Abstract

The aim of this study is to assess the conversion of a natural gas combined cycle power plant (NGCC) using an advanced gas turbine (GE9H) for CO2 pre-combustion capture. The natural gas is reformed in an auto-thermal reformer (ATR) either with pure oxygen or with air. After water-shift conversion of CO into CO2 and physical CO2 recovery, the synthesis gas contains a high fraction of H2. It is diluted with N2 and steam to lower its low heating value (LHV) for NO X emission control. Oxygen purity and reforming pressure have little impact on the performances. High-pressure reforming is preferred to reduce the process size. Air reforming results in a slightly higher efficiency but in a bigger process too. The CO2 recovery rate has a big impact on the power plant efficiency since a lot of steam is required to lower the heating value (LHV) of the synthesis gas leaving the recovery process. Two values of LHV have been assessed. Steam consumption for natural gas reforming and synthesis gas dilution are the main consuming elements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon-dioxide emissions are becoming a major concern in our society. Several ways of capturing CO2 for sequestration purpose have been assessed. Power plants fed with natural gas and coal emit a lot of CO2, about 40% of the anthropogenic emissions in the world. For this reason and also because their emissions are locally concentrated, they are the main target for CO2 emissions reduction. Chemical absorption is the most common process for recovering CO2 (Bertucco et al. 2003; Bolland and Undrum 2003; Alie et al. 2005; Aroonwilas and Veawab 2007; Davison 2007). But new processes are studied like the O2/CO2 cycle (Bolland and Mathieu 1998; Andersson and Maksinen 2002; Singh et al. 2003). Fuel conversion is also assessed. Coal gasification has gained interest in recent past years since it leads to higher efficiency than the current pulverised coal power plants (Chiesa and Consonni 1999; Kanniche and Bouallou 2007; Klemeš et al. 2007). Natural gas reforming is well known for hydrogen production. Researches have recently been made on the implementation of this technology for power production (Christensen and Primdahl 1994; Lozza and Chiesa 2002a, b; Gambini and Vellini 2005; Ertesvåg et al. 2005; Cao and Zheng 2006; Tarun et al. 2007).

This paper focuses on natural gas reforming applied to a natural gas combined cycle power plant (NGCC). The objective of reforming is to produce a synthesis gas rich in hydrogen and carbon-dioxide. In the aim of CO2 capture, CO2 must be separated from hydrogen, which will feed the combined cycle. Flue gas is thus only composed of water and nitrogen. Several configurations of the reforming process have been assessed to select the best one. Several sensitivity studies have been done on different parameters like reforming pressure, CO2 recovery rate and gas synthesis dilution for NO x formation control.

Natural gas reforming

When dealing with reforming, several technologies are available. Steam reforming is commonly used in the industrial field, ammonium and hydrogen production. Methane, which is the main component in the natural gas, is converted in a mixture of H2 and CO in a reformer. The main reactions involved in steam reforming are endothermic:

Heat supply is required to produce the steam used during steam reforming, to compensate for the heat losses in the reformer and feed the endothermic reactions. Although steam reforming is the better process for hydrogen production, it is not suitable for power production since a lot of steam must be extracted from the combined cycle for natural gas reforming.

Partial oxidation is another way of reforming natural gas. The fuel is partly burnt in the reformer to produce H2 following the reaction:

This reaction is exothermic and does not require any further heat. However, the efficiency is not very good since only two moles of hydrogen are produced by mole of methane.

The third way of producing hydrogen is the auto-thermal reforming which combines the two processes previously mentioned. The exothermic reaction of partial oxidation supplies the heat required by the endothermic reactions of steam reforming. This type of reforming is the most promising one for power production since it allows a high H2/CO molar ratio without extracting high quantity of steam. The reformer is called auto-thermal reformer (ATR).

