Abstract

A system for the quantification of the failure hazard of rock cuttings structured in the form of rating tables is proposed. Rock cuttings are classified according to their failure hazard taking into account both their drained condition and the influence that climatic conditions have on stability; the latter being the most common landslide-triggering factor. The system deals with seven types of failure including slides, topples and falls. Where possible and convenient, parameters are amalgamated using well-established expressions of safety factor increasing the objectivity of the system. In addition to triggering mechanisms, site-specific parameters related to the mean and critical precipitation height, as well as the potential for the development of adverse, water-related conditions are taken into account to arrive at a Hazard Index value.

Résumé

Un système sur la quantification du risque d’échec des déblais rocheux structuré sous la forme des tableaux d’évaluation est proposé. Les déblais rocheux sont classifiés selon leur risque d’échec prenant en compte leur condition asséchée et l’influence des conditions climatiques sur la stabilité; le dernier facteur déclenchement des glissements de terrain est le plus commun. Le système traite avec sept types d’échec, glissements, renversements et éboulements rocheux sont compris. Lorsque cela est possible et pratique, les paramètres sont fusionnés en utilisant des expressions du facteur de sécurité connues, qui accroissent l’objectivité du système. En outre des mécanismes de déclenchement, les paramètres relatifs à la moyenne et à la hauteur critique de la précipitation du site spécifique, ainsi que la possibilité du développement des conditions négatives et relatives à l’eau, sont prises en considération pour arriver au Valeur du Risque.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rock cutting instabilities are a major hazard often causing economic losses, property damage and maintenance costs, as well as injuries or fatalities. Hoek (2007) mentioned that while rock falls along highways and railways in mountainous terrains do not pose the same level of economic risk as large scale failures, which can close major transportation routes for days at a time, the number of people killed by rockfalls tends to be of the same order as people killed by all other forms of rock slope instability. Consequently, the need to adopt a classification system for the assessment of the hazard associated with failure of rock cuttings is imperative, especially when dealing with a large number of rock cuttings (e.g. as in the case of highways, due to their linear nature). Such a system would allow the classification of rock cuttings according to their failure hazard in order that preventive measures can be effectively prioritized.

Rock mass classification can be a way of evaluating the performance of rock cut slopes, based on the most important inherent and structural parameters. The disadvantages and limitations of the existing systems as regards the stability assessment of rock cuttings have been discussed in detail by Pantelidis (2009) and hence no further reference is made here. The objective of the present paper is to propose a new classification system for rock cuttings, to take account of the failure hazard, including climatic conditions as a triggering factor.

It should be noted that the term hazard used throughout the text refers to “any condition with the potential for causing an undesirable consequence” (IUGS 1997) and should not be confused with risk, which is defined as “a measure of the probability and severity of an adverse effect to health, property or the environment which is often estimated by the product of Probability x Consequences” (IUGS 1997).

The role of triggering factors in the stability of rock cuttings

The hazard for failure of a rock cutting is a function of its normal (drained) condition and the impact that a triggering factor (or a combination of triggering factors) for failure has on it. The latter refers to the triggering mechanism for failure which involves both the presence of at least one triggering factor (e.g. infiltration of pluvial water, earthquake) and the existence or development of unfavorable conditions for stability (e.g. blocked drainage paths, small distance from the seismic epicenter); see Pantelidis (2009). Many authors have discussed the relative importance of triggering factors for the failure of slopes (McCauley et al. 1985; Wieczorek et al. 1992; Wieczorek and Jäger 1996; Koukis et al. 1997; Guzzetti et al. 2003b) and suggest that those related directly or indirectly to the presence of water are the most common, even in earthquake prone-areas (Pantelidis 2009).

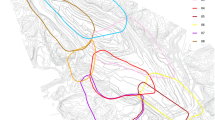

The natural process of weathering (disintegration–decomposition) gradually transforms the rock mass into a soil, thus progressively reducing the stability of a cutting. Moreover, during wet periods, the stability of cuttings is further decreased by the presence of water, the action of which, although temporary, is of major importance. Depending on the weathering grade of the rock mass, it may even prove critical for the stability of the cutting where a failure may be initiated with less intense rainfall than occurred in the past (Fig. 1). Such a situation emphasizes the interconnection between the “rock mass condition” and the “triggering factor for failure” for “failure hazard”, as well as the need for a stability assessment of rock cuttings on a periodic basis. The time interval between two successive inspections depends on the type of facility at the toe of the cutting and the likely magnitude of the consequences of a failure and would be part of a risk assessment analysis, which is beyond the objectives of the present paper. A risk assessment methodology applicable to highway rock cuttings has been proposed by Mouratidis and Pantelidis (2007).

