Abstract

The objective of the study is the development of sorbents where the sorption sites are highly accessible for the capture of mercury from aqueous and vapor streams. Only a small fraction of the equilibrium capacity is utilized for a sorbent in applications involving short residence times (e.g., vapor phase capture of mercury from coal-fired power plant flue gases). So, dynamic capacity rather than equilibrium capacity is more relevant for these kinds of situations. Rapid sorption rates and higher dynamic capacity can be achieved by increasing the accessibility of active sites and decreasing the diffusional resistance to mass transport for the adsorbing species. This requires the use of open structured sorbent materials and attachment of functional groups on the external surface area of supports. The strong interaction of sulfur containing ligands (e.g., thiol) with mercury makes them suitable candidates for immobilization on these types of materials. In this study, inorganic oxide supports like alumina and silica are functionalized with thiol moieties like mercapto silane, cysteine and poly-cysteine for capturing mercury from aqueous and vapor phase. Aqueous phase Hg (II) sorption studies with cysteine/poly-cysteine functionalized silica showed that high dynamic capacity can be achieved by attaching active sites (thiol) on the external area of supports. Vapor phase Hg capture studies with thiol-functionalized mesoporous silica (Hg0 concentration = 3.37 mg/m3 with N2 as the carrier, gas temperature = 70 °C) yielded a capacity of 143 μg Hg/g for the sorbent. Although the sulfur content for the sorbent was low (0.80 wt. %) the molar ratio of Hg captured to sulfur was comparatively high (2.86×10−3) pointing to the high accessibility of sulfur sites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The mercury pollution problems exist in various mining and metal processing waste streams and also in combustion gases (EPA 1997; SenGupta 2002). The toxicity of soluble Hg ions and elemental Hg even in very dilute concentrations has been widely reported in the literature. For aqueous waste applications, the control technologies include adsorption, precipitation, ion exchange, solvent extraction, membrane separation and bio-separation (SenGupta 2002; Marcus et al. 2002; Bhattacharyya and Butterfield 2003; Kostal et al. 2001). Selective separation of Hg2+ from other metal ions such as Ca2+, Mg2+, Fe2+, etc. would be highly desirable while treating aqueous heavy metal waste streams. Selectivity can be improved by immobilizing chelating/coordinating ligands that can bind with the metal. Numerous chelating/coordinating ligands have been employed for removing heavy metals like Hg from aqueous media( Beauvais and Alexandratos 1998).

The major chemical forms of the metal in the combustion flue gases are the zero valent elemental Hg0 and the oxidized HgCl2. Mercury speciation (elemental or oxidized) and concentration is dependent on the source, process conditions and the constituents in these gas streams (e.g., Cl2, HCl, SO2, NOx; Galbreath and Zygarlicke 1996). The predominant and thermodynamically stable form of Hg in the flue gases from coal-fired utilities is the elemental one (Hg0) due to the reducing conditions present However the oxidized HgCl2 is the major species from waste incinerators. Unlike the oxidized forms, the metal in the zero valent state is difficult to remove due its high volatility and low water solubility (SenGupta 2002). The inertness may be attributed to the 5d10 6 s2 closed shell electronic structure isoelectronic to He (1 s2; Pitoniak et al. 2003).

Due to the high selectivity and binding affinity exhibited by thiols towards mercury, thiol functionalized sorbents have been synthesized for the removal of mercury from aqueous streams (Mercier and Pinnavaia 1998a, Mercier and Pinnavaia 1998b; Feng et al. 1997; Brown et al. 2000; Nam et al. 2003; Walcarius et al. 2002; Bibby and Mercier 2002). Here, the chelating thiol ligand is immobilized on inorganic oxide supports like silica. Immobilization on an inorganic oxide support is beneficial due to the high mechanical and thermal stability of the support framework. In the case of vapor phase flue gas streams, activated carbon adsorbents have been widely experimented with for the capture of elemental Hg (SenGupta 2002; Krishnan et al. 1994). Here physical adsorption of the mercury vapor takes place on the virgin activated carbon sorbent. However, an increase in temperature adversely affects the physiosorption process resulting in a lower capacity for the sorbent. To increase the capacity and the operating temperature range, activated carbon sorbents have been impregnated with sulfur, chloride and iodide to adsorb the elemental mercury (SenGupta 2002; Hsi et al. 2001; Lui et al. 2000; Ghorishi et al. 2002). A thiol-impregnated activated carbon sorbent has also been shown to be effective in capturing elemental Hg at room temperature (Vidic and Siler 2001).

