Abstract

The predominately, wind-derived deposits forming the Loess Plateau in China are known as Wucheng loess (Q1), Lishi loess (Q2), and Manlan loess (Q3). Only Q3 loess has been intensely studied in densely populated areas, revealing that the structural strength of these aeolian sediments is directly related to their variations (anisotropy) in compressibility, water content, and, particularly, vertical jointing. Knowing the stability level of Q3 aeolian sediment is important in tunnel constructions through other types of loess. The research reported here has been mainly centered on obtaining the values of consolidation, unconfined compressive strength (UCS), direct and triaxial shear tests, Poisson’s ratio, and modulus of deformation of the Q2 loess in the Baijiapo Tunnel on the Lanyu Railway, Lanzhou, China. Included among the numerous results of these comprehensive laboratory tests are: the mean index of liquidity is 0.19; and the maximum modulus of compression in the vertical direction is 1.17. Furthermore, vertical and horizontal samples showed brittle fracture; the ratios of UCS and modulus of deformation in the vertical to the horizontal directions are 1.34 and 2.45, respectively. The wide range of various values of Lishi loess properties are closely related to variation in the density of the vertical jointing system. A new method for calculating comprehensive shear parameters is proposed and the related parameters for the Baijiapo Tunnel are recommended.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Loess and loess-like soils are widely distributed in North China. From a geotechnical point of view, collapsibility, sensitivity to water content, structural strength and vertical joints are the most significant characteristics of loess. Much has been published on these topics in China where cultural development and distribution of the population is intricately linked with the spatial extent of the loess deposits, e.g., collapsibility and its distribution, shear strength properties under different water content (Lin and Liang 1980; Feng and Zheng 1982; Qian et al. 1985; Lin and Wang 1988; Tan 1988; Gao 1996; Liu 1997; Sun 2005; Li and Miao 2006). The structural characteristics and the effect of water chemistry on the shear strength of loess have recently become a new focus (Shao and Deng 2008; Zhang et al. 2013, 2014). However, loess research has mainly focused on the geotechnical problems in foundations and slopes, in particular, those in the younger and the superficial part of loess deposits Q3 and Q4 (Malan and Holocene loess). Collapsibility is one of the most important properties of loess in the study of the engineering behaviors of Malan loess (Upper Pleistocene) which is generally <30 m thick (Lin and Liang 1980; Gao 1996). For those deep-seated tunnels excavated in Lishi loess (upper part of the Lower Pleistocene and the Middle Pleistocene) and Wucheng loess (most of the Lower Pleistocene) where the thickness ranges from 50 to 170 m (Feng and Zheng 1982), collapsibility is not of major concern to geotechnical engineers (Xie 2001). The main geological and geotechnical properties of different types of loess can be found in much literature (e.g., Lin and Wang 1988; Tan 1988). These deposits generally occur at depth where their geotechnical significance is more important to know in the construction of tunnels. Compared with the abundant studies on loess collapsibility, water sensitivity, structural strength and constitutive relationships, little attention has been directed to the anisotropic behaviour of loess and the older loess deposits, Q2 and Q1 (Lishi and Wucheng, respectively). Some of the related studies are briefly discussed here.

Anisotropy of shear strength

Shear strength test results of loess samples taken from conveyance canals and railway slopes near Baoji, Shan’xi Province of China indicated the cohesion perpendicular to the macropores was 1.25 times larger than that parallel to the macropores. The shear strength in the vertical direction is greater than in the horizontal direction, the 45° direction having the middle value. This anisotropy in shear strength under different normal stresses seemed to be more significant in loess with lower water content and normal stresses. It was suggested the anisotropy loess shear strength should be taken into account in engineering design (Qian et al. 1985).

However, shear strength determined via direct shear tests revealed quite small differences in different directions of all kinds of loess samples taken from slopes in different areas. Thus, the use of shear strength parameters obtained from conventional sampling and testing was considered acceptable by Qiao and Li (1990). This might be true for loess on slopes due to the complicated secondary disturbances such as tectonic movements, erosion, weathering and vegetation coverage. It is difficult to analyze the results given by Qiao and Li (1990) since the details of the soil sampling and testing were not provided in their book.

Mi et al. (2006) studied the influence of water content and shear direction on the cohesion and internal friction angle of Malan loess in Lanzhou by using triaxial tests. They concluded that the decrease of cohesion with an increase of water content from 8.99 to 17.25 % by artificial wetting was much more significant than that of the internal friction angle. Samples in the vertical direction had the highest cohesion followed by those in a 45° direction and then the horizontal samples. The ratios of the internal friction angle in the vertical direction to that in the horizontal direction ranged from 0.93 to 0.94, i.e., no apparent increasing or decreasing trend. However, the ratios of cohesion in the vertical direction to those in the horizontal direction ranged from 1.10 to 1.37, indicating much bigger differences (Mi et al. 2006). The anisotropy of cohesion was much bigger for loess with higher water content. The anisotropy of the internal friction angle was smaller than that of cohesion and showed no variations with water content. Since the confining pressures were 50, 100, 150 and 200 kPa, the stress–strain curves showed no peak values and the loess failed only under large stress strains (15 %). The above results can only reflect the structural or cohesion strength of loess rather than friction strength.

Comparative research on the shear behaviours of Q4 loess in the vertical and horizontal directions in Lanzhou City, Gansu Province, China, also indicated some differences in the two directions via direct shear and triaxial shear testing. Samples having a density of 1.46 g/cm3 and a water content of 5.5 % were taken at a depth of approximately 5.5 m below the ground surface. The differences between the vertical and horizontal directions were more distinct, with the average ratios of vertical parameters to horizontal parameters being 1.3. The anisotropy of Q4 loess seemed to be more noticeable under lower normal stresses or confined stresses such as 75 and 150 kPa (Liang et al. 2011).

