Abstract

Rich groundwater content can produce a complex geological environment for underground tunnels. Therefore, the brittle mechanical characteristics of hard rock exposed by tunnelling in a moist environment are of great significance. Uniaxial tests and acoustic emission (AE) analysis of sandstone with respect to different moisture conditions are described in this paper. Moisture-controlled trends of the stress–strain relationship, mechanical parameter variation, maximum instantaneous AE energy, cumulative AE energy and macro crack behaviour were analysed in detail. In addition, X-ray diffraction and scanning electron microscopy were performed to analyse the fracture surfaces of rock at the microscale. Sandstone particles were found to be more likely to slip past each other at high moisture contents, resulting in increased plastic deformation and dissipation of internal energy. Increasing moisture reduces the brittleness of hard rock and the probability of rock burst. The results reveal the mechanical mechanisms cause moisture to affect brittle hard rock and can contribute to the improvement of the design and construction of deep tunnels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In general, moisture is known to reduce rock strength and alter the failure state of rock. Moisture always has a negative effect on the mechanical properties, long-term behaviour and stability of rock masses. The effects of moisture include weathering, erosion, freeze–thaw cycling, chemical and physicochemical degradation and instigation of biological degradation (Verstrynge et al. 2014). Moisture can affect rock in one or both of two possible manners. The first manner is mechanical in nature: moisture content decreases the effective strength of rock (Masuda 2001; Reviron et al. 2009; Navarro et al. 2010; Duda and Renner 2013; Wasantha and Ranjith 2014). Baud et al. (2000) measured a reduction in brittle strength ranging from 5 to 17 % in the presence of water by conducting triaxial compression experiments. Additionally, Taibi et al. (2009) explored the water–mechanical behaviour of partially saturated soft rock at a low confining pressure through uniaxial and triaxial compressive tests. The second manner is chemical. Hydro-chemical interactions between the rock minerals change the mechanical behaviour of rock specimens (Feng et al. 2009; Shukla et al. 2013; Mathurin et al. 2014). The mineral composition is an important factor that determines the effect of moisture on the strength of rock. The subcritical crack growth of rock is considerably affected by the relative humidity and by the clay content (Nara et al. 2010, 2012). Computerized tomographic scanning (CTS) and scanning electron microscopy (SEM) were used in the real-time detection of the weakening behaviour induced in mudstone by water (Jiang et al. 2014).

Many rock burst problems under large ground stresses have been studied through engineering research and in practice (Feng et al. 2006; Jiang et al. 2010; Li et al. 2012; Chen et al. 2013; Zhang et al. 2012). Underground tunnels can be exposed to a complex geological environment due to the presence of rich groundwater content (Lipponen and Airo 2006; Perello et al. 2014; Yu et al. 2014). Therefore, further study of rock mechanical behaviour in deep hard rock tunnels in the presence of moisture is of great significance and has become a prominent research topic in the field of tunnel engineering.

The effects of groundwater on rock deformation have been studied through various field investigations (Valery and Fridrich 1993). Many methods of rock burst prevention that rely on analyses of the effects of moisture have been discussed (Frid 2000; Huang et al. 2011; Cheng et al. 2012; Song et al. 2014). A considerable amount of research has focused on rock mechanical characteristics as a function of moisture content. However, few experiments have discussed the acting mechanisms of moisture from the perspective of microscopic mineral analysis and acoustic emission (AE) energy. The influence of water on rock bursts is rarely studied.

To understand the mechanical characteristics and rock burst mechanisms of hard rock in a rich groundwater environment, a series of uniaxial mechanical tests with respect to different moisture conditions are performed in this study. Stress–strain relationships are monitored, and AE activity and SEM analysis are incorporated as well. The influence of moisture on the mechanical behaviour and rock burst potential of hard rock are primarily analysed from the perspective of microscopic failure characteristics, macroscopic mechanical behaviour and the evolution of AE energy.