Integration of the pre-combustion capture

The power plant’s flowsheet is based on a NGCC using a GE9H gas turbine. This flowsheet, which represents the gas turbine (GT), the heat recovery steam generator (HRSG), the steam turbine and the feedwater tank, has been validated with constructor’s data. Its net electrical efficiency reaches 59.5% (LHV) and it emits 338 g kW h−1 of CO2.

Power plant description

The principle of the ATR cycle is the decarbonisation of the natural gas before the gas turbine. A sketch of the power plant is given in Fig. 1. Two configurations have been assessed, oxygen reforming and air reforming.

The natural gas (NG) is available at 1.953 MPa and its composition is given in Table 1. It is converted into a synthesis gas mainly composed of H2 and CO, thanks to the auto-thermal reformer (ATR). For air reforming, compressed air is directly sent to the ATR process. And for O2 reforming, compressed air is first sent to an air separation unit (ASU), which produces liquid oxygen. A high-pressure pump is used to raise the oxygen stream pressure before evaporation. The outlet pressure depends on the reforming pressure. The CO contained in the synthesis gas is converted into CO2 in the water-shift conversion reactors (SCR). After CO-shift conversion into CO2, the carbon-dioxide is then separated from hydrogen by physical absorption. Physical absorption is used to take advantage of the high partial pressure of CO2. Methanol has been selected because of its low cost and high CO2 loading capacity at low temperature. The recovered CO2 is dehydrated and compressed until 15 MPa ready for transportation and sequestration. The synthesis gas, recovered after the CO2 separation unit, is highly rich in H2 and has in mass basis a very high low heating value (LHV). Since the synthesis gas is used as a fuel for the combined cycle, its LHV must be reduced to control NO x formation during combustion with air. For that purpose, the synthesis gas is first saturated with water, and then mixed with nitrogen recovered at the ASU exit. Finally, intermediate pressure steam (IP steam) is extracted from the steam cycle to fulfil the specification on the maximal LHV value.

The characteristics of the ATR cycle are given in Table 2. The pressure ratio of the air compressor is about 23. The turbine inlet temperature (TIT) has been fixed at 1,700 K. In the NGCC cycle, which represents the conventional case, the steam cycle is optimised for a turbine outlet temperature of 918 K. Since turbine outlet temperature is higher for the retrofitted cases, the extra heat is used to warm up the nitrogen before the synthesis gas dilution and the compressed air before entering the combustion chamber of the gas turbine. The steam cycle has three pressure levels (16.5, 2.4 and 0.32 MPa). The high pressure (HP) and the IP steam are, respectively, over-heated at 837 and 840 K. The condensation pressure is fixed at 3,900 Pa.

The steam extracted for the reforming purpose and for diluting the synthesis gas is taken into account in the material and heat balance. Liquid water at 0.1 MPa and 298.15 K is pumped and heated until 430.2 K, temperature of the feedwater tank. The mass flow of this stream corresponds to the mass flow of the steam extracted for the natural gas reforming and the synthesis gas dilution. Some low-pressure steam (LP steam) is extracted before the low-pressure steam turbine to supply that heat.

The Redlich–Kwong–Soave equation of state has been used in the cycle except where steam is involved. For this latter, the STEAMNBS model has been applied. For the capture unit, the predictive Soave–Redlich–Kwong model (PSRK) has been used since it is well suited for gas sweetening with methanol (AspenTech 2003). The UNIQUAC model has been used to determine the components activity in the liquid phase.

Natural gas reforming

The reforming process is shown on Fig. 2. Natural gas reforming requires steam and oxygen. Three reforming pressures have been studied 2, 4 and 7 MPa. The lower pressure is only devoted to air reforming. For the two higher pressures, the fuel must be compressed. For air reforming operation, air comes from the gas turbine compressor and is already around 2.3 MPa. For a higher reforming pressure, it is cooled to 303 K and then compressed. For oxygen reforming operation, a pump embedded inside the ASU process is used to raise the oxygen pressure to the ATR pressure. Increasing oxygen pressure when oxygen is in its liquid state is less expensive than when a compressor is used after oxygen evaporation in the cryogenic heat exchangers. The ASU is entirely integrated with the gas turbine. All the air required by the ASU comes from the air compressor of the gas turbine. The steam comes from the high-pressure steam turbine and does not require any further compression. Two water/carbon molar ratios have been assessed 1.4 and 1.6.