For applications involving short residence times for the sorbent (e.g., sorbent injection in coal-fired power plants), the dynamic capacity is more important than the equilibrium capacity. In general, a solid sorbent may be thought of as having varying extents of macroporous (>50 nm), mesoporous (2–50 nm) and microporous (<2 nm) regions. The pore characteristics are important with regards to accessibility of active sites, diffusion resistance to mass transport and rate of sorption. Though increased microporous area contributes to high-equilibrium capacities, these active sites in the microporous region will not be utilized in short residence applications for the sorbent. Hence, functionalizing open structured materials (macroporous or mesoporous), where the active sites are easily accessible, will be more appropriate in applications involving short residence times.

The objective of this study is the development of highly accessible sulfur-based sorbents showing fast sorption rates for the capture of mercury from aqueous and vapor streams. High accessibility and rapid sorption rate may be achieved by functionalizing highly open structures or by attaching functional groups on the external surface of supports. In this work, thiol containing molecules like 3-mercapto propyl silane, L-cysteine and poly-L-cysteine are attached to inorganic oxide supports like silica and alumina for aqueous and vapor phase mercury capture. Extensive aqueous phase mercury capture studies have been carried out in this study to address issues pertaining to particle size, site accessibility, and use of open-structured materials, on the sorption rate and dynamic capacity of the thiolated sorbents. It should be noted that that vapor phase work with the proposed sulfur moieties has not been reported in the literature.

Experimental

Materials employed and physical characterization

Materials

Mesostructured silica cellular foam (MCF), pre-derivatized epoxy functional silica (3-glycidoxy propyl silica), L-cysteine (MW=121 mg/mmol), poly-S-CBZ-L-cysteine (PLC, MW=15,000 mg/mmol, DP=63), poly-S-benzyl-L-cysteine (PLC, MW=7,700 mg/mmol, DP=40), dichloro-acetic acid, 3-glycidoxy propyl trimethoxy silane, 3-mercapto propyl trimethoxy silane, anhydrous toluene and thiolated polystyrene based macroporous resin, GT-73, used in the study were all obtained from Sigma-Aldrich. Additional materials included stock Hg standards (1,000 mg/L in 2% HNO3, Fisher Scientific) for aqueous phase analysis and 200 nm pore alumina membranes (Millipore).

Physical characterization

The physical characteristics and designation of the materials employed are given in Table 1. Surface area and pore volume measurements were made with N2 adsorption at 77.3 K (Micromeritics-ASAP 2010). Samples were degassed at 300 μm Hg at temperatures ranging from of 80–120 °C for approximately 12 h before the adsorption experiments. The specific surface areas of the materials were calculated using the multipoint BET method. The pore diameters and pore size distributions were calculated by the BJH (Barret-Joyner-Halenda) method (Gregg and Sing 1967). All the calculations were performed by the built-in software of the pore-volume analyzer.

Functionalization of Silica A with cysteine/poly cysteine

L-cysteine and poly-L-cysteine were immobilized on the commercial glycidoxy functionalized silica support (Silica A). The immobilization results from the attachment of the amino group of the cysteine (deprotonated form) to the epoxy group on the silica support (Schiff-base reaction). The idea here is to attach mercury-capturing groups on the external surface area/pore mouths of the support and the scenario is depicted in Fig. 1.

L-cysteine functionalization

L-cysteine functionalization was carried out in a 0.05 M phosphate buffer (pH 9.0) in a batch mode (3 h with stirring). At this pH, the amount of cysteine in the deprotonated form is 6.3% as calculated from the Henderson-Hasselbalch equation (Hornback 1998; pKa values for cysteine are \(\alpha - {\mathop {{\text{NH}}}\limits^ +} _3 = 10.7,\) α-COOH=2.1, SH=8.4). Higher pH was avoided since dissolution of the silica support and siloxane bond degradation occurs at high pH(Iler 1979). After functionalization, the mixture was filtered washed with deionized water in a vacuum filtration unit employing a PVDF (polyvinylidene fluoride) membrane filter (0.1 μm) and vacuum dried before use in sorption experiments.

