Abstract

Pinch analysis was initially developed as a methodology for optimizing energy efficiency in process plants. Applications of pinch analysis applications are based on common principles of using stream quantity and quality to determine optimal system targets. This initial targeting step identifies the pinch point, which then allows complex problems to be decomposed for the subsequent design of an optimal network using insights drawn from the targeting stage. One important class of pinch analysis problems is energy planning with footprint constraints, which began with the development of carbon emissions pinch analysis; in such problems, energy sources and demands are characterized by carbon footprint as the quality index. This methodology has been extended by using alternative quality indexes that measure different sustainability dimensions, such as water footprint, land footprint, emergy transformity, inoperability risk, energy return on investment and human fatalities. Pinch analysis variants still have the limitation of being able to use one quality index at a time, while previous attempts to develop pinch analysis methods using multiple indices have only been partially successful for special cases. In this work, a multiple-index pinch analysis method is developed by using an aggregate quality index, based on a weighted linear function of different quality indexes normally used in energy planning. The weights used to compute the aggregate index are determined via the analytic hierarchy process. A case study for Indian power sector is solved to illustrate how this approach allows multiple sustainability dimensions to be accounted for in energy planning.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pinch analysis is a technique that has been applied to a large set of process integration (PI) problems in the past. It was originally developed to identify rigorous heat recovery targets for heat exchanger network (HEN) in the process plants (Hohmann 1971). This technique helps define rigorous targets by considering process quantity (enthalpy) and quality (temperature). Since the 1980s, pinch analysis has grown much more popular as it is extended to various energy-intensive processes particularly in response to the increase in the cost of energy during this historical period (Linnhoff et al. 1982). There has also been significant growth in the literature (Linnhoff 1993). Today, this field is sufficiently well established such that contributions are integrated in modern textbooks (e.g., Smith 2016), reference books (Klemeš et al. 2011) and industrial handbooks (Klemeš 2013).

Many extensions of pinch analysis, other than heat transfer, have been suggested in the literature (Tan et al., 2015). The earliest extension of pinch analysis to mass exchanger network (MEN) synthesis was proposed by El-Halwagi and Manousiothakis (1989), and later to other mass integration applications for efficient use of mass separating agents (MSAs) such as solvents and adsorbents (El-Halwagi 1997). These techniques were also developed for water recovery systems, which is a special case of mass integration (Wang and Smith 1994). El-Halwagi et al. (2003) generalized this approach as resource conservation networks (RCNs), which covers a large number of industrial problems, including hydrogen network synthesis (Alves and Towler 2002) and property integration (Kazantzi and El-Halwagi 2005). The established pinch analysis techniques for various RCN problems are well documented in reviews (Foo 2009), textbooks (Foo 2012) and industrial handbooks (Klemeš 2013).

Pinch analysis has also been extended for energy planning with emission footprint constraints. Tan and Foo (2007) used CO2 footprint as the quality index for obtaining optimal targets in a methodology known as carbon emissions pinch analysis (CEPA). Different quality indices have been used overtime in different studies to expand this application. Tan et al. (2009) used water footprint as the quality index. Bandyopadhyay et al. (2010) used emergy transformity, whereas Tan and Foo (2013) used inoperability risk as the quality indices. Walmsey et al. (2014) took energy return on investment (EROI) as the quality indicator. Jia et al. (2016) used a simultaneous graphical approach to take into account multiple indices to design an energy allocation network in China. This approach was developed based on carbon, land and water footprints, combined with EROI and human risk, as sustainability indicators; however, it requires selecting one of the indicators as the primary basis for planning, while analyzing the impacts for the other four dimensions. No aggregation is proposed in the methodology, although the use of the five indicators facilitates scenario analysis for practical decision-making. Krishna Priya and Bandyopadhyay (2017) used a prioritized cost approach to determine multiple-objective solution for carbon-constrained Indian power sector. The main limitation is that each of these studies used only one footprint indices as a link to sustainability. However, there have been very few and only partially successful attempts at developing a multiple-index approach. In the PI literature, different sustainability dimensions have been operationalized as footprint metrics used within the context of life cycle assessment (LCA), for instance by De Benedetto and Klemeš (2009). Čuček et al. (2012) reviewed important footprint metrics used in sustainability analysis. On a global scale, safety limits for some of these footprints have been proposed (Rockström et al. 2009). Another notable gap in the PI literature on energy planning is the lack of methodology that accounts for sustainability aspects that are inherently difficult to quantify (e.g., the public acceptability dimension in the case of nuclear energy).