Anisotropy of UCS

Lin (1961) compared the unconfined compressive strength (UCS) between vertical and horizontal samples of Malan loess in Lanzhou. The samples were taken from depths of 1.5 to 13.5 m; variations in density and water content were 1.39–1.49 g/cm3 and 6.8–8.6 %, respectively. UCS in the vertical and horizontal directions was 45–100 and 41–71 kPa, respectively, which resulted in ratios of UCS in the vertical direction to UCS in the horizontal direction of 1.05–1.51, with a mean of 1.31 and a coefficient of variation of 0.08. The ratios had no increasing or decreasing trends with increasing depth, though the UCSs in both directions seemed to be increasing with depth (Lin 1961).

The UCSs of loess sampled from the vertical, 45° and horizontal directions, exhibited nearly the same trend of shear strength anisotropy (Qian et al. 1985), i.e., the UCS of the loess in the vertical direction was the greatest, followed by the 45° direction and then the horizontal direction. A similar ratio of 1.2 between UCS in the vertical direction and UCS in the horizontal direction was found by the Highway Design Institute of Shan’xi Province, China (Qiao and Li 1990).

Anisotropy of deformation parameters

Milovic (1988) studied the effects of sampling and water content on the deformation characteristics of loess from Yugoslavia. He found that the degrees of transverse anisotropy defined by the ratio of modulus of deformation in the vertical direction to that in the horizontal direction ranged between 1.30 and 1.60 using unconfined compression tests (Milovic 1988).

The vertical coefficient of elastic resistance and modulus of deformation determined via in situ plate load tests were much higher than the corresponding horizontal parameters for loess in the tunnels on the PDRZX near Tongguan, Shan’xi Province in China. For example, the vertical coefficient of elastic resistance of Q2 loess varied from 160 to 190 MPa/m, while the horizontal coefficient of elastic resistance was between 60 and 80 MPa/m. For the modulus of deformation, the vertical and horizontal values were 70–100 and 30–40 MPa, respectively. These indicated that the ratios of elastic resistance and modulus of deformation in a vertical direction to those in a horizontal direction were more than 2.0, and similar to the Q3 loess (Fang et al. 2009). The ratios of modulus of deformation in a vertical direction to that in a horizontal direction were also found to be more than 2.0 for the Q4 loess in Lanzhou (Liang et al. 2011).

Remarks

The above reviews indicate that anisotropy may be one of the most significant characteristics of loess, as determined from the limited research on Q3and Q4 loess. Although there had been several discussions about the influence of water content or structural strength on shear strength of Q2 loess (Xie et al. 2006; He 2008; Fang et al. 2008, 2011), and on the deformation behaviours and creep characteristics (Wu et al. 2012; Tang et al. 2014), they were mostly limited to the loess samples taken from slopes or shallow grounds, except one group of tests (Zhong 2008; Zhong et al. 2011). The research had limited focus on the anisotropy of Q2 loess. This might be attributed to the difficulty in collecting samples of the deep-seated loess. In this research, a series of laboratory tests were conducted on Q2 loess samples obtained from a deep-seated tunnel in Lanzhou. It is hoped that the comprehensive test results presented in the following sections can lead to a much better understanding of the anisotropy of Q2 loess, and thus become a useful reference for geotechnical and tunneling engineers.

Sampling and methods

Sampling

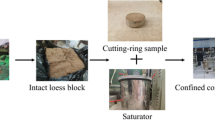

The Baijiapo Tunnel is a key part of the double-line Lanyu Railway connecting Lanzhou, the capital of northwest China’s Gansu Province, to the manufacturing hub of Chongqing in the south, with a design speed of 200 km/h. All the samples used in this research were taken from the Baijiapo Tunnel located in the eastern suburbs of Lanzhou, Gansu Province, China. The tunnel was built in loess of different geological age (mainly Q2 loess) on the high terrace of the Huanghe River, as shown in Fig. 1. The maximum burial depth and total length of the tunnel are 300 and 3,098 m, respectively. The samples were collected from an excavation face located 1,526 m away from the portal, where the burial depth of the tunnel is approximately 235 m. Because the Q2 loess was very dense and hard, it was difficult to cut the Q2 loess into a proper shape and size on the site. So the vertical orientation was marked on Q2 loess samples and then the marked loess block was immediately enclosed by a plastic membrane and placed in a plastic box filled with loess grains with in situ moisture content. After the loess blocks were taken back to the laboratory, the samples were elaborately trimmed into the required size according to the natural occurrence of loess both in vertical (or gravity direction) and horizontal directions.

Physical properties of Q2 loess

The index properties of the Q2 loess are: 31.07 % for liquid limit, 14.14 % for plastic limit, 16.9 for plasticity index (PI) and 2.74 for specific gravity. Based the Unified Soil Classification System (USCS), Q2 loess can be classified as a clay of medium plasticity (Das 2006). Other properties of Q2 loess are summarized in Table 1. The coefficients of variation of the main physical parameters are quite small except for the liquidity index, which is usually considered to be related to the mechanical behaviours of soil. Q2 loess in the Baijiapo Tunnel has a very high density and a medium water content, but much lower void ratios and a higher degree of saturation in comparison with Q2 loess from other areas, as showed in Table 2 (Wang and Lin 1990; Zhong 2008; He 2008).

The difference in physical properties might have something to do with the sampling site and burial depth. The samples of Shanxi Lishi Q2 loess were taken from a tunnel excavation working face at the burial depth of only 40 m (Zhong 2008). And the samples from Yan’an, which were collected from the steep slope surface of a loess landslide (He 2008), have very low water content and degree of saturation. It is obvious that the loess from the deeper sites compared with shallow samples, had been consolidated under high overburden pressures, and it also had little water exchange with its surrounding environment. Therefore, the burial depth has a significant effect on both the physical and mechanical properties of loess.