The concept of the proposed system

The proposed system, structured in a form of rating elements, deals with rock slides, topples and falls, adopting the Varnes (1978) classification of landslides. The failure hazard is given quantitatively for seven failure types in rock cuttings, namely, planar and wedge slides (1, 2), toppling of individual blocks (3), block and flexural toppling (4, 5) and rockfalls related either to differential weathering of a cutting face (6) or to excessive weathering of the rock mass (non-structurally controlled failure, 7). The fact that the system examines each of the likely failure types separately, not only increases its reliability but also decreases the time and effort needed for its implementation, as only the parameters relevant to a specific type of failure (the prevalent) need to be measured or estimated (Pantelidis 2009).

Following the recommendations made by Pantelidis (2009), the input data for the determination of the Hazard Index (HI) of rock cuttings are divided into two categories: (a) the normal (drained) condition of the rock cutting expressed by the factor f NC and (b) the triggering mechanism for failure expressed by the factor f TM. The flow chart for the proposed system is given in Fig. 2. It should be noted that the system deals only with rock cutting failures caused by the action of water (the triggering factor for failure).

Flow chart of the proposed system (based on Pantelidis 2009)

Quantitative attribution of rock cutting: normal condition

Sub-factors used for the quantification of the normal condition of rock cuttings

The quantitative attribution of the normal (drained) condition of rock cuttings is done using the rating elements (sub-factors) of Table 1. Each of these sub-factors is rated according to pre-determined quantitative criteria on a scale from 1 to 10, including intermediate scores if required. Depending on the structural condition of the rock cutting (which indicates the likely/possible failure type), only one or two sub-factors will be required.

Sub-factor f 1

Sub-factor f 1 applies only to the structurally controlled failure (slides and topples) and is largely based on the apparent shear strength of the discontinuities shown in Table 2. This follows Barton et al. (1974), although for small scale roughness it uses the Smoothness Factor, J s proposed by (Palmström 1995, 2001) instead of such general descriptions as rough, smooth and slickensided. Moreover, it follows the Wall Strength Grade (WSG) classification suggested by Brown (1981). This was considered important as only a slight shear displacement of individual joints often results in a very small asperity contact area and actual stresses locally approaching or exceeding the compression strength of the rock wall material.

Sub-factor f 2

Sub-factor f 2 (Table 1) is used only in the case of planar and toppling (block and flexural) failure and refers to the relative orientation of the dominant failure plane(s) with respect to the cutting face (αd−αs); see Fig. 3.

In the case of a planar failure, the sub-factor follows Hoek and Bray (1981) who proposed the plane on which sliding occurs must strike parallel or nearly parallel to the cutting face (within approximately ±20°). Thus, the adjustment angle Δα for planar slides is set by default to zero (Table 1). However, it has been observed that rock masses with very weathered discontinuity walls (WSG class: R0, R1 or R2) may fail even if the orientation of the dominant failure plane(s) with respect to the cutting face is much greater than ±20° (Fig. 4). In this case the adjustment angle Δα should be taken as 40°, 30° or 20° for Wall Strength Grade classes R0, R1 and R2, respectively.

In the case of block or flexural toppling, the sub-factor f 2 follows Goodman (1989) and assumes toppling can occur only if the layers strike parallel or nearly parallel to the strike of the slope, say within 30°. The 15° previously recommended by Goodman and Bray (1977) has been found to be too small (Goodman 1989). Therefore, as the criterion in question (±30°) is 10° wider than the respective one for planar slides (general case), an adjustment angle Δα = 10° (fixed value) should be added to the rating criteria of sub-factor f 2.

Sub-factor f 3

Sub-factor f 3 refers to the Geological Strength Index (GSI) of Marinos and Hoek (2000, 2001) and is used in the proposed system for: (a) non-structurally controlled and (b) differential weathering (undercutting) failure modes. The GSI is based upon an assessment of the lithology, structure and condition of discontinuity surfaces in the rock mass and is estimated from visual examination of the exposed rock mass (Marinos et al. 2005).

Sub-factor f 4

Sub-factor f 4—differential weathering—refers to the volume of the exposed rock mass per one meter length of slope (Fig. 5).

