Abstract

Several researchers have proved that agricultural by-products constitute good adsorbents for removing heavy metals from aqueous solution. However, few investigations have identified efficient strategies for the adsorbent′s regeneration. Hence, a global methodology for the removal of copper and nickel metals from wastewater including metal biosorption, thermal treatment and residual ash landfill is proposed. In order to validate this strategy, olive solid waste (OSW), provided by an olive oil mill from Tunisia, were used to remove copper and nickel on batch experiments. Copper and nickel were adsorbed on a monolayer of OSW surface with maximal adsorption capacity (q max) of 3.6 and 1.7 mg g−1, respectively. Contaminated OSW with copper and nickel were combusted at 850 °C in an electrical furnace. About 96 % of each metal was recovered in residual ashes that present a good secondary raw material for copper and nickel production. Low leaching transfers (≤4 %) were observed for copper and nickel from residual ashes leading to the possibility to be landfilled. Therefore, the suggested process can be used as an alternative to the classical technologies for effluent decontamination.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Discharge of untreated industrial effluents containing heavy metals is hazardous to the environment as they are toxic and their removal is highly essential for the purpose of protecting the environment and human health. Several methods, such as chemical precipitation, membrane filtration, ion exchange and adsorption are used for the removal of heavy metals from wastewaters and well described in literature (Demirbas et al. 2004; Khan et al. 2004). It is quite well know that granular activated carbon (GAC) is useful and, as a matter of fact, is recommended by the US EPA as the best available technology to remove contaminants from water and air by adsorption with higher efficiency (Veglio and Beolchini 1997; Xie et al. 2013).

In developing countries such as China, India, Malaysia, and Pakistan, the need to use low cost materials in treatment processes and operations of contaminated air and water are increasing. However, GAC technology is relatively expensive for developing countries. For this reason, cheaper and non-conventional agricultural wastes were firstly used and well described for the synthesis of activated carbon (El-Ashtoukhy et al. 2008). More recently, alternative materials from plants, such as rice (Oryza sativa), leaves of neem (Azadirachta indica), and banana peels present good adsorption capacity for the removal of minerals (metals and ammonium) from industrial and municipal wastewaters (Ang et al. 2013; Athar et al. 2013; Chen et al. 2013). New materials like nanocellulose fibers from rice straw are now developed in order to improve the adsorption capacity of heavy metals as cadmium, nickel, or lead (Kardam et al. 2013). The use of solid residues of olive mill products as bio-sorbents are in progress (Baccar et al. 2009; Hodaifa et al. 2013). This material is largely available from olive mills and could represent a good economic added value (Gharaibeh et al. 1998). Adsorption of heavy metal could be reasonably effective considering the olive solid waste composition. The plant cell wall is a macromolecular matrix that consists of different kinds of polymer chains packed together in a three dimensional structure. Olive solid waste (OSW) consists of fiber (as cellulose), lignin, and uronic acids along with oily wastes and polyphenolic compounds (Saviozzi et al. 1993). This complex matrix contains numerous fixed polyvalent functional groups (such as carboxylic, hydroxylic, and methoxy groups) and a high amount of fixed anionic and cationic functional groups. This particular composition enables olive solid waste to bind metallic ions in solutions by different mechanisms: complexation, chelation, physical adsorption, ion exchange, and electrostatic interaction (Veglio and Beolchini 1997). OSW loaded with metals are actually regenerated and reused in different cycles using ionic and acid extracting agents (Pagnanelli et al. 2002).

If biosorption capacity of several new materials from agricultural residues is now-a-days effective with determination optima adsorption parameters and kinetic and thermodynamic models, few studies are focused on the behavior of the contaminated biomass obtained after adsorption processes. The reuse of the contaminated biomass is a very important point of view for two main reasons. Development of cost-effective biomaterials is an economic challenge. Desorption phenomenon was investigated in some cases. Kardam et al. obtained with success a three-cycle regeneration of nanocellulose fibers for Cd, Ni, and Pb removal from aqueous solutions (Kardam et al. 2013). The behavior of metals accumulated in biomass after adsorption may be now-a-days solved in order to reduce impacts of the environment. For example, Aravindhan has recently proposed the reuse of chromium(III) as reductant in the manufacture of chromium sulfate from contaminated dead biomass of Bacillus subtilis (Aravindhan et al. 2012).