Poly-L-cysteine functionalization

The poly-L-cysteine (PLC) functionalization was carried out following the procedure reported by Ritchie et al. (2001). The PLC was first solubilized in pyridine and treated with the epoxy functional silica in a batch mode (3 h). The mixture was then transferred to a vacuum filtration unit for subsequent washing (ethanol followed by deionized water) and deprotection steps. Since the PLC is supplied as poly-S-CBZ-L-cysteine, deprotection of the CBZ (carbobenzoxy) group is necessary. The CBZ group was deprotected by passing a solution of 1.5 g/L NaBH4 in a sodium phosphate buffer (pH 8.0). The PLC functionalized silica was then washed with deionized water and vacuum dried before use in sorption studies.

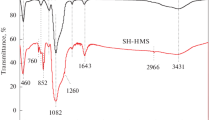

Functionalization and characterization of Silica C

The mesostructured cellular foam (MCF) siliceous materials are characterized by high porosities and relatively high surface areas (Schmidt-Winkel et al. 1999). The authors describe these materials as “composed of uniformly sized, large spherical cells that are interconnected by uniform windows to form a continuous three-dimensional pore system”. A schematic of the same is given in Fig. 2.

Silanization

Thiol functionality was imparted to the MCF silica support (Silica C) via silanization with mercapto propyl trimethoxy silane in nitrogen atmosphere under refluxing conditions. The silanization was carried out at 80 °C (6 h) using 10% (v/v) of the silane in anhydrous toluene. The mixture was then filtered, and any unreacted excess silane was removed by washing with acetone.

Physical characterization

The N2 adsorption isotherm for the functionalized and as received Silica C support is given in Fig. 3a. The isotherms are characterized by large hystereses, indicative of ink-bottle-type pore structure where large cells are connected by narrower windows (Gregg and Sing 1967). The cell and window sizes may be estimated from the adsorption and desorption branches of the isotherms, respectively (Gregg and Sing 1967). The pore size distribution of the functionalized and the as received MCF material is given in Fig. 3b.

Membrane functionalization

The alumina membranes employed in the study are characterized by uniform macro pore openings. The membrane properties are summarized in Table 2. The membrane derivatization and functionalization steps were carried out in a convective flow mode at room temperature. The membrane was first derivatized with 3-glycidoxy-propyl silane prior to functionalization with poly-L-cysteine. Epoxy derivatization was carried out by permeating a 2% (v/v) solution of the glycidoxy silane in acetone through the membrane. Here, the poly-L-cysteine functionalization was carried out in a different manner. The poly-S-benzyl-L-cysteine was first dissolved in a minimum quantity of dichloro-acetic acid. Subsequently, 10 M NaOH solution was added to the mixture and the pH adjusted to 11. The mixture was then permeated through the membrane and the functionalized membrane was washed with deionized water before use in sorption studies.

Aqueous phase Hg (II) sorption

Sorption rate and equilibrium study

Aqueous phase equilibrium sorption and rate studies of Hg (II) were carried out with the thiolated materials at room temperature and at a pH range of 5–5.5. The feed Hg (II) concentration for these experiments was in the range of 100-200 mg/L. Accurately weighed sorbent material was contacted with a known feed solution and samples taken at different times. Vigorous mixing was ensured to eliminate any external mass transfer effects. Also, the total volume of all the samples taken during a sorption run was less than 5% of the initial feed. This was done to ensure that the samples withdrawn were representative of the system at all times. The aqueous phase Hg2+ concentration was then measured by atomic absorption, and the mercury uptake by the sorbent was calculated by material balance.

Vapor phase Hg sorption

The thiolated Silica C sorbent and the alumina membranes were tested for their efficacy in capturing vapor phase elemental Hg0. Sorption runs were carried out on a fixed bed reactor in a convective flow mode at a temperature of 70 °C. In the case of membrane runs, a stainless steel membrane holder was used in place of the fixed bed. Ultra high purity grade N2 gas was used as the carrier gas for the mercury vapor.

