Abstract

Cooling shock has a significant thermal deterioration (TD) on the physical and mechanical properties of rocks in high-temperature conditions, which is a critical concern for the engineering application of the cyclic hydraulic fracturing technique in an enhanced geothermal system (EGS). In this work, cooling shock tests were carried out on granite samples to evaluate the actual TD of high-temperature rocks by cooling shocks, and multiple test methods were used to explore the effect of TD on the corresponding physical and mechanical properties of high-temperature granite. Some core conclusions from the study are as follows: (1) The wave velocity and apparent resistivity (AR) can reflect the thermal damage effect of cooling shocks on high-temperature granite. Notably, the higher the temperature of granite, the more significant change in wave velocity and AR. (2) The stress-strain curve tends to be smooth with the granite temperature increases and the cooling shocks intensify, the quiet period of acoustic emission (AE) events is lengthened, and the number is gradually reduced. (3) The TD effect of the cooling shock tends to be more significant for the samples at temperatures above 550 °C, and the peak stress continues to decrease with cooling shock strengthen. Furthermore, thermal stress is the main cause of TD to high-temperature granite. This study has the potential to guide the use of the cooling shock effect in extraction applications of geothermal engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, there has been rapid and extensive development of deep underground projects, especially new power generation projects based on EGS development. As a new type of green, safe, and renewable energy power generation project, faced by the increasingly severe global climate change, EGS has become one of the vital research projects for current capacity and emission reduction (Dipippo 2016; Speight 2015). However, because of the deep high-temperature environment when drilling, the use of a low-temperature drilling fluid cools the high-temperature drill bit and improves the rock-breaking efficiency (Huang et al. 2019; Shen et.al 2019a). However, the cooling liquid causes damage to the high-temperature borehole wall and thermal cracking. When cold water is injected into the thermal reservoir, the cooling shock increases cracking of the surrounding high-temperature rock mass. These conditions affect the project’s long-term stability and sustainability (Rong et al. 2018; Siratovich et al. 2015). Therefore, under hot and cold conditions, it is necessary to fully understand the physical and mechanical properties of rocks at high temperatures and after a cooling shock. Furthermore, for deep underground projects, such as deep underground storage of high-level radioactive nuclear waste, utilization of deep underground space, and cooling of deep mines (Isaka et al. 2018; Pan et al. 2020), therefore, we must master the changes of physical and mechanical properties of rocks in high-temperature and cooling shock conditions to determine the parameters and the basis for the design and construction of rock engineering. In surface engineering projects, such as tunnels, rock structures, and dam projects, when there are abrupt high temperatures (such as a fire) and cooling shock (Freire-Lista et al. 2016), it is essential to scientifically and accurately test and evaluate the damage to the project to ensure its stability. Therefore, it is necessary to understand the influence of extreme hot-cold conditions on the physical and mechanical properties of rocks.

Because temperature is one of the critical factors affecting rock properties, and many scholars continue to pay attention to the effect of high temperature on rocks, amounts of scholars have conducted several high-temperature laboratory test experiments on rocks. Peng et al. (2016a) heated marble to three temperature gradients (200 °C, 400 °C, and 600 °C) and then slowly cooled it to room temperature for testing. It was found that the P wave velocity and Young’s modulus gradually decreased with the temperature increase, and a model of the rock stress-strain curve after thermal damage was established. Zhao et al. (2019) performed mechanical tests on granite at different temperatures and established a granule mechanical model for verification. It was determined that thermally induced micro-cracks are the main factor leading to the degradation of mechanical rock properties. Research on high-temperature rocks has found that the main reason for the thermal cracking of rocks is the varying sensitivity of mineral particles to temperature. When rocks are subjected to high temperatures, the thermal fracture of the rocks eventually leads to a substantial reduction in their physical and mechanical properties (Huang et al. 2017; Peng et al. 2016b; Peng et al. 2019; Wang et al. 1989; Zhao 2015; Shen et al. 2020). With the advancement of research, some scholars have paid attention to the effect of rapid cooling on rocks after high temperatures and have also conducted related experimental research. Wu et al. (2019a) studied the tensile mechanical properties of granite after heating and rapid cooling; it was found that the maximum P wave velocity of the cooled sample decreases, and its tensile strength reduces. Yin et al. (2018) tested high-temperature granite after thermal shock and showed that cracks caused by rapid cooling have a significant influence on the failure mode of rock specimens under dynamic loading. Zhang et al. (2017a) studied the physical and mechanical properties of granite after heating and water-cooling treatments. It was found that heat treatment caused the thermal conductivity and P wave velocity of granite to decrease, while the gas permeability increased, and the mechanical properties of granite caused by the rapid cooling reduced. From relevant scholars and experimental studies on the impact of rock temperature, the cooling shock effect plays a significant role in reducing the physical and mechanical properties of rocks (Avanthi Isaka et al. 2019; Dong et al. 2019; Han et al. 2019; Shen et al. 2019b).

