Abstract

With increasing consumption propelled by economic prosperity, waste generation per capita in developing countries is growing quickly. Traditional approaches of open dumping and landfilling are encountering physical constraints, particularly in megacities, and the need for alternate municipal solid waste (MSW) management strategies is urgent. Among alternatives that are commonly considered are waste-to-energy technologies including incineration and plasma gasification. Previous studies convey the benefits of such technologies, but most do not consider the waste and environmental conditions in tropical megacities such as Mumbai, India, making these studies of limited use to developing countries. This article evaluates the exergetic potential of converting MSW to useful work by thermal and biochemical conversion technologies in the Indian context, considering the facts that the scale of production, composition, climate, segregation practices, moisture content of MSW, etc. in a developing tropical country like India differ significantly from those in developed societies in temperate climate locations. Both, exergy and economic analysis find gasification to be attractive in terms of its monetary return and thermodynamic efficiency. However, this analysis also identifies major hurdles in adopting advanced waste-to-energy technologies including lack of waste segregation, high moisture content, and high capital cost of the most thermodynamically efficient technology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid economic growth, rising consumerism, and increasing population in developing economies are resulting in increased utilization of material resources and adverse impact of anthropogenic activities on the environment due to generation of increasing quantity of waste. Generation of municipal solid waste (MSW) is an outcome of the linear nature of consumption and manufacturing, where resources are extracted from the earth, converted into products that are then used and discarded. Majority of industrial products that end up and stay in landfills after their use in society are derived from non-renewable energy and material feedstocks. The life cycle of such constituents of MSW consists of mineral extraction from the earth’s crust, followed by purification and concentrated by various energy intensive physical and chemical processes. These materials are then used in industry to produce various products that are bought by consumers, who discard them as waste. These materials start their life cycle in a dilute form as ores. We concentrate them by industrial processes, but in formation of products and after use, we dilute them once again by mixing diverse products in the form of municipal solid waste. Thus, the constituents of MSW include plastics, rubber, tyre, paper, cardboard, wood, metals, and organic fractions, all of which have certain chemical potential associated with them. If unattended, these MSW constituents tend to decompose by natural processes, resulting in odour, generation of new chemical species and leachate, insects and pests, creating serious health and environmental hazards. If the chemical potential of these constituent elements of MSW remains unutilized, these are likely to harm the environment and ultimately lead to overall increase in the entropy of the system. With increasing realization of these challenges, the conventional approach of considering MSW as a liability and getting rid of it is gradually giving way to methods for extracting value from MSW by converting it to useful products. Ideally, the waste products should be used as a feedstock in another process or recycled to minimize loss of value. However, if this is not possible, biochemical or thermal treatment methods may be used to recover fuel value while minimizing disposal or landfilling practices (Langenhove 2002). By-product synergy or industrial symbiosis efforts are being developed in many parts of the world. These approaches are steps towards mimicking ecological systems, in which waste from one system is utilized as resource in another to reduce environmental impact of the overall system (Langenhove 2002).

Converting waste to energy in India

In fast growing megacities of the developing world, because of the practices of open dumping and landfilling that have been practiced over the years, most of the dumping grounds are quickly getting overloaded. According to India’s Central Pollution Control Board (CPCB) 127,486 TPD (tons per day) municipal solid waste was generated in India during 2011–2012 (SWM Cell 2003). This creates a formidable challenge that is forced upon local municipal corporations who are in charge of all sorts of MSW management activities. This has created an urgent need for improved means of treatment or disposal of MSW that can treat the waste quickly and in an economically feasible, environmentally sustainable, and socially desirable manner.

Various technologies exist for handling post-recycled MSW by converting it to some useful resource. Many of them have been studied in the context of specific societies and types of waste (Mountouris et al. 2008; Eriksson et al. 2005; Tsai and Kuo 2010; Rathi 2007; Murphy and Mckeogh 2004). It is estimated that 4613 Mt/day of methane is emitted from MSW management in India (Singh et al. 2011). Emission of greenhouse gas is estimated to be 7 million tonnes in 1997, with a likely increase to 39 million tonnes by 2047 if no efforts are made to reduce the emission (Zhu et al. 2008). Because of these limitations of MSW landfilling in terms of harmful emissions (CO2, CH4, etc.), requirement of large tracks of land, longer period for disposal, longer transportation distance, and very low energy recovery, many countries are restricting this practice.

