Abstract

Expansion of dark mudrocks as a consequence of sulphate development has been known for many years, generally occurring in low pH conditions. In buildings in Dublin, ground floor heave of up to 48 mm has been recorded within 5 years of construction, with some properties showing signs of distress even before the completion of the development. In each case the ground-bearing floor slabs rested on a pyritiferous aggregate with a pH of 8–10. A new model is proposed to explain why the effect of the expansion was evident in such a short period of time.

Résumé

Le gonflement des argilites noires en conséquence du développement de sulfates est connu depuis de nombreuses années. Il apparaît généralement pour des faibles valeurs de pH. Dans des bâtiments à Dublin, des soulèvements de rez-de-chaussée jusqu’à 48 mm ont été enregistrés dans les cinq années suivant la construction, avec quelques caractéristiques correspondant à des situations critiques avant même l’achèvement du processus. Dans chaque cas le dallage sur terre plein reposait sur un matériau de remblai constitué de ces argilites concassées, pyriteuses, avec un pH de 8–10. Un nouveau modèle est proposé pour expliquer pourquoi les effets du gonflement ont pu se réaliser aussi rapidement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Although heave attributed to sulphate development was reported as long ago as the 1950s, it was only following floor heave in the Rideau Health Centre and the Bell Canada Building in Ottawa in the late 1960s that extensive investigations into the phenomenon were undertaken (Quigley and Vogan 1970; Penner et al. 1972, 1973). It was concluded that selenite (the crystal form of gypsum) had grown in bedding planes in the calcareous, pyrite-bearing Billings Shales and that the forceful growth of the crystals involved pressures sufficient to raise the ground-bearing floor slabs. In the 1970s sulphate-related floor heave was recorded in Northern England where ground-bearing floor slabs rose >20 mm. Examination indicated that the aggregate beneath the slabs was mine waste and shale (Nixon 1978).

Fasiska et al. (1974) calculated that the production of amorphous ferrous sulphate from pyrite involved a volume change of some 350%. Subsequently, Nixon (1978) reported problems related to the use of shale from the Upper Lias (Lower Jurassic) as under-floor aggregate. Nixon’s work supported the Penner et al. (1972) conclusions that with weathering, chemical reactions in material containing as little as 0.1% pyrite by weight could still result in heave. Nixon noted that the calculated volume increase from pyrite to ferric sulphate is 170 per cent.

In early 1982, serious distress was observed at the northern end of the east wing of Llandough Hospital, Cardiff. Cracks up to 40 mm wide were found behind formica facing in a first floor ward and surveys indicated differences in level of up to 81 mm, with more than 60 mm measured in many places (Hawkins and Pinches 1987a). Trial pits were undertaken both inside and outside of the distressed block. Selenite crystals (Fig. 1), similar to those shown by Nixon (1978), were found in the laminations in the dark grey Westbury Beds (Upper Triassic) beneath the ground-bearing floor slab, but none were observed in the external pits.

When bag samples from 1.5 m depth at Llandough Hospital were left unsealed in a University laboratory at some 18–20°C, over a 17 month period the acid soluble sulphate (%SO4) increased significantly while the pH decreased (Hawkins and Pinches 1987a, b; see Table 1). Subsequently, Hawkins and Wilson (1990) tested two vertical profiles at 200 mm spacings in the Lias Clay from Gloucester. After 5 months the average acid soluble sulphate value for the 28 samples had risen by 12%.

The work at Llandough Hospital confirmed that in addition to the acid soluble/water soluble sulphate contents, all ground chemistry testing should include the measurement of total sulphur, in order that the potential for future sulphates to develop can be taken into account.

The papers mentioned above highlighted the significance of the presence of bacteria, notably Thiobacillus ferrooxidans, which use amorphous ferrous sulphate (oxidized iron sulphide) as nutrient. As a consequence they reduce the thickness of the oxidized rim which develops around the degrading pyrite, such that ongoing oxidation is facilitated. These bacteria proliferate in a low pH environment (Penner et al. 1972).

In their 1992 paper Hawkins and Pinches (1992) set out the main factors which should be assessed when the potential for ground heave was being considered. They recommended a value of 0.5% S for the maximum acceptable levels of remaining sulphide (which they determined as total sulphur minus sulphur in sulphate). This was followed by TRL who in 2001 recommended 0.46% as the maximum oxidisable sulphide for material to be placed within 500 mm of concrete. Subsequently, TRL (2005) reduced the acceptable oxidisable sulphide threshold to 0.3% S.

