Abstract

Bioavailability of heavy metals present in industrial sludges and their subsequent phytotoxicity are crucial parameters to assess the associated health hazards and suitability for land application. The present study is an effort to determine the extractability of heavy metals present in different phases of the sludges, coming out of two different operations involved in petrochemical industry viz. spent caustic treatment (SCT) and waste water treatment (WWT) following the BCR sequential extraction procedure. The maximum amount of Cd and Cu was found associated with oxidizable phase, whereas Cr and Ni were best recovered in residual fractions of both the sludges. Maximum Pb was recovered in oxidizable and residual phase in the WWT and SCT sludges, respectively. The stabilization treatment undergone by sludges strongly influenced the heavy metal distribution and the phases to which they were associated. The total metal concentration in both the sludges did not exceed the limit set out by the European Legislation and was found as Cd = 0.449, Pb = 3.340, Ni = 6.530, Cr = 21.087, & Cu = 27.129 μg g−1 and Cd = 0.549, Pb = 5.664, Ni = 7.161, Cr = 27.096, & Cu = 35.479 μg g−1 in the SCT and WWT sludges, respectively. Phytotoxicity of the sludges was assessed against the germination index and the relative root and shoot growth. Sludge leachates did not adversely affect the seed germination and the early seedling growth of Mung (Phaseolus mungo) and Gram (Cicer arietinum), indicating that these metals were concentrated in the non-bioavailable fractions of sludges.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Effluent treatment plants (ETPs) produce sludge as the principal by-product. As practice, the sludge produced is either disposed off in landfills or incinerated, but both these methods are expensive and are not eco-friendly. Recycling such sludges as fertilizer or as soil conditioner in agricultural farms, forests, and gardens seems to be an attractive/alternative possibility because of the presence of valuable components such as organic matter, nitrogen, phosphorous, and other nutrients for plants growth (Jamali et al. 2008; Saruhan et al. 2010). However, because of the high heavy metal content, their application in the agricultural field poses a potential threat to the environment and health (Alonso et al. 2002; Majid et al. 2012). Heavy metals’ mobilization in the soil may make them bioavailable and they can become the part of food chain. Another problem is the potential phytotoxic nature of the organic waste, mainly due to their high salinity, excess of ammonium ions, organic compounds, or high molecular weight fatty acids which may inhibit the seed germination and plant growth (Wong et al. 2001; Hoekstra et al. 2002). The toxicity of metals present in the sludge depends on their bioavailability and mobility instead of the total metal concentration which is a function of the chemical form in which they exist (Fernandez et al. 2000; Pueyo et al. 2001; Gaber et al. 2011; Mohammed and Ayodele 2011). Chemical speciation or sequential extraction of heavy metals is a promising technique for the determination of the forms in which they are present in industrial sludges (Ahmed and Bouhadjera 2010; Achi et al. 2011; González-Corrochano et al. 2011; Odoh et al. 2011; Tamunobereton-ari et al. 2011). When the sludges are applied to soil, the information on chemical speciation of metals is valuable for predicting their mobility, bioavailability, and leaching rates (Jamali et al. 2007; Gaber et al. 2011; Mohammed and Ayodele 2011).

In accordance with the scheme proposed by the Community Bureau of Reference (BCR), now known as the Standard, Measurements and Testing Program, a sequential extraction method was applied to recover Cd, Cu, Pb, Cr, and Ni present in petrochemical industry sludge. The scheme consists of three steps which give rise to four different fractions and an additional step:

-

Step I (Exchangeable fraction associated with carbonated phases): This fraction represents the metals adsorbed on the sludges or on their essential components, denominated clays, Fe and Mn hydroxide, and humic acids. Metal adsorption is related with changes in the ionic composition of the water, which may affect the processes of adsorption–desorption.

-

Step II (Reducible fraction or fraction associated with Fe and Mn oxide): The Fe and Mn oxides act as cement or are present as nodules between particles or cover the same. The heavy metals are strongly bound to these oxides, but are thermodynamically unstable in anoxic conditions.

-

Step III (Oxidizable fraction bound to organic matter): This fraction represents the metals which are complexed or peptized by the natural organic substances. Soluble metallic forms are liberated when organic matter is attacked in oxidant conditions.

-

Step IV (Residual fraction): The residual solids mainly contain primary and secondary solids that occlude the metals in their crystalline structures.