Materials

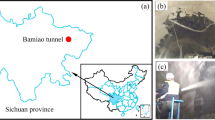

The background of engineering geology

Rock bursts have occurred many times in the Bamiao Tunnel in Sichuan Province of Southwest China. Post-failure images of rock bursts are shown in Figs. 1 and 2. These figures show that the steel arch underwent twisting deformation, leading to a continuous collapse. They also show that the failure range is wide and that the degree of failure is serious. The stratum and lithology are those of Cretaceous rock. The layers of sandstone are mainly composed of the delta–lacustrine depositional system, and the rock mass quality is very high. The rock mass has almost no structural planes or joints. These conditions increase the likelihood of rock bursts.

Two aspects are important when selecting rock samples in the study of brittle characteristics as affected by moisture: mechanical properties, including high strength and stiffness, and a strong sensitivity to water. Rock samples were obtained from a complete homogeneous rock mass in the Bamiao Tunnel. The sandstone samples were formed into cylinders based on ISRM recommendations, i.e., the sample is a cylinder with dimensions of \( \phi \) 50 × 100 mm. The coring process was controlled according to Chinese National Standard (2001) (SL264-2001).

Properties of sandstone samples

Sandstone samples were examined by X-ray diffraction to determine their mineral composition; a representative X-ray diffraction spectrum is shown in Fig. 3. Constituent mineralogical components and their compositions in sandstone are listed in Table 1. Figure 3 and Table 1 show that the framework grains of sandstone contain not only coarse particles, such as quartz and feldspar, but also clay minerals such as kaolinite, vermiculite and smectite.

The influence of water on rock is mainly via the expansion of clay minerals in water from the perspective of mineral composition. Clay minerals appear as tiny flat particles, and their surfaces can produce strong interactions with water. The sandstone in this study has three main types of clay minerals: kaolinite, vermiculite and smectite. Moreover, the hydrotropism, expansibility and shrinkage of smectite are greater than those of kaolinite and vermiculite. Differences in mineral composition can lead to different water absorption abilities and to different expansion ratios, thus resulting in the occurrence of micro cracks.

In addition, the influence of water on rock can be mainly classified into two types from the perspective of engineering geology: on the one hand, interstitial hydraulic pressure can be produced by water filling the cracks of rock, and then, the effective normal stress of any surface can be decreased. Therefore, the friction resistances of these surfaces will be decreased. On the other hand, the engineering geological characteristics can be changed through the influence of water on the rock structure. Moreover, the influence of water on the mechanical properties of rock can be classified into two types: (1) wedge action—the water molecules will impose a certain pressure on the two walls of a crack, resulting in a considerably decreased rock strength—and (2) lubrication action—a water film will be produced along the crack wall after the water enters the rock crack. The water molecules can separate the solid surface and function as a lubricant when relative shear displacement has occurred on the two walls, resulting in an increased deformation performance and decreased friction angle. In general, the internal friction angle \( \varphi ^{\prime } \) and effective normal stress \( \sigma ^{\prime } \) of any surface are decreased under the action of water. According to the shear strength equation of effective stress,

where \( \tau_{\text{f}} \) is the effective shear stress on the shear failure surface, \( c^{\prime} \) is the effective cohesion intercept between rock particles, \( \sigma^{\prime } \) is the effective normal stress on the shear failure surface, and \( \varphi ^{\prime } \) is the internal friction angle.

Equation (1) shows that \( \sigma ^{\prime } \) and \( \varphi ^{\prime } \) of internal rock gradually decrease with increasing water content. Then, rock particles are more likely to slip past each other, resulting in a decreased \( \tau_{\text{f}} \). Therefore, the rock failure strength gradually decreases.

Test methods

Sample preparation and testing

Moisture conditions were regulated by controlling the moisture content. Five levels were established by selecting the following values of the water saturation coefficient k s: 0 (dried state), 0.19, 0.48, 0.64 and 1 (saturated state). The water saturation coefficient \( k_{\text{s}} \) is calculated as follows:

where k s is the water saturation coefficient, ω a is the actual water absorption and ω sa is the water-saturated absorption.

The moisture level control procedure was as follows:

-

1.

The natural density and natural moisture content of each sample were similar because all samples originated from the same rock. The mass and size of sandstone under different moisture conditions were tested. The testing results demonstrated that the average dried density was 2.6 g/cm3.

-

2.