Thermal treatment technologies present another option for dealing with MSW. Incineration recovers the heat of waste combustion to produce electricity. It can reduce the waste mass by 70% and volume by up to 90%. Incineration is carried out at a temperature of approximately 850 °C or more, and MSW gets converted into CO2, H2O, nitrogen oxide, sulphur dioxide, HCl, along with residual inorganic ash. Technologies for converting waste to energy are quite popular in developed countries, while they are relatively new to developing countries, including India. A World Bank study suggests that for feasibility of waste-to-energy (WTE) facilities, a minimum lower caloric value of MSW should be 7 MJ/kg (The World Bank 1999). The average lower calorific value of MSW in India is in the range of 3.34–4.6 MJ/kg (Sharholy and Ahmad 2008), while the typical calorific value of unsorted MSW is around 10.4 MJ/Kg. It has been reported that, if MSW is dried and sorted to remove recyclable materials, the calorific value could be as high as 18.5 MJ/kg (Ricaud 2011). Despite the potential feasibility of waste-to-energy processes in India based at least on calorific value, existing efforts have not met with much success, as discussed in the supporting information. Previous assessments of incineration technology have shown that the energy efficiency of converting MSW to electricity is typically about 20% and to thermal products about 55% (Murphy and Mckeogh 2004). In the Indian context, given the current composition of MSW, incineration may not be a thermodynamically and economically feasible option for energy recovery (Chattopadhyay et al. 2009). Newer technologies such as plasma gasification are claimed to be capable of overcoming the shortcomings of incineration and can recover energy from MSW in an efficient and environmentally friendly manner (Mountouris et al. 2008; Janajreh et al. 2013).

Plasma gasification is a non-incineration thermal conversion process in which the constituents of MSW are dissociated, decomposed, and gasified at very high temperature (5000–15,000 °C) in an oxygen-starved environment by formation of plasma (Moustakas et al. 2005; Mountouris et al. 2008; Ducharme 2010; Byun et al. 2010, 2011; Galeno et al. 2011; Kalinci et al. 2011; Morrin et al. 2012; Hlina et al. 2014). Under these extreme conditions, almost every component including hazardous contaminants such as dioxins, furans, and pesticides dissociate, resulting in relatively small quantities of gaseous and solid emissions that are much cleaner than outputs from incineration and conventional gasification (Mountouris et al. 2008). The residue is a vitrified product called plasma rock, which is a stable glassy mixture with very low leachability (Ricaud 2011). Among the attractions of plasma gasification are that it can treat unsorted waste, and the gases produced have exergy (available energy) that can be converted into electricity or other useful work. Because of these advantages plasma gasification technology has been gaining popularity in recent years for the disposal of municipal solid waste and is being considered in tropical megacities such as Mumbai. However, due to a large electricity requirement and a costly energy source, it is necessary to examine whether these systems can be economically and thermodynamically viable as part of a long-term waste management plan for megacities like Mumbai.

The choice of technology for treatment of MSW depends on various technical, economic, social, and environmental aspects along with MSW composition. From a technical perspective, parameters such as the quantity, physical and chemical characteristics, and moisture content of the MSW need to be accounted for. Most previous thermodynamic analyses of MSW treatment have focused on European and other developed societies, where the MSW is comparatively more segregated and has higher fraction of combustible material, which makes it more suitable for thermal treatment options. In contrast, the MSW in tropical developing countries like India has higher fraction of biodegradable waste, higher moisture content and is completely unsegregated. Given the limited success of previous waste-to-energy efforts in India, it is essential to carefully evaluate the thermodynamic efficiency and economics of conversion for these technologies with respect to composition of the waste. Evaluating the cause of past failures before going for the new waste-to-energy projects may also help.