According to literature reviews, most studies have focused on the effects of high temperatures on rock physical and mechanical properties. Moreover, in recent years, related research on the rapid cooling of high-temperature rocks has gradually attracted attention. However, few scholars have studied the different effects of different cooling shocks on the physical and mechanical properties of high-temperature rocks. We tested the physical parameters and mechanical properties of granite subjected to different cooling shock treatments to reveal the differential effects caused by temperature gradients. We analyzed the associated response of granite mechanical properties and physical parameters to the effects of the cooling shock and the damage mechanism at different temperatures to determine the effect on the mechanical properties of granite. This study can provide a new evaluation and reference for related thermal engineering applications after being subjected to a temperature shock.

Materials and methods

Material preparation and test equipment

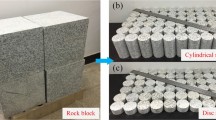

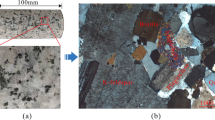

The rock samples used in this experiment are granite collected from the geotropic of Ganzi, Sichuan Province. The granite is biotite monzonite, the particles are uniform, dense, and hard, and the rocks in this area are processed into structural materials, which have been widely used in Western China. The cylinder sample from the complete granite block is obtained by rock drilling the sample. The granite ends are cut flat by the rock cutting machine, and the grinding machine polishes the end face of the sample and finally processed into a cylinder with a height of 100 mm and a diameter of 50 mm. The instrument used for heating granite is the BLMT-1200 °C high-temperature energy-saving box furnace (Bolemante Company, Henan, China). The muffle furnace can be heated up to 1200 °C, the error accuracy is in the range of ± 2 °C, and the heating time can be set, and the constant temperature can be maintained. When cold-quenching high-temperature granite, the refrigerant used is a readily available calcium chloride solution (with stable physical properties and a low freezing point of − 55 °C) and a DW-40 low-temperature test chamber (Xinxing Test Instrument Co., Hebei, China) for temperature reduction, with an adjustable test temperature range is −40 to 40 °C and temperature error of ± 2 °C. The physical parameters of the granite after a thermal shock are tested. The wave velocity tester is the NN-4B non-metal ultrasonic testing analyzer (Concord Engineering Detection Technology Co., Ltd., Beijing, China), and the resistance instrument is the digital bridge TH2811D (Zhongye Electronics Co., Ltd., Jiangsu, China). The mechanical test uses the DDL600 electronic universal testing machine (China Machinery Test Equipment Co., Ltd., Jilin, China) for uniaxial compression test, and the SAEU2S (Shenghua Xingye Technology Co., Ltd., Beijing, China) is used for AE to identify and track the internal cracking of granite during compression.

Test process

The test procedure and required instruments in this paper are shown in Fig 1. First, the granite was heated at room temperature (20 °C) to four temperature gradients (i.e., 150 °C, 350 °C, 550 °C, and 750 °C) by the BLMT-1200 °C high temperature muffle furnace. Because of the rapid heating rate, the temperature conditions of the rock change, causing different degrees of micro-cracks in the granite. Therefore, in this experiment, the granite is heated at a rate of 5 °C/min (Zuo et al., 2007). After reaching the target temperature value, the temperature is constant for 2 h so that the internal heating of the rock is uniform. For the treatment of the cold quenched solution, calcium chloride solution was cooled to three temperature gradients of 20 °C, 0 °C, and − 20 °C, respectively, by the DW-40 low-temperature test chamber. After reaching the target temperature value, the temperature was maintained for 8 h so that the whole solution could reach the target temperature value. The granite was taken out by a specially customized tool, and then immediately subjected to cooling shock, the heated granite was placed into the calcium chloride solution for cold quenching, and the granite at different temperatures and the calcium chloride solution at different temperatures were cross-tested. Concurrently, some heated granite was naturally cooled to serve as the contrast group (herein, natural cooling refers to the cooling of high-temperature rocks in a muffle furnace that is disconnected from the power supply, and the cooling rate does not exceed 5 °C/min.). After the granite was cooled to room temperature, the rock samples were tested by ultrasonic and electrical resistance tests to reflect the impact of the thermal shock on the internal damage of the granite and to analyze which of the two indicators can better reflect the internal damage of the rock caused by the cooling shock. Finally, uniaxial compression and AE tests are carried out to show the macroscopic response of granite mechanical parameters after thermal shock.

Test results

Wave velocity characteristics of granite subjected to different cooling shocks

The changes in heating and cooling of granite with four temperature gradients in this experiment are shown in Fig. 2. When the granite of the natural cooling group and the cooling shock group drops to room temperature, it was baked in the drying oven for 24 h to eliminate the effect of the water content on the wave velocity. The wave velocity test of the rock sample was then carried out immediately, and the wave velocity was used to reflect the damage caused by the cooling shock to the rock. The wave velocity test results are shown in Fig. 3.