Bioassays of metals present in the industrial sludges are of immense importance to determine their phytotoxicity, before their possible utilization in agriculture. Such bioassays are simple and have been used by many authors to determine the phytotoxicity of heavy metals due to their high sensitivity (Gothberg et al. 2002; Sahu et al. 2008; Kumar et al. 2009a, b). The objective of the present study is to develop a chemical and biologic approach to assess the potential impacts of petrochemical industry sludge through chemical characterization and bioassay.

Materials and methods

Sludge collection and pretreatment

The sludges used in the study were collected from the spent caustic treatment plant (SCTP) and waste water treatment plant (WWTP) of a petrochemical industry situated in Uttar Pradesh, India. The samples were air dried and homogenized manually to remove bigger pieces of stone, plastics, etc. The samples were then ground and sieved to obtain a fraction of less than 165 μm.

Equipment and reagents

The concentration of Cd, Cu, Pb, Cr, and Ni was determined using an atomic absorption spectrophotometer (AA 240 FS, Varian). All the reagents used in the study were of analytical grade and were obtained from E. Merck (India) Limited, Mumbai. Certified aqueous standards of the elements were used as reference.

Sludge characterization

The sludges were characterized for different physicochemical parameters viz. pH, electrical conductivity, moisture content, total solids, organic carbon, total nitrogen, and available phosphorous and potassium, following the standard analytical method (APHA 2005).

Metal determination

One gram sample of the sludge was taken in five replicates and digested overnight in a solution of HNO3:HClO4 (4:1 v/v) at 70–80 °C. The solution was allowed to evaporate by raising the temperature to 105 °C until the sludge was digested and the solution became transparent. The volume of the samples was reduced to 0.5–1.0 ml. The final volume was diluted to 50 ml with 0.1 N HNO3, filtered through 0.25-μ filter paper, and analyzed on an atomic absorption spectrophotometer (AAS) (Singh et al. 2010; Kumar et al. 2012).

Sequential extraction procedure

The sequential extraction procedure for speciation of heavy metals, proposed by the Commission of the European Communities Bureau of Reference (BCR) was followed. Analysis was performed in five replicates for both the sludge samples (n = 5).

Toxicity characteristic leaching procedure (TCLP)

Toxicity characteristic leaching procedure test was carried out to determine the mobility of both organic and inorganic analytes present in the waste, following the method of USEPA (1992).

Toxicity assessment of sludges

Sludge extracts were prepared by shaking (overnight) 5 g of sludge with 25 ml (1:5 w/v) deionized water. The suspension was filtered through Whatman No. 1 filter paper. In addition to the extract obtained, two more working concentrations (25 and 50 %) were prepared by diluting the extract and were used for bioassay, while deionized water served as the control. 30 seeds each of Mung (Phaseolus mungo) and Gram (Cicer arietinum) were placed in a petri dish lined with a double layer of Whatman No. 1 filter paper. The filter paper was moistened with 5 ml of the working concentrations. The seeds were allowed to germinate at room temperature. A 1-mm emergence from the seeds was considered as germination. Seed germination and root length (cm) of seeds were recorded after 72 h of germination. The relative seed germination (RSG), relative root growth (RRG), and the germination index (GI) were calculated following Hoekstra et al. (2002).

where G s and L s represent seed germination (%) and root elongation (cm), respectively, and G c and L c are the corresponding control values. To facilitate the comparison between different tests, the GI is expressed as a percentage in comparison to the control (100 %).

Statistical analysis

One way analysis of variance (ANOVA) and t test were performed to compare the means of the different treatments at p < 0.05. Differences between individual means were tested using the Duncan Multiple Range Test (DMRT).

Results and discussion

Characterization of the sludge

Physicochemical parameters analyzed during the sludge characterization are presented in Table 1. The pH of SCTP and WWTP sludges was 7.8 and 7.6, respectively, which may be considered as normal. Slightly alkaline pH favors the availability of elements and nutrients to the plants. Moisture content of the WWTP sludge (22.2 %) was higher than the SCTP sludge (15.5 %), which may be due to prolonged exposure of the SCTP sludge to sunlight. Electrical conductivity of the SCTP sludge was higher than the WWTP sludge, indicating high salt content in the SCTP sludge. Both the sludges contained a high level of nitrogen (N), phosphorous (P), potassium (K), and organic carbon (OC), which are the principal components for any sludge to be used in land application. Similar results were reported by Sophia and Swaminathan (2005); Bose et al. (2008); Bose and Bhattacharyya (2008); Nair et al. (2008); Li et al. (2010).

