Abstract

The inoculum to substrate (I/S) ratio is an important factor which influences the anaerobic digestion process. In this study, the effect of different I/S ratios on the performance of co-digestion of fleshings along with mixture of sludge generated during treatment of tannery wastewater was investigated. The parameters studied were biogas generation, volatile solids reduction, volatile fatty acid (VFA) production, and the stability of the digestion process based on VFA to alkalinity ratio was evaluated for various I/S ratios. Economical significance of I/S ratio as related to the volume of the anaerobic digester and the potential benefit of bio-energy generated are discussed in detail.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nearly 2,000 tanneries are located throughout India with a total processing capacity of 700,000 tonnes of hides or skins per annum. In the processing raw hides and skins into finished leather, around 500–600 kgs of process solid waste will be generated per tonne. In the waste so generated, 70–230 kgs will be fleshings (Sundar et al. 2010). These fleshings were used in industries for glue production until recently but today they are not being used since other types of glues are available. In addition to the fleshings, 28–35 m3 of wastewater and 175–225 kgs of primary and secondary sludge will be generated. The disposal of fleshings and the sludge is not encouraged into landfills due to their unstable conditions. Hence, the management of fleshings and sludge is a challenge for Indian tanning industry.

Anaerobic digestion process consists of hydrolysis, acidogenesis, acetogenesis, and methanogenesis stages, and each stage is a function of metabolic condition of the various microorganisms. Studies have been carried out for anaerobic digestion of organic fraction of municipal solid waste (OFMSW) by Bonzonella et al. (2005); sludge from wastewater treatment plants by Boualagui et al. (2004); agricultural waste by De Baere (2005); industrial waste by Mata-Alvarez et al. (1993); and vegetable market waste by Bouallagui et al. (2005).

Due to the dilution of potential toxic compounds, improved balance of nutrients, synergistic effects of microorganisms and for better biogas yield, anaerobic co-digestion studies have gained momentum in recent years (Murto et al. 2004; Yen and Brune 2007; Fernandez et al. 2005). The stability of digestate after anaerobic digestion process was investigated by Gomez et al. (2005). Co-digestion of OFMSW with wastewater was investigated by Viotti et al. (2004). Co-digestion of onion juice with wastewater sludge was studied by Romano and Zhang (2008), and grease trap sludge with sewage sludge was investigated by Davidsson et al. (2008). Anaerobic co-digestion of kitchen waste and cattle manure for stable performance with better biogas generation was studied by Li et al. (2009). Ramanujam (2002) and Thangamani et al. (2009) investigated anaerobic co-digestion of fleshings and primary sludge. The effect of pretreatment processes such as ozonation and ultrasonication to enhance biogas generation on co-digestion of fleshings and sludge was studied by Sri Bala Kameswari et al. (2010).

For the optimization of the anaerobic digestion process, the selection of inoculum source and the inoculum to substrate (I/S) ratio are the important operational parameters for the assessment of anaerobic biodegradability of solid wastes (Sanchez et al. 2001; Lopes et al. 2004). It is always better to use active anaerobic inoculum or inoculum from animal waste such as bovine manure to reduce digestion period and digester volume (Obaja et al. 2003; Callaghan et al. 2002; Lopes et al. 2003; Sosnowski et al. 2003). Forster-Carneiro et al. (2007) carried out experiments on anaerobic thermophilic digestion of MSW using the various inoculum sources such as corn silage, restaurant digested waste mixed with rice hulls; cattle excrement; swine excrement; digested sludge; and swine excrement mixed with sludge. They found that digested sludge and swine excrement mixed with sludge are the better sources of inoculum. As reported by Forster-Carneiro et al. (2008), only limited information is available on total solids content and the proportion of the inoculum required during start-up period of anaerobic digestion of solid wastes. For the anaerobic solid-state fermentation, the inoculum with high methanogenic activity and low biodegradability are necessary, and the findings were validated using a mathematical model (Kalyuzhnyi et al. 2000). The use of the granular sludge and suspended sludge as inoculum for the bio-methanation of kitchen waste with 0.5–2.3 waste/inoculum ratio was investigated by Neves et al. (2004) and stated that when composition of waste fluctuates it is better to use granular sludge to prevent acidification. Raposo et al. (2006) carried out studies on influence of the I/S ratio on anaerobic digestion of maize waste. In order to improve the rate limiting step of hydrolysis during anaerobic digestion process, the enzyme application is an option to enhance the digestion process and was investigated using commercial grade Steapsin lipase by Sri Bala Kameswari et al. (2011).