The size and natural weight of the samples were measured, and the dried weight was calculated from the average density and volume in the dried state. Then, the saturated weight as a function of the water saturation coefficient of each sample was calculated with the set moisture content and dried weight.

-

3.

A temperature range from 105 to 110 °C was used to achieve the dried condition. First, all samples were dried. Second, the dried samples were exposed to water, whose absorption served to establish different moisture conditions. If the moisture content exceeded the set value, the sample was placed in air to decrease its internal moisture content. The entire process was controlled by monitoring the weight of the sample in real time.

The average mass increase of the water-saturated sandstone in comparison to dried sandstone was determined to be approximately 6.8 g. The mass difference following water absorption between each level was approximately 1.7 g when the water content was divided into five levels. It is difficult to accurately control moisture content during sample preparation; therefore, a certain error exists between the actual water absorption and the set water absorption. The rock samples before the test are shown in Fig. 4. Their physical properties are listed in Table 2.

Test principles and methods

Uniaxial compression tests were conducted by imposing an axial load on samples under unconfined conditions at different moisture conditions and by measuring the resulting axial deformation. Wawersik and Fairhurst (1970) divided the failure pattern of rock into two types (I, II) according to the stress–strain curve obtained during uniaxial compression tests (Fig. 5). Type I corresponds to stable failure. The accumulated deformation of rock samples after the peak does not continue to drive crack growth. However, a crack can be further expanded by subjecting the rock to additional loading. Rock characterized by low hardness tends to exhibit type I characteristics. Type II corresponds to unstable failure. Additional external loading is not necessary to promote failure; instead, the sudden outburst of accumulated strain energy can cause rock failure. In general, brittle hard rock often tends to exhibit type II characteristics and is susceptible to rock bursts. The complete stress–strain curve was measured and enabled the calculation of the uniaxial compressive strength, elastic modulus and Poisson’s ratio.

Failure type under uniaxial compression (according to Wawersik and Fairhurst 1970) I stable failure, II unstable failure

The loading rate was controlled at an axial displacement rate of 0.1 mm/min in the elastic deformation stage and then at a lateral deformation rate of 0.03 mm/min until ultimate failure when the sample entered the failure stage.

Test results

The effects of water on the mechanical behaviour, AE characteristics and fracturing behaviour of sandstone are discussed below.

Effects of water on mechanical behaviour

The characteristics of the mechanical behaviour under various moisture conditions are discussed in terms of five categories: (1) stress–strain response, (2) uniaxial peak strength, (3) axial peak strain behaviour, (4) elastic modulus and (5) Poisson’s ratio.

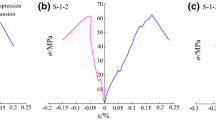

Stress–strain response

The stress–strain characteristics obtained from the uniaxial compression tests under different moisture conditions are shown in Fig. 6.

-

1.

The stress–strain curves are in accordance with the type II curve under different moisture conditions. Moreover, the peak strengths were relatively high (up to 90 MPa), and the peak strains were all relatively small (less than 9 × 10−3). The sandstone exhibits high strength—an enabling factor of rock bursts—as well as brittle failure characteristics.

-

2.

Elastic deformation stage: The stress–strain curve slightly increased when the stress level was low, therein presenting a concave shape. This indicates that sandstone features a relatively small number of microscopic cracks, which results in the compression of internal particles in the sandstone. The stress–strain curve transitions to a straight line when the pressure increases to a certain value, producing a convex shape. This feature indicates that the microscopic cracks have entered into the stable extending stage.

-

3.

The stage after peaking: The stress–strain curve decreased after the peak. The loading rate control was converted to the lateral deformation control of 0.03 mm/min until complete failure when the sample entered the failure stage. Hysteresis appeared after the peak as a result of the use of lateral deformation control. Moreover, the cohesion of sandstone is high, and the bond strength between particles is inhomogeneous, resulting in a plastic deformation stage indicated by the part of the curve exhibiting a convex shape. The stress was quickly reduced, and the change in strain also decreased, which indicating a brittle failure.

Uniaxial peak strength

The dependence of the uniaxial peak strength on the moisture content is shown in Fig. 7.