The author supports this latter value with regard to the integrity of concrete, but cautions that at this level, heave problems could still occur.

This paper discusses the reasons for the very quick development of sulphate-related distress in properties constructed in the Dublin area within the last 10 years. In each case, the ground-bearing floor slabs were founded on aggregate produced from interbedded Carboniferous limestone and mudrock which contained pyrite (FeS2). Doors jamming and cracks in the walls were reported sometimes within a matter of months, although their cause was not appreciated at the time. Subsequently, floors were found to be rising by up to a millimetre a month.

In the light of the new information obtained during recent work on the dark argillaceous limestone/calcareous mudrock used as aggregate beneath the Dublin buildings, some modifications to the model advocated by Hawkins and Pinches in the 1980s and 1990s are proposed.

Oxidation of pyrite

Pyrite may be present in rocks in three forms:

-

(a)

Cubes/lumps—with a low specific surface hence often considered as the least reactive form;

-

(b)

Framboids—clusters of “seeds” some 3–20 μm across which, because of their high specific surface, mean the framboids (raspberries) are much more reactive;

-

(c)

Pyrrhotite—the most unstable form.

Although in some instances pyrrhotite was identified in aggregate from beneath ground-bearing floor slabs in the Dublin area, it is considered that this mineral may be more common in the original bedrock than has hitherto been appreciated. The fact that it is not identified in the testing may be simply because it has already reacted before the aggregate is removed from beneath the floors slabs and tested. As a consequence, its potential presence and influence in the quick development of sulphate-related heave cannot be discounted.

As noted above, it has generally been assumed that without a low pH environment, conducive to the proliferation of acidophilic bacteria, oxidation of the sulphides and thus the physical manifestation of heave would be impeded. In Dublin, however, the pH is commonly 8–10 and as much as a third of the aggregate used beneath the floor slabs is calcareous.

Rate of reactions

In view of the scale of the problem in Dublin, extensive testing has been undertaken on material removed from beneath ground-bearing floor slabs. In particular, a considerable amount of Scanning Electron Microscope (SEM) work has been carried out, including not only backscatter electron images but also the use of the microprobe to allow localised detailed chemical analyses. As a consequence of this work a new mechanism to explain the fast rate of sulphate-induced heave is proposed.

Whilst cubic pyrite may show small reaction rims, where oxygen and moisture can access framboidal pyrite the oxidation rims are much more pronounced. Figure 2 shows a 2D image of an oxidising framboid where, during the development of the sulphate rim, some seeds have been moved away from the main cluster. Cracks are seen in the ferrous sulphate rim which would facilitate the continuation of the oxidation process. As indicated in Fig. 2, the combined area of the seeds and their associated ferrous sulphate rims can be some 5–10 times that of the original framboid.

In 3D, the ferrous sulphate rims appear as spheres or “footballs”, with the cracks showing on the periphery (Fig. 3). In addition to causing a direct expansion of the aggregate, the development of these ferrous sulphate rims frequently results in expansion, producing a crack which propagates through the aggregate fragment towards an adjacent oxidizing framboid, causing dilation and facilitating further ingress of oxygen and moisture.

Microprobe analysis has indicated that the ferrous sulphate rim may contain up to 20% sulphate (although in view of the limitations of the laboratory testing facilities used it is possible that background material may have influenced this value). In time, the relative quantity of sulphate decreases and the proportion of iron increases, such that the rim itself becomes reddened. Analysis indicates the rim has degenerated to an iron oxide.

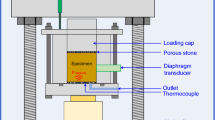

As has long been appreciated (e.g. Quigley and Vogan 1970; Penner et al. 1972), sulphuric acid released with the oxidation of pyrite moves in the host material until it encounters calcium carbonate, with which it will react to produce calcium sulphate. The product mineral has a volume approximately double that of the original components. Although gypsum is not generally present in undisturbed dark Carboniferous strata, in the placed Dublin aggregate semi-quantitative weight % proportions of gypsum of up to 9% were identified using X-ray diffraction. When samples were assessed for further growth of gypsum using the accelerated test procedure, i.e. placed in a moist oven at 35°C (see Hawkins and Pinches 1987b), after only 8 weeks SO4 values up to 12% were measured.

Although selenite crystals are seen on the edges of aggregate particles and infilling cracks, scanning electron microscopy has shown that frequently selenite has grown in/on discontinuities within the particle itself. As seen in Fig. 1, the crystals themselves only occupy some 10–20% of the surface area within the aggregate particle. However, as they act to “prop” open the discontinuities, the resultant expansion of the host material is much greater than simply the volume of the selenite itself.