The concept of aggregation has been applied extensively in the context of sustainability assessment (Sikdar 2003). It is conceptually possible to calculate a single sustainability index as an aggregate of different metrics, provided that compensation effect is assumed and that the relative importance of the different metrics is known (Sikdar 2009). This approach defines an aggregate quality indicator of sustainability based on which a multiple quality index pinch analysis approach is proposed. The aggregate indicator is assumed to be a weighted linear combination of multiple indices. In order to obtain these weights, analytic hierarchy process (AHP), a decision analysis method, has been used. This is a systematic decision analysis framework that uses a problem decomposition approach to handle complex problems (Saaty 1980). AHP breaks the problem down into a hierarchical structure of an objective, criteria and alternatives. The structure then provides the basis for decomposing the problem into a set of local pairwise comparisons of decision elements (i.e., alternatives or criteria). Prioritization of these elements is achieved using a calibrated pairwise comparison scale which gives an equivalent numerical weight ratio for subjective or linguistic judgments by subject or domain experts (Saaty 1980). These ratios can then be consolidated into a set of overall weights using the well-known eigenvector method (Saaty 1980).

AHP is a popular decision analysis technique due to its simplicity and versatility. AHP has been applied to a wide range of problems in the literature. Applications of AHP in process engineering problems include selection of reactor configuration (Hanratty and Joseph 1992), product selection (Qian et al. 2007), evaluation of safety measures (Arslan 2009), sustainable process design (Othman et al. 2010) and early-stage pharmaceutical process design (Perez-Vega et al. 2011). There are numerous reviews of AHP applications in the literature, focusing on applications (Vaidya and Kumar 2006), methodological extensions (Sipahi and Timor 2010) and comparison with alternative approaches (Pohekar and Ramachandran 2004). One of the most vital uses of AHP is that it can be combined easily with other techniques. Another recent review surveys developments in methodological aspects of AHP (Ishizaka and Labib 2011), while Ho (2008) reviewed various hybrid methodologies that combine AHP with other techniques, such as mathematical programming. The weights of criteria calculated from AHP can form inputs to other methodologies.

In this paper, a novel hybridization of AHP with pinch analysis for sustainable energy systems planning using multiple quality indices is developed, thereby addressing a weakness of previously developed pinch analysis approaches to similar problems. The rest of the paper is organized as follows. A formal problem statement is defined in “Problem statement” section. General methodology is stated in “Methodology” section. “Case study of Indian power sector” section demonstrates the multiple-index pinch analysis (MIPA) technique by solving two illustrative case studies. Finally, conclusions and prospects of future work are given in “Conclusions” section.

Problem statement

The formal problem statement is adapted from the original energy planning problem proposed by Tan and Foo (2007) and may be stated as follows:

-

Given a set of energy sources, designated as SOURCES = {i|i = 1, 2, …, M}, to be allocated to energy demands. Each source (e.g., coal, oil) has an available energy of S i and is characterized by quality indices SQ ik with respect to a set of quality aspects QUALITY = {k|k = 1, 2, …, O}.

-

It is assumed that all quality indices k have two important properties (Tan and Foo 2013). Firstly, low numerical values are more desirable. Secondly, the indices must conform to linear mixing rules (Bandyopadhyay 2006). Appropriate mathematical transformations may be used for indices that do not possess these properties. Furthermore, the quality indices may be measurable quantitative factors (e.g., carbon footprint) or numerical expressions of subjective factors (e.g., social acceptability).