It can be seen from the figure that the damage caused by the high temperature on the internal structure of granite is very significant. As the temperature of the rock increases, thermal breakage occurs inside the granite, and its average wave velocity shows a decreasing trend. Comparing the wave velocity values of the natural cooling group and the cooling shock − 20 °C group, after the cooling shock, the average longitudinal wave velocity of granite decreases by 11.7% at 150 °C, 24.2% at 350 °C, 63.8% at 550 °C, and 61.5% at 750 °C, indicating that the cooling shock aggravated the damage and deterioration of the internal structure of high-temperature granite and hindered the transmission of sound waves. As the granite temperature increases, the damage caused by the cooling shock is more significant. At approximately 550 °C, the quartz transformation leads to further expansion of micro-cracks in the rock (Shen et al. 2019a), and the wave velocity of the rock shows a greater attenuation range. Moreover, comparing the granite wave velocity values of the various temperature gradients of the cooling shock group, in addition to individual anomalous points due to the anisotropy of rock minerals, it can be seen that the average wave velocity of the rocks generally decreases, as the temperature of the refrigerant decreases. The tendency of the damage, especially the damage caused by the refrigerant at − 20 °C, is more significant. Therefore, the result of using the wave velocity index to characterize the damage caused by the cooling shock to granite is summarized as follows: with the increase of granite temperature and the decrease of the cooling shock temperature, the average wave velocity of granite generally shows a downward trend, and the attenuation range of the longitudinal wave velocity of granite in the cooling shock group below 0 °C is the largest.

AR characteristics of granite subjected to different cooling shocks

After the wave velocity test is completed, the rock resistance test is performed. The true resistivity of each mineral in the rock is used to determine the mechanical properties of the rock and can be used to test the development of micro-fissures in the rock. In this study, the AR of granite was tested to reflect the internal damage of granite.

Figure 4 shows the relationship between the AR of the granite in the natural cooling group and the cooling shock groups. It can be seen from the figure that the AR of the cooling shock group is greater than that of the natural cooling group, and the difference brought by the cooling shock temperature gradient is significant, that is, the AR of granite increases with the decrease of the cooling shock temperature. This indicates that the decrease of the temperature of the refrigerant and the increase of the thermal stress caused by the expansion of the pores inside the granite and the expansion of new cracks lead to a decrease in the electrical conductivity of the granite. As the temperature of granite increase, the AR of each test group shows a general increasing trend due to the anisotropy of the granite mineral particles, which leads to inconsistent deformation, and the displacement of the lattice surface of adjacent particles squeeze and slip (Hofmann et al. 2015; Wang and Cai 2018). The displacement of the lattice surface of adjacent particles causes the development and coherence of fissures and adjacent micro-fissures, leading to an increase in the AR. This effect is significant in the 550 °C and 750 °C groups. At this stage, the irreversible crystal morphology caused by quartz phase transformation intensifies the degree of deterioration of the rock’s internal structural damage; therefore, the change in the AR is most significant at this stage, especially at a 0 °C cooling shock. The AR increases to 861.84 KΩ, with a change range of 48.7%.

Mechanical and AE characteristics of granite subjected to different cooling shocks

When the rock breaks down, energy is released in the form of elastic waves. AE systems are used to monitor this phenomenon and can accurately show the process of stress rock failure, which is related to the stress state and the rock failure process. Therefore, the AE images can effectively “track” and reveal the process of rock fracture development. Figures 5,6, 7, and 8 show the relationship between the AE and the stress strain of different high-temperature granite after different cooling shocks (due to the limited storage conditions of the equipment, acoustic emission signals were not collected at the stage of rock elastic development). It can be seen from the curve in the figure that the AE activity shows different characteristics with a change in the loading time, and the whole process is divided into an inactive period and an active period. In the early stage of loading, since the granite is in the stage of compaction and elastic development, the AE activity is not significant, and with the increase of the granite temperature and the decrease of the cooling shock temperature, the inactive period of AE in this stage is longer. The increase at 550 °C and 750 °C is more substantial, which shows that after the effect of high temperature and cooling shock, the degree of damage in the rock body increases, and the porosity increases. With the increase of the micro-fracture density, the compaction and elastic development stage take longer in the loading process (Sirdesai et al. 2018; Zhang et al. 2017b). With continuous loading, the accumulated energy in the rock continues to increase. When the first stress drop occurs, the AE activity is significantly strengthened, the amplitude increases, the AE enters the active period, and the AE event changes from “single peak” to “multipeak”. When entering the plastic and failure stage, the characteristics of the stress and strain become nonlinear, the accumulated energy of the rock is constantly released, and an internal fracture occurs. For each rupture, there are high peaks of AE events and sudden change points, which also represent the new stress equilibrium point of the rock in the process of failure. When the accumulated energy reaches the limit of the structure, several elastic waves are released, corresponding to a sudden wave peak of the AE event. Thereafter, a new stress balance is obtained in the rock, and the AE enters an inactive period until the final failure (Zhao et al. 2006). With the reduction of the cooling shock temperature, the peak stress of granite decreases, the AE event becomes more complex and changeable, the ringing amplitude increases, and the failure strain peak point increases. With the increase of the granite temperature, this change becomes more significant, which means that the formation of early cracks in the rock is accelerated by high temperature, and the damage rate of the rock is increased after the cooling shock (Chmel and Shcherbakov 2014; Zhu et al. 2018). This phenomenon is more pronounced at 750 °C, and the stress-strain curve becomes gradually smoother, indicating that the lithology of granite changes after the cooling shock, which makes its friability increase, and the mechanical properties gradually change from brittleness to ductility (Ge and Sun 2018).