Natural gas and steam are preheated until 923 K in the heat exchanger HATR and the oxygen stream, coming either from the ASU or from the air compressor, is preheated until 873 K. In the ATR, natural gas is switched to a synthesis gas containing H2 and CO. This synthesis gas leaves the reformer at 1,323 K. The airflow extracted from the air compressor of the gas turbine is calculated to reach this temperature. At this temperature, the conversion rate of methane is close to 94%.

The product stream is used to preheat the incoming streams. This is an advanced option since metal-dusting problems may arise in this hot gas–gas exchanger. The product stream is still at high temperature and is used to produce high-pressure steam thanks to the heat exchangers H1 and H2. The CO is converted into CO2 with the remaining steam in the high temperature shift reactor SCR1 (643 K) and the low temperature shift reactor SCR2 (573 K). More than 92% of CO is converted into CO2 within the two shift reactors.

The heat released during these exothermic reactions is used to produce high-pressure steam. Water coming from the feedwater tank is first pumped and preheated in the heat exchanger H2. The hot liquid water is sent to the gas–liquid separator F1. The liquid water is evaporated in the heat exchanger H1 whereas steam is recovered at the top of the separator. This HP steam is sent to the steam cycle to be overheated before being injected in the high pressure steam turbine.

CO2 recovery process

Process description

The CO2 recovery is based on physical absorption by methanol (Fig. 3) and is quite conventional (Kohl and Nielsen 1997). The synthesis gas is cooled until 243 K and is sent to the absorber. The rich solvent (S3) enters a series of four gas–liquid separators (F1–4) working respectively at 1, 0.5, 0.27 and 0.14 MPa. The gas phase of the first separator is recycled back to the absorber in order to improve the hydrogen recuperation in the cleaned synthesis gas. The gas streams of the three latter separators, released at different pressures, are compressed and mixed. In the heat exchanger H1, the rich solvent (S5), recovered at the bottom of the last separator, cools the synthesis gas, the recycled stream from F1 and the lean solvent. But, since it is not sufficient, an ammonia chilling process is required to sustain the refrigeration at 243 K. The final heat exchange takes place in H2. The rich solvent is thermally regenerated in the stripper by using low-pressure steam coming from the LP steam drum of the steam cycle. The lean CO2 loading in the solvent has been fixed at 0.07 mol CO2/mol methanol. Since the main part of CO2 has been recovered from the gas–liquid separators, the stripper does not require much steam. The steam flow coming out the low-pressure drum is thus largely sufficient. Moreover, the steam temperature is adequate to the stripper boiler. At the top of the stripper, a gas stream rich in CO2 is recovered. It is compressed until 0.5 MPa and mixed with the main CO2 stream (S8). This stream is cooled at 243 K for limiting methanol loss. CO2 is compressed until 9.5 MPa in an intercooled compressor. The cooling temperature has been fixed at 303.15 K. At this pressure and temperature, the CO2 flux is at supercritical state. A supercritical pump is used to raise the pressure until 15 MPa. The isentropic efficiency of the compressors is equal to 0.85.

Thermodynamic model

The thermodynamic model PSRK has been used in this process. To improve the accuracy in the liquid composition, the UNIQUAC model has been added to calculate the activity of the different components in the liquid phase. The binary parameters have been fitted on available literature data (Table 3). Some of the data have been used for parameters regression, other only for the assessment of vapour–liquid equilibria. For the methanol–H2 and methanol–CO2 systems, (Descamps et al. 2005) have already determined the binary parameters.