-

An aggregate sustainability index SCQ i can be determined for each source i. This factor is assumed to be a weighted average of multiple quality indices, \(SCQ_{i} = \sum_{k} w_{k} SQ_{ik}\). The weights are assumed to be determined via AHP and are normalized such that \(\sum_{k} w_{k} = 1\). These weights reflect the priority assigned by the decision-maker to different quality aspects.

-

Given a set of energy demands, designated as DEMANDS = {j|j = 1, 2, …, N}. Each demand requires an energy supply of D j and has a maximum aggregate sustainability limit of DCQ j . As with the sources, this factor is assumed to be a weighted average of multiple quality (or impact) indices, \(DCQ_{j} = \sum_{k} w_{k} DQ_{jk}\). However, no unique limit is set for each quality index, which differentiates this problem from the generalized form described by Tan and Foo (2013). Instead, overall sustainability is measured in terms of the limiting factor DCQ j , which allows a compensatory effect to be considered for different criteria. In other words, good performance with respect to one quality index can offset poor performance elsewhere. Such an assumption is used in aggregation-based methods of computing sustainability (Sikdar 2009).

-

It is further assumed that there exists a high-quality energy resource F, whose aggregate quality index is FCQ, which is again determined as \(FCQ = \sum_{k} w_{k} FQ_{k}\). This stream is analogous to the externally resource in RCN problems (Foo 2012).

-

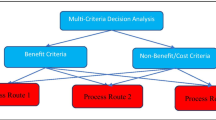

The energy sources and demands in the system can potentially be matched as shown in the superstructure given in Fig. 1. The problem is to optimally allocate energy streams, so as to maximize utilization of internal energy sources (i.e., minimize requirement for the high-quality energy resource) while ensuring that the aggregate quality index limits of the demands are satisfied. Note that, even though the latter resource is generally desirable, in practice it may be necessary to determine the minimum requirement needed to achieve system goals (Tan and Foo 2007).

Methodology

Different graphical and algebraic methods have been developed for solving source–sink problems. For details, the reader is referred to the review paper by Foo (2009) for resource conservation problems, or Foo and Tan (2016) for various environmental footprint problems. A brief tutorial on CEPA can also be found in a recent book chapter (Tan and Foo 2017). The underlying similarity of all these seemingly diverse methodologies is highlighted in a recent paper (Bandyopadhyay 2015), while the wide range of applicability to different industrial problems can be seen in the textbook by Foo (2012).

The broad objective of the method is to obtain an allocation network of all sources which satisfy the demands based on several quantitative and qualitative indicators. The first step in doing so is to form a linear combination of all quality indices. To do this, AHP is used for weighting. The computational details of the procedure are shown in “Appendix.” Using the weights determined, an aggregate sustainability index can then be calculated. However, each quality index must be normalized before calculation of the aggregate sustainability index. Quantitative indices are normalized relative to the largest value present in the data set. On the other hand, qualitative indicators are quantified via AHP (see “Appendix”) and then normalized by division by the maximum value. It must be noted that this normalization is to ensure a uniform scale of values ranging from 0 to 1 before combining them using the weights obtained earlier. Also, a reverse scale is ensured during normalization, i.e., lower value denotes more desirable quality. In the case of quality indices that do not follow a reverse scale (e.g., EROI), inverse of the indicator may be considered as the quality and normalized as above. Once the normalized values of both quantitative and qualitative indices are obtained, the aggregate sustainability index can be calculated as a simple weighted linear combination of these values. This aggregate sustainability index is then supplied to the pinch analysis to calculate the resource requirement and network allocation. Overall aggregation procedure is shown in Fig. 2. The detailed steps of targeting and network synthesis are well established in the PI literature and need not be described here. In the next section, case studies are solved to illustrate the methodology based on the energy sector of India, which has a significant place among BRICS (Brazil, Russia, India, China and South Africa) countries and has been noted for its potential for industrial decarbonization (Iftikhar et al. 2016).