The particle size distribution of Q2 loess in the Baijiapo Tunnel is presented in Fig. 2 and Table 3. The results show that the percentage of Baijiapo Q2 loess particles with a diameter <0.005 mm is larger than that of the Yan’an and Xi’an Q2 loesses. The average clay-size fraction (% finer than 2 μm by weight) is 23.6 %. Thus, the activity (A) of Baijiapo Q2 loess is 1.30 according to the following empirical equation developed:

where PI and PSF are plasticity index and the percentage finer than 2 μm by weight, respectively. Therefore, Q2 loess can be classified as active clay (Chen et al. 1994).

Tests and methods

The tests used to compare the anisotropy of Q2 loess in the Baijiapo Tunnel were a 1-h quick consolidation test (OQC), an unconfined compressive test (UCT), a direct shear test (QDS), and an unconsolidated and undrained triaxial shear (UUTS) test. Sample sizes and other details are summarized in Table 4. The above-listed testing methods were selected to study the anisotropy of Q2 loess from a tunnel engineering point of view as follows.

-

1.

The compressibility of loess is a very useful parameter that can be used to analyze the structural strength under lateral confined conditions (Hu et al. 2004). The consolidation compressive test was chosen because the test period of the standard consolidation compression test was too long. Thus, the OQC compression test was adopted based on the following considerations: (a) consolidation settlement of the soil sample in a consolidation cell occurs in a very short time—about 90 % is reached in the first 1 h; (b) settlement under each consolidation pressure in OQC compression tests are directly proportional to those in 24-h standard compressive consolidation tests; (c) the OQC test can be used as a quick and effective method for the classification of soil compressibility when a settlement calculation with a high accuracy is not required (Zhang 1995).

-

2.

Although an UCT is considered appropriate for classification (Ramamurthy 2004), it is arguable if it can be used to evaluate the mechanical properties of soil. This is because the stress conditions of most soils under a natural environment are different from those after sampling and testing due to stress relaxation. From a geological viewpoint, there are at least three factors distinguishing soil from rock, namely cementation of particles, joints and primary stress. Generally speaking, most soils are weakly cemented compared with rocks and can be treated as a continuum since few joints or discontinuities exists. Most soils are only under self-weight stress, while most rocks are under both self-weight stress and tectonic stress, where the latter might be more significant than the former. Based on the three distinctive properties between soils and rocks, it can be inferred that soils are more sensitive to stress relaxation. Nevertheless, for rocks under tectonic stress, the stress relaxation after excavation is also dramatic and can be compared with that for soils under primary stress. Since the Q2 loess in the Baijiapo Tunnel behaves like a ‘weak rock’ from the viewpoint of high density, low void ratio, hard blocks and joints, the UCT test was chosen to determine not only the compressive strength of Baijiapo Q2 loess under an unconfined state, but also the deformation parameters.

-

3.

Although there are several inherent disadvantages of direct shear testing, it is still widely used to obtain shear strength parameters in routine geotechnical practice around the world because it is inexpensive, fast and simple. To be specific, for tunnel engineering, a quick direct shear test (QDS), and a UUTS test are considered more suitable for characterizing the mechanical behaviour of geo-material during tunneling (Ling et al. 1996). Therefore, both QDS and UUTS tests were adopted to get a better insight into the strength property of undisturbed Q2 loess in the Baijiapo Tunnel.

-

4.

Loess soil with an average density equal to 2.07 g/cm3 was sampled at a depth of 235 m, where the intact Q2 loess before excavation and sampling is under vertical gravitational stress of about 4.865 MPa. It might be more reasonable to use the triaxial apparatus with a higher confined pressure like that used in rock mechanics, but due to the limited measurement range of the triaxial apparatus, a confined pressure of 400 kPa is large enough for evaluating the shear strength of Q2 loess in this paper. Besides, the range of confined pressures in this paper is commonly used both in research and in engineering design in China, whether the soil samples are taken near ground surface or in deep tunnels and boreholes (e.g., Feng and Zheng 1982; Zhong et al. 2011; Fang et al. 2008).

It should be pointed out that the sampling operations and tests mentioned above were carried out strictly in accordance with the Chinese Standard for Soil Test Method-GB/T 50123 (The National Standards of the People’s Republic of China 1999), which is similar to international standards (e.g., Kalinski 2005).

Results

Compressibility

The results of the consolidation compressive tests are presented in Figs. 3, 4 and 5. As shown in Fig. 3, the lateral confined compressive deformation of both horizontally oriented (H1–H3) and vertically oriented (V1–V3) Q2 loess samples were quite small, even under a consolidation pressure of 600 kPa. The change in void ratio was also relatively small (Fig. 3). This yielded medium compressibility with a modulus of compression (E s) ranging from 4 to 12 MPa, and an index of compression (a) ranging from 0.1 to 0.4 MPa−1 (Fig. 4). It should be pointed out that, in Fig. 4, the data points under a specific compressive pressure represent the corresponding coefficient of compression or modulus of compression at the intervals of this pressure and that which was neighboring previously, e.g., a or E s at a compression pressure of 100 kPa were actually the values corresponding to the pressures ranging from 50 to 100 kPa. Although the compressive strain and void ratio increased steadily with the compressive pressures (Fig. 3), no clear increasing or decreasing trends in the coefficient of compression or modulus of compression can be observed in Fig. 4, which might be attributed to the abnormally lower void ratio. The vertical samples seemed to have a bigger coefficient of compression or smaller modulus of compression at each consolidation pressure than those of the horizontal samples, which indicated that the compressibility on the vertical direction of Q2 loess were 10–20 % larger than that on the horizontal direction under a consolidation pressures of 300 kPa (approximately 5 % when the consolidation pressures were larger than 300 kPa). In other words, little anisotropy existed under higher pressures (Fig. 5). Note that a shown in Fig. 5 is the mean values of all six samples.

