Abstract

This paper presents a comprehensive investigation into weathered granitic gneiss in Guangzhou, China, including its formation, grading, classification, and the geotechnical characteristics of different weathered states. The granitic weathering profiles are graded into five weathered states: fresh rock, slightly weathered, moderately weathered, highly weathered, and completely weathered. The fresh rock and the slightly weathered rock have good mechanical behaviour. The highly weathered granitic gneiss was found to possess a relatively higher permeability than the other weathered states, in which the fissure water is usually stored. Geotechnical characteristics of the weathered granitic gneiss that poses geohazards during excavation are identified, including: (1) uneven grain size distribution, (2) water softening of the residual soils, and 3) spherical weathered boulder. The following potential geohazards are identified: (1) quicksand and piping, (2) water–ground settlement or even collapse due to water softening, (3) trenching difficulties in a diaphragm wall, and (4) instability of the lattice columns. Countermeasures for preventing these geo-hazards are proposed, including (1) rate-controlled drilling of dewatering wells, (2) grouting in both sides of retaining walls, and (3) deep hole blasting of large-size residual gravel boulders. These measures has been demonstrated to be useful in construction of Zhongxin Station.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The geotechnical characteristics of weathered granitic profiles are currently given a lot of attentions during construction. As a type of granitoid, granitic gneiss is more susceptible to being weathered into blocks and soils, than granite (Lee et al. 1994; Vinasco et al. 2006). Since its chemical and geotechnical properties change with the degree of weathering, the granitic weathering profiles have been conventionally divided into several grades from the bottom up (Dearman et al. 1978). Generally, the weathered granitic gneiss still possesses high compressive strength, but is also characterised by poor homogeneity, low moisture and sensitivity to moisture alternation (Gilkes and Suddhiprakarn 1979; Lan et al. 2003; Shen et al. 2015a; Cui et al. 2016). Weathered granitic gneiss is a major geological type which is widely distributed in the southeastern areas of China (Lan et al. 2003). The formation of weathered granitoid in southeast China is mainly attributed to the tropical and sub-tropical climate there, which brings a good amount of sunshine and water. Among the areas where granitic weathering profiles are distributed, the weathered granitic gneiss found in Guangzhou is the most typical form.

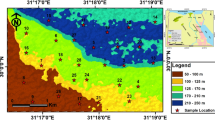

Located in the south-east of China, Guangzhou lies at a latitude of 23° north and on the shore of the South China Sea. Figure 1a gives a geological map of Guangzhou city. Guangzhou can be divided into three secondary geological structural zones: the Zengcheng Hilly Area, the Guanghua Basin, and the Pearl River Delta Basin (Wu and Huang 2006; Hong et al. 2008; Zhao et al. 2009; Shen et al. 2015b). Granitic weathering profiles in Guangzhou are widespread throughout the Zengcheng Hilly Area and the northern areas of the Guanghua Basin, and were generally formed in the Mesozoic Yanshanian period. The bedrock there involves several generic types of granite, including the remelting type, the syntectic type, and the differentiation type (Jiang et al. 2003, 2004; Cui et al. 2016). There are more than twelve types of stratum in the ground, most of which mainly consist of soils weathered from granitic gneiss.

Under rapid urbanisation, massive amounts of capital have been invested in the construction of airports, intercity surface transportation systems and underground transit systems in the southeast of China (Qian and Rong 2008; Shen 2000; Shen et al. 2010, 2014, 2016; Xu et al. 2012; Wang et al. 2013; Du et al. 2014; Wu et al. 2015a, b, c). During construction, the complex geotechnical characteristics of weathered granitic gneiss, especially its sensitivity to moisture alternation, creates huge difficulties and dangers in construction, such as ground settlement, quicksand and even ground collapse (Luo and Chen 2014; Cui et al. 2015a, b, 2016; Wu et al. 2015d). By literature survey, it was found that the relevant researches mostly focus on the distribution, grading, and physical and chemical properties of weathered granitic gneiss. Very few investigations have studied the geotechnical characteristics of weathered granitic gneiss and the potential geo-hazards involved with engineering activities. Weathered granitic gneiss should, therefore, be further studied in detail (Jiang et al. 2005, 2011; Chen et al. 2012).

The objectives of this study are (1) to investigate the formation, classification, and geotechnical characteristics of weathered granitic gneiss geology; and (2) to evaluate the potential geo-hazards during pit construction in weathered granitic gneiss.