Discussion

Discussion on the granite physical parameters and mechanical properties after cooling shock

The physical parameters of rock materials are closely related to the mechanical properties, and the detection of physical parameters can reflect the changes in mechanical properties. Both wave velocity and electrical resistance can be used as sensitive parameters for detecting micro-structures in rock samples and can conclusively reveal the degree of micro-crack development, which reflects the changes in the mechanical properties of the rock.

Before the uniaxial compression test, the wave velocity test results of high-temperature granite after the cooling shock (Fig. 3) show that the wave velocity of granite gradually decreases with an increase in the temperature and a decrease in the cooling shock temperature. Because the wave propagation velocity is significantly related to the medium, the reduction of the wave velocity indicates that the original defects of the internal structure of the granite are increased after the application of high temperature. In comparison with the results of the cooling shock, the lower the cooling shock, the lower the wave velocity of the granite, which means that after the impact of the cooling shock, the defects inside the granite are increased further, and new cracks develop and penetrate the rock body. Therefore, the density of the fissures significantly reduces the acoustic wave conduction (Sun et al. 2017). The results of the subsequent resistance test of granite (Fig. 4) show that the AR of granite shows the opposite effect as that on the wave velocity. AR gradually increases with an increase in the granite temperature and a decrease in the cooling shock temperature. However, the results show that different cooling shocks exacerbate the internal damage of granite because the change in the AR of the medium directly affects the micro-cracks in the medium (the rock samples are dried before testing to eliminate the effect of water content in the pores). Both physical parameters can reflect the increase of the degree of damage of the internal structure of granite after exposure to high temperatures and a cooling shock, which significantly reduces the mechanical performance of the rock (Kumari et al. 2017). The granite stress-strain curve in Fig. 9 is the result of verifying the correlation between the two physical parameters. Compared with the natural cooling group, the peak strain of the granite increases, and the peak stress decreases after the cooling shock. The behavior shown by the parameters is a vital basis of reference for the stability evaluation and assessment of tunnels, building fires, and other projects.

From the results displayed by the two indicators, the physical parameters of the rock’s internal damage can be more accurately evaluated by using the wave velocity because of the difference in the electrical conductivity characteristics of the internal structure of the rock. This structure brings about the difference between the superior and inferior directions of dielectric conduction. In other words, the thermal stress caused by the temperature gradient will inevitably affect the stress equilibrium state of the internal structure of granite. Therefore, the formation, development, directional arrangement, and pore penetration of micro-cracks in the medium are the main reasons that cause the change in the resistance of the medium. However, the change in resistance along the direction of the fracture is not the same as that in the direction of the vertical fracture. The actual resistance parallel to the direction of the fracture is larger than the actual resistance in the vertical fissure direction. The influence of the water content on the fissure is eliminated by drying the rock samples before testing. As a result, the direction of the anisotropic principal axis of the resistivity change caused by cracks will form the dominant direction along the direction of the most substantial change in resistivity (Feng et al. 2000). Therefore, when studying the anisotropy of changes in the rock resistance, changes in the internal structure index of the rocks have become the main factor. The anisotropy of the minerals due to the varying sensitivity to temperature causes the uncertainty of this change to be significant, which is also the reason for the abnormal points in Fig. 4, because the AR value is determined by many factors, such as the true resistance of mineral stones, the distribution of electrical bodies, the advantages and disadvantages of transmit direction, and the strong anti-interference ability of the wave velocity, and the quantitative analysis index of rock thermal damage is not as suitable for use in the analysis as the wave velocity.

Discussion on the damage mechanism of high-temperature granite caused by cooling shock

The stress-strain comparison curves of the rocks under different cooling shocks at different temperatures are shown in Fig. 10. In order to more intuitively show the reduction of the mechanical strength of granite under different cooling shocks, Fig. 11 shows the peak stress curve of granite after different cooling shocks. The highlight of this study lies in the effects of different cooling shocks on granite. Three points need to be considered in Fig. 10. First, the change of the peak stress of granite, i.e., with the decrease of the cooling shock temperature, has a general decreasing trend; second, the change of the peak strain of granite, i.e., with the decrease of the cooling shock temperature, has a gradually increasing trend; third, with the increase in temperature and the cooling shock, the granite stress-strain curve gradually becomes smooth. The changes in the above three points are all because of thermal stress. The transition of thermal stress to the brittle ductility of granite makes the stress curve smooth. Thermal stress causes the increase of the pore size of the granite structure and the expansion of micro-cracks, thereby reducing the mechanical properties of the granite. Therefore, thermal stress is a crucial factor in the analysis (Liu et al. 2016; Sirdesai et al. 2017).