The coefficient of compression a 1–2 and the modulus of compression E s1–2 under consolidation pressures between 100 and 200 kPa are summarized in Table 5. It seems that the variations of the parameters, mainly due to differences in density and water content, did not create differences between vertical samples and horizontal samples. In contrast, the average values shown in Fig. 4 clearly indicate a difference between vertically oriented samples and horizontally oriented samples. Both the vertical and horizontal samples can be classified as being of medium compressibility since a 1–2 values fall in the range of 0.1–0.5 MPa−1 or E s1–2's ranging between 5 and 20 MPa (Chen et al. 1994). The mean a 1–2 of vertical samples, V1 and V2, is 17 % larger than that of horizontal samples, H1 and H2, while the mean E s1–2 is 14 % smaller than the horizontal samples.

Unconfined compressive strength

Since the Q2 loess in the Baijiapo Tunnel behaves like a ‘weak rock’ from the viewpoint of high density, low void ratio, hard blocks and joints, the UCT test was chosen to determine not only the compressive strength of Baijiapo Q2 loess in an unconfined state, but also the deformation parameters. The deformation parameters were determined as described below.

Both axial and transverse deformations were measured during the unconfined compression test. As shown in Fig. 3, the axial strain is defined as the ratio of length change to the original length of the cylinder sample, i.e., ε y = Δl/l, and the transverse strain is defined as the ratio of diameter change to original diameter, i.e., ε x = Δd/d. The average modulus of deformation and average Poisson’s ratio are defined as follows:

where σ 50 is the stress point of one half of the UCS, and ε y50 and ε x50 are the axial and transverse strains corresponding to the σ 50, respectively.

The volumetric strain during compression is determined by Eq. (3) (Liu and Tang 1999):

The Poisson’s ratio at the maximum volumetric strain, v Vmax, is determined according to:

where ε x,Vmax and ε y,Vmax are the transverse and axial strain corresponding to the stress point of the maximum volumetric strain, respectively.

The results of UCS tests are presented in Table 6 and Figs. 6 and 7. According to the Chinese Code for Soil Test for Railway Engineering-TB 10102/J 338-2004 (The National Standards of the People’s Republic of China 1999), the samples can be classified as one group or one type only when the maximum difference is <0.03 g/cm3 in density and 2 % in water content. Therefore, the samples presented in Table 6 can be divided into two groups. The first group has five samples, H1, H4, V7, V8 and V9 with a mean density of 2.06 g/cm3 and a mean water content of 17.4 %. The second group also has five samples (i.e., H3, V2, V3, V6 and V10) whose mean density and mean water content are 2.10 g/cm3 and 16.3 %, respectively. Thus the mean UCS and modulus of deformation (E 50) of vertical samples and horizontal samples can be determined for the above two groups. The calculated coefficients of anisotropy in UCS and E 50 are presented in Table 7, where the UCS of vertical samples is about 25 % higher than that of horizontal samples, while E 50 of vertical samples is much bigger than that of the horizontal samples with ratios more than 2.0. For all the samples, the vertical samples had much higher (up to 34 %) UCSs than that of horizontal samples. The ratios of the vertical sample E 50 to the horizontal sample E 50 are approximately on the same order of magnitude compared with other studies. For example, the deformation modulus of Q2 loess was about 30–40 MPa in the horizontal direction, and 60–80 MPa in the vertical direction, as determined via plate loading tests, in the test tunnels at a burial depth of 120–160 m in Tongguan, Shan’xi Province (Fang et al. 2009). The physical properties of the above Q2 loess samples are: 1.95 g/cm3 for density, 15.0 % for water content, 0.584 for void ratio and 68.8 % for degree of saturation, which are very close to the Q2 samples tested in this research. Such a big difference in the modulus of deformation in the vertical and horizontal directions may be attributed to the combination of relatively higher ratios of UCS but much lower compressive strain in the vertical direction as compared to those in the horizontal direction.

Modulus of deformation and Poisson’s ratio

The average failure strain of all nine vertically oriented samples was 1.29 %, much less than 1.98 %, an average value of the horizontally oriented samples. This indicates that the Q2 loess had a brittle failure mechanism in both directions but would fail at a much lower strain in the vertical direction. This degree of failure strain is very close to that obtained by other researchers (e.g., Xie et al. 2006; He 2008). The average volumetric strains at peak strength are also obviously different in two directions with −0.112 % (samples H1–H4) for horizontally oriented samples and −0.642 % (samples V1–V4) for vertically oriented samples, which suggests the volumetric contraction of vertically oriented samples was bigger than that of horizontal samples, though smaller volume dilation occurred for vertical samples than that of horizontal samples before the maximum volume strain (Fig. 7).

The Poisson’s ratio in the vertical direction is lower than that in the horizontal direction; for example, 0.40 for horizontally oriented sample H3 compared to 0.35, 0.37 and 0.28 for vertically oriented samples V1, V3 and V4, respectively. This can be attributed to a combination of less axial strain and more volumetric contraction at the stress failure point.

Shear strength by quick direct shear test

The results of direct shear tests of both horizontally and vertically oriented samples are summarized in Tables 8 and 9. Figure 8 shows the shear strength in the horizontal and vertical directions. While the shear deformation increased as the normal stress increased, the shear stiffness was nearly the same, only slightly increased with the normal stress. Direct shear testing showed that nearly all the stress–displacement curves had peak strengths. All the shear stress versus shear displacement curves developed along a similar slope before the peak stress points, and dropped abruptly after the peak strength. So the failure mechanism of Q2 loess under direct shear can be classified as brittle failure regardless of sampling direction. The ratios of the mean stiffness of vertical samples to that of horizontal samples were about unity, which means no difference in different directions.