No information is available on I/S ratio required for the co-digestion of fleshings, i.e., lipid rich waste along with a mixture of sludge generated during treatment of tannery effluents. Hence in this present study, the primary objective is (i) to ascertain the optimum I/S ratio that influences the co-digestion of tannery solid wastes, (ii) to assess the performance of co-digestion of fleshings along with mixture of sludge generated during treatment of tannery wastewater with respect to biogas generation, and (iii) to estimate the economic considerations for arriving at the digester capacity required and potential benefit from biogas generation.

Experimental set-up

For the optimization of I/S ratio, the co-digestion experiments were carried out in batch reactors of 650 ml amber glass bottles. The substrates selected for the co-digestion studies were (i) fleshings, a process solid waste and (ii) the primary and secondary sludge generated during the treatment of tannery wastewater. The co-digestion studies were carried out with a total volatile solids (VSs) input of 7.5 g on dry weight basis (2.5 g VS from fleshings, 4.5 g VS from the primary sludge, and 0.5 g VS from the secondary sludge) with C/N ratio of 6.0 in all the reactors, i.e., R1, R2, R3, R4, R5, R6, and R7. For nitrogen-rich waste, lower values of C/N ratio in the range of 6–9 is suitable for anaerobic digestion as reported by Mshandete et al. (2004).

In this study, I/S ratios of 0.25, 0.50, 0.67, 1.00, 1.50, and 2.20 were adopted for the respective reactors R1–R7. For these ratios, the inoculums added were 1.87, 3.75, 5.00, 7.50, 11.22, 14.96, and 17.28 g, respectively. The details are presented in Table 1. For each I/S ratio, duplicate reactors were operated, and the performance is reported for the observed mean values.

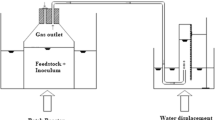

After adding the substrates and the inoculum, the reactors were closed with a rubber cap and an aluminum seal to make them air tight. Nitrogen gas was purged at the rate of 15 ml per second for 25 min into the reactors to remove oxygen and to maintain anaerobic conditions. The biogas generation from the reactors were monitored by means of water displacement method based on Mariotte principle (i.e., the volume of water displaced is equivalent to volume of biogas generated Itodo et al. 1992). The experimental set-up is shown in Fig. 1.

Materials and methods

Characteristics of inoculum, substrates, and digestate

In this study, the inoculum was obtained from an anaerobic digester operating for the digestion of waste-activated sludge (WAS) generated from treatment of domestic sewage located at Chennai, India. Fleshings are the solid wastes generated during the processing of raw hides or skins into finished leather. Fleshings samples were collected from a commercial tannery. Primary and secondary sludge samples were collected from a common effluent treatment plant (CETP) exclusively operating for the treatment of tannery wastewater situated at Chennai, India. At the end of digestion period, digestate samples were characterized.

Analytical procedures

The details of characterization of inoculum, substrates, i.e., fleshings, primary sludge, secondary sludge and digestate samples were given in Table 2. The samples were analyzed in triplicate, and the mean value as well as standard deviation are reported.

The methane content present in the biogas was analyzed with a Thermo Scientific Cerus 800 model gas chromatography (GC) fitted with a thermal conductivity detector (TCD) and a 1.83 m × 3.18 mm ID stainless steel packed column with a molecular sieve of 5A. The oven, injector and detector temperatures were kept at 50, 70, and 200°C, respectively. Helium was used as carrier gas at a flow rate of 2 ml/min. Once after biogas generation was ceased and the digestate samples were centrifuged at 10,000 rpm with a centrifugal force of 19.46 KN for 15 min, and then the supernatant was analyzed for alkalinity and VFA. The VFA was measured with the help of GC fitted with flame ionization detector (FID) and a capillary column of 0.32 mm ID and 60 m length. The oven, injector and detector temperatures were kept at 110, 180, and 220°C, respectively. Helium was used as carrier gas at a flow rate of 2 ml/min with split ratio of 1:10. 1 μl of acidified samples were injected to GC to analyze VFA composition for acetic, propionic, isobutyric, butyric, isovaleric, valeric, isocaproic, and heptonic acids individually. Acetic acid equivalent of VFA was used to calculate the ratio of VFA to alkalinity ratio.