After adsorption and regards to European Regulation, contaminated OSW must be defined as hazardous waste depending of their residual concentration of metals (European decision. 2000). Their reuse may be solved and the present study proposes an original solution. Because OSW presents high heating value of 19,500 kJ kg−1 close to those found for conventional biomasses, the novelty would be the energy recovery of contaminated biomass during incineration process (Chouchene et al. 2010). If this solution would efficiently reduce the volume, some environmental points related to air regulations must be controlled. During incineration, the behavior of metals is an important point of view. Metal transfer to the exhaust must be avoided and metals must be recovered in bottom ashes. Incineration defined as a combustion process is the best solution for contaminated OSW because high flues gas treatment technologies are imposed by regulations in order to control and minimize contaminant transfer to the exhaust (Laitinen 2007; Ohlstrom and Makkonen 2007). In addition, the potential release of metals to the environment is normally evaluated using standardized water leaching tests together with analysis of the elemental composition of the ash related to disposal regulations (European Standard EN NF EN X31-210 1992).

Our original investigation focuses on two heavy metals, copper and nickel commonly found in runoff or industrial waste such as electroplating, printed circuit board, wire drawing and chemical materials industries. The discharge of these metals into receiving waters is detrimental to human health and the environment. The present paper deals with the removal of these two metals from aqueous solutions using olive solid waste as-received. Hence, it aims to determinate biosorption kinetics and isotherms by varying parameters of metal ions concentration, contact time and temperature. The main objective of this research is to concentrate these metal ions in ashes by the combustion of contaminated OSW at high temperature (850 °C) close to the minimal temperature found in an industrial incinerator. The last point is to test the mobility of copper and nickel from residual ashes to environment using the water as reagent. According to European regulations, their criteria mobility in the Environment will impose the choice of landfills require for their disposal (Council decision of the 19 December 2002).

Experimental

Materials and reagents

OSW was provided by an olive oil mill in Mahdia, Tunisia. It was dried in the sun in order to get humidity below to 10 %. OSW was grounded and sieved. The size fraction with particle diameter (d) between 1 and 1.6 mm. Metal solutions were prepared by dissolving appropriate amounts of Cu (NO3)2 and N2NiO6·6H2O in distilled water.

Batch adsorption experiments

Batch experiments were carried out in a glass beaker by shaking a fixed mass of olive solid waste (1 < d < 1.6 mm), with a fixed metal concentration, according to selected experimental condition at 500 rpm. In these one-cycle biosorption experiments, initial pH was around 5.5. After agitation, the solid was removed by filtration through a fritted filter. Different contact times were studied between 30 and 180 min in order to study the influence of this parameter. Final metal concentrations in the filtrates as well as in the initial solution were determined by flame atomic absorption spectroscopy (FAAS) using a Varian Absorption Spectrometer. Sorbed metal concentrations were obtained from the difference after equilibrium, amount of metal (Cu or Ni) ions retained on the solid sorbent was determined from the difference between the absorbance of the metal ion before (C 0) and (C eq) after shaking with OSW. Biosorption percentage (%E) was then determined employing the following Eq. (1):

Amount of metal ion sorbed per mass of adsorbent at equilibrium (q e, mg g−1) was calculated from the standard following Eq. (2):

where C 0 and C eq are the initial and final metal concentrations expressed in mg L−1,

V, the solution volume in L and W, the mass of the sorbent solid in g.

Various parameters such as contact time, initial concentration, and temperature were examined to determine the biosorption mechanism.

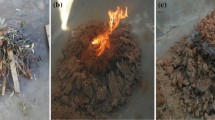

Contaminated OSW combustion

Contaminated OSW by copper and nickel at initial concentration of 40 mg L−1 were dried and burnt in an oven at 850 °C for 45 min. In order to control the amount of each metal recovered in the ashes, a microwave mineralization by acid digestion of the contaminated biomass and the residual ashes obtained during the thermal treatment was performed.

Leaching tests

Leaching tests were performed on residual ashes from combustion tests of contaminated OSW. They were carried out with a batch leaching procedure according to the French standard (European Standard EN NF EN X31-210 1992) with a liquid ratio of 10 L kg−1. Experiments were done with 1 g of each ash in 10 mL of deionised water. Solutions were shacked for 24 h at 120 rpm with 4 h stand-off at the night. After each experiment, the water phase was filtered through a 0.45 μm filter using a vacuum filtration device. Finally, all filtrates were analyzed for their levels of copper and nickel using flame atomic absorption spectroscopy (AAS).