The moisture content strongly influenced the uniaxial peak strength, and increasing moisture content reduced the peak strength. The peak strength was 171.89 MPa when \( k_{\text{s}} = 0 \). The peak strength rapidly decreased to 132.40 MPa, corresponding to a strength reduction of 23 %, as the moisture content was increased to 0.19. With further increase in moisture, the peak strength decreased in a more gradual manner. Finally, the peak strength reached 103.39 MPa (60.2 % of the peak strength of dried sandstone) when \( k_{\text{s}} = 1.00 \).

Axial peak strain variation

The dependence of the axial peak strain on moisture content is shown in Fig. 8.

Figure 8 shows that the axial peak strain decreased with increasing moisture content. The maximum axial peak strain was 8.38 × 10−3 when \( k_{\text{s}} = 0 \). However, the peak strain decreased to 6.62 × 10−3, and a strain reduction of 21 % was observed when the moisture content was increased to 0.19. The peak strain continued to decrease with an increasing moisture content, reaching a minimum of 6.12 × 10−3 (corresponding to 73.1 % of the axial peak strain of dried sandstone) when \( k_{\text{s}} = 1.00 \).

Elastic modulus

The elastic modulus of sandstone was calculated as suggested by the Chinese National Standard (2001) (SL264-2001):

where \( E_{50} \) is the elastic modulus of rock (GPa), \( \sigma_{50} \) is the stress value corresponding to 50 % of the peak value, and \( \varepsilon_{\text{L50}} \) is the strain in the lengthwise direction when the stress value is \( \sigma_{50} \).

The dependence of the elastic modulus on the moisture content is shown in Fig. 9.

The elastic modulus decreased with increasing moisture content. The maximum elastic modulus was 19.42 GPa when \( k_{\text{s}} = 0 \). A reduction of 39 % was observed when the moisture content reached 0.64; past this point, the elastic modulus rapidly decreased. The minimum elastic modulus was 15.23 GPa (representing 78.4 % of the elastic modulus of dried sandstone) when \( k_{\text{s}} = 1.00 \).

Poisson’s ratio

Poisson’s ratio was calculated as suggested by Chinese National Standard (2001) (SL264-2001):

where \( \mu_{50} \) is Poisson’s ratio, \( \varepsilon_{\text{L50}} \) is the axial strain corresponding to \( \sigma_{50} \), and \( \varepsilon_{\text{d50}} \) is the circumferential strain corresponding to \( \sigma_{50} \). The axial and circumferential strains are assumed to be compressive and tensile, respectively.

Measured values of the Poisson’s ratio as a function of moisture content are shown in Fig. 10.

The values generally increased with increasing moisture content. The minimum Poisson’s ratio was 0.076 when \( k_{\text{s}} = 0 \). In addition, the Poisson’s ratio increased to 0.087 and then decreased to 0.078 before decreasing again. The Poisson’s ratio reached 0.155 when \( k_{\text{s}} = 1.00 \), and this value was approximately 2.04 times the Poisson’s ratio of dried sandstone.

Effects of water on AE energy

AE occurs as a result of energy being released from the original microscopic cracks in rock. The observed AE characteristics during failure play an important role in the analysis of brittle failure mechanisms.

Figure 11 shows the AE energy rate as a function of time for all samples. Axial stress measurements over time are plotted in the same figures. It is clear that the internal energy of sandstone is continuously accumulated with time. The energy is suddenly released and the rock sample undergoes failure when the strain energy reaches the maximum threshold of the rock. The process of energy release exhibits the characteristics of brittle failure when the water saturation coefficient is low (see Fig. 11a, b) and the characteristics of plastic failure when the coefficient is high (see Fig. 11c–e). Overall, the AE energy is not easily detectable during the initial period, and it is maximized at the moment of failure. In Fig. 11a, b, the AE energy was detectable during and after failure. In Fig. 11c–e, the AE energy was detectable before and during failure. The AE energy before failure increased and the AE energy after failure decreased with increasing moisture. Moreover, the peak energy rate decreased with increasing moisture.

Maximum instantaneous AE energy

The relationship of maximum instantaneous (MI) AE energy with moisture content is shown in Fig. 12.