Weathered granitic gneiss

Formation

Granitic gneiss, also known as biotite k-feldspar gneiss, is the result of granite formed by metamorphism. Granite is a type of magmatic rock that is formed by strong invasive activity of granitic magma intruding into sedimentary strata and then cooling. In this process, the massive buried acidic volcanic rock is transformed into granite. Then, under rock stress, minerals in granite are extruded and finally recrystallise into granitic gneiss. Thus, the mineral composition of granitic gneiss is chemically similar to granite, which is composed of feldspar, biotite, quartz, and hornblende. It is characterised by an alternately light and dark stratified structure. Unweathered granitic gneiss is compact and hard, with high compressive strength and good corrosion resistance. However, once the granitic gneiss is exposed on the ground surface, in touch with water, the air and sunshine, shear slip failure will occur along the weak structural plane of its stratified structure. By physical and chemical weathering, it continues to change and finally forms into weathered granitic gneiss in various weathered states. Weathered granitic gneiss, which is block-shaped, has a coarse grain composition including quartz, feldspar and mica, mostly filled with clay minerals which are mainly derived from weathered feldspar. Some granitic weathered profiles are directly exposed on the ground surface, but most of them are covered by alluvial deposition.

Grading of weathered state

As one type of granitoid, the weathered state of granitic gneiss has the same engineering grading as weathered granite. At present, the grading index for the weathered state of granitoid rock is not unified. Different types of grading indices and a comprehensive range of classifications have been presented in previous studies. Generally, researchers divide the granitic weathering profiles into five weathered states: fresh rock, slightly weathered, moderately weathered, highly weathered, and completely weathered (Iliev 1967; Dearman et al. 1978; Irfan et al. 1978). To classify the weathered granitic gneiss according to these five weathered states, the common method which is internationally credited is the comprehensive grading method. This method involves various indices for the comprehensive classification of the weathered states of granitoid rock. It classifies the weathered states mainly based on geological descriptions of granitic weathering profiles, along with indices such as point load, seismic wave velocity and standard penetration value (Lan et al. 2003). The geological descriptions and several indices for the grading of weathered granitic gneiss are summarised in Tables 1 and 2 (Ruxton and Berry 1957; Dearman 1975; Cui 1992; Irfan 1996; Wu et al. 1999; Shang et al. 2008). As the schemes show, with the increase in the degree of weathering, the core samples of granitic gneiss weathering profiles change from dark grey columns to yellow clastic blocks, and finally to purplish red sandy soils. In terms of the soil composition, the feldspar and biotite have been chemically weathered into clay minerals, while the primary minerals are mainly clastic debris physically weathered from quartz. The values of the quantitative indices (e.g., point loading strength, velocity of longitudinal wave and standard penetration test value) all change from high to low with the increase in the degree of weathering. As indicated in Table 2, the standard penetration test is mainly used to classify weathered granitic gneiss with a high degree of weathering.

Geotechnical characteristics of weathered granitic gneiss in Guangzhou

The granitic gneiss weathering profiles in Guangzhou are highly developed, with a thickness ranging from 10 to 50 m, and reaching depths of up to 100 m. It mainly belongs to the ‘Al-enriched’ weathering group, which is the product of the latest stage of weathering (Lan et al. 2003). Composed of granitic gneiss, sandy shale, and metamorphic sandstone, the granitic weathering profiles occurring in Guangzhou are the most typical forms found in southeast China. The fresh rock and slightly weathered granitic gneiss have maintained the structure and properties of the parent rocks. They are compact and hard enough to serve as bearing layers for major industrial projects. For the moderately weathered profiles, 50–90 % of the granitic gneiss was moderately weathered. Though distinct cleavage has developed, the moderately weathered granitic gneiss stills maintains the rock structure of its parent rock and its integrity as rock. Thus, the moderately weathered granitic gneiss still has high compressive strength and good autostability, which can serve as a bearing layer for general projects.

When fresh rock is weathered into highly weathered granitic gneiss, 50–70 % of the minerals in granitic gneiss, mainly feldspar, and is highly or completely weathered. The major contributing factor of the compressive strength of highly weathered granitic gneiss is the strength of the weathering product rather than the rock structure of granitic gneiss. As the cleavage is highly developed, and the clay minerals are too few to fill the cracks, the highly weathering profiles have a relatively higher permeability than weathered granitic gneiss in the other weathered states. Generally, a good deal of fissure water is stored in the cracks of highly weathered granitic gneiss. Thus, the highly weathered profiles is hydrous, permeable, and is usually treated as a confined aquifer.

The completely weathered granitic gneiss and its residual soils (eluvial soils of granitic gneiss) severely obstruct and jeopardise construction in sites where the granitic gneiss weathering profiles are distributed. The weathered soils are mainly made up of hard sandy clay, with medium strength and low compressibility. Since they have a high content of clay minerals, the completely weathered soils are relatively impermeable. Their permeability coefficient generally ranges from 1 × 10−6 to 1 × 10−4 cm/s, which is affected by the content of clay in the soils. The main geotechnical characteristics of the completely weathered granitic gneiss and its residual soils are as follows:

-

1.

Uneven grain size distribution. In the completely weathered granitic gneiss, coarse granules (grain size > 0.1 mm) and fine particles (grain size < 0.05 mm) constitute the main grain composition, while soil particles between 0.05 and 0.1 mm are far less prevalent. Due to this specific grain size distribution, the weathered soil features the characteristics of both sandy soil and clayey soil at the same time. This specific grain size distribution makes it possible for fine particles to flow through the pore space between coarse granules when under high hydrodynamic pressure. Because of this, precautions to prevent piping and quicksand are necessary when excavating in completely weathered granitic gneiss.