Results and discussion

Biosorption performance

The removal of copper and nickel from aqueous solution was examined for an initial metal concentration of 40 mg L−1 at different contact time. Figure 1 reveals that both metals removal seems to occur in two steps. The first step shows a rapid metal uptake for the first 30 min, while the second step is characterized by a slow metal removal until reaches equilibrium. Indeed, 58 % of the copper was removed by olive solid waste after 30 min while 38.1 % of the nickel was removed after the same contact time. Hence, it can be concluded that olive solid waste has a better affinity to copper compared to nickel. The first rapid step is probably due to the abundant availability of active sites on the material, and with the gradual occupancy of these sites, biosorption becomes less efficient in slower step. Based on the results shown in Fig. 1, a shaking time of 120 min was assumed to be suitable for subsequent biosorption experiments.

The effect of temperature on the copper and nickel biosorption on OSW was investigated. Figure 2 shows that the maximum biosorption capacity is slightly altered with changes in temperature. In fact, biosorption capacities for both metals decrease with increasing temperature. Adsorption capacity decreases from 2.7 to 2.23 mg g−1 for Cu(II) and from 1.7 to 1.46 mg g−1 for Ni(II). This result is an agreement with literature (Serpaud et al. 1994). These authors have studied the adsorption of Cu, Cd, Zn, and Pb by surface sediment in a small stream polluted by the industrial drain of electro-refinery. They noted the importance of some experimental parameters such as pH, sediment concentration, and temperature. In particular, they have observed that an increase of temperature decreases the adsorption of metal due to exothermic character of the adsorption phenomena.

Biosorption kinetics

Biosorption kinetics, expressed in terms of rate of solute removal, that control residence time of the sorbate in the solid-solution interface, is one of the most important aspects of the operation defining the efficiency of the process. It is necessary from the standpoint of treatment plant design to predict the rate at which the pollutant is removed from the aqueous solution. To reach our purpose, a pseudo-second-order equation was applied to analyze batch experiments at different temperature (20, 30, 40, and 60 °C). Several authors also used the pseudo-second order equations to determine biosorption kinetics in divalent metal ions using different biosorbent materials (Ho et al. 2004; Fiol et al. 2006; Hawari et al. 2009). The rate equation for the reaction may be represented by the following expression (3):

where k is the biosorption rate constant (g mg−1 min−1), q e the amount of metal ion sorbed in the equilibrium (g mg−1), and q t is the amount of metal ion on the sorbent surface at any time t (g mg−1).

By separating variables and integrating the equation at the limits, t = 0, q t = 0 and t = t, q t = q t; the following expression (4) is obtained:

Equation (4) is rearranged to obtain the flowing linear form (5):

By plotting t/q t versus t, values for k, q e and the product kq 2e (which represents the rate of the initial biosorption) can be determined. Figure 3 presents plots of t/q t versus time for the copper adsorption at different temperatures for initial concentration of metal at 40 mg L−1. Similar experiments were also performed for Nickel. Plots of t/q t for both metals are linear indicating that process follows the pseudo-second order rate equation.

Kinetic parameters at different temperatures are presented in Table 1. The obtained values for coefficient of determination (R 2) are more than 0.98 which indicates that the second-order kinetic model describes well the removal of copper and nickel using olive solid waste as an adsorbent.

As mentioned in Table 1, the biosorption rate k rises with temperature for copper and nickel. However, the maximum biosorption capacity tends to decrease with the temperature. Moreover, copper adsorption rates are higher compared to nickel ones. Similar results were found by Fiol et al. for the adsorption of nickel and copper by olive stones with the same initial concentration of 40 mg L−1 (Fiol et al. 2006). Hence, OSW have higher biosorption affinity to copper than nickel when temperature increases.

In order to determine biosorption nature of both metals, activation energy E a, was calculated from an Arrhenius plot. The Arrhenius equation was given by the following Eq. (6):

where, k biosorption rate (g mg−1 min−1), E a Activation energy (J mol−1), A pre-exponential factor (s−1), and R gas constant (J mol−1 K−1).