The results shown in Table 8 indicate that both the peak shear strength and the residual strength in the vertical direction are slightly larger than those in the horizontal direction. However, for the average shear strength parameters, there is a large difference between different directions. As can be seen from Table 9, the mean peak and residual cohesions in the vertical direction are approximately 1.2 times larger than those in the horizontal direction, while the mean peak internal friction angle (φ P) and the mean residual internal friction angle (φ R) in the vertical direction are 0.9 and 1.0 of those in horizontal direction, respectively. This indicates that vertical sampling would generally yield higher peak cohesion but a lower peak angle of internal friction compared to horizontal sampling. For the residual shear parameters, the cohesion of vertically oriented samples would be slightly higher than the horizontally oriented samples, while the internal friction angle remains unchanged. The findings of this research are consistent with those reported by others (for example, Qian et al. 1985; Qiao and Li 1990).

The ratio of peak cohesion to residual cohesion of Q2 loess varied from 2.6 to 2.3 for horizontal samples and 2.5 to 3.0 for the vertical samples. The mean peak cohesions of both vertical samples and horizontal samples was about 2.8–2.9 times larger than the residual cohesions, while the differences in the internal friction angle in two directions were much smaller compared with the cohesions.

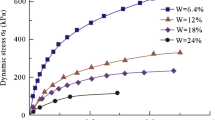

Shear strength by unconsolidated and undrained triaxial shear

The normalized stress and strain curves of the samples in horizontal and vertical directions under different confined pressures are plotted in Fig. 9. It shows that the differences of failure strains at the normalized peak stress was very small (2.1 and 1.9 % for horizontal and vertical samples, respectively), which means that the anisotropy of the triaxial shear behaviourss of the Q2 loess in this study mainly depends on the axial stress while the failure strains are at the same levels. The upper limit of the envelopes denotes strain-hardening under higher confined pressures, while the bottom limit of the envelopes indicates strain-softening under lower confined pressures. The average gradients of the stress and strain curves (for both the horizontal and vertical samples) below the normalized peak stress seemed to be a constant (0.5 %). The deformation behaviours under triaxial compression was much different from that under unconfined compression (presented in Table 6; Fig. 6), which may be attributed to the structural strength of the over-consolidated Q2 loess when the samples is under zero or low confined pressures.

The envelopes of the normalized stress and strain curves under different confined pressures. Note HA-100 means the sample A in horizontally oriented sample A subjected to a confined pressure of 100 kPa, while VD-100 means the sample D in vertically oriented sample D subjected a confined pressure of 100 kPa

The results of unconsolidated and undrained triaxial tests are plotted in Fig. 10. As Table 10 shows, the difference between the horizontal and vertical strengths of Q2 loess reduces with increasing confining pressure. This might be attributed to the damage or loss of inherent structural strength, which may be related to geological age and deposition environment. The values for frictional resistance (φ of about 29°–30°) are, indeed, indicative of granular, non-cohesive loess material with a complete loss of structural strength.

Although the mean peak strength and residual strength in the horizontal and vertical directions did not show much difference under different confining pressures, except at a confining pressures of 100 kPa (see Table 10), both the peak cohesions and residual cohesions of the vertically oriented samples were approximately 1.4 times larger than that of the horizontally oriented samplings (refer to Table 11). While the mean peak internal friction angle of the vertically oriented samples was about 4.5° or 13 % lower than that of the horizontally oriented samples, the difference for the mean residual internal friction angle was only 1.5° or 5 %, which indicates that the differences between the residual strength in horizontal and vertical directions may be ignored (Table 11). It needs be pointed out that similar results were obtained from the direct shear tests conducted in this research. Therefore, the anisotropy of Q2 loess was quite obvious for peak strength parameters, especially for the peak cohesions.

The ratios of peak cohesion to residual cohesion of Q2 loess varied from 1.7 to 2.2 for horizontal samples and 1.8 to 2.5 for vertical samples, with a mean value of 2.0 and 2.1 for horizontal and vertical samples, respectively. These ratios based on the UUTS tests are much smaller than those obtained from the QDS tests. This difference can be attributed to the inherent shortcomings of the direct shear test, including shear failure occurring on a designated plane that may not be the weakest one and changes in the area of the shear surface during shearing.

Summary of the anisotropy of Q2 loess

It is well known that the mechanical behaviours of loess are very sensitive to its density, water content, percentage of clayey grains, and microstructure (Feng and Zheng 1982; Qian et al. 1985; Liu 1997; Xie 2001), which causes variation in its mechanical parameters. This is supported by the testing results presented in this paper, for example, the 0.2 % difference in water content between samples V7 and V8 led to a 49 % difference in UCS or a 30 % difference in E t. Such variations make it hard to clearly identify the anisotropic behavior of Q2 loess, despite anisotropy existing, especially with UCS, modulus of deformation, peak cohesion and residual cohesion. The higher cohesions of vertically oriented samples determined via QDS tests might be partially attributed to their relatively lower water content, but the results of UUTS tests showed very obvious differences between the vertical and horizontal directions. Table 12 presents the anisotropy of Q2 loess from various points of view using the mean parameters of all the above tests, which may statistically prove the anisotropy of the Q2 loess in the Baijiapo Tunnel.

Discussion

Characteristics of Q2 loess in the Baijiapo Tunnel

Comparison of the results of this study with those from other areas in China (Table 13) reveals that water content, UCS and the internal friction angle of Q2 loess in the Baijiapo Tunnel fall into the normal range reported by other researchers, but Q2 loess from the Baijiapo Tunnel has much higher percentage of fine grains <0.005 mm, with a higher density and cohesion, and lower void ratio. For example, the residual cohesion of Q2 loess in the Baijiapo Tunnel was even larger than the peak cohesion of Q2 loess from other areas, and the peak cohesion of Q2 loess was at least twice that listed in Table 13. Since there was limited description of sampling and test methods related to the results presented in Table 12, it is not easy to estimate the relationships between the physical properties and mechanical behaviours, though many researches had proved the importance of water content, density and percentage of clayey particles as they relate to strength and deformation behaviours of loess (e.g., Qian et al. 1985; Wang and Lin 1990; Li and Miao 2006).