Case study of Indian power sector

To demonstrate MIPA, a case study related to the sustainable electricity sector planning for India has been considered. The present electrical demand of India (181.56 GW) is met by electricity generated from coal, oil, natural gas, hydro, nuclear, and renewable sources. The latter is taken as the high-quality energy resource in this example. For the aggregate sustainability index, the component quantitative indices are:

-

Carbon footprint (kt CO2-e/GWh) which measures the contribution of an energy system to climate change.

-

EROI (dimensionless) which measures the energy productivity of a system, in terms of cumulative net energy production per unit of energy invested for capital inputs (Hall et al. 2009).

-

Land footprint (m2 y/kWh) which measures the geographic area occupied by an energy system.

-

Water footprint (m3/MWh) which measures the water stress caused by an energy system.

-

Risk to human lives which is a qualitative measure of potential harm to inhabitants through pollutants, accidents, etc.

Detailed values of the existing power plants and corresponding qualities are given in Table 1 (Krishna Priya and Bandyopadhyay 2017). Assuming a 7% annual growth over next 5 years, the electricity demand of India is expected to be 254.65 GW (also tabulated in the last row of Table 1). It may be noted that actual values of these indices for the demand should be decided by the Indian Government based on the economic and societal development considerations. It is assumed, for simplicity, that the enhanced demand will be met from the renewable sources while satisfying aggregate sustainability index.

Based on the opinions of the expert, a pairwise comparison matrix between different quality indices (also known as the judgment matrix) is prepared and shown in Table 2. Applying the methodology of AHP (see “Appendix”), relative weights for different indices are calculated and shown in Table 3. The aggregate sustainability quality index can now be defined as the weighed sum of the five qualities using the weights given in Table 3. It may be noted that the largest eigenvalue for the judgment matrix is 5.066 with a consistency index of 0.0165 (see “Appendix”). However, to calculate the numerical value of the aggregate sustainability index, the subjective criterion risk to humans should be quantified. AHP is applied as described in “Appendix” (detailed calculations are not shown for brevity). Based on the normalized weights, the quantitative values for different attributes of risk to humans are obtained as follows: very high risk is 1; high risk is 0.629; medium risk is 0.206; and low risk is 0.085. To take care of the different numerical values, all quality indices are normalized to obtain a value within the range [0, 1]. Furthermore, all quality indices should follow the inverse scale (lower numerical value denotes better quality). Quality indices such as carbon footprint, land footprint, and water footprint already follow an inverse scale, and hence, they are normalized with respect to the corresponding maximum value. It should be noted that EROI does not follow the inverse scale (i.e., larger values of EROI are more desirable), and hence, 1/EROI is used as the quality index instead. These normalized indices and the aggregate sustainability indices for different sources and the demand are presented in Table 4.

Note that, for the demand, it is assumed that there is no strict limit to be met for each individual criterion or index; a limit is only specified for the aggregate quality index. However, the latter is determined from the desired value of each individual quality index. This compensatory effect is commonly used in sustainability assessment and assumes that good scores with respect to some aspects can offset poor scores elsewhere (Sikdar 2009). Weights serve to reflect the relative importance of the different quality indices. Furthermore, while there is no hard constraint on individual quality indices, the individual limits are effectively made tighter by the application of larger weight factors, or more relaxed by using smaller weights.