Arrhenius plots for both copper and nickel are given in Fig. 4.

The calculated activation energy E a, for copper and nickel were 36 kJ mol−1 and 26 kJ mol−1, , respectively. Some of the assigned values of E a (kJ mol−1) include 8–25 to physical adsorption, 20–40 to pore diffusion and greater than 84 to ion exchange (Ayoob et al. 2008). The obtained values of activation energy in this study showed that nickel and copper biosorption are a physical nature and pore diffusion-controlled in the rate-limiting processes according to Ayoob et al.

Likewise, Nuhoglu and Malkoc were found that nickel adsorption on washed olive solid waste with lower particle size diameters (0.15 < d < 0.25 mm) was physical nature (Nuhoglu and Malkoc 2009). Copper and nickel adsorption are established by weak forces bonding in our tests experiments.

Biosorption isotherms

Adsorption capacity of the Cu(II) and Ni(II) ions was studied as a function of the initial concentration of metallic ions (20, 40, 60, 100, and 150 mg L−1) at 20 °C. Figure 5 presents the obtained copper and nickel biosorption isotherms. It is seen that adsorption capacity increases with initial concentration of the solution and reaches a plateau for the highest concentrations.

Higher capacity is observed for copper than nickel with maxima values at 3.6 and 1.5 mg g−1, respectively. Value for copper is very close to this found by Blazquez with Spanish olive stone (Blazquez et al. 2011). Adsorption of nickel on waste olive pomace was studied by Nuhoglu and Malkoc (2009). They obtained a maximum value of 10.6 mg g−1 for nickel at pH 5 and 25 °C. This difference is attributed to the particle size of olive waste pomace that plays a major role in the adsorption process. With smaller particle sizes (0.15 < d < 0.25 mm), Nuhoglu significantly increased the adsorption capacity in aqueous solution. The BET surface area of his adsorbent was five time higher than (1.24 m2 g−1) our sieved OSW sample (0.252 m2 g−1).

Adsorption equilibrium data for Cu and Ni metals were fitted by the non-competitive Langmuir model from the following Eq. (7):

where q is the amount of metal adsorbed (mg g−1), q max is the maximum metal uptaken per unit mass of sorbent (mg g−1), C eq is the equilibrium concentration of sorbate in solution (mg L−1), and b is the Langmuir constant related to energy of biosorption (L mg−1) which reflects quantitatively the affinity between the sorbent and the sorbate.

The linear form of the Langmuir adsorption isotherm is represented by the Eq. (8):

The values of q max and b were calculated from the slope and intercept of the Langmuir plot of C eq versus C eq/q e.

The biosorption equilibrium data were also fitted by Freundlich isotherm model according to the following Eq. (9):

where K F and 1/n F are empirical constants indicating biosorption capacity and biosorption intensity, respectively.

The applicability of Freundlich model was also analyzed by plotting ln(q e) versus ln(C e) with q e and C e expressed in mg g−1 and mg L−1, respectively. The constants n F and K F can be determined from the slope and intercept, respectively.

The obtained Langmuir and Freundlich parameters for both metals biosorption are presented in Table 2.

According to the coefficient of correlation obtained, the model of Langmuir well correlates the experimental data for both metals. Therefore, the adsorption of each studied metal occurs on a homogeneous surface by monolayer biosorption with a finite number of active sites without interaction between adsorbed molecules. In addition, there are uniform energies of adsorption onto the surface and no transmigration of the adsorbate (Tiwari et al. 1995).

When comparing the maximal adsorption capacities of OSW, copper has the highest q max than nickel. Hence, OSW has a better affinity to copper than for nickel. Similar results were obtained by (Fiol et al. 2006). They found that the relative affinity order of olive stones with smaller diameter between 0.75 and 1.5 mm, on the basis of b values, was Cu>Ni>Pb>Cd at 20 °C.

The comparison of the regression coefficient values from the Langmiur model with these of Freundlich model revealed that Langmiur model has a better fitting model than Freundlich model as the former has a higher correlation regression coefficient than the later. This indicates a monolayer of copper or nickel ions adsorbed on OSW surface. Therefore, maximal adsorption capacities indicate the metal ions order in the monolayer, copper > nickel.