Exergy analysis has been found to be an appropriate method for material resource accounting, identifying and reducing losses, and improving process efficiency (Ukidwe and Nandan 2005; Dai et al. 2014). In recent studies, exergy analysis has also been used for the assessment of various MSW treatment technologies (Zhou et al. 2011). Zhoe et al. (2011) performed exergy analysis of various treatment options for MSW in South Beijing. This study estimated the exergetic efficiency of compost, incineration, and landfill in South Beijing as 5.98, 14.23, and 2.92%, respectively (Zhou et al. 2011). Zhoe et al. explained how mechanical separation helps in improving their exergetic conversion efficiencies. Murphy and Mckeogh evaluated MSW treatment technologies in the Irish context using techno-economic and environmental emission analysis of incineration and gasification (Murphy and Mckeogh 2004). For Irish society, the net thermodynamic efficiency of conversion of MSW to electricity by incineration and gasification was estimated as 15.3 and 27.2%, respectively (Murphy and Mckeogh 2004).

The present study examines and compares MSW treatment options of landfill, incineration, and plasma gasification for Mumbai city based on exergy and cost analysis to support technology selection. The approach is extended to other Indian cities by considering difference in composition, climate, segregation practices, moisture content, etc. that are representative of a typical tropical megacity. These characteristics can be very different in such cities, as compared to cities in developed societies, where previous such studies have been conducted. The contribution of this work is through the application of exergy and cost analysis to provide new insight into the relevance and challenges of adopting waste-to-energy technologies in developing countries.

Approach

The approach adopted in this work determines the exergy of each stream in selected processes for managing MSW. These calculations are based on information about the temperature, pressure, and composition of each stream, and relevant equations and calculations are provided in the supporting information. This work also determines the capital and operating costs of each technology based on data for the city of Mumbai. Exergy analysis along with economic analysis can shed light on the practicability of the proposed process. Exergy analysis is preferred over energy analysis because the latter can only account for contribution of fuels and energy resources, while exergy is more comprehensive since it also accounts for materials use. Further, exergy is more rigorous since it accounts for the first and second laws, while energy only considers the first law.

Exergy is defined as a measure of the potential of a system to do work, and as “entropy free energy” (Ayres et al. 2011). It is the maximum possible work that may be obtained from a system by bringing it to thermodynamic equilibrium with the surroundings by a sequence of reversible processes. Exergy is only defined with respect to the reference environment, to which the system, being investigated will finally be in thermodynamic equilibrium. Energy analysis is based on first law of thermodynamics, whereas exergy analysis is based on the second law. Exergy analysis gives both quantitative and qualitative analysis of the resource (Joshi et al. 2009; Morris and Szargut 1986). Unlike energy, exergy is not subjected to a conservation law, rather, exergy gets destroyed due to irreversibilities (such as friction, mixing, chemical reactions, and heat transfer) in any real process (Joshi et al. 2009). Exergy analysis reveals whether or not and by how much it is possible to design more efficient energy systems by reducing inefficiencies. Exergy analysis along with economic analysis can shed light on the practicability of the proposed process (Morris and Szargut 1986).

Physical exergy attributes to the temperature, pressure, and potential head gradient between the system and the surrounding (end state). Physical exergy is given by

where h and S are the specific enthalpy and entropy, respectively, T denotes temperature, with subscript 0 indicating the reference environment.

The amount of thermal exergy (B th) transfer associated with heat transfer (Q r ) (across a system boundary (r) at constant temperature (T r ) is given by

Chemical exergy (B ch) is attributed to the chemical composition difference between the system and the reference environment (sink) and is the maximum amount of work that can be extracted from any substance as it attains equilibrium with one of the three sinks: atmosphere, sea water, and the top layer of the earth’s crust (Ayres 2003). The chemical exergy of any compound can be calculated from the standard chemical exergy values of the elements, considering its reference reaction as follows (Vorst et al. 2011; Rivero and Garfias 2006).

where \(\gamma_{k} \;{\text{and}}\;b_{{{\text{ch}},k}}^{0}\) are the number of moles and the standard chemical exergy (kJ/mol) of the kth reference species, respectively. The reference temperature, T 0 and standard pressure p 0 are assumed to be 298.15 K and 101,325 Pa, respectively (Vorst et al. 2011).