Toxicity characteristic leaching of metals

The mobility of metals following TCLP is presented in Table 2. Results revealed that Cu is the easiest and most leachable metal, i.e., 0.462 and 0.413 mg l−1 in the SCTP and WWTP sludges, respectively. The metals present in both the sludges followed the given pattern of leaching: Cu > Cr > Pb > Ni > Cd. However, the leachable contents of these metals present in both the sludges were below the limits suggested by Alloway (1968); Bowen (1979); Kabata-Pendias and Pendias (2001).

Total heavy metal content

The use of sludges from treatment plants as fertilizer/soil conditioner depends on their heavy metal contents. The limits are established by the European Legislation (Directive 86/278/EEC) and represent the maximum permitted concentration of heavy metals in sludge destined for agriculture use. The total heavy metal content of the sludges was within the maximum permitted levels mentioned in the directive (Table 3).

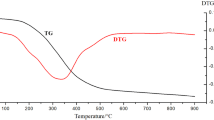

Sequential extraction of metals

The heavy metal recovery from the sludges subjected to sequential extraction scheme is presented in Fig. 1 and Table 4. The sum of the metals recovered in four fractions was reasonably similar to the total metal contents obtained after digestion of the original samples. Recovery of metals in different phases ranged between 75 and 97 %, which is in good agreement with the findings of Tokalioglu et al. (2000); Da Silva et al. (2002); Fuentes et al. (2003, 2004); Corrochano et al. (2011). Maximum amount of metals was recovered in the oxidizable fraction of the sludges except for Cr and Ni, which is to be expected given the affinity of organic matter for these elements and the formation of stable complexes (Scancar et al. 2000; Da Silva et al. 2002; Fuentes et al. 2003, 2004; Corrochano et al. 2011).

Approximately 95 % of Cr was recovered in the oxidizable and residual fraction, whereas the first and second stages of metal recovery did not exceeded 5–6 % in both sludges. The sum of Cr recovered in four fractions accounted for 88.63 and 82.78 % in SCTP and WWTP sludge, respectively. Similar results were reported by Tokalioglu et al. (2000) and Da Silva et al. (2002). Approximately 94 % of Pb was recovered after four stages of sequential extraction in both the sludges. The highest proportion of Pb was recovered in residual fraction (40.09 %) in SCTP sludge, whereas in case of WWTP sludge, it was maximum in the oxidizable fraction (72.71 %). Highest amount of Cd in both sludges was extracted in the oxidizable fraction (SCTP = 44.71 % and WWTP = 41.35 %). Further, the total Cd recovery was 94.65 and 96.90 % in SCTP and WWTP sludge, respectively. Nickel was variably distributed in the different fractions of the process; however, the maximum recovery was observed in the fourth stage of the extraction procedure, which accounted for about 57 and 35 % in WWTP and SCTP sludge, respectively. Total Ni recovery was 93.41 (SCTP) and 75.69 % (WWTP) in the sludge. Similar results were reported by Odoh et al. (2011). Copper was mainly associated with the organic matter and the highest exchangeable percentage was obtained in the oxidizable fraction of both the sludges; similar results were found by Fuentes et al. (2003). It may be because of the affinity of organic matter for this type of element and the formation of stable complexes (Da Silva et al. 2002; Fuentes et al. 2006; Corrochano et al. 2011). The sum of the last two fractions accounted for about 79 and 84 % of the total Cu in SCTP and WWTP sludges, respectively, whereas the total Cu recovery from SCTP and WWTP sludge was approximately 81 and 86 %, respectively. Results indicate that Cu was associated with strong organic ligands and probably occluded in minerals like quartz and feldspars (Fuentes et al. 2004; Odoh et al. 2011).

Phytotoxicity test

The phytotoxicity results are presented in Fig. 2a–c. Germination of both the crops was not significantly affected on exposure to sludge extracts and remained at a higher level. However, seed germination has been regarded as a less sensitive method than root elongation when used as a bioassay for the evaluation of phytotoxicity (Wong et al. 2001; Kumar et al. 2009a, b). C. arietinum exposed to both the sludge extracts showed better root growth as compared to the control; however, the GI and shoot growth were reduced with respect to the control on exposure to the SCTP sludge extract. Exposure of P. mungo to the WWTP and SCTP sludge extracts showed better GI, RSG, and RRG, which may be attributed to a higher degree of mineralization and availability of organic carbon and nitrogen in sludge extracts (Walter et al. 2005).

Conclusions

Petrochemical industry sludge may be used as soil amendments because of high organic matter as well as nutrients (N, P, and K). Moreover, the metals were concentrated in the oxidizable and reducible fraction and hence not easily bioavailable, which makes it suitable for soil amendment. The phytotoxicity test confirmed that none of the sludges have any inhibitory effect during early seedling growth of C. arietinum and P. mungo. Present findings can contribute in making the policies for the management of industrial solid waste; however, they cannot be directly correlated for predicting the “in situ” metal behavior in the soil. To obtain the optimum application rates and to properly evaluate the effects of sludges on plants, the laboratory bioassays should be complemented with field experiments, in which an appropriate quantity of sludge should be added to the field according to its particular needs.