Metal balance after contaminated OSW combustion

To calculate the balance of metallic element recovered in ash and volatilized part, levels of both copper and nickel in contaminated OSW and in residual ashes after combustion at 850 °C were determined.

Both experiments were carried out with metal initial concentration of 40 mg L−1, following the general metal uptake procedure described above. The analytical results obtained for these samples are given in Table 3. Both amounts of copper and nickel recovered in ashes are quite close to that captured by OSW during contamination process with a recovery value of 96 %. Reddy et al. have obtained similar result during decontamination of water solutions containing copper by India barks. They recovered 83 % of copper under CuO specie in the residual ashes after thermal treatment by thermogravimetric analysis at 1,000 °C (Reddy et al. 1997). Metal behaviors in combustion systems and particularly during waste combustion processes and coal-fired power plants are well described since the end of the seventeen’s (Klein et al. 1975). Theoretical studies at thermodynamic equilibrium demonstrated that the presence of chlorine in a lot of wastes (municipal and industrial) is one of the best parameter that allows the volatility of some metals (Wu and Biswas 1993; Trouvé et al. 1998). Chloride species are mainly volatilized at high temperatures instead of oxides. Copper and nickel contained in organic matrixes (municipal waste and coal) are slightly transferred in fly ashes during combustion whatever the presence of chlorine (Klein et al. 1975; Fernandez et al. 1992) with their oxide forms dominating. CuO and NiO are very stable species at high temperatures. These two metals are poorly vaporized in these our experiments according to literature data. Combustion of contaminated OSW would be an efficient solution to concentrate metallic elements in ashes. As suggested by Reddy et al., these ashes could be as secondary raw material for copper and nickel production.

Metal balance after leaching tests of residual ashes

One of the last and drastic solution concerns the disposal of ashes in landfill. To control the release of these components (copper and nickel) to the environment, experiments were carried out according to standardized water leaching tests EN NF X31-210. The amount of water-soluble metal species obtained from ashes were determined by using AAS. Results are given in Table 4.

Copper and nickel were released as traces into the water phase. These results show that nickel and copper are not easily solubilized and transferred to the natural environment. Their leaching values are lower than limits imposed by the European council decision for the landfill of non-hazardous waste (Council decision of the 19 december 2002). Cu and Ni exist in ashes under insoluble chemical forms in water, which is in good agreement with other published results. Karlfeldt et al. have found that the leaching behavior of an element does not only depend on the speciation of the element itself, but also on the matrix of the material. For example, a very important factor for the leaching behavior of a specific element is whether it is mainly present inside the particle or on the surface (Karlfeldt and Steenari 2007). Moreover, Fujimori et al. have revealed that copper was found on the surfaces of the ash particles whereas nickel was found inside the particles and on the surfaces (Fujimori et al. 2002). Encapsulation of the metal species inside ash particles could explain some of the low-leaching behaviors found in the present study. However, more data is needed to obtain a general picture of how the metals are distributed in and on ash particles and to clarify the mechanisms leading to these distributions (Fujimori et al. 2002).

The presence of copper and nickel in leaching solutions represents 4.5 and 4.2 % of the initial content in contaminated OSW. It is important to report that the initial amounts of copper and nickel in OSW were found were 100 % between ashes and leachates. These differences are probably due to relative errors.

Conclusion

Performance of the removal of copper and nickel from aqueous solutions by olive solid waste was studied at laboratory scale. An important point of view of this study focused on environmental solutions for residual contaminated OSW. Energy recovery by combustion at high temperature was studied and metal contents in ashes and their leaching behavior were determined.

OSW has biosorption affinity to copper and nickel. The experimental data were well fitted by the second-order kinetic model. Langmuir isotherm better fitted the experimental data since the correlation coefficients for Langmuir isotherm was higher than the Freundlich isotherm for both metals. Copper and nickel were adsorbed in monolayer on the surfaces of OSW. Based on maximal adsorption capacities (q max), OSW has a higher affinity to copper than nickel.

The incineration of contaminated OSW may be an environmentally acceptable solution for elimination of wastes generated during the decontamination of industrial effluents. Transfer to the exhaust should be reduced at minima due to both new abatement technologies in the flue gas treatment (electrostatic precipitators) and the high amounts of Cu and Ni remained in residual ashes (Laitinen. 2007; Ohlstrom and Makkonen 2007). Residual ashes leaching experiments showed that amounts of copper or nickel under water-soluble forms are low. Therefore, this pollution would not be transferred to the environment in case of landfill requirement.