Description of the experimental set up

The set up used for the vapor phase mercury experiments is shown in Fig. 4. A certified Hg permeation device obtained from Vici Metronics, Santa Clara, CA is used as the source of elemental Hg. The permeation tube is rated to emit 197 ng/min of Hg at 70 °C. The dehumidified N2 carrier gas is maintained at a flow rate of 60 mL/min. The gas passes through a preheating zone where it is heated to approximately 75 °C before coming into contact with the permeation device. The permeation device is kept in a U-tube filled with glass beads in an oil bath maintained at 70 °C. The Hg0-laden gas at ~70 °C is then contacted with the sorbent in a fixed bed quartz reactor or with the membrane in the stainless steel holder. The quartz reactor tube is 10 cm long and has an OD of 1.27 cm and an ID of 0.8 cm. The sorbent was supported on a glass wool bed (~100 mg, ~1.0 cm high). Approximately 100 mg of the thiol sorbent was placed atop the bed (sorbent bed height = ~1.0 cm) resulting in an empty bed contact time (EBCT) of 0.5 s. In the case of the membrane runs the contact time was 0.07 s. A mercury analyzer (Buck Scientific Cold Vapor Hg Analyzer) was kept online to determine breakthrough for the sorbent. The tubing employed is Teflon as the material is inert towards mercury (Granite et al. 2000). The arrangement of the stainless steel three-way valves (A, B, C and D) makes it possible to flush the lines with pure N2 and pass the Hg vapor directly to the KMnO4 trap bypassing the sorbent bed.

Experimental protocol

The KMnO4 trap arrangement may be used to verify the output of the Hg permeation tube. The Hg-laden gas was passed directly to the trap for 1 h prior to and at the completion of any sorption run. The Hg laden KMnO4 trap was then dissolved in 10% (v/v, 1.8 M) H2SO4 for liquid phase Hg analysis (1.5 g KMnO4 per 100 mL of the acid; Shendrikar et al: 1984). The excess permanganate in the impinger solution was reduced with 12% (w/v) sodium chloride-12% (w/v) hydroxylamine sulfate solution and analyzed for mercury content using cold vapor atomic absorption spectroscopy (Cetac-6000 A). In this way, the average inlet Hg0 mass flow rate and concentration may be calculated On completion of the sorption experiments the spent sorbent was digested in a 50% HNO3-KCl mixture (0.1 g KCl per 10 mL acid) for 3 h (Martinez and Rucandio 2003) Here, salts like KCl increase the solubility of mercury bound to thiol in nitric acid resulting in a quantitative recovery of the metal. Aqueous equilibrium Hg sorption studies with subsequent digestion were conducted with a commercial thiol-functional silica (designated here as Silica B) to verify the digestive procedure Recovery of the metal in the magnitude of 92±2.2% resulted. The sorbent digest was then analyzed by ICP-OES Cold Vapor Mercury Analyzer for mercury content.

Aqueous phase Hg analysis

The aqueous phase Hg analyses were done using Atomic Absorption (Varian FS 220), ICP (Varian pro-vista ICP-OES) and Cold Vapor Mercury Analyzer (Cetac-6000 A). The measurements were made at an absorption wavelength of 253.7 nm for the element. Atomic absorption was employed for the concentration ranges (15–200 mg/L), ICP for the range (1–15 mg/L), and concentrations up to 1,000 ppb were measured using the cold vapor technique. Measured values, RSD and errors associated with the various Hg analytical techniques employed in the study are given in Table 3.

Results and discussion

Aqueous phase Hg sorption

Aqueous phase Hg (II) experiments have been carried out mainly to show the role of particle size and accessibility of sorption sites on the dynamic capacity of thiolated sorbents, importance of dynamic sorption capacity as opposed to equilibrium sorption capacity and temperature dependence of Hg sorption. The thiolated macroporous polystyrene resin, the cysteine/poly-cysteine functionalized Silica A sorbents and the thiol functionalized Silica B sorbents were used for these purposes. Since thiols are reported to react with mercury in a 1:1 molar ratio, aqueous equilibrium Hg sorption may be used to quantify the thiol content in the sorbents (Mercier and Pinnavaia 1998b; Feng et al. 1997). Blank runs with the silica materials prior to functionalization were also carried out to ascertain any pick up of Hg (II). Results obtained showed a mercury capacity of <2 mg/g silica material.

Effect of particle size on sorption kinetics

Sorption experiments were made using the macroporous thiolated resin to study the effect of particle size on the Hg uptake kinetics. Runs were made with the resin as supplied and the resin grounded to micron size particles. The wet thiolated resin as supplied (750 μm) was therefore first ethanol exchanged, ground to fine particles (15 μm) and vacuum dried before use. The grounding process, apart from reducing the particle size, leads to a much higher exposure of the thiol sites.