The elemental composition of the feed MSW is given in Table 1 based on a report published by the Department of Science and Technology, Government of India on Energy from Waste (Sikka 2000). These data represent average composition over a year. From the fraction of each constituent, and the values of standard chemical exergy of each element, chemical exergy associated with the MSW has been estimated and the details are provided in the supporting information. This composition information and a daily MSW production rate of 7,500 tons/day in Mumbai are used to calculate the exergy of waste, as shown in the supporting information. Exergy of other inputs and outputs from each MSW management process is determined according to the technology used, as described in the next section.

The definition of exergy efficiency is\({\text{Exergy}}\;{\text{efficiency}} = \frac{{{\text{Exergy}}\;{\text{of}}\;{\text{output}}}}{{{\text{Exergy}}\;{\text{of}}\;{\text{feed}}\;{\text{MSW}}}}.\)

MSW treatment options

Landfill

Even though landfilling of MSW is commonly practiced in India, arrangements for the collection and utilization of landfill gas (LFG) are missing. If the gas is collected in a scientific and systematic manner, it could turn into an asset by being a fuel source, as identified by the International Energy Agency’s study on the Methane Utilisation Potential in India (The International Energy Agency (IEA) 2008). This exergy analysis is for the situation where LFG is collected and converted into electricity. The volumetric/mass flow rate of all the constituents of the LFG is determined using the Landfill Air Emissions Estimation model developed by USEPA (US EPA 1985; Wang et al. 2013), and the details are given in "Approch" section of the supporting information.

Estimating the exergy efficiency of the technologies used for the conversion of MSW, the quantity of electricity generated is multiplied by its exergy factor. Since electricity can be converted completely into work with no loss, its exergy factor is 1 (Gohlke 2009). The feed of 7500 tonnes MSW is considered to be available at the inlet of the dryer at the reference temperature of 298.16 K and atmospheric pressure.

Exergy efficiency for the landfilling option is evaluated based on estimated exergy content of MSW feed, landfill gas, and generated electricity. This exergy efficiency for Mumbai city was estimated to be 0.82%.

Incineration

Disadvantages of landfilling such as threat of groundwater pollution from landfill leachate, scarcity of land for landfill, and health and environmental problems associated with open dumping have directed attention towards modern incineration of waste with adequate flue gas and fly ash cleaning units. The flue gas from incineration has excess heat, which is further utilized to generate electricity. CO2, N2, O2, and water vapour are the major components of the flue gas. There are other constituents of flue gas like SOx, NOx whose concentration varies depending on the operating conditions (Ricaud 2011). The residue ash after combustion of MSW in the incinerator also contains harmful solids in the form of heavy metals, which need to be treated and recovered from ash before it is exposed to the environment. Incineration of MSW can result in mercury emissions, exposure to which can cause severe health and environmental impact (Hu 2010). Globally, waste disposal, primarily from incineration, contributes to about 8% of the total anthropogenic mercury emissions (Hu 2010). Table 2 represents the exergy associated with the flue gases from incineration. Generally, the exergy flow analysis is represented using a Grassmann diagram, which gives an overview of the actual exergy flow and losses in the process. The thickness of each stream in this diagram is proportional to the exergy associated with the respective stream (Zvolinschi et al. 2007). It shows the location of irreversibilities and helps in identifying potential opportunities for improvement (Sciubba 2008). Based on a detailed exergy analysis of an MSW incineration process, the exergy associated with the various streams is estimated and shown in the Grassmann diagram in Fig. 1. Different colours are used to represent the exergy flows, with exergy losses shown in red. This analysis shows that largest losses occur across the incinerator. This may be attributed to the entropy generation by the highly irreversible combustion process.

Plasma gasification

For plasma gasification, it was assumed that the total organic carbon present in the feed MSW gets completely converted to CO and CO2 and no unburned carbon remains after gasification in the plasma furnace. The initial moisture content in MSW fed to the plasma furnace after drying, temperature range of the syngas (CO, H2, CO2,) produced, and quantity of electric energy supplied to the plasma furnace for generating plasma gas between electrodes are based on the published literature (Mountouris et al. 2008; Ducharme 2010). Electric energy consumption was considered to be 185 kWh/ton (Ducharme 2010). The plasma furnace is operated with a supply of electricity obtained from the generation of plasma gas, and in this case it was assumed that air is heated and elevated to the plasma state. Exergy was estimated for the flows across each of the unit operations in the process of plasma gasification of MSW using material and thermodynamic data, as described in "Cost analysis" section of the supporting information. Table 3 represents the exergy associated with the flue gases from plasma gasification. The MSW initially contains 68% moisture, but such high moisture content is not suitable for plasma process. The dried MSW with permissible moisture content of up to 26% is fed to the plasma furnace at atmospheric temperature and pressure. The furnace is supplied with electricity to generate the plasma gas by passing electric current through specially designed electrodes. The gas that is introduced between the electrodes for forming plasma can be oxygen, helium, etc., but mostly air is used as gas input to plasma furnace, since it is most economical (Mountouris et al. 2006). Here it is assumed that gasification reaches equilibrium. All the CH4 formed further gets converted to CO2.