The MI AE energy decreased with increasing moisture content. The maximum moisture-dependent MI AE energy was 32.65 × 103 aJ when \( k_{\text{s}} = 0 \). The MI AE energy decreased to a minimum value of 18.82 × 103 aJ when \( k_{\text{s}} = 1.00 \). The energy exhibited a sudden reduction when the moisture content was changed from 0.48 to 0.64.

Cumulative AE energy

The cumulative AE energy was calculated as the summation of the AE energy before time t:

where \( E_{\text{c}} \) is the cumulative AE energy and t is time.

The dependence of the cumulative AE energy on the moisture content is shown in Fig. 13.

The cumulative AE energy decreased with increasing moisture content. The cumulative AE energy of dried sandstone was 30.6 × 106 aJ but decreased to a minimum of 16.2 × 106 aJ at the saturation point. Moreover, the cumulative energy exhibited a sudden reduction when the moisture content was changed from 0.48 to 0.64.

Figures 12 and 13 demonstrate that the MI AE energy and cumulative AE energy decreased with increasing moisture content and exhibited sudden decreases when the moisture content was increased from 0.48 to 0.64. Microscopic cracks are more likely to initiate and propagate at the larger end of this range, resulting in the reduction in MI AE energy and cumulative AE energy.

Effects of water on fracture behaviour

Table 3 presents post-failure samples at different moisture levels. Note that the width and length of the failure cracks increase with increasing moisture content. Moreover, the decrease in the failure plane angle with increasing moisture content implies a decrease in the friction angle, possibly as a result of the increasing degree of plastic behaviour exhibited by the sandstone under conditions of higher moisture.

In addition, microscopic failure features at the fracture surface at different moisture levels can be identified by SEM, as shown in Fig. 14. In Fig. 14a, the surface is smooth and exhibits a shallow stepped pattern, which is conclusive evidence of brittle deformation. In Fig. 14b, the surface is relatively smooth, and shallow fluvial patterns can be observed, indicating some degree of plastic deformation. In Fig. 14c, the surface is rough, and a large number of river patterns have joined to form a cleavage crack, thus indicating a greater amount of plastic deformation. An obvious feature of Fig. 14d is that the layer structural plane is dilacerated. Figure 14e shows prominent roughness and signs of large-scale failure in the form of local arc-shaped patterns. From the microscopic characteristics described above, it can be concluded that the fracture surface becomes coarser with increasing moisture content.

Discussion

This study reveals important behaviours regarding water-based weakening mechanisms in sandstone. In addition, the moisture effect response and its influence on strength are highlighted. X-ray diffraction and SEM were used to characterize the weakening influence of water. The progressive fracturing behaviour of sandstone was also analysed by monitoring AE events.

The X-ray diffraction results show that the original sandstone contains clay minerals, resulting in particle swelling at different water content levels in water, which increases the inter-particle pore space and promotes inter-particle slip. Then, the internal frictional angle and effective normal stress of internal rock gradually decrease with increasing water content. Consequently, the effective normal stress and the friction force between the particles are affected (see Fig. 15a, b). Therefore, the compressive strength of the rock sample decreases, and the internal energy is released relatively early because of particle slippage under the action of external stress.

The uniaxial test verified the above analysis from a macroscale perspective. The uniaxial compressive strength and elastic modulus decreased considerably, and the peak axial strain decreased moderately, whereas the Poisson’s ratio increased with increasing moisture. The decreasing failure plane angle with increasing moisture implies a decrease in friction angle, which is connected to the increasing amount of plastic behaviour exhibited by the sandstone at higher moisture levels. Moreover, the axial strain of saturated sandstone substantially increased, whereas the axial stress remained constant, thus indicating that the reservoir capacity of the strain energy decreased with increasing moisture. The internal energy was dissipated through the process of plastic strain, which provided an alternative to brittle fracture.

Furthermore, AE tests were also conducted in this study. The AE energy results indicate that the internal released energy increased before failure and that the maximum released energy decreases with increasing water content (see Fig. 11). A mechanical explanation for this is that the energy was previously dissipated through inter-particle slippage promoted by increases in the inter-particle pore space.