For the N2–CO2 and methanol–N2 systems, the data regression system of Aspen Plus™ has been used to fit the experimental data. The methanol–CO2–N2 tertiary system has been evaluated from the binary parameters. Among 58 points, 3 points are inadequately represented by the binary parameters. These points correspond to a very high CO2 content in the liquid phase. Since the CO2 concentration in the methanol does not reach those values in our CO2 recovery process, it has been considered that binary parameters are sufficient to predict the tertiary system. Without these 3 points, the standard deviation on the liquid composition is lower than 11%.

Low heating value limitation

The synthesis gas recovered from the CO2 capture process is highly rich in H2 and must be diluted before being burnt in the combustion chamber of the gas turbine. This is required to have a better control on the NO x formation. The synthesis gas pressure is set to 2.8 MPa (expansion if the reforming pressure is above 4 MPa or compression if the reforming pressure is at 2 MPa). It is then heated to 523 K and saturated with water. The different heat duties required in this process are provided by the cooling of compressed air before the ATR or the ASU and also of the synthesis gas at the SCR2 exit. When an ASU is used, the synthesis gas is then diluted with the nitrogen recovered at the ASU exit and which is compressed prior to the dilution. For air reforming, the synthesis gas is already diluted with N2. Intermediate pressure steam is finally added to complete the dilution. This steam is extracted from the combined cycle. A conservative value of 4.8 MJ kg−1 for the LHV represents the base case. However, this value has been increased to 7.0 MJ kg−1 to assess the impact on the cycle efficiency.

Results

Influence of the oxygen purity

For O2 reforming, a sensitivity study has been made on the oxygen purity. For a reforming pressure of 4 MPa, several purities have been assessed from 85 to 95 mol% (Fig. 4). Increasing the purity from 85 to 95 mol% results in an efficiency decrease of 0.3%-point for a CO2 recovery rate in the absorber ranging from 75 to 95% (Fig. 4). The absorber is not very sensitive to small variations of CO2 concentration in the reformed stream. When increasing oxygen purity from 85 to 95%, the CO2 concentration in the synthesis gas rises from 24.7 to 25.1 mol%. This leads to a decrease in the methanol flow from 75.0 to 72.1 kg s−1. The benefit on the installation size is therefore negligible in comparison with the efficiency drop. In the following, only the cases with a purity of 85 mol% will be considered.

Influence of the reforming pressure

Five configurations were studied (Fig. 5), two for oxygen reforming and three for air reforming. An evaluation at 1.95 MPa was selected for air reforming because all the streams are already at sufficient pressure. Thus, no further compression is required.

Reforming pressure has little influence on the net efficiency for a pressure ranging from 4 to 7 MPa. The pros and cons of a higher pressure are offset.

The disadvantages of a higher pressure are:

-

•

Higher compression work (air, natural gas).

-

•

Steam extracted at higher pressure for reforming purpose.

-

•

Lower conversion of hydrocarbons in the auto-thermal reformer, limiting the CO2 recovery rate.

-

•

Higher intermediate steam consumption for lowering the LHV of the synthesis gas. This is a consequence of the lower hydrocarbons conversion. At the CO2 recovery process exit, the synthesis gas is less diluted with CO2. More steam is required to fulfil the specification on the synthesis gas LHV.

The benefits of a higher pressure:

-

•

Smaller installations size.

-

•

Lower methanol flow due to the higher partial pressure of CO2 in the synthesis gas. For a CO2 recovery rate of 85%, the methanol flow drops from 346 to 246 kg s−1 when the reforming pressure is increased from 4 to 7 MPa. The steam consumption in the stripper is lower too. The chilling system is less energy consuming due to a lower solvent flow and to a higher expansion of the solvent in the first gas–liquid separator.

-

•

The expansion of the cleaned synthesis gas until 2.8 MPa produces more power.

In Fig. 5, it can be noticed that the net efficiency of the power plant with air reforming decreases faster than with O2 reforming when the CO2 recovery rate increases. This is due to a higher increase in the solvent flow with the CO2 recovery rate. The more the CO2 is diluted the higher the solvent flow. The chilling process becomes more energy consuming.