Results and discussion

Characteristics of inoculum and substrates

The inoculum selected for this study is suspended in nature. According to Neves et al. (2004), methane yield was similar for granular and suspended sludge used as inoculum. From the elemental analysis of C, H, N, S, and O of inoculum, fleshings, primary sludge, and secondary sludge, the empirical formulas were obtained as C7H10NS2O8, C175H295N43SO132, C8H12NSO11, and C6H9NSO11, respectively. The C/N ratio for above said were 6.38 ± 0.40; 3.53 ± 0.27, 6.77 ± 0.10, and 4.99 ± 1.28. The characteristics of inoculum and substrates are reported in Table 3.

Process stability

Optimization of I/S ratio for biogas and methane generation

For optimization of I/S ratio for co-digestion of fleshings and the mixture of tannery sludge (primary and the secondary sludge), experiments were carried out in batch reactors by varying the I/S ratio as reported in Table 1. The biogas generation was monitored on daily basis, and cumulative biogas generation is presented in Table 4 and it compares the cumulative biogas generated with different I/S ratios with a constant substrate input of 7.5 g of VS.

As the I/S ratio was increased from 0.25 to 2.30, there was an increase in biogas generation of 1087–2933 ml was observed. Daily biogas generation for different I/S ratios is presented in Fig. 2. It was also observed that the substrate utilization rate (SUR) increased with increase in the amount of inoculum. Irrespective of I/S ratio, the maximum biogas generation was observed for the residence time of 35–45 days. However, the batch reactors were operated for residence time of 50 days wherein biogas generation was ceased.

When I/S ratio decreased, methanogenic activity slow down resulting in decrease in generation of biogas was observed. Similar findings were observed by Hashimoto (1989) for the batch fermentation of wheat straw when I/S ratio was below 0.25, methane yield was reduced drastically. Chynoweth et al. (1993, 2001) reported that at an F/M ratio of 0.5 maximum conversion rate of substrate was reached, and Owen et al. (1979) reported 1.0 as a standard for organic fraction of solid waste.

In this study, when I/S ratio increased from 0.25 to 2.30, 145–391 ml of biogas generation per gram of VS added was observed. The increase in biogas generation for I/S ratio of 0.25–2.30 is reported in Table 4, and it is evident that when I/S ratio increased from 0.50 to 1.00 a substantial increase in biogas generation was observed whereas for I/S ratio increased from 1.00 to 2.30, though an increase in biogas generation of 1.5–2.12% was observed; however, it is marginal w.r.t amount of inoculum added. The use of more inoculum amount in co-digestion process has no significant influence on biogas generation beyond certain point. However, excessive use of inoculum leads to an increase in digester volume unnecessarily required for the co-digestion. Hence, it was observed from the present studies that the I/S ratio of 1.0 wherein maximum conversion rate of substrate was observed w.r.t amount of inoculum added beyond which the increase was marginal only.

The methane content of biogas is 70% irrespective of I/S ratio. With this as the basis, the methane yield (ml) at different I/S ratios was deducted from the volume of the biogas generation. Then, the methane yield (ml) was converted as the methane yield per gram of VS added by dividing the methane yield by VS added, and the data are presented in Table 4. The methane yield varied from 101.5 to 274.7 ml/g of VS added, and the variations of specific methane production rate for different I/S ratios are presented in Fig. 3. A methane yield of 211 ± 6 ml/g of VS added was observed for anaerobic digestion of maize waste by Raposo et al. (2006). Methane yield depends on lipid, protein, and carbohydrate content present in the substrate (Neves et al. 2008; Shanmugam and Horan 2009). In this study, the methane yield was up to 268.1 ml/g of VS added was observed as fleshings one of the substrates selected for the study contains mainly lipids. The lipids are attractive substrates for anaerobic digestion. Similar observations have been noticed by Gunaseelan (1997) and reported that 0.11–0.42 m3 methane yield per kg of VS added depending on the composition of carbohydrates: lipids: protein present in the waste.