From the known values of volumetric/molar composition of the syngas and total moles of syngas, the kmoles of each constituent have been estimated and the values are tabulated in Table S8 in supporting information. Material and exergy flow across the other unit operation of the plasma gasification process of MSW has been estimated and the details are given in "Cost analysis" section of supporting information. Exergy associated with the various streams was estimated and shown in the Grassmann diagram in Fig. 2

Considering the reactions mentioned in supporting information that are most likely to occur in plasma gasification of MSW, the quantity of the syngas and its composition were estimated. These quantities were also used in the exergy analysis of the incineration process, and the quantity of heat energy emitted from the plasma gasification of MSW was estimated as tabulated in Table S9 of the supporting information. Thermodynamic properties of the various constituent gases after incineration are available from (Yaws 1999). Assuming the use of combined cycle operation, i.e. steam turbine followed by gas turbine for electricity generation from the syngas obtained, whose efficiency is 45.5% (Ameri et al. 2008). The total electricity produced from plasma gasification of 7500 tonnes/day of MSW is estimated as 227.29 (MW).

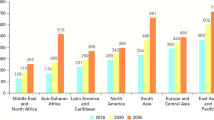

Since electricity is supplied to the plasma furnace for the gasification of MSW, and for the drying operation, we need to subtract the exergy associated with electricity supplied from the total electricity produced. The net electricity generated from the plasma gasification of 7500 tonnes of MSW was estimated to be 202.73 MW. From the known values of electricity produced and exergy of MSW input, the exergy efficiency was estimated to be 21.92%. From the analysis of the exergy flow across all flows of plasma gasification process of MSW conversion, the magnitude and location of the exergy losses were identified. The maximum exergy loss was found to be across the plasma furnace and turbine. The exergy efficiency for the thermal conversion process and particularly for the plasma gasification process was examined with respect to change in carbon fraction in the feed MSW. It was observed that the exergy efficiency is roughly linearly proportional to the organic carbon content of the feed MSW. Figure 3 shows the change in exergy efficiency with respect to carbon content in MSW. Based on the elemental composition of the MSW mentioned in Table 1, the exergy efficiency for the MSW conversion to electricity by plasma gasification process was found to be 21.9%. Using this approach, exergy efficiency of waste from various other cities in India was calculated based on their composition given in Table S11. The results summarized in Fig. 4 show that some cities such as Ahmedabad, Nagpur, and Visakhapatanam can have higher exergy conversion efficiency (in the range of 25%). Lower exergy conversion efficiency could be attributed to higher percentage of moisture and/or lower organic carbon content in the MSW. Cities having higher exergy conversion potential can be considered as candidates for thermal treatment options like incineration and plasma gasification.

Cost analysis

Many studies have focused on the techno-economic aspects of the MSW treatment process for various societies (Singh et al. 2009). Some studies have also been reported on the economics of MSW management in Indian context (Yedla and Kansal 2003). Here we shed light on the economic aspects of the MSW treatment options for Mumbai city, particularly for landfill, incineration, and plasma gasification options, while accounting for all the fixed and working capital expenses. Cost associated with the containers and transportation vehicles was referred from a study on economic aspects of MSW management in Mumbai (Yedla and Kansal 2003). For landfill process, it was assumed that the landfill gas gets scientifically collected and it is further converted to electricity. The plant life for all three options (landfill, incineration, and plasma gasification) was assumed to be 20 years. The details of the cost analysis calculation are given in supporting information. Table S13 in supporting information summarizes the cost associated with the treatment of MSW in Mumbai using landfilling.