The generation of thermal stress and rock fractures is caused by the different thermal properties of minerals. These properties include the inconsistency of the thermal properties of mineral particles; the particles cannot freely expand and contract (the particles are mutually constrained); and the particles inside the rocks cause the uneven distribution of thermal stress. Thermal stress has been identified as the primary mechanism of thermal degradation, and the large number of micro-cracks caused greatly reduces the physical and mechanical properties of rocks (Griffiths et al. 2017; Zhang et al. 2019). When high-temperature granite is cooled, the mineral particles shrink sharply, and the core area of the rock that has not been affected by the cooling shock is still in a high-temperature expansion state. Because of the high-temperature gradient between the two regions, tensile tangential stress is formed on the rock surface. When the thermal stress exceeds the thermal stress limit of the structure itself, new micro-cracks are generated in the sample (Kim et al. 2013). Because of the different crystalline structure of each mineral component, the thermal stress limit threshold is also different; therefore, the cracking morphology is also different. We carried out a comparative display based on the theoretical calculation method of Kumari et al. (2018) to evaluate the difference in the thermal stress caused by different cooling shocks: σ = EΔαΔT, where E, Δα, and ΔT are the Young’s modulus of the matrix and the thermal expansion coefficient of granite at different temperatures and temperature difference. The results are shown in Table 1.

After the refrigerant contacts the rock surface, a high-temperature gradient causes a strong cooling shock on the rock surface. According to the theoretically calculated thermal stress value in Table 1, the thermal stress generated at 150 °C and the cooling shock at 20 °C can be seen. The value is about 33 MPa, which is enough to cause tensile cracks on the surface of the rock. The thermal stress at 750 °C and the cooling shock of − 20 °C reach 334 MPa. As a result, the rock cementation matrix and the weaker mineral grains of the rock are destroyed, and inter-granular cracks are generated inside the rock structure, which leads to the degradation of the mechanical rock properties. As shown in Table 2., it can be seen that the granite cracking is more serious with the cooling shock temperature decreases; when the temperature of the refrigerant decreases and the temperature of the granite increases, the degree of cracking on the surface of the granite gradually increases in accordance with the thermal stress values in Table 1, which shows that the cracking mechanism reflected by the thermal stress value is consistent with the testing effect. However, it is impossible to achieve such large thermal stress in practical tests because the theoretical formula ignores the convective heat transfer coefficient and heat transfer coefficient between solids and liquids, but the values show the differences caused by different cooling shocks. Although the high-temperature process on the rock is subjected to and the cooling shock is very complicated, there are many factors that affect the magnitude of the thermal stress (mineral, particle size, temperature, and thermal parameters); however, the convective heat transfer coefficient and heat transfer coefficient play an important role in the thermal fracture of rocks and have been confirmed by related studies (Tang et al. 2016; Welty & Rorrer 2009). Even if an extremely low-temperature cooling shock liquid, such as liquid nitrogen is used, if its convective heat transfer coefficient and conductivity coefficient are not high, the effect of reducing the physical and mechanical properties of the rock cannot be achieved (Wu et al. 2019b; Wu et al. 2019c). Although the theoretically calculated values in Table 1 do not match the actual thermal stresses, the theoretical values still show the difference in thermal stress generated under the same conditions as the thermal parameters of the medium. Therefore, the mechanism of thermal stress produced by different cooling shocks is worth our attention and reference. Future research needs to consider the calculation of the thermal stress generated in the processes of cooling and heating to obtain results similar to practical values. Furthermore, more detailed research is required on the spatial distribution of micro-cracks in rock bodies caused by the cooling shock.

Potential application assumption of cooling shock in EGS projects

The cooling shock has a broad range of application prospects in the fields of geotechnical engineering. From the current application and implementation scheme of EGS, room temperature hydraulic fracturing technology is usually adopted to improve the porosity and permeability of rocks (Zhao et al. 2015; Pan et al. 2019). According to experimental results, the effect of cooling shocks on high-temperature granite is significant, which provides a new scheme for the establishment of EGS. The refrigerant, which can carry a large amount of cold energy, is injected into the deep high-temperature rock mass, and the thermal stress caused by the large temperature difference results in a denser micro-fracture network in the rock mass, as shown in Fig. 12, which can greatly increase the heat flux, permeability, and porosity (Chaki et al. 2008; Wang et al. 2013), thereby it can improve the extraction efficiency of geothermal energy. However, it does not mean that the lower the refrigerant temperature, the better the drip thermal energy extraction is, and the greater the cold energy, the longer the heat recovery time of the heat storage layer. Besides, according to the experiments, the thermal stress increases with the enhancement of the cooling shock, and the mechanical properties of granite continue to decrease, which means that when the thermal stress caused by cooling shocks exceeds the equilibrium threshold of the deep surrounding rock system, or when the original steady-state is broken, the energy increases to the limit, inducing micro-earthquakes and causing damage to the local people, property, and ecology. Therefore, when using cooling shocks to implement fracturing technology, we should comprehensively consider the fracturing effect and engineering safety to optimize the range of cooling shock temperatures.