Normal condition of rock cutting (factor f NC)

Planar sliding

Planar failure refers to the sliding of a rock block(s) along one or a set of parallel failure planes oriented unfavorably with respect to the cutting face. Neglecting any external load that may act on the rock cutting, the safety factor against planar sliding is given by Eq. 1.

where, φ and β d are the friction and dip angle of the dominant discontinuities, respectively. If the angle φ is unknown, it is suggested that the apparent shear strength given in Table 2 is used. It is assumed that the cohesive strength along the failure plane(s) is zero.

Reducing the safety factor value into a scale from 1 to 10 and taking into account the relative orientation of dominant failure plane(s) through the sub-factors f 1 and f 2, respectively, the stability condition of rock cuttings under drained conditions is given quantitatively by the factor f NC (Eq. 2). The coefficient 0.1 in Eq. 2 is used so that the value of factor f NC also ranges between 1 and 10.

Wedge sliding

Wedge failure refers to the sliding of a rock block(s) along two intersecting failure planes (“A” and “B”) oriented unfavorably with respect to the cutting face. The flatter of the two planes is called plane “A”. Neglecting any external load that may act on the rock cutting, the safety factor against wedge sliding is given by Eq. 3 (Hoek and Bray 1981). It is assumed that the cohesive strength along planes “A” and “B” is zero.

where, A and B are dimensionless factors depending on the dip and dip direction of the two planes, obtained from the charts proposed by Hoek and Bray (1981). φ Α and φ B are the friction angles along planes “A” and “B” respectively. If the friction angles are unknown, it is suggested that the apparent shear strength given in Table 2 is used.

The direction of sliding of kinematically possible wedges is less restricted than with plane failures as there are two planes on which movement can take place (Wyllie 1999). Thus, for wedge slides, the sub-factor f 2 is ignored and the stability of rock cuttings under drained conditions is given by the sub-factor f 1:

Finally, it is noted that, according to Hoek and Bray (1981), a wedge having a factor of safety under drained conditions in excess of 2.0 is unlikely to fail even under the most severe combination of conditions to which the cutting is likely to be subjected.

Toppling of individual blocks

This type of failure refers to the rotation of an individual rock block around a fixed edge on its base. Two cases are distinguished:

(a) A rock block will topple if its centre of gravity lies outside the outline of the base of the block, resulting in the development of a critical overturning moment (Maurenbrecher and Hack 2007). Neglecting any external load that may act on the rock block, the stability condition in this case can be expressed through the safety factor against overturning given by the ratio of the resisting moment and the overturning moment:

where, W and tanω are the weight and the slenderness (b/h) of the rock block and δ is the dip of the dominant discontinuities (Fig. 6a).

Topple of individual rock block. a Overturning around the outer (pivot) edge of the block base (Maurenbrecher and Hack 2007). b and c Distribution of stresses below the block. Overturning may occur when the rock block fractures near the pivot edge due to inadequate bearing capacity (σ 1 > σ ult)

Reducing the safety factor value into a scale from one to ten through the sub-factor f 1, the stability condition of an individual rock block against topple (under drained conditions) is introduced quantitatively into the system by the factor f NC through Eq. 6.

(b) A rock block will topple if the weight of the block exceeds the ultimate bearing capacity of the material around the pivot edge at its base (Hack 1996). This is particularly important as weathering generally affects the outer sides of rock blocks (Brown 1981). The safety factor in this case can be expressed as the available compressive strength at the base of the rock block (JCS) divided by the maximum stress imposed by the weight of the rock block at the contact (σ 1):

The maximum and minimum stress below the base of the rock block due to its own weight (σ 1 and σ 2, respectively) is obtained through Eq. 8, commonly used in retaining wall and spread footing stability problems (Fig. 6b, c).

where, e is the eccentricity (e = M k /W y ), M k is the moment of the weight force about the center of the base (M k = W x h/2), Wy and W x are the weight components perpendicular and parallel to the rock block base (W y = γ(blh)cos β d and W x = γ(blh)sin β d) and b, l and h are the width, length and height of the rock block, respectively.

Substituting W y and M k into Eq. 8, for the simple geometry of Fig. 6b and c, the maximum and minimum stress at the rock block base are obtained (σ 1 and σ 2, respectively):

where, tanω, β d and γ are the slenderness (b/h), the dip angle of the base and the unit weight of the rock block, respectively.

Equations 8–10 stand only for e < b/6. If the eccentricity e is equal to or greater than b/6, the rock block is not bearing on its whole base but only on the front edge and therefore σ 1 = W/l.