The air reforming case at 1.95 MPa is the worst one. This case presents a different configuration compared to the two other pressures. There is no more compression of the air flow or the natural gas. But this is offset by a less effective CO2 recovery process and a synthesis gas compression after this unit.

For a reforming pressure higher than 4 MPa, the power plant using air reforming has a higher net efficiency than the power plant with O2 reforming. For a CO2 recovery rate lower than 80%, the efficiency is about 0.6–0.8%-point higher according to the reforming pressure. But beyond this recovery rate, the difference between the two configurations decreases. The recovery process is less effective with air reforming since the CO2 concentration in the synthesis gas drops from 24.7 mol% for O2 reforming to 16.2 mol% for air reforming. Air reforming will lead to a bigger installation size due to the dilution with nitrogen. But O2 reforming requires an ASU.

The maximum recovery rate achievable decreases with the reforming pressure since fewer hydrocarbons are converted in the reformer. The remaining hydrocarbons are burnt in the combustion chamber of the gas turbine and produce CO2 which is emitted to the atmosphere.

Influence of the H2O/C molar ratio

For O2 reforming at 7 MPa, two H2O/C molar ratios have been assessed 1.4 and 1.6 (Fig. 6). With the lower value, the efficiency increases by 0.5%-point since less amount of steam is extracted from the combined cycle. But this case must be paid with attention as low amount of steam favours carbon deposition on the catalysers of the reformer. Moreover, the hydrocarbons and CO conversions are lower. For the present case, the conversion of methane decreases from 95.0 to 93.9% and the conversion of CO from 94.1 to 92.0%. This will penalise the CO2 recovery rate since more hydrocarbons and CO will be burnt in the combustion chamber of the gas turbine.

Influence of the synthesis gas dilution

A test with a LHV value of 7.0 MJ kg−1 for a reforming pressure of 7 MPa (Fig. 7) shows that the net electrical efficiency increases by 2.3%-points comparing with the case with a LHV value of 4.8 MJ kg−1. The steam flow extracted from the combined cycle is highly reduced in the former case enhancing the efficiency of the steam cycle. The steam flow extracted from the steam cycle is reduced by 75.6%, from 78.4 to 11.3 kg s−1 whereas, in the same time, the natural gas flow decreases only by 9.9%. The natural gas flow has been reduced to respect the compression ratio of the gas turbine.

While increasing the LHV value, the gas turbine efficiency decreases from 44.8 to 40.3%-points for 85% global CO2 recovery since the synthesis gas is not diluted with steam. Taking into account the reduction of the natural gas flow, the gas turbine output is reduced by 18.9%, from 436.8 to 354.2 MW. In the same time, the power produced by the steam turbine increases from 124.2 to 175.2 MW, that is to say a 41.1% increase in spite of a lower fuel flow.

Influence of the recovery rate

As previously mentioned, the CO2 recovery rate has a big impact on the net efficiency, particularly at high recovery rate. The efficiency decreases with the recovery rate comes partly from the recovery process but mainly from the steam extraction for the synthesis gas dilution. Actually, the steam flow extracted is as high as the CO2 recovery rate is high since the synthesis gas is less diluted with CO2. The low heating value of the synthesis gas is reported at different locations in Table 4 for the case O2 reforming at 7 MPa and H2O/C = 1.6. Increasing the CO2 recovery rate leads to a higher LHV at the exit of the recovery process. The successive dilutions with water and nitrogen are not sufficient for fulfilling the final specification of 4.8 MJ kg−1. Between the two recovery rates, the steam extraction increases from 60.5 to 74.6 kg s−1. The net efficiency decreases by 1.5%-points.

Outcome

Seven cases have been compared (Table 5): 4 cases with O2 reforming and 3 cases with air reforming.

With O2 reforming, the CO2 stream purity is independent of the reforming pressure, the H2O/C molar ratio and the final LHV. However, with air reforming, the purity is as low as the reforming pressure is low. This is due to a higher solvent flow in the absorber which solubilises more inert gases like N2. For a greater purity, the recovery process must be modified, implying a higher investment cost and higher penalty on the power plant efficiency.