References

Achi MM, Uzairu A, Gimba CE, Okunola OJ (2011) Chemical fractionation of heavy metals in soils around the vicinity of automobile mechanic workshops in Kaduna Metropolis, Nigeria. J Environ Chem Ecotoxicol 3(7):184–194

Ahmed AB, Bouhadjera K (2010) Assessment of metals accumulated in Durum wheat (Triticum durum Desf.), pepper (Capsicum annuum) and agricultural soils. Afr J Agric Res 5(20):2795–2800

Alloway WH (1968) Agronomic controls over the environmental cycling of trace elements. Adv Agron 20:235–275

Alonso E, Callejon M, Jimenez JC, Ternero M (2002) Heavy metal extraction forms in sludge from waste water treatment plants. Chemosphere 47:765–775

American Public Health Association [APHA] (2005) Standard methods for the examination of water and wastewater, 21st edn. American Water Works Association, Washington, DC

Bose S, Bhattacharyya AK (2008) Heavy metal accumulation in wheat plant grown in soil amended with industrial sludge. Chemosphere 70(7):1264–1272

Bose S, Chandrayan S, Rai V, Bhattacharyya AK, Ramanathan AL (2008) Translocation of metals in pea plants grown on various amendment of electroplating industrial sludge. Bioresour Technol 99(10):4467–4475

Bowen HJM (1979) Environmental chemistry of the elements. Academic Press, New York

Corrochano BG, Azcárate A, Gonzalez MR (2011) Heavy metal chemical fractionation and immobilization in lightweight aggregates produced from mining and industrial waste. Int J Environ Sci Tech 8(4):667–676

Da Silva I, Abate G, Lichting J, Masini J (2002) Heavy metal distribution in recent sediments of Tiete-Pinheiros rever system in Sao Paulo state, Brazil. Appl Geochem 17:105–116

Fernandez A, Perez-Cid B, Fernandez E (2000) Comparison between sequential extraction procedure and single extraction for metal partitioning in sewage sludge samples. Analyst 125:1353–1357

Fuentes A, Llorens M, Saez J, Soler A, Aguilar MI, Ortuno JF, Meseguer VF (2003) Simple and sequential extraction of heavy metals from different sewage sludges. Chemosphere 54:1039–1047

Fuentes A, Llorens M, Saez J, Soler A, Aguilar MI, Ortuno JF, Meseguer VF (2004) Phytotoxicity of heavy metals speciation of stabilized sewage sludges. Hazard Mater 143:161–169

Fuentes A, Llorens M, Saez J, Soler A, Aguilar MI, Ortuno JF, Meseguer VF (2006) Ecotoxicity, phytotoxicity and extractability of heavy metals from different stabilized sewage sludges. Environ Pollut 143:355–360

Gaber SE, Rizk MS, Yehia MM (2011) Extraction of certain heavy metals from sewage sludge using different types of acids. Biokemistri 23(1):41–48

González-Corrochano B, Alonso-Azcárate J, Rodas M, Barrenechea JF, Luque FJ (2011) Microstructure and mineralogy of lightweight aggregates manufactured from mining and industrial wastes. Constr Build Mater 25(8):3591–3602

Gothberg A, Greger M, Bengtsson BE (2002) Accumulation of heavy metals in water grown spinach (Ipomoea aquatica) cultivated in the Bangkok region, Thailand. Environ Toxicol Chem 21:19–34

Hoekstra NJ, Bosker T, Lantinga EA (2002) Effects of cattle dung from farms with different feeding strategies on germination and initial root growth of cress (Lepidium sativum L.). Agric Ecosys Environ 93:189–196

Jamali MK, Tasneem GK, Arain MKJ, Afridi MB, Jalbani HIN, Memon AR, Ansari R, Shah A (2007) The feasibility of using an industrial sewage sludge produce in Pakistan as agricultural fertilizer used for cultivation of Sorghum bicolor L. Arch Agron Soil Sci 53(6):659–671

Jamali MK, Kazi TG, Arain MB, Afridi HI, Memon AR, Jalbani N, Shah A (2008) Use of sewage sludge after liming as fertilizer for maize growth. Pedosphere 18(2):203–213