-

2.

Water softening. The content of silt and clay in the residual soils of weathered granitic gneiss can be as much as 20 %. In the natural state, residual soils have good mechanical properties, controlled by their soil structure and mineral composition. However, when the soils are subjected to water alternation, such as water soaking and flowing water construction, they can be water-softened, decomposed and finally deprived of their bearing capacity. Generally, in Guangzhou, the softening coefficient of completely weathered granitic gneiss is less than 0.36. The feldspar in granitic gneiss is the main source from which the silt and clay in residual soils are derived. As it can be weathered and formed into clay minerals, the more feldspar is contained in the parent rock, the more susceptible the weathered soils are to water alternation.

-

3.

Spherical weathering. In the weathering process, the feldspar which makes up two-thirds of granitic gneiss is first hydrolysed and carbonated into kaolinite, and then is further decomposed into weathered soils. At the same time, as minerals like quartz are difficult to weather and decompose, these minerals in granitic gneiss are usually formed into single rocks. When these rocks are exposed, their ledges are easily eroded by weathering from different directions. As a result, individual quartzose rock is gradually weathered into a boulder which is close to the sphere. The weathered rocks, or so-called boulders, are irregularly distributed in highly and completely weathered zones. The boulders are generally moderately and slightly weathered granitic gneiss and are too hard and compact for pit excavation and shield tunneling. Pretreatment is, therefore, necessary before construction.

Geology and hydrogeology at the construction site

Overview of the project

The study case, Zhongxin Station, is a subway station on Guangzhou Metro Line 21. It is located in Zhongxin Town and the west of the Zengcheng Hilly Area, as marked by the black star in Fig. 1a. Figure 1b gives an overview of the study site. The designed station site is intended to be built along the Guang-Shan Road, which is a main arterial route which carries heavy freight traffic. The surrounding dense residential housing and shops are mostly low-rise buildings built on shallow foundations. The study site is bordered by denuded monadnocks to the north, and is elsewhere surrounded by an alluvial plain. As a two-storey, island-type platform station, the overall designed length, width and depth of the station pit are 342.3, 29.7 and 11 m, respectively.

Site geology and hydrogeology

The geological conditions of this construction site are complex. Figure 2 gives a geological plan of the area around Zhongxin Station. The ground of the surrounding area is basically rock of the Middle Triassic to the Late Jurassic period, which was gradually formed by multiphase magmatic intrusion during the Yanshan tectonic stage. Figure 3 shows a geological section view of Zhongxin Station, as section A–A marked in Fig. 1b. The lithologic patterns of each stratum are tabulated in Table 3. The subsoil of section A–A mainly consists of 20 m of overlying loose sediment from the Quaternary period, and granitic gneiss from the Proterozoic era, including several alluvial–pluvial soft strata, eluvial soils of granitic gneiss (also called residual soils), and completely, highly, moderately and slightly weathered granitic gneiss. Boulders in this area are mainly clustered together around the designed diaphragm wall area, in the residual soils and in the completely weathered granitic gneiss. Figure 4 shows core samples from core-drilling in position A’–A’ marked in Fig. 3. The characteristics of the soil samples vary greatly in the vertical direction. The soil on the surface is relatively dry and has been weathered into granular particles. From 5 m to 15 m below the ground, the soils in this layer are highly saturated and plastic, with poor permeability. Beyond that, the strata mostly consist of granitic gneiss weathered to varying degrees, as seen in Fig. 4. The geotechnical profiles and soil properties of the subsoils in the whole study site are summarised in Fig. 5. The water content of the soil strata in this site ranges from 22.2 to 49.1 %, with permeability varying from 5.8 × 10−8 to 3 × 10−4 m/s. Cohesion of these soils mainly ranges from 5.42 to 35 kPa, but the cohesion of slightly weathered granitic gneiss can reach 1200 kPa. The boulders found in this site are depicted in Fig. 1c. Table 4 tabulates the profiles of the boulder groups.

Geological section view of Zhongxin Station (as section A–A shown in Fig. 1b)

Soil samples from core drilling in position A’–A’ marked in Fig. 3

The groundwater at this site can be classified into two types, pore water in the loose stratum of the Quaternary, and fissure water in bedrock cracks. The pore water mainly exists as phreatic water in the superficial loose sandy strata, and is recharged by rainfall. Fissure water in this site is found in the cracks of the highly weathered granitic gneiss. In this site, the permeability of the completely weathered soils is around 3 × 10−6 m/s, while the permeability of the highly weathered granitic gneiss is around 4 × 10−5 m/s. Thus, the completely weathered granitic gneiss acts as a relatively impermeable layer, and the fissure water in the highly weathered granitic gneiss layer is considered to be confined water.