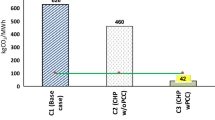

For a 85% CO2 recovery rate, the net efficiency ranges between 43.7 and 46.7% (on LHV basis). Comparing with the conventional NGCC, the efficiency loss lies between 12.7 and 15.8%-points. The quantity of avoided CO2 is about 270 g kW h−1.

Some simulations have been carried out to determine the respective penalty due to fuel conversion, CO2 recovery and synthesis gas dilution. To assess the impact of natural gas reforming, simulations without CO2 capture were performed. For determining the impact of steam extraction for reforming purpose, we have considered steam injection in the ATR without removing steam from the combined cycle as if steam was produced elsewhere.

The fuel conversion accounts for a loss of about 5.0–6.5%-points for a LHV value of 4.8 MJ kg−1 and about 9.0%-points for a LHV value of 7.0 MJ kg−1. The gap between the two cases comes from the difference of the efficiency of the gas turbine: around 44% for the first case and 40% for the second case. More than a half of this loss is due to steam extraction for natural gas reforming. The other part is due to the compressors (natural gas, air, etc.) and to the fuel conversion. Indeed a part of fuel is burnt during reforming. The heat released will not be used in the gas turbine since it is recovered for steam production. However, the steam turbine is less efficient than the gas turbine, which penalises the combined cycle.

The rest of the efficiency loss is due to CO2 recovery. For a LHV of 4.8 MJ kg−1, this penalty ranges between 7.4 and 9.4%-points for a CO2 recovery rate ranging from 70.5 to 89.4%. About 20% of this penalty is due to the recovery process itself (compressor, chilling system and low-pressure steam consumption for solvent regeneration). The other 80% is due to the steam extraction for synthesis gas dilution. For a LHV of 7.0 MJ kg−1, the CO2 recovery penalty is lower, from 2.2 to 4.0%-points for a CO2 recovery rate ranging from 69.0 to 87.6%. The recovery process penalty and the steam extraction penalty are highly dependant of the CO2 recovery rate.

Comparison with previous works

The efficiency losses found in this study are higher than those of previous works. But those works did not take into account the lowering of the synthesis gas LHV for NO x control. Kvamsdal et al. (2007) and Ertesvåg et al. (2005), who considered air-blown ATR and CO2 chemical absorption, reported respectively an efficiency loss of 9.9 and 9.99%-points comparing with their respective base case. According to the composition of their synthesis gas, the LHV should be about 9–10 MJ kg−1. Ertesvåg et al. (2005) also showed that preheating the streams entering the reformer improves the cycle efficiency. Thus, increasing the temperature from 871 to 1,073 K increases the efficiency by 1.6%-points. Bolland and Undrum (2003) assessed a power plant with an air-blown ATR. They used supplementary firing to preheat the streams in the reforming process. Their efficiency loss is about 12.7%-points mainly due to the change of fuel and the supplementary firing. They reported that a H2 fraction of 50 vol% is not acceptable for the classical natural gas low-NO x burners but that some preliminary experiments with high H2 concentration give promising results with synthesis gas burners of classical (IGCC without CO2 capture). Lozza and Chiesa (2002a, b) studied two type of methane reforming: auto-thermal reforming and steam reforming. They found that auto-thermal reforming leads to a higher efficiency. The cycle efficiency reaches 48.5%, which represents a loss of 7.6%-points in comparison with their base case. But the LHV of the synthesis gas is equal to 9.6 MJ kg−1 before the combustion chamber of the gas turbine.