Using the aggregate sustainability indicators as the quality index for the overall problem, procedures for pinch analysis may be applied to determine the minimum requirement of the renewables. In this case, the energy planning pinch diagram (described in more detail in Tan and Foo 2007) is used to plot composite curves, with total power generation (in GW) plotted along the horizontal axis, and the composite quality index previously computed signifying the quality; as a result, the vertical axis represents a dimensionless load that reflects the overall burden on system sustainability burden. Figure 3 shows the composite curves generated directly from the data. It can be seen that the solution is infeasible due to the intersection of the composite curves. Then, as shown in Fig. 4, the source composite curve is translated or shifted along a locus (indicated in red) whose slope corresponds to that of the most sustainable option (i.e., renewables) until the two curves no longer intersect. Note that, in this optimal solution, the two composite curves are merely tangent to each other at a threshold point on the rightmost extremity of the sink composite curve. It may thus be concluded that the optimal mix shown in Table 5 requires that an additional 75.44 GW of renewables should be installed and 2.35 GW of coal-based power plants should be shut down to achieve the desired level of sustainability. These changes will be sufficient to meet the increased demand for electricity, while satisfying the previously determined aggregate sustainability goals for the system. This result can be verified by multiplying the percentage shares in Table 5 by the quality indices in Table 4, which then gives the sustainability loads shown in Table 6. Note that the aggregate dimensionless load (0.382) meets the aggregate dimensionless sustainability limit (0.382). This result is particularly interesting, because the optimal mix actually exceeds the desired individual load values for all the indices except EROI. However, EROI has a significantly higher weight than three of the other indices, accounting for 34% of the aggregate index (see Table 3), and the load is only half that of the desired value indicated in the second column of Table 6. Meanwhile, the dimensionless carbon footprint load (whose weight is 49%) is about 15% in excess of the desired level. This result reflects the importance of EROI in planning sustainable energy systems; to be viable in the long term, such systems should produce much more energy than is required to build them in the first place (Hall 2017). This concern is particularly true in large developing countries like India, where demand for energy is likely to grow faster than the world average. On the other hand, some exceedance of the desired level of carbon footprint can be justified in order to achieve a high EROI value. For the other three indices (whose weights are just 0.07, 0.07 and 0.04, respectively), the loads are far in excess of individual values, because these indices only weakly influence the overall quality index. Nevertheless, the excesses are compensated for by the advantage with respect to EROI, as indicated both by the aggregate index, and the orientation of the composite curves in Fig. 4. These results are of course dependent on the weights; furthermore, in complex, practical decision-making applications, this MIPA method should be used in conjunction with conventional single-index pinch analysis (i.e., applied separately to each individual index) to provide the energy planners with a more comprehensive framework for analysis (Jia et al. 2016).

Conclusions

The MIPA method for energy planning problems has been developed in this paper. This approach uses AHP to determine an aggregate quality index and thus take into account multiple quality indices within the pinch analysis framework. It overcomes the key limitation of previously developed pinch analysis approaches to sustainable energy system planning, provided that the assumption is met that the individual quality indices are compensatory—i.e., high values for some criteria can be compensated for by low values elsewhere. This assumption typically holds for practical sustainability problems with multiple indicators. Furthermore, the use of AHP allows subjective or qualitative aspects to be approximately quantified and integrated into the pinch analysis framework. An illustrative case study has been solved to demonstrate this methodology.

Future work can focus on extending this methodology to address practical planning issues, such as geographic disaggregation, multi-period systems, and the presence of multiple stakeholders. Furthermore, it may be possible to consider other methods, such as principal component analysis, to supplement the MIPA approach.

References

Alves JJ, Towler GP (2002) Analysis of refinery hydrogen distribution systems. Ind Eng Chem Res 41:5759–5769

Arslan O (2009) Quantitative evaluation of precautions on chemical tanker operations. Process Saf Environ Prot 87:113–120

Bandyopadhyay S (2006) Source composite curve for waste reduction. Chem Eng J 45:5287–5297

Bandyopadhyay S (2015) Mathematical foundation of pinch analysis. Chem Eng Trans 45:1753–1759

Bandyopadhyay S, Sahu GC, Foo DCY, Tan RR (2010) Segregated targeting for multiple resource networks using decomposition algorithm. AIChE J 56:1235–1248