Potential geo-hazards during pit construction and prevention measures

Ground settlement and collapse

The susceptibility of completely weathered granitic gneiss to softening by water, and the confined water stored in highly weathered granitic gneiss are the two main threats jeopardising construction in granitic gneiss weathering profiles. In its natural state, the upper part of the highly weathered granitic gneiss is hard, sandy and soil-like, while the lower part still retains some of the structure of the parent rock in the form of friable gravel. Fissure water is generally stored in the cracks of highly weathered rock. This layer is separated from the completely weathered layer by brown sandy clay in the upper part of the highly weathered granitic gneiss. However, when the layer is drilled or disturbed, the confined water in the highly weathered aquifer will flush through the gaps in the earth into the completely weathered layer and its residual soils. Subjected to moisture alternation, the completely weathered granitic gneiss is quickly water-softened and decomposed, losing its soil structure and bearing capacity. This may bring about ground settlement and ground collapse around the pit.

As the completely weathered granitic gneiss acts as an impermeable layer due to its low permeability, fissure water stored in the highly weathered granitic gneiss is under pressure. As shown in Fig. 3, part of the pit base will be close to and even, in places, unavoidably protruding through the highly weathered confined aquifer. Therefore, to protect the foundation pit from water ingress before the completion of the base slab, dewatering wells should be drilled to drain the confined water. Dewatering of the sandy confined aquifer may lead to ground settlement or even ground collapse if preventative measures are not taken (Shen and Xu 2011, Shen et al. 2013a; Xu et al. 2012a, b, 2013a, b, 2015; Wu et al. 2014). During dewatering, the drainage of the highly weathered granitic gneiss can lead to compaction of the confined sandy layer, resulting in ground settlement. In normal conditions, the wells continue to dewater the confined water in the highly weathered granitic gneiss during construction. However, if there is leakage in the diaphragm wall, the pore water in the Quaternary strata outside the pit may also be drained, with the soft layer correspondingly consolidated. The consolidation and settlement of these two aquifers can result in serious ground settlement around the foundation pit, and, therefore, jeopardise nearby buildings and traffic.

Another hazard resulting from dewatering is quicksand. The confined aquifer in this field is the sandy layer. Figure 6 depicts the grain size distribution curves of the completely weathered granitic gneiss in Zhongxin station. It can be seen that the medium-size grains (0.05–0.1 mm) are comparatively less common than the coarse grains and the fine grains. During pumping, fine grains such as silt in these layers could easily pass through coarse-grained sand under hydrodynamic pressure, resulting in quicksand and piping. Severe quicksand and piping will introduce large quantities of water and soil into the foundation pit, causing ground collapse and damage to surrounding buildings.

To prevent these potential geo-hazards, reinforcement such as chemical grouting should be undertaken to strengthen the soil (Bell 1996; Xu et al. 2014). Moreover, to reduce the disturbance to surrounding soil, a rate-controlled drilling method is recommended during drilling dewatering wells. The rate-controlled drilling method is as follows: (1) when soft layers are encountered, the drilling machine should drill with low pressure and at a low speed; (2) once it enters the granitic weathering profiles, the drilling rate should be increased to reduce the time that the water-softened layer is in contact with groundwater. The structure of the dewatering well is depicted in Fig. 7. The upper part of the well is filled with clay balls to isolate the water-softened layer from the water in the well. This drilling method has been proved to be suitable for the particular strata distributed within the study site.

Obstructions to diaphragm wall trenching and lattice column construction

Boulder groups present difficulties for both diaphragm wall trenching and pit excavation. Before diaphragm wall casting, grooving is needed to provide a key for the reinforcing cage. Trenching in a loose soft layer is relatively easy. However, at this site, some boulder groups obstruct the trenching and construction of diaphragm walls, as depicted in Fig. 1c. Six boulder groups have been uncovered within the designed area of the diaphragm wall. Inappropriate treatments could cause disturbance to the surrounding weathered soils as well as to the soft clay above, resulting in ground subsidence and collapse. Boulder groups also present problems for the pit excavation. Small boulders can be easily removed from the pit, but in basin and island excavations, it is difficult to remove large boulder groups from the soil slope. During rain storms, boulders embedded in the slope are likely to be washed out of the earth by the rain, leading to landslides and slope failure.

Lattice columns could collapse during the pit excavation if they are inadvertently constructed on boulders. At the initial stage of pit construction, lattice columns should be cast onto bedrock as a support structure for the struts and the columns of the underground structure. The lattice columns are so crucial that any instability in them may lead to overall damage to the entire pit construction. However, as they are composed of moderately weathered granitic gneiss, boulder groups are likely to be erroneously used as the bearing stratum in lattice column construction. When they are used as a bearing layer, most boulder groups are required to support heavy loads which could easily crush them during the excavation. Some boulder groups are just thick and strong enough to bear heavy loads. But, it is difficult to maintain the verticality of the lattice columns during construction, which will cause eccentric load transferring of supports connected on lattice columns. Moreover, because of their spherical shape and their mobility, most boulders would fail to remain still and would be susceptible to sliding under the eccentric vertical load. Without any end-bearing support, the lattice columns could collapse by buckling, thereby causing cutting and bending failures in the reinforced concrete struts. As a consequence, the diaphragm walls would become unstable under the high lateral earth pressure from the surrounding earth outside. The foundation pit would then be ultimately in danger of overturning. As the conclusion, boulder groups seriously jeopardise the security of pit construction and obstruct diaphragm wall trenching, and, therefore, need to be removed before construction.