Incineration process of contaminated OSW appears to be a convenient solution for the remediation of these two metals. Metal trapping in the ashes revealed that copper and nickel are not volatilized at 850 °C. Because 96 % of metal are remained in ash, acid extraction may be intended to recover both metals in electroplating, circuit board, and wire drawing manufactories. Another investigation seems necessary to determine the speciation of the element itself and the matrix of the ash. This may give useful information about different ways of reuse of copper and nickel.

References

Ang XW, Sethu VS, Andresen JM, Sivakumar M (2013) Copper(II) ion removal from aqueous solutions using biosorption technology: thermodynamic and SEM–EDX studies. Clean Techn Environ Policy 15:401–407

Aravindhan R, Selvamurugan AFM, Rao JR, Balachandran UN (2012) Adsorption, desorption, and kinetic study on Cr(III) removal from aqueous solution using Bacillus subtilis biomass. Clean Techn Environ Policy 14:727–735

Athar M, Farooq U, Ali SZ, Salman M (2013) Insight into the binding of copper(II) by non-toxic biodegradable material (Oryza sativa): effect of modification and interfering ions. Clean Techn Environ Policy. doi:10.1007/s10098-013-0664-9

Ayoob S, Gupta AK, Bhakat PB, Bhat VT (2008) Investigations on the kinetics and mechanisms of sorptive removal of fluoride from water using alumina cement granules. Chem Eng J 140:6–14

Baccar R, Bouzid J, Feki M, Montiel A (2009) Preparation of activated carbon from Tunisian olive-waste cakes and its application for adsorption of heavy metal ions. J Hazar Mat 162:1522–1529

Blazquez G, Martín-Lara MA, Dionisio-Ruiz E, Tenorio G, Calero M (2011) Evaluation and comparison of the biosorption process of copper ions onto olive stone and pine bark. J Indus Eng Chem 17:824–833

Chen YN, Liu CH, Nie JX, Luo XP, Wang DS (2013) Chemical precipitation and biosorption treating landfill leachate to remove ammonium–nitrogen. Clean Techn Environ Policy 15:395–399

Chouchene A, Jeguirim M, Khiari B, Trouvé G, Zagrouba F (2010) Study on the emission mechanism during devolatilization/char oxidation and direct oxidation of olive solid waste in a fixed bed reactor. J Anal Appl Pyrolysis 86:168–174

Council decision of the 19 December 2002 establishing criteria and procedures of waste at landfills

Demirbas E, Kobya M, Senturk E, Ozkan T (2004) Adsorption kinetics for the removal of chromium(VI) from aqueous solutions on the activated carbons prepared from agricultural wastes. Water SA 30:533–540

El-Ashtoukhy Z, Amin ES, Abdelwahab NK (2008) Removal of lead(II) and copper(II) from aqueous solution using pomegranate peel as a new adsorbent. Desalination 223(223):162–173

European Decision 2000/532/CE (2000) Commission decision of 3 May 2000 replacing decision 94/3/EC establishing a list of wastes pursuant to article 1(a) of council directive 75/442/EEC on waste and council decision 94/904/EC establishing a list of hazardous waste pursuant to article 1(4) of council directive 91/689/EEC on hazardous waste

European Standard EN NF EN X31-210 (1992) Déchets—Essais de lixiviation

Fernandez MA, Martinez L, Segarra M, Garcia JC, Espiell F (1992) Behavior of heavy metals in the combustion gases of urban waste incinerators. Environ Sci Technol 26:1040–1047

Fiol N, Villaescusa I, Martinez M, Miralles N, Poch J, Serarols J (2006) Sorption of Pb(II), Ni(II), Cu(II) and Cd(II) from aqueous solution by olive stone waste. Sep Purif Technol 50:132–140

Fujimori E, Shiozawa R, Iwata S, Chiba K, Haraguchi H (2002) Multielement and morphological characterization of industrial waste combustion fly ash as studied by ICP-AES/ICP-MS and SEM–EDS. Bull Chem Soc Jpn 75:1205–1213