Variations in pH and oxidation reduction potential (ORP)

At the end of digestion period, the pH and ORP for different I/S ratios were observed and the same are presented in Fig. 4. The pH varied from 7.1 to 7.3 which is an indication that souring of digesters did not occur during the co-digestion irrespective of I/S ratio. Oxidation reduction potential is a measure of the degree of metabolic reactions that take place during anaerobic digestion process. The ORP was ranged from −409 to −351 mV. The methanogens can develop in an environment where pH is 6.5–7.6 and ORP is −300 mV. The biogas generation was influenced by methanogenic activity and I/S ratio maintained for the reactors. The biogas generation depends on the conversion of substrate into volatile fatty acids (VFAs) and the further conversion of VFA into methane.

VFA production

At the end of the digestion period, individual composition of VFA, i.e., acetic, propionic, isobutyric, butyric, isovaleric, valeric, isocaproic, and heptonic acid was analyzed for various I/S ratios. The total VFA was calculated based on acetic acid equivalent of individual compositions of VFA, and the same is reported in Table 5. It was observed that, for I/S ranging from 0.50 to 2.30, total VFA was in the range of 32.1–192.1 mg/l. For an I/S ratio of 0.25, the total VFA was 2444.4 mg/l. However, because of sufficient buffering capacity, the VFA concentration of 2444.4 mg/l did not cause process disturbance due to acidification. The total VFA composition at the end of digestion period did not exceed the concentration of 40 mM and did not affect the process balance. It was observed from the Table 5 that propionic acid and butyric acid concentrations are well below the process inhibition and ultimate digester failure reported by Ahring et al. (1995) and Hill et al. (1987). However, the nature of substrate, composition of substrate, and operating conditions will govern the individual composition of VFA during co-digestion of solid wastes as reported by Angelidaki and Ahring (1993), and the same phenomenon was observed in this study also.

VFAs to alkalinity ratio

VFA to alkalinity ratio is an important parameter useful to assess the stability the anaerobic digestion process. The critical values of the ratio for digester stability are (i) less than 0.4—performance of the digester is stable; (ii) 0.4–0.8—some instability will occur; and (iii) greater than 0.8—performance of the digester is significantly unstable as reported by Switzenbaum et al. (1990) and Zickerfoose and Hayes (1976). In this study, the VFA to alkalinity ratio for various I/S ratios are presented in Table 4. It was observed that VFA to alkalinity ratio is 0.01–0.20 for I/S ratios 0.50–2.30 which implies that the digesters are under stable operating conditions. For the I/S ratio of 0.25, VFA to alkalinity ratio was 0.7. Inspite of the methane generation and VS reduction, there are chances of instability during co-digestion of tannery solid wastes. Alkalinity is the range of 2000–3500 mg/l in the reactors which are within the range of 2000–4000 mg/l required for digesters performing under stable conditions (Pohland and Bloodgood 1963).

Economic considerations for arriving digester capacity and from bio-energy generation for various I/S ratios

The I/S ratio is an important parameter to assess the biodegradability of wastes and also useful for start-up of the anaerobic digesters. In this study, for various I/S ratios, reactor volume required and the energy generation in terms of kWh are presented in Table 6. Considering biogas generation and percent increase in biogas generation for various I/S ratios, maximum substrate conversion rate was observed with I/S ratio of 1.00 and resulted in generation of 383 ml of biogas per gram of VS added.

In general, the digester volume will be arrived based on the quantity of fresh waste to be digested and quantity of digested sludge to be withdrawn from the digester on daily basis. The equation to arrive the digester volume is given below:

where V is the Digester volume m3, V f is the volume of fresh sludge added m3 per day, V d is the volume of digested sludge withdrawn m3 per day, and T is the residence time (days).