To eliminate the impact of boulders, more boreholes should be drilled to give a detailed geotechnical investigation of boulder distribution. For boulders which are smaller than 800 mm, direct removal by trenching machine is recommended. For larger boulders, deep hole blasting is an appropriate and effective way. After drilling, PVC pipes should be inserted into the exploration holes as support and to provide a channel for the explosives. Around the blasting area, empty holes should be drilled to act as release channels for the high pressure of the explosion. Finally, the explosives can then be detonated to crush the boulders into pieces smaller than 300 mm, which can then be easily removed. The structure of the blasting holes and their arrangement are illustrated in Fig. 8.

After deep hole blasting, core samples were recovered to verify the effectiveness of the blasting. Figure 9 shows the geological drilling samples from boulder group B2 before and after the blasting. As shown in Fig. 9a, the boulder samples from the completely weathered granitic gneiss were long column-like, hard and compact. But in Fig. 9b, the cores were all clastic blocks smaller than 300 mm. Compared with the boulder samples before, it is apparent that the treatment would make it easy to directly trench the broken boulder stones out. In the process of deep hole blasting, no broken stones were projected from the blasting hole, suggesting little effect on the surrounding environment. Therefore, deep hole blasting is an effective method for treating the boulders safely and harmlessly.

Slope failure and long-term instability

Slope failure during excavation and long-term instability of the subway station are also potential geo-hazards because of the specific local geological conditions in which soft soils lie over hard soils. In this project, the open cut method is used to excavate the foundation pit. The thick soft layer in this site is characterised by high water content, poor permeability, high compressibility, and low anti-shearing strength. When the earth inside the pit is removed, the soft layer outside is liable to be disturbed by building loads nearby, causing large deformation and slope failure. However, other than the soft stratum, the granitic gneiss weathering profiles present the biggest threat to the entire project. The completely weathered layer and its residual soils can be water-softened and decomposed when it gets wet during the process of dewatering, causing a reduction in ground bearing capacity and water ingress at the bottom of the pit. Thus, when the passive earth pressure decreases, bottom heave and even slope failure are likely to occur. Additionally, the disintegration of the hard stratum caused by water will also threaten the long-term stability of the whole subway station.

To prevent potential slope failure and large wall deformation, high-pressure fracture grouting can be used to stabilise the area around the diaphragm walls (Chen et al. 2015; Shen et al. 2008, 2013b, c, d; Wang et al. 2013; Zhang et al. 2015; Wu et al. 2015e). A sectional view of the grouting range is depicted in Fig. 10. Along the inner edge of the diaphragm wall, a square area was subjected to the grouting procedure and was stabilised to hold the diaphragm wall. Outside the wall, the grouting procedure was conducted using fracture grouting to form a wedge-shaped area outside retaining walls to retain the earth and buildings close to the walls. Working as a retaining wall, the wedge-shaped grouting area has an overlap of 5 m with the square area inside to prevent it from overturning forward.

After the treatment, the lateral deformation of the diaphragm walls and settlement of nearby buildings were monitored. The observation points and monitored buildings are marked in Fig. 1c. As shown in Fig. 11, the lateral deformation of the observed points ranges from 0 to 17.5 mm, which is less than the warning value of 24 mm. Another observation is that, retained by the grouting in the inner edge of the walls, the deep-seated deformations of the wall did not bulge out at the position of the base slab, which differentiates from the bulging shape observed in previous studies (Pakbaz et al. 2013; Tan et al. 2015a, b; Tan and Wang 2015a, b; Wang et al. 2013, 2014). Table 5 shows the basic information and final settlement of five buildings which were monitored. As indicated, all the settlements of these buildings were lower than the warning value of 15 mm. Therefore, the high-pressure fracture grouting effectively reduced the ground settlement, as well as reducing the impact on the adjacent ground.

Application prospect of preventative measures

All the preventative measures proposed in this study have broad prospects for further application. The rate-controlling, well drilling method is demonstrated to be generally applicable for compound strata where loose sediments overlie a water-softened granitic layer, as the disturbances to both the soft layer and granitic weathered layer are reduced as much as possible. The corresponding dewatering well structure is also suitable in many situations to isolate a water-softened layer from water in the wells. For deep hole blasting, it efficiently crushes boulder groups into clastic blocks smaller than 300 mm, which is convenient for trenching out. Compact and hard rock masses can be easily cut and crushed by shock waves generated by an explosion. Therefore, besides boulder crushing, deep hole blasting also can be applied to cave mines, vertical shafts, cave depots, and tunneling. In this case study, high-pressure fracture grouting was utilized to prevent slope failure and large wall deformation, as well as to reduce the impact on adjacent ground. For further application, high-pressure fracture grouting is an effective measure for building foundation reinforcement and ground stabilisation to reduce building settlement and ground subsidence.