Joints or fissures in loess and their effects on mechanical properties

Sun (1997) might be the first in China to study joints or fissures in loess, as early as in 1958 when he was investigating the loess slopes in Northwestern China. His conclusions on joints in loess include: (1) the joints developed in Q1 and Q2 loess were mainly structural or tectonic joints, while column joints were mainly developed in Q3 (Manlan) loess. All the joints in loess were uniquely uniformly distributed; (2) the structural joints in Q1 and Q2 loess might be vertical or at about 30o to the vertical, giving an X-shaped pattern in the horizontal view, indicating the shear or compressive-shear mechanism; (3) there would be a different predominant occurrence of structural joints in Q1 and Q2 loess in different areas, which has nothing to do with the local topography, and this controls the development and distribution of a gully or ground fissure; (4) gully distribution in loess also has a regular pattern with several predominant occurrences and uniformly distributed spacing, around 400–500 m, which might have resulted from karst development in the structural joints in loess (Sun 1997).

Wang (1996) investigated tens of thousands of in situ joints in loess in many areas in China and classified joints in loess into five types: (1) primary joints, (2) weathering joints, (3) slumping joints, (4) collapsible joints and (5) tectonic joints, among which the primary joints and structural joints were universally developed and distributed in all kinds of loess. Other three types of joints were distributed in very limited ranges and can be observed only in the surface of a slope, steep gully and/or ground. The primary joints in loess might be developed during loess deposition and subsequent consolidation, and could not break its single loess layer. The tectonic joints in loess were mainly formed up to 3 m long during the tectonic process in a fixed direction, and cutting through not only its loess layer but also others. These joints form the path for underground water, cavities, wells and pseudo-karst in loess. As to the tectonic joints in Q1 and Q2 loess, the joints plane was smooth and distinct like the shear joints in rock. The average spacing of tectonic joints in Q1 and Q2 loess was normally more than 0.8 m with sparse distribution. While the tectonic joints in Q3 loess could be characterized as an obscure and fractured joints plane, approximately 0.5 m in spacing, densely distributed, and <1 m in extension from the top to the bottom (Wang et al. 1994; Wang 1996).

Dijkstra et al. (1994) noticed the natural shear systems and microfissures in Q2 loess and Q1 loess in Lanzhou, and discussed their effects on sampling, shear strength and variations of loess based on the results of direct shear testing, ring shear testing and in situ direct shear testing. They found that the natural shear systems in loess resulted in an increase in apparent effective internal friction angle but an decrease in effective cohesion when the normal stress was <200 kPa. However, if the normal stress was larger than 200 kPa, both effective internal friction values were very close to those of intact loess or loess without natural shear systems (Dijkstra et al. 1994). The shear strength obtained from the in situ direct shear test was generally lower than that obtained by laboratory testing. Thus, laboratory tests could be a good way to describe the structural strength, but the in situ test should be closer to the actual conditions of loess (Dijkstra 2001). The natural shear systems described by Dijkstra et al. (1994) and Dijkstra (2001) actually have the same meanings as the joints discussed by Sun (1997), Wang et al. (1994), Wang (1996) and Lu et al. (2005) in terms of physical nature and mechanical effects.

The above discussion indicates that the differences between Q2 loess in the Baijiapo Tunnel and Q2 loess from other areas in China could be attributed to the different joint types and distribution, i.e., the joints in the Baijiapo Q2 loess are mainly the sparsely distributed primary and tectonic joints, while the joints in other Q2 loess listed in Table 13 were a combination of different types of joints (e.g., primary and tectonic joints with slumping joints or weathering joints) due to their locations on a superficial slope, in a gully or in shallow, buried ground, where the loess might encounter much more water and stress disturbances. On the other hand, the primary and tectonic joints in Q2 loess deep-seated in the Baijiapo Tunnel act as the drainage path for underground water, thus resulting in uneven distribution in water content and density in each loess block, though the stress relaxation effect on loess after excavation is unclear. Hence, the anisotropic mechanical properties of Q2 loess discussed above can also be caused by the three key factors: (a) consolidation conditions due to deep burial depth, (b) joints and (c) stress relaxation after excavation.

The importance of studying Q2 loess anisotropy in tunnel engineering

The parameters for calculating and designing tunnels in loess are usually obtained by testing loess samples from boreholes drilled vertically (i.e., perpendicular to the ground surface), which means only vertically oriented samples are taken into account in most studies. The use of the test results of vertical samples may lead to an underestimate of the pressures on support structures. Although the impact of ignoring the anisotropy of Q2 loess on tunnel design may be reduced by using a higher factor of safety or a conservative, but uneconomic, design method, the anisotropy of mechanical behaviours as well as tectonic joints of deep-seated Q2 or Q1 loess may cause unstable loess blocks and related uneven load on linings, crown collapse, or fracture of tunnel sidewalls in loess (Wang 1996; Sun 1997). Based on the results presented in this paper, the parameter values calculated based on test results using conventional vertical sampling need to be justified. From the results of Q2 loess testing in this research, it is recommended that Poisson’ ratio and the peak and residual cohesion should be reduced by 10–30 %, and the modulus of deformation and the coefficient of elastic resistance reduced by at least 50 %. Modification of other parameters, such as density and internal friction angle, are not required. The difference of the failure strains under low confined pressures between vertical and horizontal directions should also be taken into account in designing and constructing support structures for tunnels in loess.