In case of batch reactors, the withdrawal of digested sludge will not be practiced; however, the size of the reactor should be sufficient enough to hold the substrate as well as inoculum. Optimization of I/S ratio is not only an important operational parameter for assessment of anaerobic biodegradability of solid wastes but it also helps in arriving the reactor volume required for co-digestion of tannery solid wastes. The results obtained from the batch reactor studies are useful in arriving the size of the reactor required for pilot scale to avoid under design or over design of the digester volume.

Hence in this study, considering the results obtained from batch reactor studies, the digester volume was arrived for a pilot scale digester to digest the solid waste generated during processing one tonne of raw hides and skins into finished leather. Hence it is appropriate to consider I/S ratio and to conduct the studies in batch and pilot scale reactors before implementing the co-digestion process in full-scale plants especially for continuous mode of operation. However, such studies are lacking in case of solid waste management and one of the reasons for failure also. Though the science of anaerobic digestion is well established but the process efficiency in terms of biogas generation purely depends on the parameters like I/S ratio, activity of the inoculum, and biodegradability of the waste.

Considering I/S ratio of 1.0 as the optimum, additional reactor volume required for the ratios beyond 1.0 are 33, 67, and 87%, respectively, required for I/S ratios of 1.50, 2.00, and 2.30; and the net incremental benefit in terms of bio-energy generation is 1.57, 2.09, and 2.09% only. Similarly, for I/S ratios below 1.0, i.e., for 0.67, 0.5, and 0.25, the reduction in reactor volume is 22, 33, and 50%, respectively. For these I/S ratios, the decrement in terms of bio-energy generation is 50.7, 53.8, and 62.1%. Hence optimization of I/S ratio is not only beneficial for arriving at the reactor volume but also maximizing the benefits of bio-energy generation. However, the co-digestion of tannery solid waste is an integrated solid management option and hence arriving digester volume and economic benefits are to be ascertained based on pilot scale studies before full-scale implementation of the process in tanneries.

Conclusions

For various I/S ratios, i.e., for 0.25, 0.50, 0.67, 1.0, 1.5, 2.00, and 2.30 studied in this study, an increase in biogas generation of 1087–2933 ml was observed.

When I/S ratio increased from 1.0 to 2.3, the increase in biogas generation was 1.5–2.12% and the increase in I/S beyond 1.0, significant increase in biogas generation was not observed. The use of more inoculum amount in co-digestion process has no significant influence on biogas generation and it ultimately leading to increase in digester volume. For the I/S ratio of 1.0, maximum conversion rate of substrate was observed which resulted in generation of 383 ml of biogas per gram of VS added.

Considering I/S ratio as 1.0 as the optimum, additional reactor volume required beyond the optimum ratio of 1.0 resulted an additional volume of 33, 67, and 87%, respectively, required for I/S ratio of 1.50, 2.0, and 2.30, and the net incremental benefit in terms of bio-energy generation is 1.57, 2.09, and 2.09% only. Similarly for I/S ratios below 1.0, i.e., for 0.667, 0.5, and 0.25, the reduction in reactor volume is 22, 33, and 50%. For these I/S ratios, the decrement in terms of bio-energy generation is 50.7, 53.8, and 62.1%. Hence optimization of I/S ratio is not only beneficial for arriving the reactor volume but also maximizing the benefits of bio-energy generation also.

References

Advisor, Central Public Health and Environmental Engineering Organization (CPHEEO), Ministry of Urban Development (2000) Manual on Municipal Solid Waste (MSW) Management. Government of India, New Delhi

Ahring BK, Sandberg M, Angelidaki I (1995) Volatile fatty acids as indicators of process imbalances in anaerobic digesters. Appl Microbiol Biotechnol 43:559–565

Angelidaki I, Ahring BK (1993) Thermophilic anaerobic digestion of livestock waste: the effect of ammonia. Appl Microbiol Biotechnol 38:560–564

APHA (1998) Standard methods for the examination of water and wastewater. American Public Health Association, Washington, DC

Bonzonella D, Pavan P, Mace S, Cecchi F (2005) Dry anaerobic digestion of differently sorted organic municipal solid waste: a full scale experience. In: Proceedings of the fourth international symposium of anaerobic digestion of solid waste, vol 1. Copenhagen, pp 85–92