Conclusions

Based on the analysis of geological and geotechnical characteristics of weathered granitic gneiss and potential geo-hazards during excavation, the following conclusions can be drawn.

-

1.

In the study area, the following geotechnical characteristics of weathered granitic gneiss may induce geohazards during excavation: 1. uneven grain size distribution of completely weathered granitic gneiss, 2. water softening of the residual soils, and 3. spherical weathering. Since there is less medium-size particles (0.05–0.1 mm), fine particles can easily flow through pores formed by large-size particles, which will cause quicksand and piping hazards during groundwater pumping. The residual soils of granitic gneiss have a stable mechanical behaviors in its natural state. However, when subjected to water soaking or flowing water construction, it would be water-softened and decomposed, causing ground settlement or even collapse. The existence of spherical weathering of granitic gneiss may lead to difficulty in diaphragm wall trenching and instability of the lattice columns.

-

2.

The granitic weathering profiles are divided into five grades, that is, fresh, slightly weathered, moderately weathered, highly weathered, and completely weathered rock. The slightly and moderately weathered granitic gneiss keep the basic rock texture of the fresh rock, with high compressive strength and good self-stability. Since many fissures have developed in the highly weathered granitic gneiss, it is more permeable than the other four grades. Thus, confined aquifers are mostly formed in highly weathered granitic gneiss. The completely weathered granitic gneiss has a high content of clay particles so that it has low hydraulic conductivity.

-

3.

To prevent the aforementioned geohazards during excavation, the following measures are proposed: 1. rate-controlled drilling of dewatering wells, 2. grouting in both sides of retaining walls, and 3. deep hole blasting of large-size residual gravel boulders. The drilling rate of dewatering wells was controlled to avoid the water softening of the residual soils as well as to reduce the disturbance to overlaying soft clay. High-pressure fracture grouting was conducted to form a wedge-shaped area outside retaining walls to retain the earth and buildings close to the walls. Size-controlled blasting was conducted in deep holes to crush large-size boulders into blocks smaller than 300 mm, which was used to avoid obstruction of large-size boulders on the construction of diaphragm walls and lattice columns. These measures have been proved to be effective in construction of Zhongxin Station, and can provide good reference to engineering practices in similar ground.

References

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237

Chen F, Lin H, Zhang Y, Lu Z (2012) Ground subsidence geo-hazards induced by rapid urbanization: implications from InSAR observation and geological analysis. Nat Hazard Earth Syst Sci 12(4):935–942

Chen M, Shen SL, Arulrajah A, Wu HN, Hou DW, Xu YS (2015) Laboratory evaluation on the effectiveness of polypropylene fibers on the strength of fiber-reinforced and cement-stabilized Shanghai soft clay. Geotext Geomembr 43(6):515–523

Cui GY (1992) The problem of rock weathering zoning in foundation specification of harbor engineering. Tech Harb Eng 1–2:12–22 (in Chinese)

Cui QL, Wu HN, Shen SL, Xu YS, Ye GL (2015a) Chinese karst geology and measures to prevent geohazards during shield tunneling in karst region with caves. Nat Hazard 77(1):129–152

Cui QL, Shen SL, Xu YS, Wu HN, Yin ZY (2015b) Mitigation of geohazards during deep excavations in karst regions with caverns: a case study. Eng Geol 195(2015):16–27

Cui QL, Wu HN, Shen SL, Xu YS (2016) Geological difficulties of socket diaphragm walls in weathered granite in Shenzhen, China. Bull Eng Geol Environ. doi:10.1007/s10064-015-0740-y

Dearman WR (1975) Weathering classification in the characterisation of rock: a revision. Bull Eng Geol Environ 14(1):123–127

Dearman WR, Baynes FJ, Irfan TY (1978) Engineering grading of weathered granite. Eng Geol 12:345–374

Du YJ, Jiang NJ, Liu SY, Jin F, Singh DN, Puppala AJ (2014) Engineering properties and microstructural characteristics of cement-stabilized zinc-contaminated kaolin. Can Geotech J 51(3):289–302

Gilkes RJ, Suddhiprakarn A (1979) Biotite alteration in deeply weathered granite. I. Morphological, mineralogical, and chemical properties. Clays Clay Min 27(5):349–360

Hong L, Lianwang C, Yujiang L (2008) Numerical simulation of active faults in guangzhou area. J Geod Geodyn 2:008

Iliev IG (1967) An attempt to estimate the degree of weathering of intrusive rocks from their physico-mechanical properties. In: Proceedings of the 1st Congress International Society for Rock Mechanics, vol 1, Lisbon, pp 109-114