By comparison with post-combustion capture, the efficiency loss found in this study is higher (Aroonwilas and Veawab 2007; Davison 2007). This way of capturing CO2 seems not to be the right choice unless improvements are made on the acceptable level of the LHV of the synthesis gas. Technologies using hydrogen-separating membranes can help reducing the efficiency loss in comparison with classical auto-thermal reforming. Kvamsdal et al. (2007) reported a 3%-points increase when using hydrogen membrane instead of auto-thermal reformer. But this technology is not yet mature.

Conclusion

This study focused on the conversion of a NGCC for CO2 pre-combustion capture. Oxygen reforming was compared with air reforming. With O2 reforming, a sensitivity study showed that O2 purity has little impact on the performances of the CO2 recovery process, whereas the air separation unit consumption increases. With O2 reforming, it is useless to produce a high purity oxygen stream. Air reforming displays a higher efficiency but the final CO2 purity is lower. Moreover, the reforming process and the recovery process will have bigger scale. However, O2 reforming requires an air separation unit.

At low CO2 recovery rate, reforming pressure has little effect on the cycle efficiency. But, when increasing the recovery rate, the CO2 recovery process is less efficient since the solvent flow rate increases very quickly for the highest CO2 recovery rate.

Low H2O/C molar ratio is beneficial to the cycle efficiency since less steam is extracted from the steam cycle. But fewer hydrocarbons are converted in the reformer. The recovery process is thus less efficient. Moreover, decreasing this ratio can lead to carbon deposition on the catalysers of the reformer.

Particular attention was paid to the LHV of the synthesis gas which was set sufficiently low to control NO x formation in the combustion chamber of the gas turbine. For a reforming pressure of 7 MPa and a CO2 recovery rate of 85%, O2 reforming and air reforming lead, respectively, to an efficiency loss of 15.0 and 14.3%-points for a LHV value of 4.8 MJ kg−1. For a value of 7.0 MJ kg−1, the efficiency loss is reduced to 12.7%-points for O2 reforming. Air separation unit, steam extraction for the reformer and synthesis gas dilution are the main causes of reduction in the power plant efficiency.

The CO2 recovery rate has influence not only on the recovery process but also on the quantity of steam extracted from the combined cycle for lowering the LHV of the synthesis gas. This latter accounts for 80% of the efficiency loss due to CO2 recovery for a LHV value of 4.8 MJ kg−1. This point is always forgotten in the literature, which explains that the cycle efficiencies reported by the different authors are higher than those found in this study.

Improvements of hydrogen-separating membranes for natural gas reforming can contribute to lower the efficiency loss. Gas turbine burners must be developed to lower the NOx formation during synthesis gas combustion. This will allow decreasing the steam dilution before the combustion chamber and improving the steam cycle efficiency.

References

Al-Sahhaf TA, Kidnay AJ, Dedy Sloan E (1983) Liquid + vapor equilibria in the N2 + CO2 + CH4 system. Ind Eng Chem Fundam 22:372–380

Aroonwilas A, Veawab A (2007) Integration of CO2 capture unit using single- and blended-amines into supercritical coal-fired power plants: Implications for emission and energy management. Int J Greenh Gas Control 1:143–150

Aspentech (2003) Aspen physical property system—physical property methods and models 12.1

Alie C, Backham L, Croiset E, Douglas PL (2005) Simulation of CO2 capture using MEA scrubbing: a flowsheet decomposition method. Energy Convers Manage 46(3):475–487

Andersson K, Maksinen P (2002) Process evaluation of CO2 free combustion in an O2/CO2 power plant. Master thesis T2002–258. Chalmers University of Technology, Sweden

Bertucco A, Elvassore N, Monteforte A (2003) Assessment of technical feasibility of CO2 capture and sequestration from flue gases by process simulation. In: Proceeding 6th Italian conference on chemical and process engineering, Pisa, Italy. Chemical engineering transactions, vol 3, pp 1093–1098

Bolland O, Mathieu P (1998) Comparison of two CO2 removal options in combined cycle power plants. Energy Convers Manage 39(16–18):1653–1663

Bolland O, Undrum H (2003) A novel methodology for comparing CO2 capture options for natural gas-fired combined cycle plants. Adv Environ Res 7:901–911