Figure 5a compares the sorption kinetics of the thiolated resin as supplied with the ethanol exchanged grounded sample. As expected, the grounded sample has a high dynamic capacity (~50 mg/g Hg adsorbed in 1 min) as compared to the resin as supplied (~5 mg/g Hg adsorbed in 1 min, linear interpolated value using dynamic capacity at 5 min). In the grounded resin, the thiol functionality is highly exposed and the diffusion path is less due to the smaller particle size resulting in a higher dynamic capacity.

Effect of particle size on the sorption rate of Hg (II) on thiolated polystyrene resin; feed Hg (II)=0.98 mM (197 mg/L), pH 5.5, temperature=25 °C. b Sorption rate of Hg (II) on thiolated polystyrene resin; linear behavior at % equilibrium <30%, feed Hg (II)=0.98 mM (197 mg/L), pH 5.5, temperature = 25 °C

The desirability of a smaller particle size and open structure for sorbents can be easily seen from the analytical solution pertaining to batch adsorption of a strongly adsorbed species onto a porous sorbent (Ruthven 1984; Suzuki 1990)

where,

and, r p is the radius of the particle, ε p is the porosity of the sorbent, D e is the effective diffusivity of Hg species, and c 0 is the initial bulk solution concentration. q t and qeq are the adsorbed phase concentration at time t and equilibrium respectively. For the fractional uptake range below 0.3, Eq. (1) can be approximated to show that

for a spherical sorbent (Suzuki 1990). Equations (2) and (3) indicate the dependence of fractional approach to equilibrium on mass transport by diffusion. A higher diffusivity for the sorbate species will lead to a faster approach to equilibrium. Also, from Eq. (3), it can be seen that a plot of the fractional uptake versus the square root of time will be a straight line passing through the origin. It may be noted that the effective diffusion coefficient may be estimated from the slope of this plot by using porosity and particle size distribution data. The linear plots for the thiolated sorbents are given in Fig. 5b. The diffusion coefficients are 2 to 3 orders of magnitude lower than that observed for free ionic species in homogeneous aqueous medium (Bibby and Mercier 2002). The difference may be attributed to the strong interaction between the Hg and thiol sites on the sorbent leading to pore restrictions.

Though Eq. (1) is strictly applicable for batch sorption experiments satisfying the infinite volume condition, it captures the effect of particle size and porosity (open structure) on the dynamic capacity. The infinite volume condition stipulates the solution volume be so large that the bulk solution concentration may be taken as a constant for the entire sorption process (Helfferich 1995). From Eq. (1), the time required for reaching equilibrium capacity (also designated as stoichiometric time by Ruthven 1984) may be written as

It follows from Eq. (4) that a decrease in particle size and an increase in porosity (open structured materials) will lead to a faster approach to equilibrium capacity.

Site accessibility, dynamic capacity and equilibrium capacity

Sorption runs with Silica A functionalized with cysteine/poly cysteine and thiol functionalized Silica B were made to study the effect of site accessibility on dynamic capacity as well as to compare dynamic and equilibrium sorption capacity. The Hg (II) uptake of these sorbents is given in Fig. 6. It must be noted that the thiol functionalized Silica B sorbent has very similar physical characteristics (porosity, surface area, particle size) to the Silica A material. As can be seen, the approach to equilibrium is fastest for the cysteine functionalized silica, ~80% of the equilibrium value (28±0.5 mg/g) is attained within a minute. In the case of Silica A functionalized with poly-cysteine, ~50% of the equilibrium value (20±1 mg/g) was attained within a minute. Approximately 10% of the equilibrium value (199±4 mg/g) was reached for the thiol functional Silica B during the same amount of time. The approach to the equilibrium value is much faster for the Silica A sorbent functionalized with cysteine and poly-cysteine as compared to the thiol functional Silica B sorbent due to the high accessibility of sites. Here, the attachment of the cysteine/poly cysteine molecules takes place mainly on the external surface or pore mouths of the sorbent leading to high accessibility for the sorbate species. As evident, this leads to a lower equilibrium capacity since only the external surface/pore mouths are utilized for attachment. However, in applications involving short contact times much of the sorbent capacity is not utilized. Figure 7 compares the dynamic capacity for the various sorbents for a minute duration. The % equilibrium value (a measure of accessibility) and the corresponding dynamic capacity are plotted here for the various sorbents. It can be easily seen that for the thiol-functionalized silica B sorbent 90% of the capacity is not utilized. Although the equilibrium capacity of the Silica B sorbent is high, the dynamic capacity of cysteine/poly-cysteine functionalized Silica A sorbents are similar in magnitude to that of the Silica B sorbent. In other words, the utilized capacity and accessibility of sites are critical in short residence time applications.