Irfan TY (1996) Mineralogy, fabric properties and classification of weathered granites in Hong Kong. Q J Eng Geol Hydrogeol 29(1):5–35

Irfan TY, Dearman WR (1978) Engineering classification and index properties of a weathered granite. Bull Int Assoc Eng Geol 17(1):79–90

Jiang MJ, Konrad JM, Leroueil S (2003) An efficient technique for generating homogeneous specimens for DEM studies. Comput Geotech 30(5):579–597

Jiang MJ, Leroueil S, Konrad JM (2004) Insight into strength functions of unsaturated granulates by DEM analysis. Comput Geotech 31(6):473–489

Jiang MJ, Yu HS, Harris DA (2005) Novel discrete model for granular material incorporating rolling resistance. Comput Geotech 32(5):340–357

Jiang MJ, Yan HB, Zhu HH, Utili S (2011) Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses. Comput Geotech 38:14–29

Lan HX, Hu RL, Yue ZQ, Lee CF, Wang SJ (2003) Engineering and geological characteristics of granite weathering profiles in South China. J Asian Earth Sci 21(4):353–364

Lee SG, Masuda A, Kim HS (1994) An early proterozoic leuco-granitic gneiss with the REE tetrad phenomenon. Chem Geol 114(1):59–67

Luo Q, Chen X (2014) Experimental research on creep characteristics of Nansha soft soil. Scientific World J 2014:8

Pakbaz MS, Imanzadeh S, Bagherinia KH (2013) Characteristics of diaphragm wall lateral deformations and ground surface settlements: case study in Iran-Ahwaz metro. Tunn Undergr Space Technol 35:109–121

Qian Q, Rong X (2008) State, issues and relevant recommendations for security risk management of China’s underground engineering. Chin J Rock Mech Eng 4:649–655 (in Chinese)

Ruxton BP, Berry L (1957) Weathering of granite and associated erosional features in Hong Kong. Geol Soc Am Bull 68(10):1263–1292

Shang YJ, Shi YY, Jin WJ, Yuan GX, Sun YC (2008) Discussion on relationship between weathering crust zonation and basic quality classification of rock mass. Chin J Rock Mech Eng 27(9):1858–1864 (in Chinese)

Shen J (2000) Chinese urbanization and urban policy. China Rev 1:455–480

Shen SL, Xu YS (2011) Numerical evaluation of land subsidence induced by groundwater pumping in Shanghai. Can Geotech J 48(9):1378–1392

Shen SL, Han J, Du YJ (2008) Deep mixing induced property changes in surrounding sensitive marine clays. J Geotech Geoenv 134(6):845–854

Shen SL, Du YJ, Luo CY (2010) Evaluation of the effect of double-o-tunnel rolling-correction via applyone-side block loading. Can Geotech J 47(10):1060–1070

Shen SL, Ma L, Xu YS, Yin ZY (2013a) Interpretation of increased deformation rate in aquifer IV due to groundwater pumping in Shanghai. Can Geotech J 50(11):1129–1142

Shen SL, Wang ZF, Yang J, Ho EC (2013b) Generalized approach for prediction of jet grout column diameter. J Geotech Geoenviro Eng 139(12):2060–2069

Shen SL, Wang ZF, Horpibulsuk S, Kim YH (2013c) Jet grouting with a newly developed technology: the twin-jet method. Eng Geol 152(1):87–95

Shen SL, Wang ZF, Sun WJ, Wang LB, Horpibulsuk S (2013d) A field trial of horizontal jet grouting using the composite-pipe method in the soft deposits of Shanghai. Tunn Undergr Space Technol 35:142–151

Shen SL, Wu HN, Cui YJ, Yin ZY (2014) Long-term settlement behavior of the metro tunnel in Shanghai. Tunn Undergr Space Technol 40:309–323

Shen SL, Wang JP, Wu HN, Xu YS, Ye GL (2015a) Evaluation of hydraulic conductivity for both marine and deltaic deposits based on piezocone testing. Ocean Eng 110(2015):174–182

Shen SL, Wu YX, Xu YS, Hino T, Wu HN (2015b) Evaluation of hydraulic parameters from pumping tests in soft deposits, Tianjin, China. Comput Geotech 7:196–207

Shen SL, Cui QL, Ho EC, Xu YS (2016) Ground response to multiple parallel Microtunneling operations in cemented silty clay and sand. J Geotech Geoenviron Eng 142(4):04016001(1–11)

Tan Y, Wang D (2015a) Structural behaviors of large underground earth-retaining systems in Shanghai. I: unpropped circular diaphragm wall. J Perform Constr Facil ASCE 29(2):04014058

Tan Y, Wang D (2015b) Structural behaviors of large underground earth-retaining systems in Shanghai. II: multipropped rectangular diaphragm wall. J Perform Constr Facil ASCE 29(2):04014059

Tan Y, Li X, Kang Z, Liu J, Zhu Y (2015a) Zoned excavation of an oversized pit close to an existing metro line in stiff clay: case study. J Perform Constr Facil ASCE 29(6):04014158