It is necessary to ensure that the refrigerant circulating fluid reaches the fracturing zone and still maintains a low-temperature state to ensure the effect of cooling shock cracking; although cooling shock technology has great potential in increasing geothermal energy production, it has difficulties in practical applications. Therefore, the implementation of the technology places higher requirements on the low-temperature resistance and thermal insulation characteristics of the pipeline. The wellbore can use double-layer casing, the inner pipeline is low-temperature-resistant stainless steel, and the inner fluid is a low-temperature fluid. The insulation material is filled between the inner and outer pipes, such as carbon dioxide, nitrogen, and vacuum tubes. The outermost layer of the tubes can be rock wool, asbestos, fiberglass, and other new insulation materials. Cooling energy dissipation of the fracturing fluid is significantly minimized so that it can exert the maximum fracturing effect. Moreover, when a tunnel fire suddenly occurs, water is sprayed to cool down the area, and rock engineering bodies in the cold area are exposed to a high temperature. The effect of cooling shock on the rock mass is vital, and the extent of damage to the engineering body can be evaluated and repaired in time. Therefore, the goal of reducing the loss to a minimum can be achieved. Furthermore, with the continuous advancement of the project to the deep earth, the high-temperature and high-pressure environment poses challenges to drilling. Because the cooling shocks can reduce the mechanical properties of rocks, a low-temperature drilling fluid can be used to accelerate the rock-breaking speed of high-temperature hard rocks, thereby achieving the purpose of improving the construction efficiency and cost of the project.

Conclusions

In this paper, we carried out cross tests of different cooling shock effects on granite at different temperatures and tested the physical parameters and mechanical properties of granite. The response relationship between physical parameters and mechanical properties of granite is analyzed, and the cooling shocks at different temperatures are compared to determine their influence on the mechanical properties of granite. The main conclusions are summarized as follows:

-

(1)

The longitudinal wave velocity of granite subjected to a cooling shock decreases at varying degrees compared with natural cooling, and with the increase of the granite temperature, the magnitude of the wave velocity attenuation of granite subjected to cooling shock further increases. At high temperatures above 550 °C, the cooling shock effect is more significant, and the longitudinal wave velocity attenuation of granite in the cooling shock group below 0 °C is the greatest. Additionally, the physical parameters of the longitudinal wave velocity of the rock reflect the thermal damage of the granite after the cooling shock better than other parameters. Because the solution of prevention is more effective than resolution in the face of disasters in actual engineering, the wave velocity can be used as a superior physical parameter for the quantitative determination of thermal damage to rocks.

-

(2)

The AR of the cooling shock group is larger than that of the natural cooling group. As the cooling shock temperature decreases, the AR of granite increases. Because of the sensitivity of the resistance and the structural index of the medium, a change in the main resistivity along the direction of fracture can be used to reflect the position or area of the fracture expansion, which is useful in coal, gas, and oil exploitation, and the establishment of geothermal reservoirs, which needs to be further explored.

-

(3)

With the increase of the granite temperature and the strengthening of cooling shock, the inactive period of the AE event is prolonged, the abrupt peak event is reduced, and its lithology changes from brittleness to ductility, which makes the stress-strain curve smooth. Concurrently, the difference of the cooling shocks is also highlighted in the high-temperature section above 550 °C, and the enhancement of the cooling shocks further aggravates the damage of the internal structure of the rock and the expansion of fissures. As a result, the peak stress of granite decreases, and the peak strain increases.

References

Avanthi Isaka BL, Ranjith PG, Rathnaweera TD, Perera MSA, De Silva VRS (2019) Quantification of thermally-induced microcracks in granite using X-ray CT imaging and analysis. Geothermics 81:152–167. https://doi.org/10.1016/j.geothermics.2019.04.007

Chaki S, Takarli M, Agbodjan WP (2008) Influence of thermal damage on physical properties of a granite rock: porosity, permeability and ultrasonic wave evolutions. Constr Build Mater 22(7):1456–1461. https://doi.org/10.1016/j.conbuildmat.2007.04.002

Chmel A, Shcherbakov I (2014) Temperature dependence of acoustic emission from impact fractured granites. Tectonophysics 632:218–223. https://doi.org/10.1016/j.tecto.2014.06.015

Dipippo R (2016) Geothermal power plants: principles,Application,Case Studies and Environmental Impact (Third Edition)

Dong Z, Sun Q, Ranjith PG (2019) Surface properties of grayish-yellow sandstone after thermal shock. Environ Earth Sci 78(14). https://doi.org/10.1007/s12665-019-8451-5

Feng C, Jigang X, Jinzhen A, Chunting M, Dayuan C (2000) Experimental study on anisotropy of rock resistivity and microfissure propagation orientation. Acta Seismol Sin 22(03):310–318

Freire-Lista DM, Fort R, Varas-Muriel MJ (2016) Thermal stress-induced microcracking in building granite. Eng Geol 206:83–93. https://doi.org/10.1016/j.enggeo.2016.03.005

Ge Z, Sun Q (2018) Acoustic emission (AE) characteristics of granite after heating and cooling cycles. Eng Fract Mech 200:418–429. https://doi.org/10.1016/j.engfracmech.2018.08.011

Griffiths L, Heap MJ, Baud P, Schmittbuhl J (2017) Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int J Rock Mech Min Sci 100:138–150. https://doi.org/10.1016/j.ijrmms.2017.10.013

Han G, Jing H, Su H, Liu R, Yin Q, Wu J (2019) Effects of thermal shock due to rapid cooling on the mechanical properties of sandstone. Environ Earth Sci 78(5). https://doi.org/10.1007/s12665-019-8151-1

Hofmann H, Babadagli T, Yoon JS, Zang A, Zimmermann G (2015) A grain based modeling study of mineralogical factors affecting strength, elastic behavior and micro fracture development during compression tests in granites. Eng Fract Mech 147:261–275