Cao W, Zheng D (2006) Exergy regeneration in an O2/CO2 gas turbine cycle with chemical recuperation by CO2 reforming of methane. Energy Convers Manage 47(18–19):3019–3030

Chiesa P, Consonni S (1999) Shift reactors and physical absorption for low-CO2 emission IGCCs. J Eng Gas Turbines Power 121:295–305

Christensen TS, Primdahl II (1994) Improve syngas production using autothermal reforming. Hydrocarbon Process 73(3):39–44

Davison J (2007) Performance and costs of power plants with capture and storage of CO2. Energy 32:1163–1176

Descamps C, Coquelet C, Bouallou C, Richon D (2005) Solubility of hydrogen in methanol at temperatures from 248.41 to 308.20 K. Thermochim Acta 430:1–7

Ertesvåg IS, Kvamsdal HM, Boland O (2005) Exergy analysis of a gas-turbine combined cycle power plant with precombustion CO2 capture. Energy 30:5–39

Gambini M, Vellini M (2005) Comparative analysis of H2/O2 cycle power plants based on different hydrogen production systems from fossil fuels. Int J Hydrogen Energy 30:593–604

Kanniche M, Bouallou C (2007) CO2 capture study in advanced integrated gasification combined cycle. Appl Thermal Eng 27:2693–2702

Klemeš J, Bulatov I, Cockerill T (2007) Techno-economic modelling and cost functions of CO2 capture processes. Comput Chem Eng 31:445–455

Kohl A, Nielsen R (1997) Gas purification. Gulf Publishing Company, Houston

Kvamsdal H, Jordal K, Bolland O (2007) A quantitative comparison of gas turbine cycles with CO2 capture. Energy 32:10–24

Laursen T, Andersen SI (2002) High-pressure vapor–liquid equilibrium for nitrogen + methanol. J Chem Eng Data 47:1173–1174

Lozza G, Chiesa P (2002a) Natural gas decarbonization to reduce CO2 emission from combined cycles—part I: partial oxidation. J Eng Gas Turbines Power 124(1):82–88

Lozza G, Chiesa P (2002b) Natural gas decarbonization to reduce CO2 emission from combined cycles—part II: steam-methane reforming. J Eng Gas Turbines Power 124(1):89–95

Singh D, Croiset E, Douglas PL, Douglas MA (2003) Techno-economic study of CO2 capture from an existing coal-fired power plant MEA scrubbing vs. O2/CO2 recycle combustion. Energy Convers Manage 44(19):3073–3091

Tarun CB, Croiset E, Douglas PL, Gupta M, Chowdhury MHM (2007) Techno-economic study of CO2 capture from natural gas based hydrogen plants. Int J Greenhouse Gas Control 1:55–61

Weber W, Zeck S, Knapp H (1984) Gas solubilities in liquid solvents at high pressures: apparatus and results for binary and ternary systems of N2, CO2, and CH3OH. Fluid Phase Equilib 18:253–278

Yorizane M, Yoshimura S, Masuoka H, Miyano Y, Kakimoto Y (1985) New procedure for vapour–liquid equilibria. Nitrogen + Carbon Dioxide, Methane + Freon 22, and Methane + Freon 12. J Chem Eng Data 30:174–176

Zeck S, Knapp H (1986) Vapor–liquid and vapor–liquid–liquid phase equilibria for binary and ternary systems of nitrogen, ethane and methanol: experiment and data reduction. Fluid Phase Equilib 25:303–322

Acknowledgments

The authors wish to thank ARMINES and EDF (Electricité de France) for their financial support to this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s10098-008-0184-1

Rights and permissions

About this article

Cite this article

Amann, JM., Kanniche, M. & Bouallou, C. Reforming natural gas for CO2 pre-combustion capture in combined cycle power plant. Clean Techn Environ Policy 11, 67–76 (2009). https://doi.org/10.1007/s10098-008-0167-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-008-0167-2