Comprehensive shear strength parameters of Q2 loess

As numerous studies consistently show, the density and water content of loess (and nearly all clayey soils) are the two key factors influencing strength. Even small differences in density and water content will cause significant differences in its shear strength. Therefore, it is required that the relative differences in density and water content should be <0.03 g/cm3 and 2 %, respectively (Standard for Soil Test Method GB/T50123-1999). However, samples produced from a single loess block might have different characteristics, reflecting variable depositional conditions, sampling disturbance and directions, which would make it difficult to determine suitable parameters for theoretical calculations and engineering designing. Because the anisotropy and dispersion of loess are both inherent and inevitable, how to adequately make use of the limited intact samples and their test results will always be a challenge. Normally, this problem is solved by using the average values of each set of tests. As for the shear strength parameters of loess, the average values of cohesion and internal friction angle from a single set of tests only represents the strength characteristics of a limited area around the samples. For larger sampling scopes, due to the differences in density and water content, the cumulative shear strength is derived from all the soil blocks under various pressures. Thus, a new method to determine the comprehensive shear strength parameters can be suggested, as Fig. 11 shows, i.e., combine all the results of the different confined pressures and their corresponding axial stresses from all the horizontally oriented and the vertically oriented sample testing. The parameters obtained by the new method and conventional method of average values are listed in Tables 14 and 15. It can be seen from these tables that, except for the peak cohesions between the two methods, the other three parameters are close with little differences (within 10 %). Furthermore, this new method gives a larger internal friction angle but smaller cohesion for horizontally oriented samples (i.e., −22.6 % for H and −14.9 % for total). This study suggests that the parameters presented in Table 14 in bold face letters can be recommended.

Conclusions

The anisotropic behaviour of deep-seated Q2 loess in the Baijiapo Tunnel on the Lanyu Railway in China was investigated by a series of laboratory tests including OQC compression, unconfined compression, QDS and triaxial shear tests. Comparative study on the Q2 loess with other Q2 loess reported in the literature revealed several interesting characteristics as follows:

-

1.

A much finer clay-size fraction, a higher density (and related dry density) and degree of saturation, and a lower void ratio were seldom found in other literature. The mean index of liquidity was 0.19 with most samples lower than 0.25. This made it very hard for in situ sampling and laboratory test preparation.

-

2.

Q2 loess can be classified as having medium compressibility, according to its coefficient of compression and modulus of compression. The anisotropy of compressibility under consolidation pressures below 300 kPa was greater than that above 300 kPa. The ratios of the coefficient of compression and modulus of compression in the vertical direction compared to those in the horizontal direction were no more than 1.17.

-

3.

Samples in vertical and horizontal directions demonstated a brittle failure mechanism with small strains. The ratio (averages of all the samples) of UCS and modulus of deformation in the vertical direction to those in horizontal direction were 1.34 and 2.45, respectively. This large difference reflects much lower resultant strains in the vertical directions, as do the 16–23 % Poisson’s ratios in the vertical direction, which are also larger than those in the horizontal direction.

-

4.

All the failure modes of samples in both directions were brittle shear or strain-softening with outstanding peak strength, no matter how high the normal stress or confined pressure. Although the anisotropy of peak or residual shear strength in both shear tests showed a difference of <15 %, the peak and residual cohesions in the vertical direction were much bigger than those in the horizontal direction, i.e., 36 and 42 %, respectively, by triaxial testing, and 17 and 19 %, respectively, by direct shear testing. Anisotropy of the internal friction angle was small compared with those of peak cohesions. The mean ratio of peak cohesion to residual cohesion was 2.1. The peak and residual cohesion, as well as void ratio, of the Q2 loess in the Baijiapo Tunnel exceeded the statistical scope of much of the existing research.

-

5.

The design parameters obtained from the laboratory tests using conventional (i.e., vertically oriented) samples should be justified. Based on the laboratory test results presented in this paper, it is suggested that, for the vertically oriented samples, the cohesion and Poisson’ ratio should be reduced by 10–30 %, and modulus of deformation and coefficient of elastic resistance be reduced by at least 50 %. No changes are needed for density and internal friction angle.

References

Chen ZY, Zhou JX, Wang HJ (1994) Soil mechanics. Tsinghua University Press, Beijing

Das BM (2006) Principles of geotechnical engineering, 6th edn. Nelson, Canada

Dijkstra TA (2001) Geotechnical thresholds in the Lanzhou loess of China. Quat Int 76(77):21–28

Dijkstra TA, Rogers CDF, Smalley IJ, Derbyshire E, Li YJ, Meng XM (1994) The loess of north-central China: geotechnical properties and their relation to slope stability. Eng Geol 36:153–171

Fang XW, Chen ZH, Shen CN, Wang HW, Liu HJ (2008) Triaxial shear properties of undisturbed Q2 loess. Chin J Rock Mech Eng 27(2):383–389

Fang QB, Ma JL, Yu Y, Yang JM, Wang XD (2009) Experimental research on elastic resistant coefficient, deformation and compressive modulus of surrounding rock in large-section loess tunnel. Chin J Rock Mech Eng 28(Suppl 2):3932–3937

Fang XW, Shen CN, Chen ZH, Zhang W (2011) Triaxial wetting tests of intact Q2 loess by computed tomography. China Civ Eng J 44(10):98–106

Feng LC, Zheng YW (1982) Collapsible loess in China. Chinese Railway Publishing House, Beijing, pp 12–74

Gao GR (1996) The distribution and geotechnical properties of loess soils, lateritic soils and clayey soils in China. Eng Geol 42:95–104

He QF (2008) Study on the mechanical and rheological properties of Yan’an Q2 loess. PhD thesis, Chang’an University, Xi’an

Hu ZQ, Shen ZJ, Xie DY (2004) Deformation properties of structural loess. Chin J Rock Mech Eng 23(24):4142–4146