Boualagui H, Haouari O, Touhami Y, Ben-Cheikh R, Marouani L, Hamdi M (2004) Effect of temperature on the performance of an anaerobic tubular reactor treating fruit and vegetable waste. Process Biochem 39:2143–2148

Bouallagui H, Touhami Y, Ben Cheikh R, Hamdi M (2005) Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem 40:989–995

Callaghan FJ, Wase DAJ, Thayanithy K, Forster CF (2002) Continuous co-digestion of cattle slurry with fruit and vegetable wastes and chicken manure. Biomass Bioenergy 27:71–77

Chynoweth DP, Turick CE, Owens JM, Jerger DE, Peck MW (1993) Biochemical methane potential of biomass and waste feedstocks. Biomass Bioenergy 5:95–111

Chynoweth DP, Owens JM, Legrand R (2001) Renewable methane from anaerobic digestion of biomass. Renew Energy 22:1–8

Davidsson A, Lovstedt C, la Cour Jansen J, Gruvberger C (2008) Co-digestion of grease trap sludge and sewage sludge. Waste Manag 28:986–992

De Baere L (2005) Will anaerobic digestion of solid waste survive in the future? In: Proceedings of the fourth international symposium of anaerobic digestion of solid waste, vol 1. Copenhagen, pp 34–51

Fernandez A, Sanchez A, Font X (2005) Anaerobic co-digestion of a simulated organic fraction of municipal solid wastes and fats of animal and vegetable origin. Biochem Eng J 26:22–28

Forster-Carneiro T, Perez M, Romero LI, Sales D (2007) Dry-thermophilic anaerobic digestion of organic fraction of the municipal solid waste: focusing on the inoculum sources. Bioresour Technol 98:3195–3203

Forster-Carneiro T, Perez M, Romero LI (2008) Influence of total solid and inoculum contents on performance of anaerobic reactors treating food waste. Bioresour Technol 99:6994–7002

Gomez X, Cuetos MJ, García AI, Morán A (2005) Evaluation of digestate stability from anaerobic process by thermo gravimetric analysis. Thermochim Acta 426:179–184

Gunaseelan VN (1997) Anaerobic digestion of biomass for methane production: a review. Biomass Bioenergy 13:83–114

Hashimoto AG (1989) Effect of inoculum/substrate ratio on methane yield and production rate from straw. Biol Wastes 28:247–255

Hill DT, Cobb SA, Bolte JP (1987) Using volatile fatty acid relationships to predict anaerobic digester failure. Trans ASAE 30:496–501

Itodo LN, Lucas EB, Kucha E (1992) The effect of media material and its quality on biogas yield. Niger J Renew Energy 3:45–49

Kalyuzhnyi S, Veeken A, Hamelers B (2000) Two-particle model of anaerobic solid-state fermentation. Water Sci Technol 41:43–50

Li R, Chen S, Li X, Lar JS, He Y, Zhu B (2009) Anaerobic codigestion of kitchen waste with cattle manure for biogas production. Energy Fuels 23:2225–2228

Lopes WS, Leite VD, Prasad S (2003) Performance of anaerobic reactors in the biostabilization of organic solid wastes. J Solid Waste Technol Manag 29:108–117

Lopes WS, Leite VD, Prasad S (2004) Influence of inoculum on performance of anaerobic reactors for treating municipal solid waste. Bioresour Technol 94:261–266

Mata-Alvarez J, Viturtia A, Llabres-Luengo P, Cecchi F (1993) Anaerobic digestion of the Barcelona central market organic waste: experimental study. Bioresour Technol 39:39–48

Mshandete A, Kivaisi A, Rubindamayugi M, Mattiasson B (2004) Anaerobic batch co-digestion of sisal pulp and fish wastes. Bioresour Technol 95:19–24

Murto M, Bjornsson L, Mattiasson B (2004) Impact of food industrial waste on anaerobic co-digestion of sewage sludge and pig manure. J Environ Manag 70:101–107

Neves L, Oliveira R, Alves MM (2004) Influence of inoculum activity on the bio-methanization of a kitchen waste under different waste/inoculum ratios. Process Biochem 39:2019–2024