Table 4 gives the gross comparison of the three technologies based on their input and output flows. It shows that even though the plasma gasification technology consumes electricity for its operation, it has highest conversion potential as the net electricity generation from this technology is larger than that from incineration and landfill.

Overall comparison of the three technologies considered for the treatment of MSW in Mumbai is in Table 5. It shows plasma gasification has higher exergy conversion efficiency compared to landfill and incineration. Total capital investment for the plasma gasification is marginally high, but it may be recovered with revenue from carbon credit cost and higher tipping fees. A significant hurdle in adopting this technology is the high fixed capital cost.

Outlook

Wasteful use of resources encouraged by economic growth and changing lifestyles is resulting in generation of massive quantities of MSW in urban areas of developing countries. An alarming situation has been reached for many developing cities due to most dumping sites becoming overloaded, and municipal corporations being unable to upgrade the facilities required to handle the increasing quantities of the generated MSW (Dorn et al. 2012). In addition to running out of landfill space, health and environmental concerns with MSW management are major challenges all over the globe, particularly in megacities of developing countries. Choosing appropriate strategies can benefit from the use of systematic methods for assessing technological, economic, and ecological aspects of available alternatives. In addition, such studies conducted in cities of developed countries located in temperate climates are often not useful for cities in developing countries and tropical climates.

The thermodynamic and economic assessment of MSW treatment options in Mumbai city conducted in this work shows that in the Indian context, among the thermal conversion treatment processes, thermodynamic conversion potential for plasma gasification is higher making it more efficient than incineration for converting MSW to electricity. Plasma gasification gives a higher output in power generation and exhibits much lower levels of environmental emissions. This technology is also attractive since it can handle unsegregated waste, which is the nature of waste in most developing countries. This work shows that exergetic efficiency of conversion of the thermal treatment processes is strongly dependent on composition of the MSW. Based on economic assessment, it can be inferred that gasification has the highest profit per rupee invested among the methods considered. However, the high capital cost of incineration and plasma gasification presents a challenge in their adoption in a developing country like India, particularly with the current lack of segregation and collection facilities. Existing approaches such as landfilling or incineration are also not desirable due to requirement for large land area and undesirable emissions.

What is needed for developing societies like those in India’s cities that do not have sufficient infrastructure and governance to deal with large quantities of waste is a system of waste minimization through recycling, reuse, and industrial symbiosis that converts the waste to some useful form. Systems like those used in The Netherlands, where they employ a combination of recycling, composting, and incineration in such a fashion that a minimum quantity of waste ends up in landfill (Annepu 2012), may be considered for adoption in Mumbai. If manufacturers are required to share the responsibility of the disposal of their products that would also encourage innovation that would result in waste reduction. It would also discourage manufacturers from using packaging material that is difficult to reuse or recycle. This requires societal and corporate acceptance that the role of producers does not end simply after handing over the products to retailers or the end-use consumers.

One advantage in developing countries is that most items that can be recycled get recycled. However, with increasing waste generation, it may become necessary to start charging households per unit of waste generated. Customer incentive schemes to return containers made from items such as plastics, glass, and metal after their use may enhance the collection, reuse, and recycle of materials more effective. Quantity of waste handed over to the municipal corporation per household could be limited by regulation or economic disincentives. Ultimately, what is needed is reducing the generation of waste, segregation of generated waste, and selection of disposal method according to the type of waste by best suited and thermodynamically, economically, and environmentally sustainable means of disposal. All of these may collectively help to deal with MSWM in a more technologically and environmentally feasible manner.