Kabata-Pendias A, Pendias H (2001) Trace elements in soils and plants. CRC Press Inc., Boca Raton

Kumar N, Bauddh K, Singh R, Anand K, Barman SC, Singh DP (2009a) Phytotoxicity of trace metals (Cu and Cd) to gram (Cicer aerientinum) and mung (Phasiolus mungo). J Ecophysiol Occup Health 9(2):59–65

Kumar N, Kumar S, Bauddh K, Anand K, Dwivedi N, Singh DP (2009b) Phytotoxicity of industrial effluent to Raphanus sativus L. and Trigonella foenumgracum L. J Ecophysiol Occup Health 9:163–169

Kumar N, Bauddh K, Barman SC, Singh DP (2012) Accumulation of metals in selected macrophytes grown in mixture of drain water and tannery effluent and their phytoremediation potential. J Environ Biol 33:323–327

Li C, Xie F, Ma Y, Cai T, Li H, Huang Z, Yuan G (2010) Multiple heavy metals extraction and recovery from hazardous electroplating sludge waste via ultrasonically enhanced two-stage acid leaching. J Hazard Mater 178(1–3):823–833

Majid NM, Islam MM, Riasmi Y (2012) Heavy metal uptake and translocation by Jatropha curcas L. in sawdust sludge contaminated soils. Aust J Crop Sci 6(5):891–898

Mohammed SS, Ayodele JT (2011) Comparison of extraction techniques for the determination of Ni, Cu, Zn and Pb in maize grown soils of Kaduna metropolis, Nigeria. Asian J Agric Sci 3(5):397–400

Nair A, Juwarkar AA, Devotta S (2008) Study of speciation of metals in an industrial sludge and evaluation of metal chelators for their removal. J Hazard Mater 152(2):545–553

Odoh R, Agbaji EB, Kagbu JA, Thomas SA (2011) Heavy metal speciation in agricultural farmland in some selected local government areas of Benue state, Nigeria. Arch Appl Sci Res 3(3):560–573

Pueyo M, Rauret G, Luck D, Yli-Halla M, Muntau H, Quevauvilla Ph, Lopez-Sanchez JF (2001) Certification of the extractable contents of Cd, Cr, Cu, Ni, Pb and Zn in a freshwater sediment following a collaboratively tested and optimized three step sequential extraction procedure. J Environ Monit 3–2:243–250

Sahu RK, Katiyar S, Yadav AK, Kumar N, Srivastava J (2008) Toxicity assessment of industrial effluent by bioassays. Clean Air Soil Water 36:517–520

Saruhan V, Gul I, Aydin I (2010) The effects of sewage sludge used as fertilizer on agronomic and chemical features of bird’s foot trefoil (Lotus corniculatus L.) and soil pollution. Sci Res Essays 5(17):2567–2573

Scancar J, Milacic R, Strazar M, Burica O (2000) Total metal concentration and partitioning of Cd, Cr, Cu, Fe, Ni and Zn in sewage sludge. Sci Total Environ 250:9–19

Singh R, Singh DP, Kumar N, Bhargava SK, Barman SC (2010) Accumulation and translocation of heavy metals in soil and plants from fly ash contaminated area. J Environ Biol 31:421–430

Sophia AC, Swaminathan K (2005) Assessment of the mechanical stability and chemical leachability of immobilized electroplating waste. Chemosphere 58(1):75–82

Tamunobereton-ari I, Omubo-Pepple VB, Tamunobereton-ari NA (2011) Speciation of heavy metals (Cu, Pb, Ni) pollutants and the vulnerability of groundwater resource in Okrika of Rivers state, Nigeria. Am J Sci Ind Res 2(1):69–77

Tokalioglu S, Kartal S, Elci L (2000) Determination of heavy metals and thier speciation in lake sediments by flame atomic absorption spectrometry after a four stage sequential extraction procedure. Anal Chim Acta 413:33–40

U.S. Environmental Protection Agency [USEPA] (1992) Toxicity characteristic leaching procedure. Method 1311. USEPA, Washington, DC

Walter I, Martinez F, Cala V (2005) Heavy metal speciation and phytotoxic effects of three representative sewage sludges for agricultural uses. Environ Pollut 139:507–514

Wong JWC, Li K, Fang M, Su DC (2001) Toxicity evaluation of sewage sludges in Hong Kong. Environ Int 27:373–380

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Bauddh, K., Kumar, S. et al. Extractability and phytotoxicity of heavy metals present in petrochemical industry sludge. Clean Techn Environ Policy 15, 1033–1039 (2013). https://doi.org/10.1007/s10098-012-0559-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-012-0559-1