.chemrev.6b00311

Zhang H, Zhang P, Ye J, Wu Y, Fang W, Gou X, Zeng G (2016b) Improvement of methane production from rice straw with rumen fluid pretreatment: A feasibility study. Int Biodeterior Biodegrad 113:9–16

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82(5):815–827. https://doi.org/10.1007/s00253-009-1883-1

Zhao X, Li S, Wu R, Liu D (2017) Organosolv fractionating pretreatment of lignocellulosic biomass for efficient enzymatic saccharification: chemistry, kinetics, and substrate structures. Biofuels, Bioprod Biorefin 11(3):567–590. https://doi.org/10.1002/bbb.1768

Acknowledgements

This research was supported by the Yildiz Technical University, Civil Engineering Faculty, Environmental Engineering Department.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kurt Kara, G., Doluk, R., Civelek Yoruklu, H. et al. Biomethane production kinetics of rumen pretreated lignocellulosic wastes. Clean Techn Environ Policy 23, 2941–2954 (2021). https://doi.org/10.1007/s10098-021-02214-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02214-9