Effect of temperature and pH

It is well known that Hg (a soft acid) binds strongly with thiol (soft base) moieties with the stability constants being of the order of magnitude of 10–14 (log K values; Martell et al. 1995). Aqueous phase runs were made to study the temperature dependence of Hg sorption on thiolated materials (25–50 °C). The sorption behavior of cysteine functionalized Silica A sorbent and the thiolated resin are shown in Fig. 8. The uptake characteristics are similar pointing to a sorption behavior independent of temperature for the range studied. The equilibrium capacities are of the same order of magnitude, implying a weak dependence of the stability constant on the temperature. Sorption studies carried out at pH 3 and 5 showed that for thiol functional silica sorbents the equilibrium capacity is independent of the pH for the range studied. The values obtained were respectively 204 mg Hg/g and 199±4 mg Hg/g of the material. Similar results have been reported for thiol-functionalized silica sorbents (Nam et al. 2003; Walcarius et al. 2002). However, equilibrium sorption capacity is thermodynamically limited and depends on the various species present (Ritchie et al. 2001; Pitzer 1991).

Temperature stability of thiol sorbents

In coal-fired power plant type applications, the injected sorbents are exposed to temperatures in the range of 70–100 °C for short contact times (of the order of seconds). With this in mind, temperature stability studies of thiol-functionalized silica sorbents were carried out using the Silica B sorbent. The sorbent was heated to 100 °C in an inert atmosphere and maintained at that temperature for 5–15 min. Subsequently, aqueous phase sorption rate studies were carried out with the sorbent to ascertain Hg capture efficiency or any loss in thiol functionality. Figure 9 compares the Hg (II) uptake kinetics of thiol- functionalized Silica B sorbent subjected to varying degrees of heat treatment. Similar sorption behavior shows that the heat treatment does not lead to any appreciable loss in functionality for the sorbent.

Vapor phase Hg sorption

The aqueous phase Hg sorption studies have shown the desirability of smaller particle size and open structure for sorbent materials meant for short residence times applications. Consequently, vapor phase mercury studies were carried out with the highly open thiol- functionalized Silica C sorbent (7.5 μm) Also, alumina membranes (200 nm pore size) were used to immobilize the longer chain poly-cysteine molecules. The length of the linear chain was calculated to be 17.2 nm using an average repeat unit length of 0.43 nm (Miller et al. 2001). The highly open straight pore membrane was selected to provide high accessibility of sites for Hg capture. Thiol estimation of the Silica C sorbent and the alumina membrane by aqueous phase equilibrium Hg (II) binding experiments yielded respectively a sulfur content of 0.80 and 4.45 wt. %. The average inlet Hg0 mass flow rate and concentration were respectively calculated as 202±22 ng/min and 3.37±037 mg/m3. It must be noted that the inlet Hg0 concentration is much higher than the concentration ranges involved in flue gases (2–200 μg/m3; SenGupta 2002) The reason for using higher concentrations is the attainment of quick breakthrough for the sorbent.

Figure 10 shows the dynamic adsorption profile for the thiol-functionalized Silica C sorbent. Approximately 95% break through for the sorbent occurs around 85 min. A capacity of 143 μg/g resulted for the sorbent following the analysis of the sorbent digestive solution. The linear segment of the adsorption profile points to continuous use of the thiol sites until saturation. Approximately, 83% of the Hg passed was removed by the sorbent (based on total Hg0 passed for 85 min). For the alumina membrane, a sorption experimental run of 6-h duration yielded a capacity of 156 μg Hg/g sorbent. Table 4 summarizes the results for the thiol -functionalized Silica C sorbent and poly-cysteine functionalized alumina membrane.

Mercury sorption data based on a mass basis of the sorbent are not indicative of the accessible active centers for Hg capture. Furthermore, the value depends on the density of the material. Hg sorption based on a total sulfur/thiol basis (adsorption sites) on the other hand, is a measure of the accessible groups for mercury capture and may be used for estimating the capture efficiencies of different materials. Towards this end, calculated molar ratio of Hg captured to total sulfur content for the thiolated materials are also included in Table 4.