Tan Y, Wei B, Zhou X, Diao Y (2015b) Lessons learned from construction of Shanghai metro stations: importance of quick excavation, prompt propping, timely casting and segmented construction. J Perform Constr Facil ASCE 29(4):04014096

Vinasco CJ, Cordani UG, González H, Weber M, Pelaez C (2006) Geochronological, isotopic, and geochemical data from Permo-Triassic granitic gneisses and granitoids of the Colombian Central Andes. J S Am Earth Sci 21(4):355–371

Wang ZF, Shen SL, Ho CE, Kim YH (2013) Investigation of field-installation effects of horizontal twin-jet grouting in Shanghai soft soil deposits. Can Geotech J 50(3):288–297

Wang ZF, Shen SL, Ho CE, Xu YS (2014) Jet grouting for mitigation of installation disturbance. Geotech Eng ICE Proc 167(GE6):526–536

Wu HD, Huang WH (2006) Seismic database management system of Guangdong digital seismograph network. South China J Seismol 26(2):66–71 (in Chinese)

Wu HN, Huang RQ, Sun WJ, Shen SL, Xu YS, Liu YB, Du SJ (2014) Leaking behavior of shield tunnels under the Huangpu River of Shanghai with induced hazards. Nat Hazard 70(2):1115-1132

Wu HW, Shang YJ, Qu YX (1999) Chemical weathering indices and zoning for granitic weathering crusts in Hong Kong. Chin J Eng Geol 3:177–185 (in Chinese)

Wu HN, Shen SL, Liao SM, Yin ZY (2015a) Longitudinal structural modelling of shield tunnels considering shearing dislocation between segmental rings. Tunn Undergr Space Technol 50(2015):317–323

Wu HN, Shen SL, Ma L, Yin ZY, Horpibulsuk S (2015b) Evaluation of the strength increase of marine clay under staged embankment loading: a case study. Mar Georesour Geotechnol 33(6):532–541

Wu YX, Shen SL, Xu YS, Yin ZY (2015c) Characteristics of groundwater seepage with cutoff wall in gravel aquifer. I: field observations. Can Geotech J 52(10):1526–1538. doi:10.1139/cgj-2014-0285

Wu YX, Shen SL, Yin ZY, Xu YS (2015d) Characteristics of groundwater seepage with cutoff wall in gravel aquifer. II: numerical analysis. Can Geotech J 52(10):1539–1549. doi:10.1139/cgj-2014-0289

Wu YX, Shen SL, Wu HN, Xu YS, Yin ZY, Sun WJ (2015e) Environmental protection using dewatering technology in a deep confined aquifer beneath a shallow aquifer. Eng Geol 196(2015):59–70. doi:10.1016/j.enggeo.2015.06.015

Xu YS, Ma L, Shen SL, Sun WJ (2012a) Evaluation of land subsidence by considering underground structures penetrated into aquifers in Shanghai. Hydrogeol J 20(8):1623–1634. doi:10.1007/s10040-012-0892-9

Xu YS, Ma L, Du YJ, Shen SL (2012b) Analysis on urbanization induced land subsidence in Shanghai. Nat Hazards 63(2):1255–1267. doi:10.1007/s11069-012-0220-7

Xu YS, Huang RQ, Han J, Shen SL (2013a) Evaluation of allowable withdrawn volume of groundwater based on observed data. Nat Hazard 67(2):513–522

Xu YS, Shen SL, Du YJ, Chai JC, Horpibulsuk S (2013b) Modelling the cutoff behavior of underground structure in multi-aquifer-aquitard groundwater system. Nat Hazard 66(2):731–748

Xu YS, Shen SL, Ma L, Sun WJ, Yin ZY (2014) Evaluation of the blocking effect of retaining walls on groundwater seepage in aquifers with different insertion depths. Eng Geol 183:254–264

Xu YS, Yuan Y, Shen SL, Yin ZY, Wu HN, Ma L (2015) Investigation into subsidence hazards due to groundwater pumping from Aquifer II in Changzhou, China. Nat Hazard 78(1):281–296

Zhang N, Shen SL, Wu HN, Chai JC, Yin ZY (2015) Evaluation of performance of embankments with reinforcement on PVD-improved marine clay. Geotext Geomembr 43(6):506–514

Zhao Q, Lin H, Jiang L, Chen F, Cheng S (2009) A study of ground deformation in the Guangzhou urban area with persistent scatterer interferometry. Sensors 9(1):503–518

Acknowledgments

The research work described herein was funded by the National Basic Research Program of China (973 Program: 2015CB057806) and partially funded by the National Natural Science Foundation of China (NSFC; Grant No. 41372283). These financial supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, M., Shen, SL., Wu, HN. et al. Geotechnical characteristics of weathered granitic gneiss with geo-hazards investigation of pit excavation in Guangzhou, China. Bull Eng Geol Environ 76, 681–694 (2017). https://doi.org/10.1007/s10064-016-0915-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-016-0915-1