Čuček L, Klemeš JJ, Kravanja Z (2012) A review of footprint analysis tools for monitoring impacts on sustainability. J Clean Prod 34:9–20

De Benedetto L, Klemeš JJ (2009) The environmental performance strategy map: an integrated LCA approach to support the strategic decision-making process. J Clean Prod 17:900–906

El-Halwagi MM (1997) Pollution prevention through process integration: systematic design tools. Academic Press, San Diego

El-Halwagi MM, Manousiothakis V (1989) Synthesis of mass-exchange networks. AIChE J 35:1233–1244

Foo DCY (2009) A state-of-the-art review of pinch analysis techniques for water network synthesis. Ind Eng Chem Res 48:5125–5159

Foo DCY (2012) Process integration for resource conservation. CRC Press, Boca Raton

Foo DCY, Tan RR (2016) A review on process integration techniques for carbon emissions and environmental footprint problems. Process Saf Environ Prot 103:291–307

Hall CAS (2017) The history, future, and implications of EROI for society. Lect Notes Energy 36:145–169

Hall CAS, Balogh S, Murphy DJR (2009) What is the minimum EROI that a sustainable society must have? Energies 2:25–47

Hanratty PJ, Joseph B (1992) Decision-making in chemical engineering and expert systems: application of the analytic hierarchy process to reactor selection. Comput Chem Eng 16:849–860

Ho W (2008) Integrated analytic hierarchy process and its applications—a literature review. Eur J Oper Res 186:211–228

Hohmann (EC) (1971) Optimum networks for heat exchange. Ph.D. thesis, University of Southern California

Iftikhar Y, He W, Wang Z (2016) Energy and CO2 emissions efficiency of major economies: a non-parametric analysis. J Clean Prod 139:779–787

Ishizaka A, Labib A (2011) Review of the main developments in the analytic hierarchy process. Expert Syst Appl 38:14336–14345

Jia X, Li Z, Wang F, Foo DCY, Tan RR (2016) Multi-dimensional pinch analysis for sustainable power generation sector planning in China. J Clean Prod 112:2756–2771

Kazantzi V, El-Halwagi MM (2005) Targeting material reuse via property integration. Chem Eng Prog 101:28–37

Klemeš JJ (ed) (2013) Handbook of process integration. Elsevier, Cambridge

Klemeš JJ, Friedler F, Bulatov I, Varbanov P (2011) Sustainability in the process industry—integration and optimization. McGraw-Hill, New York

Krishna Priya GS, Bandyopadhyay S (2017) Multiple objectives pinch analysis. Resour Conserv Recycl 119:128–141

Linnhoff B (1993) Pinch analysis: a state-of-art overview. Chem Eng Res Des 71:503–522

Linnhoff B, Townsend DW, Boland D, Hewitt GF, Thomas BEA, Guy AR, Marshall RH (1982) A user guide on process integration for the efficient use of energy. Institute of Chemical Engineers, Rugby

Othman MR, Repke J-W, Wozny G (2010) Incorporating negative values in AHP using rule-based scoring methodology for ranking of sustainable chemical process design options. Comput Aided Chem Eng 28:1045–1050

Perez-Vega S, Peter S, Salmeron-Ochoa I, Nieva-de la Hidalga A, Sharratt PN (2011) Analytical hierarchy processes (AHP) for the selection of solvents in early stages of pharmaceutical process development. Process Saf Environ Prot 89:261–267

Pohekar SD, Ramachandran M (2004) Application of multi-criteria decision making to sustainable energy planning—a review. Renew Sustain Energy Rev 81:365–381

Qian Y, Huang Z, Yan Z (2007) Integrated assessment of environmental and economic performance of chemical products using analytic hierarchy process approach. Chin J Chem Eng 15:81–87