Liu et al. (2000) have studied the effect of sulfur-to-carbon ratio and the effect of sulfur impregnation temperature on the vapor phase Hg uptake for sulfur-impregnated activated carbons. The molar ratio of Hg captured to total sulfur content calculated for these sorbents falls in the range of 0.24×10−3–3.17×10−3. However, the sulfur content is higher for these sorbents (~10% for the high-capacity sorbents). As can be seen, the calculated values are in the same order of magnitude as the thiolated sorbents used in this study. However, the sulfur loading for the thiolated sorbents is lower compared to activated carbon sorbents. Indeed, it has been documented in literature that the actual capacity of sulfur-impregnated activated carbon is much less than the theoretical, primarily due to the inaccessibility of sulfur sites in the microporous region of the activated carbon (SenGupta 2002).

For the poly-L-cysteine functionalized alumina membrane, though the sulfur content is higher compared to that of the thiol-functionalized Silica C sorbent, the Hg sorption based on sulfur basis is lower. This may be due to the masking of some thiol groups on these comparatively longer chain molecules. A random coil formation for the immobilized molecule may result in the inaccessibility of some thiol sites for Hg sorption.

Applications

The thiolated sorbents can be used for the remediation of aqueous and vapor mercury waste streams. The high selectivity of thiols towards mercury can be utilized for the removal of the metal from aqueous industrial waste streams (such as mining operations, non-ferrous metal production, etc.). The thiolated sorbents can also be used for mercury removal from flue gas streams of coal-fired power utilities where the residence time for the sorbents is of the order of 2–10 s. Results from this study can be extrapolated to show that high in-duct removal efficiency (high dynamic capacity) can be achieved by attaching active sites either on the external surface of support materials or inside a highly open structured sorbent. In both the cases, the sites are highly accessible.

Conclusions

Aqueous phase sorption studies with the thiolated polystyrene resin establish the fact that higher dynamic capacity is achieved for sorbents with open structure and smaller particle size where the sites are highly accessible. Aqueous phase sorption studies of Silica A functionalized with cysteine/ poly- cysteine have showed that dynamic capacity as opposed to equilibrium capacity is more critical in short residence time applications for the sorbent. Vapor phase Hg capture studies for thiol-functionalized Silica C sorbent and poly-cysteine functionalized alumina membranes at 70 °C show that the functionalization of open structured inorganic oxide support materials with thiol groups provides a promising route for capturing elemental mercury from vapor streams. Future work will also involve the synthesis of nanoparticle (such as Fe/Cu) aggregates with organic sulfur coating to further enhance Hg sorption capacities.

References

Beauvais RA, Alexandratos SD (1998) Polymer-supported reagents for the selective complexation of metal ions: an overview. React Func Polym 36:113–123

Bhattacharyya D, Butterfield DA (2003) New insights into membrane science and technology: polymeric and biofunctional membranes. Elsevier, Amsterdam

Bibby A, Mercier L (2002) Mercury (II) ion adsorption behavior in thiol-functionalized mesoporous silica microspheres. Chem Mater 14:1591–1597

Brown J, Richer R, Mercier L (2000) One-step synthesis of high capacity mesoporous Hg2+ adsorbents by non-ionic surfactant assembly. Microporous Mesoporous Mater 37:41–48

EPA (1997) Mercury study report to congress. Technical Report EPA-452/R-97–003, EPA, Triangle Research Park, North Carolina

Feng X, Fryxell GE, Wang L-Q, Kim AY, Liu J, Kemner KM (1997) Functionalized monolayers on ordered mesoporous supports. Science 276:923–926

Galbreath KC, Zygarlicke CJ (1996) Mercury speciation in coal combustion and gasification flue gases. Environ Sci Technol 30:2421–2426

Granite EJ, Pennline HW, Hargis RA (2000) Novel sorbents for mercury removal from flue gas. Ind Eng Chem Res 39:1020–1029

Gregg SJ, Sing KSW (1967) Adsorption, surface area and porosity. Academic Press, London

Ghorishi SB, Keeney RM, Serre DS, Gullett BK, Jozewicz WS (2002) Development of a Cl-impregnated activated carbon for entrained-flow capture of elemental mercury. Environ Sci Technol 36:4454–4459

Helfferich F (1995) Ion exchange. Dover, New York

Hornback JI (1998) Organic chemistry. Brooks/Cole, California

Hsi H-C, Rood MJ, Rostam-Abadi M, Chen S, Chang R (2001) Mercury adsorption properties of sulfur-impregnated adsorbents. J Environ Eng 128:1080–1089