References

Ameri M, Ahmadi P, Khanmohammadi S (2008) Exergy analysis of a 420 MW combined cycle power plant. Int J Energy Res 32:175–183. doi:10.1002/er.1351

Annepu RK (2012) Sustainable solid waste management in India. Thesis Earth Engineering Center, Columbia University, New York

Ayres R (2003) Exergy, power and work in the US economy, 1900–1998. Energy 28:219–273. doi:10.1016/S0360-5442(02)00089-0

Ayres RU, Talens Peiró L, Villalba Méndez G (2011) Exergy efficiency in industry: Where do we stand? Environ Sci Technol 45:10634–10641. doi:10.1021/es202193u

Byun Y, Namkung W, Cho M et al (2010) Demonstration of thermal plasma gasification/vitrification for municipal solid waste treatment. Environ Sci Technol 44:6680–6684. doi:10.1021/es101244u

Byun Y, Cho M, Chung JW et al (2011) Hydrogen recovery from the thermal plasma gasification of solid waste. J Hazard Mater 190:317–323. doi:10.1016/j.jhazmat.2011.03.052

Chattopadhyay S, Dutta A, Ray S (2009) Municipal solid waste management in Kolkata, India—a review. Waste Manag 29:1449–1458. doi:10.1016/j.wasman.2008.08.030

Dai J, Chen B, Sciubba E (2014) Ecological accounting based on extended exergy: a sustainability perspective. Environ Sci Technol 48:9826–9833. doi:10.1021/es404191v

Dorn T, Flamme S, Nelles M (2012) A review of energy recovery from waste in China. Waste Manag Res J Int Solid Wastes Public Clean Assoc ISWA 30:432–441. doi:10.1177/0734242X11433530

Ducharme C (2010) Technical and economic analysis of Plasma-assisted Waste-to-Energy processes. Research Paper I. School of Engineering and Applied Science, Columbia University

Eriksson O, Reich MC, Frostell B, Bjo A (2005) Municipal solid waste management from a systems perspective. J Clean Prod 13:241–252. doi:10.1016/j.jclepro.2004.02.018

Galeno G, Minutillo M, Perna A (2011) From waste to electricity through integrated plasma gasification/fuel cell (IPGFC) system. Int J Hydrog Energy 36:1692–1701. doi:10.1016/j.ijhydene.2010.11.008

Gohlke O (2009) Efficiency of energy recovery from municipal solid waste and the resultant effect on the greenhouse gas balance. Waste Manag Res 27:894–906. doi:10.1177/0734242X09349857

Hlina M, Hrabovsky M, Kavka T, Konrad M (2014) Production of high quality syngas from argon/water plasma gasification of biomass and waste. Waste Manag 34:63–66. doi:10.1016/j.wasman.2013.09.018

Hu Y (2010) China needs to control mercury emissions from municipal solid waste (MSW) incineration. Environ Sci Technol 44:7994–7995

Janajreh I, Raza SS, Valmundsson AS (2013) Plasma gasification process: modeling, simulation and comparison with conventional air gasification. Energy Convers Manag 65:801–809. doi:10.1016/j.enconman.2012.03.010

Joshi AS, Dincer I, Reddy BV (2009) Thermodynamic assessment of photovoltaic systems. Sol Energy 83:1139–1149. doi:10.1016/j.solener.2009.01.011

Kalinci Y, Hepbasli A, Dincer I (2011) Exergoeconomic analysis of hydrogen production from plasma gasification of sewage sludge using specific exergy cost method. Int J Hydrog Energy 36:11408–11417. doi:10.1016/j.ijhydene.2010.11.124

Langenhove HRVAN (2002) Quantitative assessment of solid waste treatment systems in the industrial ecology perspective by exergy analysis. Environ Sci Technol 36:1130–1135

Morrin S, Lettieri P, Chapman C, Mazzei L (2012) Two stage fluid bed-plasma gasification process for solid waste valorisation: technical review and preliminary thermodynamic modelling of sulphur emissions. Waste Manag 32:676–684. doi:10.1016/j.wasman.2011.08.020

Morris DR, Szargut J (1986) Standard chemical exergy of some elements and compounds on the planet earth. Energy 11:733–755. doi:10.1016/0360-5442(86)90013-7

Mountouris A, Voutsas E, Tassios D (2006) Solid waste plasma gasification: equilibrium model development and exergy analysis. Energy Convers Manag 47:1723–1737. doi:10.1016/j.enconman.2005.10.015

Mountouris A, Voutsas E, Tassios D (2008) Plasma gasification of sewage sludge: process development and energy optimization. Energy Convers Manag 49:2264–2271. doi:10.1016/j.enconman.2008.01.025

Moustakas K, Fatta D, Malamis S et al (2005) Demonstration plasma gasification/vitrification system for effective hazardous waste treatment. J Hazard Mater 123:120–126. doi:10.1016/j.jhazmat.2005.03.038