Gharaibeh SH, Abu-el-sha’r WY, Al-Kofahi MM (1998) Removal of selected heavy metals from aqueous solutions using processed solid residue of olive mill products. Wat Resea 32:498–502

Hawari A, Rawajfih Z, Nsour N (2009) Equilibrium and thermodynamic analysis of zinc ions adsorption by olive oil mill solid residues. J Hazard Mat 168:1284–1289

Ho YS, Chiu WT, Hsu CS, Huang CT (2004) Sorption of lead ions from aqueous solution using tree fern as a sorbent. Hydrometallurgy 73:55–61

Hodaifa G, Ochando-Pulido JM, Driss Alami SB, Rodriguez-Vives S, Martinez-Ferez A (2013) Kinetic and thermodynamic parameters of iron adsorption onto olive stones. Ind Crops Prod 49:526–534

Kardam A, Raj KR, Srivastava S, Srivastava MM (2013) Nanocellulose fibers for biosorption of cadmium, nickel, and lead ions from aqueous solution. Clean Techn Environ Policy. doi:10.1007/s10098-013-0634-2

Karlfeldt K, Steenari BM (2007) Assessment of metal mobility in MSW combustion ashes using water as the reagent. Fuel 86:1983–1993

Khan NA, Ibrahim S, Subramaniam P (2004) Elimination of heavy metals from wastewater using agricultural wastes as adsorbents. Malays J Sci 23:43–51

Klein DH, Andren AW, Carter JA (1975) Pathways of thirty-seven trace elements through coal-fired power plant. Environ Sci Technol 9:973–979

Laitinen A (2007) Electrostatic precipitators in small scale wood combustion. In: Hytönen K, Jokiniemi J (eds) Reduction of fine particle emissions from residential wood combustion workshop in Kuopio on May 22–23, 2007. University of Kuopio, Kuopio

Nuhoglu Y, Malkoc E (2009) Thermodynamic and kinetic studies for environmentaly friendly Ni(II) biosorption using waste pomace of olive oil factory. Bioresour Technol 100:2375–2380

Ohlstrom M, Makkonen P (2007) Technologies for controlling fine particle emissions. In: Hytönen K, Jokiniemi J (eds) Reduction of fine particle emissions from residential wood combustion, Workshop in Kuopio on May 22–23, 2007. University of Kuopio, Kuopio

Pagnanelli F, Toro L, Veglio F (2002) Olive mill solid residues as heavy metal sorbentmaterial: a preliminary study. Waste Manag 22:901–907

Reddy BR, Mirghaffari N, Gaballah I (1997) Removal and recycling of copper from aqueous solutions using treated Indian barks. Resour Conser Recycl 21:227–245

Saviozzi A, Riffaldi R, Levi-Minzi R, Scagnozzi A, Vanni G (1993) Decomposition of vegetation-water sludge in soil. Bioresour Technol 44:223–228

Serpaud B, Al-Shukry R, Casteignau M, Matejka G (1994) Heavy metal adsorption (Cu, Zn, Cd and Pb), by superficial stream sediments: effects of pH, temperature and sediment composition. Revue des Sciences de l’Eau 7:343–365

Tiwari DP, Singh DK, Saksena DN (1995) Hg(II) adsorption from aqueous solutions using rice-husk ash. J Environ Eng 121:479–481

Trouvé G, Kauffmann A, Delfosse L (1998) Comparative thermodynamic and experimental study of some heavy metals behavior during automotive shredder residues incineration. Waste Manag 18:301–307

Veglio F, Beolchini F (1997) Removal of metals by biosorption: a review. Hydrometallurgy 44:301–316

Wu CY, Biswas P (1993) An equilibrium analysis to determine the speciation of metals in an incinerator. Combust Flame 93:31–40

Xie R, Wang H, Chen Y, Jiang W (2013) Walnut shell-based activated carbon with excellent copper (II) adsorption and lower chromium (VI) removal prepared by acid–base modification. Environ Progr Sust Energy 32:688–696

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chouchene, A., Jeguirim, M. & Trouvé, G. Biosorption performance, combustion behavior, and leaching characteristics of olive solid waste during the removal of copper and nickel from aqueous solutions. Clean Techn Environ Policy 16, 979–986 (2014). https://doi.org/10.1007/s10098-013-0680-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-013-0680-9