Huang Y-H, Yang S-Q, Tian W-L, Zhao J, Ma D, Zhang C-S (2017) Physical and mechanical behavior of granite containing pre-existing holes after high temperature treatment. Arch Civ Mech Eng 17(4):912–925. https://doi.org/10.1016/j.acme.2017.03.007

Huang Z, Wu X, Li R, Zhang S, Yang R (2019) Mechanism of drilling rate improvement using high-pressure liquid nitrogen jet. Petrol Explor Dev+ 46(4):810–818. https://doi.org/10.1016/s1876-3804(19)60239-9

Isaka B, Gamage R, Rathnaweera T, Perera M, Chandrasekharam D, Kumari W (2018) An influence of thermally-induced micro-cracking under cooling treatments: mechanical characteristics of Australian granite. Energies 11(6):1338. https://doi.org/10.3390/en11061338

Kim K, Kemeny J, Nickerson M (2013) Effect of rapid thermal cooling on mechanical rock properties. Rock Mech Rock Eng 47(6):2005–2019. https://doi.org/10.1007/s00603-013-0523-3

Kumari WGP, Ranjith PG, Perera MSA, Chen BK, Abdulagatov IM (2017) Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng Geol 229:31–44. https://doi.org/10.1016/j.enggeo.2017.09.012

Kumari WGP, Ranjith PG, Perera MSA, Chen BK (2018) Experimental investigation of quenching effect on mechanical, microstructural and flow characteristics of reservoir rocks: thermal stimulation method for geothermal energy extraction. J Pet Sci Eng 162:419–433. https://doi.org/10.1016/j.petrol.2017.12.033

Liu X, Yuan S, Sieffert Y, Fityus S, Buzzi O (2016) Changes in mineralogy, microstructure, Compressive Strength and Intrinsic Permeability of Two Sedimentary Rocks Subjected to High-Temperature Heating. Rock Mech Rock Eng 49(8):2985–2998. https://doi.org/10.1007/s00603-016-0950-z

Pan DD, Li SC, Xu ZH, Zhang YC, Lin P, Li HY (2019) A deterministic-stochastic identification and modelling method of discrete fracture networks using laser scanning: development and case study. Eng Geol 262:105310. https://doi.org/10.1016/j.enggeo.2019.105310

Pan DD, Xu ZH, Lu XM, Zhou LQ, Li HY (2020) 3D scene and geological modeling using integrated multi-source spatial data: methodology, challenges, and suggestions. Tunn Undergr Space Technol 100:103393. https://doi.org/10.1016/j.tust.2020.103393

Peng J, Rong G, Cai M, Yao M-D, Zhou C-B (2016a) Physical and mechanical behaviors of a thermal-damaged coarse marble under uniaxial compression. Eng Geol 200:88–93. https://doi.org/10.1016/j.enggeo.2015.12.011

Peng J, Rong G, Cai M, Yao M, Zhou C (2016b) Comparison of mechanical properties of undamaged and thermal-damaged coarse marbles under triaxial compression. Int J Rock Mech Min Sci 100(83):135–139

Peng J, Rong G, Tang Z, Sha S (2019) Microscopic characterization of microcrack development in marble after cyclic treatment with high temperature. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-019-01494-2

Rong G, Peng J, Cai M, Yao M, Zhou C, Sha S (2018) Experimental investigation of thermal cycling effect on physical and mechanical properties of bedrocks in geothermal fields. Appl Therm Eng 141:174–185. https://doi.org/10.1016/j.applthermaleng.2018.05.126

Shen Y-J, Hou X, Yuan J-Q, Zhao C-H (2019a) Experimental study on temperature change and crack expansion of high temperature granite under different cooling shock treatments. Energies 12(11):2097

Shen Y-J, Wang Y-Z, Yang Y, Sun Q, Luo T, Zhang H (2019b) Influence of surface roughness and hydrophilicity on bonding strength of concrete-rock interface. Constr Build Mater 213:156–166. https://doi.org/10.1016/j.conbuildmat.2019.04.078

Shen Y-J, Yang H-W, Xi J-M, Yang Y, Wang Y-Z, Wei X (2020) A novel shearing fracture morphology method to assess the influence of freeze–thaw actions on concrete–granite interface. Cold Reg Sci Technol 169. https://doi.org/10.1016/j.coldregions.2019.102900

Siratovich PA, Villeneuve MC, Cole JW, Kennedy BM, Bégué F (2015) Saturated heating and quenching of three crustal rocks and implications for thermal stimulation of permeability in geothermal reservoirs. Int J Rock Mech Min Sci 80:265–280. https://doi.org/10.1016/j.ijrmms.2015.09.023

Sirdesai NN, Singh TN, Gamage RP (2017) Thermal alterations in the poro-mechanical characteristic of an Indian sandstone–a comparative study. Eng Geol 226:208–220

Sirdesai NN, Gupta T, Singh TN, Ranjith PG (2018) Studying the acoustic emission response of an Indian monumental sandstone under varying temperatures and strains. Constr Build Mater 168:346–361. https://doi.org/10.1016/j.conbuildmat.2018.02.180