Murphy JD, Mckeogh E (2004) Technical, economic and environmental analysis of energy production from municipal solid waste. Renew Energy 29:1043–1057. doi:10.1016/j.renene.2003.12.002

Rathi S (2007) Optimization model for integrated municipal solid waste management in Mumbai, India. Environ Dev Econ 12:105–121

Ricaud A (2011) Practical and economic viability of small scale Energy-from-Waste. Thesis Imperial College London

Rivero RÃ, Garfias M (2006) Standard chemical exergy of elements updated. Energy 31:3310–3326. doi:10.1016/j.energy.2006.03.020

Sciubba E (2008) Critical review exergy: its potential and limitations in environmental science and technology. Environ Sci Technol 42:2221–2232

Sharholy M, Ahmad K (2008) Municipal solid waste management in Indian cities—a review. Waste Manag 28:459–467. doi:10.1016/j.wasman.2007.02.008

Sikka P (2000) Energy from MSW refused derived fuel (RDF) pelletization-a pilot Indian plant. Department of Science & Technology, Government of India

Singh K, Kelly SO, Sastry MKS (2009) Municipal solid waste to energy: an economic and environmental assessment for application in Trinidad and Tobago. J Assoc Prof Eng Trinidad Tobago 38:42–49

Singh RP, Tyagi VV, Allen T et al (2011) An overview for exploring the possibilities of energy generation from municipal solid waste (MSW) in Indian scenario. Renew Sustain Energy Rev 15:4797–4808. doi:10.1016/j.rser.2011.07.071

SWM Cell (2003) Status report on municipal solid waste management. Konkan Division, All India Institute of Local Self Government, Mumbai

The International Energy Agency (IEA) (2008) Turning a liability into an asset: landfill methane utilisation potential

The World Bank (1999) Decision makers’ guide to municipal solid waste incineration. The World Bank Washington, Washington

Tsai W, Kuo K (2010) An analysis of power generation from municipal solid waste (MSW) incineration plants in Taiwan. Energy 35:4824–4830. doi:10.1016/j.energy.2010.09.005

Ukidwe, Nandan (2005) Thermodynamic Input-output LCA of the 1997 U.S. Economy with application to electricity generation. In: AiChE Annual Meeting. pp 13233–13562

US EPA UE (1985) Chapter 2: solid waste disposal, AP 42, Fifth Edition, Volume I. http://www.epa.gov/ttnchie1/ap42/ch02/. Accessed 20 Sept 2014

Vorst GVD, Dewulf J, Aelterman W, Witte BD, Langenhove HV (2011) A systematic evaluation of the resource consumption of active pharmaceutical ingredient production at three different levels. Environ Sci Technol 45:3040–3046

Wang X, Nagpure AS, Decarolis JF, Barlaz MA (2013) Using observed data to improve estimated methane collection from select U.S. Landfills. Environ Sci Technol 47:3251–3257

Yaws C (1999) Chemical properties handbook. McGraw-Hill, New York

Yedla S, Kansal S (2003) Economic insight into municipal solid waste management in Mumbai: a critical analysis. Int J Environ Pollut 19:516–527

Zhou C, Hu D, Wang R, Liu J (2011) Exergetic assessment of municipal solid waste management system in south Beijing. Exol Complex 8:171–176. doi:10.1016/j.ecocom.2011.01.006

Zhu D, Ansani P, Anapolsky S, Mani S (2008) Improving municipal solid waste management in India. The World Bank Washington, Washington

Zvolinschi A, Kjelstrup S, Bolland O, van der Kooi HJ (2007) Exergy sustainability indicators as a tool in industrial ecology. J Ind Ecol 11:85–98. doi:10.1162/jiec.2007.1142

Acknowledgements

Partial financial support was provided by the University Grants Commission, Government of India.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jadhao, S.B., Shingade, S.G., Pandit, A.B. et al. Bury, burn, or gasify: assessing municipal solid waste management options in Indian megacities by exergy analysis. Clean Techn Environ Policy 19, 1403–1412 (2017). https://doi.org/10.1007/s10098-017-1338-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-017-1338-9