Combined with the SEM results, it can be concluded that the fracture surface becomes coarser with increasing moisture content. This is due to the higher internal friction angle and effective normal stress between particles under the condition of low moisture content. Therefore, particles rarely slip, and a crack is directly generated when the sandstone is under the stress effect. Finally, the failure fracture presents brittleness and smoothness. On the contrary, the internal friction angle and effective normal stress decrease, resulting in a higher probability of particles slipping past each other under high moisture content conditions. Therefore, particle slippage and plastic deformation occur primarily when the sandstone is under the stress effect, leading to the generation of cracks. Clearly, the accumulation of internal energy is preferentially dissipated through particle slippage, and the released energy decreases at the moment of ultimate failure. The failure fracture presents plasticity and roughness.

Conclusion

The following conclusions can be drawn from the analysis of the stress–strain curves, mechanical parameters, AE energy, macro failure modes and microscopic failure features under different moisture conditions:

-

1.

With X-ray diffraction technology, the sandstone in this study is found to contain three types of clay minerals: kaolinite, vermiculite and smectite. Differences in mineral composition can lead to different water absorption abilities and to different expansion ratios, thus resulting in the occurrence of microscopic cracks. Moreover, the internal friction angle and effective normal stress of particles decreases because of the water absorption abilities of clay minerals. Sandstone particles are more likely to slip past each other at a higher moisture content.

-

2.

Sandstone has a high strength, which is associated with brittle failure and a greater likelihood of rock bursts. The uniaxial compressive strength and elastic modulus significantly decrease, whereas the Poisson’s ratio and peak axial strain increase with moderately increasing moisture. These mechanical results are in good agreement with the AE results. The AE phenomenon shows that MI energy and cumulative energy decrease with increasing moisture. The dissipative energy before failure increases with increasing moisture, meaning that partial internal energy dissipates in advance. It can be concluded that the brittle failure phenomenon of sandstone becomes less prominent and that plastic failure predominates with increasing moisture, revealing that moisture could inhibit rock bursts.

-

3.

The SEM results show that the fracture surface becomes coarser with increasing moisture content. The microcosmic reasons are that particles rarely slip and that cracks are directly generated under low moisture conditions when the sandstone is under the stress effect, leading the failure fracture to present brittleness and smoothness. On the contrary, particle slippage and plastic deformation occur primarily at a higher moisture content, leading to the generation of cracks. The failure fracture presents plasticity and roughness. In response, the microscopic failure surface becomes rougher, and the characteristics of plastic failure became more prominent. It can be concluded that the brittleness of sandstone decreases and that its plasticity increases with increasing moisture.

References

Baud P, Zhu WL, Wong TF (2000) Failure mode and weakening effect of water on sandstone. J Geophys Res Solid Earth. 105(B7):16371–16389

Chen BR, Feng GL, Li Q et al (2013) Analysis of microseismic characteristic and rock burst risk during TBM excavation under deeply burried tunnel. Disaster Adv. 6(s1):122–128

Cheng WM, Nie W, Zhou G, Yu YB, Ma YY, Xue J (2012) Research and practice on fluctuation water injection technology at low permeability coal seam. Original Research Article. Saf Sci 13(8):851–856

Chinese National Standard (2001) SL264-2001 Specifications for rock tests in water conservancy and hydroelectric engineering. The National Ministry of Water Resources of People’s Republic of China, Beijing (in Chinese)

Duda M, Renner J (2013) The weakening effect of water on the brittle failure strength of sandstone. Int J Solids Struct 192(3):1091–1108

Feng XT, Pan PZ, Zhou H (2006) Simulation of the rock microfracturing process under uniaxial compression using an elasto-plastic cellular automaton. Int J Rock Mech Min Sci 43(7):1091–1108

Feng XT, Ding WX, Zhang DX (2009) Multi-crack interaction in limestone subject to stress and flow of chemical solutions. Int J Rock Mech Min Sci 46(1):159–171

Frid V (2000) Electromagnetic radiation method water-infusion control in rock burst-prone strata. J Appl Geophys 43(1):5–13

Huang BX, Liu CY, Fu JH, Guan H (2011) Hydraulic fracturing after water pressure control blasting for increased fracturing. Original Research Article. Int J Rock Mech Min Sci 20(2):976–983