Speight, & James (2015) Geothermal energy: renewable energy and the environment, second edition, by william e. glassley. Energy Sources Part A Recovery Utilization & Environmental Effects 37(18):2039–2039. https://doi.org/10.1080/15567036.2015.1085286

Sun H, Sun Q, Deng W, Zhang W, Lü C (2017) Temperature effect on microstructure and P-wave propagation in Linyi sandstone. Appl Therm Eng 115:913–922. https://doi.org/10.1016/j.applthermaleng.2017.01.026

Tang SB, Zhang H, Tang CA, Liu HY (2016) Numerical model for the cracking behavior of heterogeneous brittle solids subjected to thermal shock. Int J Solids Struct 80:520–531. https://doi.org/10.1016/j.ijsolstr.2015.10.012

Wang X, Cai M (2018) Modeling of brittle rock failure considering inter- and intra-grain contact failures. Comput Geotech 101:224–244. https://doi.org/10.1016/j.compgeo.2018.04.016

Wang HF, Bonner BP, Carlson SR, Kowallis BJ, Heard HC (1989) Thermal stress cracking in granite. J Geophys Res 94(B2):1745. https://doi.org/10.1029/JB094iB02p01745

Wang X, Schubnel A, Fortin J, Guéguen Y, Ge H (2013) Physical properties and brittle strength of thermally cracked granite under confinement. J Geophys Res Solid Earth 118(12):6099–6112. https://doi.org/10.1002/2013jb010340

Welty JRWC, Rorrer GW (2009) Fundamentals of momentum, heat, and mass transfer. Wiley and Sons, New York

Wu X, Huang Z, Cheng Z, Zhang S, Song H, Zhao X (2019a) Effects of cyclic heating and LN2-cooling on the physical and mechanical properties of granite. Appl Therm Eng 156:99–110. https://doi.org/10.1016/j.applthermaleng.2019.04.046

Wu X, Huang Z, Zhang S, Cheng Z, Li R, Song H, Huang P (2019b) Damage analysis of high-temperature rocks subjected to LN2 thermal shock. Rock Mech Rock Eng 52(8):2585–2603. https://doi.org/10.1007/s00603-018-1711-y

Wu Q, Weng L, Zhao Y, Guo B, Luo T (2019c) On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates. Eng Geol 253:94–110. https://doi.org/10.1016/j.enggeo.2019.03.014

Zhao XD, Tang CA, Li YH, Yuan RF, Zhang JY (2006) Study on AE activity characteristics under uniaxial compression loading. Chin J Rock Mech Eng 25(S2):3673–3678

Yin T, Zhang S, Li X, Bai L (2018) Evolution of dynamic mechanical properties of heated granite subjected to rapid cooling. Geomech Eng 16(5):483–493

Zhang Y, Sun Q, Cao L, Geng J (2017a) Pore, mechanics and acoustic emission characteristics of limestone under the influence of temperature. Appl Therm Eng 123:1237–1244. https://doi.org/10.1016/j.applthermaleng.2017.05.199

Zhang F, Zhao J, Hu D, Skoczylas F, Shao J (2017b) Laboratory investigation on physical and mechanical properties of granite after heating and water-cooling treatment. Rock Mech Rock Eng 51(3):677–694. https://doi.org/10.1007/s00603-017-1350-8

Zhang F, Zhao J, Hu D, Shao J, Sheng Q (2019) Evolution of bulk compressibility and permeability of granite due to thermal cracking. Géotechnique 69(10):906–916. https://doi.org/10.1680/jgeot.18.P.005

Zhao Z (2015) Thermal influence on mechanical properties of granite: a microcracking perspective. Rock Mech Rock Eng 49(3):747–762. https://doi.org/10.1007/s00603-015-0767-1

Zhao Y, Feng Z, Xi B, Wan Z, Yang D, Liang W (2015) Deformation and instability failure of borehole at high temperature and high pressure in hot dry rock exploitation. Renew Energy 77:159–165. https://doi.org/10.1016/j.renene.2014.11.086

Zhao Z, Dou Z, Xu H, Liu Z (2019) Shear behavior of Beishan granite fractures after thermal treatment. Eng Fract Mech 213:223–240. https://doi.org/10.1016/j.engfracmech.2019.04.012

Zhu D, Jing H, Yin Q, Han G (2018) Experimental study on the damage of granite by acoustic emission after cyclic heating and cooling with circulating water. Processes 6(8):101. https://doi.org/10.3390/pr6080101

Zuo J, Xie H, Zhou H, Peng S (2007) Experimental research on thermal cracking of sandstone under different temperature. Chin J Geophys 04:1150–1155

Acknowledgments

We thank for the supports from the National Natural Science Foundation of China (Grant Nos. 41772333), the Natural Science Foundation of Shaanxi Province, China (Grant No.2018JQ5124), and the Shaanxi Province New-Star Talents Project of Science and Technology (Grant No. 2019KJXX-049). We would also like to acknowledge the entire team for their efforts.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shen, Y., Hou, X., Yuan, J. et al. Thermal deterioration of high-temperature granite after cooling shock: multiple-identification and damage mechanism. Bull Eng Geol Environ 79, 5385–5398 (2020). https://doi.org/10.1007/s10064-020-01888-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-01888-7