Iler RK (1979) The chemistry of silica: solubility polymerization colloid and surface properties and biochemistry of silica. Wiley, New York

Kostal J, Mulchandani A, Chen W(2001) Tunable biopolymers for heavy metal removal. Macromolecules 34:2257–2261

Krishnan SV, Gullett BK, Jozewicz W, (1994) Sorption of elemental mercury by activated carbons. Environ Sci Technol 28:1506–1512

Liu W, Vidic RD, Brown TD (2000) Impact of flue gas conditions on mercury uptake by sulfur-impregnated activated carbon. Environ Sci Technol 34:154–159

Marcus Y, SenGupta AK, Marinsky JA (2002) Ion exchange and solvent extraction, vol 15. Dekker, New York

Martinez RF, Rucandio MI (2003) Study of extraction conditions for the quantitative determination of Hg bound to sulfide in soils from Almaden (Spain). Anal Bioanal Chem 375:1089–1096

Martell AE, Smith RM, Motekaitis RM (1995) NIST critically selected stability constants of metal complexes. NIST Standard Reference Database 46 Version 20, NIST Standard Reference Data, Gaithersburg, Maryland

Mercier L, Pinnavaia TJ (1998a) Heavy metal ion adsorbents formed by the grafting of a thiol functionality to mesoporous silica molecular sieves: factors affecting Hg (II) uptake Environ Sci Technol 32:2749–2754

Mercier L, Pinnavaia TJ (1998b) A functionalized porous clay heterostructure for heavy metal ion (Hg2+) trapping. Microporous Mesoporous Mater 20:101–106

Miller TC, Kwak E-S, Howard ME, Bout DAV, Holcombe JA (2001) An in situ study of metal complexation by an immobilized synthetic biopolymer using tapping mode cell atomic force microscopy. Anal Chem 73:4087–4095

Nam KH, Gomez-Salazar S, Tavlarides LL (2003) Mercury (II) sorption from waste waters using a thiol functional adsorbent. Ind Eng Chem Res 42:1955–1964

Pitoniak E, Wu C-Y, Londeree D, Mazyck D, Bonzongo J-C, Powers K, Sigmund W (2003) Nanostructured silica-gel doped with TiO2 for mercury vapor control. J Nanoparticle Res 5:281–292

Pitzer KS (1991) Activity coefficients in electrolyte systems 2nd edn. CRC, Boca Raton, Florida

Ritchie SMC, Kissick KE, Bachas LG, Sikdar SK, Parikh C, Bhattacharyya D (2001) Polycysteine and other poly amino acid functionalized microfiltration membranes for heavy metal capture. Environ Sci Technol 35:3252–3258

Ruthven DM (1984) Principles of adsorption and adsorption processes. Wiley, New York, pp 180–183

SenGupta A K (2002) Environmental separation of heavy metals: engineering processes. Lewis, Boca Raton, Florida

Schmidt-Winkel P, Lukens WW, Zhao D, Yang P, Chemelka BF, Stucky GD (1999) Mesocellular siliceous foams with uniformly sized cells and windows. J Am Chem Soc 121:254–255

Shendrikar A, Damie A, Gutkneckt WF (1984) Technical report, EPA-600/7–84–089, US EPA, Research Triangle Park, North Carolina

Suzuki M (1990) Adsorption engineering. In: Chemical engineering monographs, vol 25. Elsevier, Amsterdam, pp 97–99

Vidic RD, Siler DP (2001) Vapor-phase elemental mercury adsorption by activated carbon impregnated with chloride and chelating agents. Carbon 39:3–14

Walcarius A, Etienne M, Bessiere J (2002) Rate of access to the binding sites in organically modified silicates. 1. Amorphous silica gels grafted with amine or thiol groups. Chem Mater 14:2757–2766

Acknowledgments

The project has been funded by the US EPA and their support is highly appreciated. Thanks are also due to Vasilie Smuleac for his help in functionalizing the alumina membranes. The authors are thankful to Tricia Coakely at the Environmental Research and Training Laboratory (ERTL), University of Kentucky, Lexington for her help in aqueous Hg analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Makkuni, A., Bachas, L.G., Varma, R.S. et al. Aqueous and vapor phase mercury sorption by inorganic oxide materials functionalized with thiols and poly-thiols. Clean Techn Environ Policy 7, 87–96 (2005). https://doi.org/10.1007/s10098-004-0260-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-004-0260-0