Rockström J, Steffen W, Noone K, Persson A, Chapin FS, Lambin EF, Lenton TM, Scheffer M, Folke C, Schellnhuber HJ, Niykvist B, De Wit CA, Hughes T, Van der Leeuw S, Rodhe H, Sorlin S, Snyder PK, Constanza R, Svedin U, Falkenmark M, Karlberg L, Corell RW, Fabry VJ, Hansen J, Walker B, Liverman D, Richardson K, Crutzen P, Foley JA (2009) A safe operating space for humanity. Nature 461:472–475

Saaty TL (1980) The analytic hierarchy process. McGraw-Hill, New York

Sikdar SK (2003) Sustainable development and sustainability metrics. AIChE J 49:1928–1932

Sikdar SK (2009) On aggregating multiple indicators into a single metric for sustainability. Clean Technol Environ Policy 11:157–161

Sipahi S, Timor M (2010) The analytic hierarchy process and analytic network process: an overview of applications. Manag Decis 48:775–808

Smith R (2016) Chemical process: design and integration, 2nd edn. Wiley, Chichester

Tan RR, Foo DCY (2007) Pinch analysis approach to carbon-constrained energy sector planning. Energy 32:1422–1429

Tan RR, Foo DCY (2013) Pinch analysis for sustainable energy planning using diverse quality measures. In: Klemeš JJ (ed) Handbook of process integration. Elsevier, Cambridge

Tan RR, Foo DCY, Aviso KB, Ng DKS (2009) The use of graphical pinch analysis for visualizing water footprint constraints in biofuel production. Appl Energy 86:605–609

Tan RR, Bandyopadhyay S, Foo DCY, Ng DKS (2015) Prospects for novel pinch analysis application domains in the 21st century. Chem Eng Trans 45:1741–1746

Tan RR, Foo DCY (2017) Carbon emissions pinch analysis for sustainable energy planning. In: Abraham M (ed) Encyclopedia of sustainable technologies. Elsevier, Amsterdam. doi:10.1016/B978-0-12-409548-9.10148-4

Vaidya OS, Kumar S (2006) Analytic hierarch process: an overview of applications. Eur J Oper Res 169:1–29

Walmsley MRW, Walmsley TG, Atkins MJ, Kamp PJJ, Neale JR (2014) Minimising carbon emissions and energy expended for electricity generation in New Zealand through to 2050. Appl Energy 135:656–665

Wang YP, Smith R (1994) Waste water minimisation. Chem Eng Sci 49:981–1006

Author information

Authors and Affiliations

Corresponding author

Appendix: Analytic hierarchy process (AHP)

Appendix: Analytic hierarchy process (AHP)

A brief overview of the computational aspects of AHP is given here. Details of the AHP framework are described extensively in the literature, and particularly in key reference books (Saaty 1980). The discussion below pertains to determination of weights of criteria, but the procedure is also applicable to quantifying scores for qualitative or subjective criteria. The methodology computes the weight vector (w) of n elements from pairwise comparisons summarized in a positive reciprocal square matrix A:

where

In general, experts are asked to give n(n−1)/2 pairwise comparisons of criteria. Each ratio value (a ij ) is based on a standard 9-point scale (Saaty 1980). Table 7 gives the 9-point scale for both criteria and alternatives. The relative weights (w) of the criteria are found using the normalized right eigenvector associated with the principal eigenvalue (λ max) of A:

The weights are normalized so as to sum to unity:

In the case of a perfectly consistent pairwise comparison matrix, λ max is equal to n. Otherwise, the eigenvector method can also be used to measure a consistency index:

Other than the eigenvector approach described here, the weights can also be calculated using the simpler geometric mean method, which yields approximately the same results, but for which a consistency index cannot be calculated.

Rights and permissions

About this article

Cite this article

Patole, M., Bandyopadhyay, S., Foo, D.C.Y. et al. Energy sector planning using multiple-index pinch analysis. Clean Techn Environ Policy 19, 1967–1975 (2017). https://doi.org/10.1007/s10098-017-1365-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-017-1365-6