Jiang Q, Feng XT, Xiang TB (2010) Rock burst characters and numerical simulation based on a new energy index—a case study of tunnel under 2500 m depth. Bull Eng Geol Environ 69(3):381–388

Jiang Q, Cui J, Feng XT, Jiang YT (2014) Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bull Eng Geol Environ 73(4):1293–1301

Li SJ, Feng XT, Li ZH (2012) In situ monitoring of rock burst nucleation and evolution in the deeply buried tunnels of Jinping II hydropower station. Eng Geol 137(6):85–96

Lipponen A, Airo ML (2006) Linking regional-scale lineaments to local-scale fracturing and groundwater inflow into the Paijanne water-conveyance tunnel, Finland. Near Surf Geophys 4(2):97–111

Masuda K (2001) Effects of water on rock strength in a brittle regime. J Struct Geol 23(11):1653–1657

Mathurin FA, Drake H et al (2014) High cesium concentrations in groundwater in the upper 1.2 km of fractured crystalline rock—influence of groundwater origin and secondary minerals. Geochim Cosmochim Acta 132:187–213

Nara Y, Hiroyoshi N, Yoneda T et al (2010) Effects of relative humidity and temperature on subcritical crack growth in igneous rock. Int J Rock Mech Min Sci 47(4):640–646

Nara Y, Morimoto K, Hiroyoshi N et al (2012) Influence of relative humidity on fracture toughness of rock: implications for subcritical crack growth. Int J Solids Struct 49(18):2471–2481

Navarro V, Alonso J, Calvo B, Alonso J, Calvo B et al (2010) A constitutive model for porous rock including effects of bond strength degradation and partial saturation. Int J Rock Mech Min Sci 47(8):1330–1338

Perello P, Baietto A, Burger U et al (2014) Excavation of the Aica-Mules pilot tunnel for the Brenner base tunnel: information gained onwater inflows in tunnels in granitic massifs. Rock Mech Rock Eng 47(3):1049–1071

Reviron N, Reuschle T, Bernard J-D (2009) The brittle deformation regime of water-saturated siliceous sandstones. Geophys J Int 178(3):1766–1778

Shukla R, Ranjith PG, Choi SK et al (2013) Mechanical behaviour of reservoir rock under brine saturation. Rock Mech Rock Eng 16(1):83–93

Song DZ, Wang EY, Liu ZT et al (2014) Numerical simulation of rock-burst relief and prevention by water-jet cutting. Int J Rock Mech Min Sci 70:318–331

Taibi S, Duperret A, Fleureau J-M (2009) The effect of suction on the hydro-mechanical behavior of chalk rocks. Original Research Article. Eng Geol 18(2):40–50

Valery M, Fridrich S (1993) Hydrogeomechanical problems in mining. Mine Water Environ 66(10):35–40

Verstrynge E, Adriaens R, Elsen J et al (2014) Multi-scale analysis on the influence of moisture on the mechanical behavior of ferruginous sandstone. Constr Build Mater 54:78–90

Wasantha PLP, Ranjith PG (2014) Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng Geol 178(21):91–101

Wawersik W, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci 7(5):561–575

Yu J, Li TB, Zhang JZ et al (2014) Stress characteristics of surrounding rocks for inner water exosmosis in high-pressure hydraulic tunnels. J Cent South Univ 21(7):2970–2976

Zhang CQ, Feng XT, Zhou H (2012) Case histories of four extremely intense rock bursts in deep tunnels. Rock Mech Rock Eng 45(3):275–288

Acknowledgments

This work is supported by the National Natural Science Foundation of China under grant nos. 41230635, 41272330 and 41572283. This work is also supported by funding provided by the Science and Technology Office of Sichuan Province (2015JQ0020). This work is supported by the research fund of the State Key Laboratory of Geohazard Prevention and Geoenvironment Protection (Chengdu University of Technology) under grant nos. SKLGP2012Z003 and SKLGP2014Z002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, G., Li, T., Guo, F. et al. Brittle mechanical characteristics of hard rock exposed to moisture. Bull Eng Geol Environ 76, 219–230 (2017). https://doi.org/10.1007/s10064-016-0857-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-016-0857-7