As noted by Wellman and Wilson (1965), more energy is required to initiate a new crystal than to enlarge an existing one, hence large crystals will grow preferentially, exerting a considerable pressure of crystallization. Not surprisingly, therefore, in addition to the “isolated” selenite crystals, elsewhere the form of gypsum growth resembles a “rosette” (Fig. 4), with individual conjoined crystals growing outwards from a central nucleus. The growth of these rosettes in incipient discontinuities (Fig. 5), only millimetres apart, results in considerable expansion of the placed fill.

It is postulated that the initial expansion experienced in the Dublin properties is related to the development of the ferrous sulphate rims, prior to the subsequent dilation due to selenite crystals or rosettes prising open the rock fragments. Whilst some workers have advocated the use of chemical analysis alone to determine whether the cause of heave/distress is related to sulphates, the author considers it is essential to undertake detailed optical and SEM analysis in order to both establish the nature of the pyrite and to appreciate the way in which the ferrous sulphate rims are produced.

Summary and conclusions

A new model is put forward to explain the rapid manifestation of distress in buildings related to the development of sulphates in aggregate beneath ground-bearing floor slabs. It is noted that with the oxidation of pyrite, at least one, and often all, of the following processes may occur:

-

(a)

Development of a rim of ferrous sulphate around oxidising pyrite/framboid seeds, causing dilation of the host material. This is more significant in a high pH environment where acidophilic bacteria are less prolific.

-

(b)

This expansion causes the development and propagation of cracks between framboids, further breaking down the aggregate particle and facilitating ingress of oxygen and moisture.

-

(c)

The release of sulphuric acid which interacts with calcium carbonate to form selenite. The selenite crystals typically occupy only 10–20% of the surface area of the discontinuity/incipient discontinuity. The force of crystallisation opens the discontinuity with the crystals acting as “props” resulting in expansion greater than the volume of the new crystals.

-

(d)

The growth of selenite “rosettes” in discontinuities/incipient discontinuities, frequently in close proximity, further expanding the aggregate particle.

In the author’s opinion, the speed with which the reactions will take place cannot be assessed on chemistry alone, as it is important to appreciate the presence of framboidal pyrite/pyrrhotite which react much more quickly than “lumps” of iron sulphide. For this reason, for the process to be fully understood, the skills of an experienced petrographer are required.

Further work is being undertaken to elucidate the formation and significance of the cracks in the ferrous sulphate rims and the form in which the gypsum grows, as well as the associated pressures of crystallisation.

References

Fasiska E, Wagenblast N, Dougherty MT (1974) The oxidation mechanisms of sulphide minerals. Bull Ass Eng Geol 11:75–82

Hawkins AB, Pinches GM (1987a) Cause and significance of heave at Llandough Hospital, Cardiff: a case history of ground floor heave due to gypsum growth. QJEG 20:41–57

Hawkins AB, Pinches GM (1987b) Sulphate analysis on black mudstones. Geotechnique 37:191–196

Hawkins AB, Pinches GM (1992) Understanding sulphate generated heave resulting from pyrite degradation. In: Hawkins AB (ed) 1997, Ground chemistry. Implications for Construction, Balkema, pp 51–75

Hawkins AB, Wilson SLS (1990) Sulphate increase in laboratory prepared samples. QJEG 23:383–385

Nixon PJ (1978) Floor heave in buildings due to the use of pyritic shales as fill material. Chem Ind pp 160–164

Penner E, Eden WJ, Grattan Bellew PE (1972) Expansion of pyritic shales. In: Canadian building digest, vol 152. National Research Council of Canada

Penner E, Eden WJ, Gillott JE (1973) Floor heave due to biochemical weathering of shale. In: Proceedings 8th International Conference on Soil Mechanics and Foundation Engineering, vol 11. Moscow, pp 151–158

Quigley RM, Vogan RW (1970) Black shale heaving at Ottawa, Canada. Can Geotech J 7:106

Wellman HW, Wilson AT (1965) Salt weathering: a neglected erosive agent in coastal and arid environments. Nature 205:1097–1098

Acknowledgments

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hawkins, A.B. Sulphate heave: a model to explain the rapid rise of ground-bearing floor slabs. Bull Eng Geol Environ 71, 113–117 (2012). https://doi.org/10.1007/s10064-011-0408-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-011-0408-1