Kalinski ME (2005) Soil mechanics laboratory manual. Wiley, USA

Li BX, Miao TD (2006) Research on water sensitivity of loess shear strength. Chin J Rock Mech Eng 25(05):1003–1008

Liang QG, Zhao L, An YF, Zhang YJ (2011) Preliminary study on anisotropy of Q4 loess in Lanzhou. Rock Soil Mech 33(1):17–23

Lin CY (1961) Penetration test on loess in Lanzhou. In: Study on fundamental properties of loess, by Research Office of Institute of Civil Construction, Chinese Academy of Sciences. Science Publishing House, Beijing, pp 95–103

Lin ZG, Liang WM (1980) Distribution and engineering properties if loess and loess-like soils in China: schematic map of engineering geological zoning. Bull Int Assoc Eng Geol 21:112–117

Lin ZG, Wang SJ (1988) Collapsibility and deformation characteristics of deep-seated loess in China. Eng Geol 25:271–282

Ling RH, Han BC, Qu YX (1996) Excavation effect of large-span deep buried loess tunnel. J Eng Geol 4(3):65–70

Liu ZD (1997) Mechanics and engineering in loess, vol 1–18. Shan’xi Science and Technology Publishing House, Xi’an, pp 366–389

Liu YR,Tang HM (1999) Rock mass mechanics. China University of Geosciences Press, Wuhan

Lu QZ, Peng JB, Chen ZX, Li XA (2005) Research on characteristics of cracks and fissures of loess and their distribution in Loess Plateau of China. J Soil Water Conserv 19(5):191–194

Mi HZ, Li RM, Niu JX (2006) Experimental investigation of shear strength characteristics of intact loess in Lanzhou. J Lanzhou Univ Technol 32(4):109–111

Milovic D (1988) Stress deformation properties of macroporous loess soils. Eng Geol 25:283–302

Qian HJ, Wang JT, Luo YS (1985) Foundations on collapsible loess. China Architecture Industry Publishing House of Beijing, Beijing, pp 20–50

Qiao PD, Li ZJ (1990) Engineering geology in loess areas. Water Conservancy and Electric Power Publishing House, Beijing, pp 52–60

Ramamurthy T (2004) A geo-engineering classification for rocks and rock masses. Int J Rock Mech Min Sci 4:89–101

Shao SJ, Deng GH (2008) The strength characteristics of loess with different structures and its application in analyzing the earth pressure on loess tunnel. China Civ Eng J 41(11):93–98

Sun GZ (1997) Collected works of Guangzhong Sun on geological engineering. Weapon Industry Publishing House, Beijing, pp 223–257

Sun JZ (2005) Loessology: part 1. Press of Archeology Society of Hong Kong, Hong Kong, pp 1–80

Tan T (1988) Fundamental properties of loess from Northwestern China. Eng Geol 25:103–133

Tang H, Dang Q, Duan Z, Zhao FS, Song F (2014) Study on creep characteristics of Q2 loess of Xianyang Area in the Guanzhong Basin. J Disaster Prev Mitig Eng 34(6):758–763, 770

The 1st Design Institute of China Ministry of Railway (1975) Manual of tunnel design in railway engineering. People’s Railway Press, Beijing, pp 391–399

The National Standards of People’s Republic of China (1999) Standard for soil test method (GB/T50123-1999). China Planning Press, Beijing

Wang JM (1996) The theory on tectonic joints in loess and its application. China Water Conservancy and Hydropower Publishing House, Beijing, pp 15–23, 148–165

Wang YY, Lin ZG (1990) Structural characteristics, physical and mechanical properties of loess in China. Science Press, Beijing

Wang JM, Ni YL, Sun JZ (1994) A study on structural joints in loess and its practical applications. J Eng Geol 2(4):31–42

Wu WJ, Chen WW, Song BH, Feng LT, Ye WL (2012) Experiment on the shear characteristics of undisturbed Q2 loess in Lanzhou. J Lanzhou Univ (Nat Sci) 48(6):21–25

Xie DY (2001) Exploration of some new tendencies in research of loess mechanics. Chin J Geotech Eng 23(1):3–13

Xie X, Zhao FS, Wang YT, Lin B, Wang DH (2006) Comparative study on mechanical features of structural Q2 and Q3 loess. J Xi’an Univ Sci Technol 26(4):451–455, 468

Zhang W (1995) Discussions on mechanical test for loess. Geotech Investig Surv 3:6–12

Zhang FY, Wang GH, Kamai T, Chen WW, Zhang DX, Yang J (2013) Undrained shear behavior of loess saturated with different concentrations of sodium chloride solution. Eng Geol 155:69–79

Zhang FY, Wang GH, Kamai T, Chen WW (2014) Effect of pore-water chemistry on undrained shear behaviour of saturated loess. Q J Eng Geol Hydrogeol (online first)

Zhong ZL (2008) Study on constitutive model of Q2 intact loess and its application in tunnel engineering. PhD thesis, Chongqing University, Chongqing

Zhong ZL, Zhang J, Liu ZL, Fang JB, Zhou Y (2011) Test on engineering properties of unsaturated undisturbed loess Q2. J Chongqing Univ 34(2):120–124

Acknowledgments

This study was partially supported by the National Science Foundation of China (41262010 and 41402252), the Program for Changjiang Scholars and Innovative Research Team in University (IRT1139), China, and the Foundation for Basic Research Innovative Groups of Gansu Province, China (145RJIA332). The authors also appreciate the editor and referees for their valuable comments that led to substantial improvement of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, Q., Li, J., Wu, X. et al. Anisotropy of Q2 loess in the Baijiapo Tunnel on the Lanyu Railway, China. Bull Eng Geol Environ 75, 109–124 (2016). https://doi.org/10.1007/s10064-015-0723-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-015-0723-z