Neves L, Gonçalo R, Oliveira R, Alves MM (2008) Influence of composition on the biomethanation potential of restaurant waste at mesophilic temperatures. Waste Manage 28:965–972

Obaja D, Mace S, Costa J, Sans C, Mata-Alvarez J (2003) Nitrification, denitrification and biological phosphorus removal in piggery waste-water using sequencing batch reactor. Bioresour Technol 87:103–111

Owen WF, Stuckey DC, Healy JB Jr, Young LY, McCarty PL (1979) Biossay for monitoring biochemical methane potential and anaerobic toxicity. Water Res 13:485–492

Peavy HS, Rowe DR, Tchobanoglous G (1985) Environmental engineering. McGraw-Hill International Editions, Civil Engineering Series, New York, p 577

Pohland FG, Bloodgood DE (1963) Laboratory studies on mesophilic and thermophilic anaerobic sludge digestion. J Water Pollut Control Fed 35:11–42

Ramanujam RA (2002) Biomethanation-technological amenability for sustainable solid waste management in tanneries. 36th LERIG

Raposo F, Banks CJ, Siegert I, Heaven S, Borja R (2006) Influence of inoculum to substrate ratio on the biochemical methane potential of maize in batch tests. Process Biochem 41:1444–1450

Romano RT, Zhang R (2008) Co-digestion of onion juice and wastewater sludge using an anaerobic mixed biofilm reactor. Bioresour Technol 99(3):631–637

Sanchez E, Borja R, Weiland P, Travieso L, Martın A (2001) Effect of substrate concentration and temperature on the anaerobic digestion of piggery waste in a tropical climate. Process Biochem 37:483–489

Shanmugam P, Horan NJ (2009) Simple and rapid methods to evaluate methane potential and biomass yield for a range of mixed solid wastes. Bioresour Technol 100:471–474

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic codigestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7:609–616

Sri Bala Kameswari K, Chitra Kalyanaraman, Thanasekaran K (2010) Effect of ozonation and ultrasonication pretreatment processes on co-digestion of tannery solid wastes. Clean Technol Environ Policy. doi:10.1007/s10098-010-0334-0

Sri Bala Kameswari K, Chitra Kalyanaraman, Porselvam S, Thanasekaran K (2011) Enhancement of biogas generation by addition of lipase in the co-digestion of tannery solid wastes, CLEAN Soil Air Water (accepted)

Sundar VJ, Gnanamani A, Muralidharan C, Chandrababu NK, Mandal, AB (2010) Recovery and utilization of proteinous wastes of leather making: a review. Rev Environ Sci Biotechnol 10(2):151–163. doi: 10.1007/s11157-010-9223-6

Switzenbaum MS, Giraldo-Gomez E, Hickey RF (1990) Monitoring of the anaerobic methane fermentation process. Enzym Microb Technol 12:722–730

Thangamani A, Suseela R, Ramanujam RA (2009) Anaerobic co-digestion of hazardous tannery solid waste and primary sludge: biodegradation kinetics and metabolite analysis. Clean Technol Environ Policy 12(5):517–524. doi: 10.1007/s10098-009-0256-x

Viotti P, Genova PD, Falcioli F (2004) Numerical analysis of the anaerobic co-digestion of the organic fraction from municipal solid waste and wastewater: prediction of the possible performances at Olmeto plant in Perugia (Italy). Waste Manag Res 22:115–128

Yen HW, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour. Technol 98:130–134

Zickerfoose A, Hayes RBJ (1976) Anaerobic sludge digestion: operations manual, (EPA 430/9–76-001). US National Technical Information Service, SpringField, VA

Acknowledgments

Authors are thankful to the Director, Central Leather Research Institute (CLRI), Adyar, Chennai, India for permitting to publish this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sri Bala Kameswari, K., Chitra Kalyanaraman, Porselvam, S. et al. Optimization of inoculum to substrate ratio for bio-energy generation in co-digestion of tannery solid wastes. Clean Techn Environ Policy 14, 241–250 (2012). https://doi.org/10.1007/s10098-011-0391-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-011-0391-z