As with the former cases, the safety factor value is reduced in scale from 1 to 10 through sub-factor f 1; however, in this case the triggering mechanism factor is ignored, thus HI = f 1 (HI = Hazard Index). The effects of hydrostatic pressure are also not included.

Flexural and block toppling

Flexural toppling (Fig. 7a), as defined by Goodman (1989) occurs where a series of beds are steeply inclined away from a rock face. In rocks such as slates, schists, interbedded limestones and mudstones etc., at the rock face, each layer tends to bend downwards under its own weight. In such a situation, flexural cracks develop in the outer face of the cutting.

Block toppling (Fig. 7b) was described by Hoek and Bray (1981) as occurring where there are frequent close joints in the rock mass such that the weight centroid falls outside the base of the column/block. As a consequence, the blocks tend to tilt forward as rigid columns, in contrast to the flexural toppling described by Goodman (1989).

According to the kinematic analysis proposed by Goodman and Bray (1977) and Goodman (1989), if the dip of the layers is δ, then flexural or block toppling failure in a cut slope inclined β s with horizontal can occur if:

where, φ is the friction along discontinuity planes, β s is the slope angle and δ is the dip of dominant discontinuities (Fig. 7a). It is assumed that cohesion along the discontinuities is zero.

“Kinematics” refers to the motion of bodies without reference to the forces that cause them to move. Many rock cuts are stable on steep slopes even though they contain steeply inclined planes of weakness with exceedingly low strength; this happens when there is no freedom for a block to move along the weak surface because other ledges of intact rock are in the way. Should the blockage be removed by erosion, excavation or development of cracks, the slope would fail immediately (Goodman 1989).

The Mohr–Coulomb form of the Goodman–Bray criterion also allows for the determination of a factor of safety (Maurenbrecher and Hack 2007):

Reducing the safety factor value into a scale from one to ten and taking into account the relative orientation of dominant failure plane(s) through the sub-factors f 1 and f 2, respectively, the stability of rock cuttings under drained conditions is given quantitatively into the system by the factor f NC through Eq. 13. The coefficient 0.1 in Eq. 13 is used in order that the value of f NC (between 1 and 10) can favour the homogeneity of the system with different slopes and failure types.

Differential weathering (slope undercutting)

The “differential weathering” type of failure (Fig. 5) occurs where a weaker horizon is weathered preferentially producing an overhang. This may be exacerbated by the water in an adjacent hillslope seeping naturally to the lowest point of the cutting.

The stability condition of an undermined rock cutting under drained conditions is given quantitatively into the system by the factor f NC:

Sub-factors f 3 and f 4 are related to the GSI and the weight of the unsupported (due to undercutting) rock mass per one meter length of slope. The GSI index expresses in essence the ability of the outcropping rock mass to bear its own weight.

Non-structurally controlled failure

The “non-structurally controlled” type of failure deals with:

-

1.

rock which contains a number of randomly oriented discontinuities but behaves as if it were an isotropic mass,

-

2.

rock cuttings with a loose surface (e.g. due to inefficient blasting) and/or;

-

3.

highly weathered rock slope masses, where rock blocks occasionally detach from the cutting face regardless of the fact that the dominant discontinuities may be favorably oriented.

In the proposed system, this type of failure is examined using the GSI that corresponds to sub-factor f 3 in the system (Table 1). The normal condition of the rock cutting is given through Eq. 15.

Quantitative attribution of the triggering mechanism for failure (factor f TM)

General

The following are taken into account to introduce a quantitative attribution of the triggering mechanism for failure into the system (factor f TM):

-

a.

The climatic conditions (precipitation and freezing periods), which are responsible for the vast majority of cut slope failure incidents. The incorporation of these factors into the system means it can be adapted to local climatic conditions, increasing its objectivity and reliability (Pantelidis 2009).

-

b.

The ways in which rain water can trigger a failure, i.e. as underground water and as surface water. According to Pantelidis (2009), three cases are distinguished:

-

Case 1:

rainwater entering the ground upslope of the rock cutting results in lateral groundwater pressures;

-

Case 2:

water enters into discontinuities exposed in the cutting face;

-

Case 3:

water disturbs/moves loose stones or blocks over the cut face or washes out infilling material.

-

Case 1:

-

c.

Where the discontinuity geometry produces wedges such that water in the cracks can freeze, expand and produce hydrostatic pressures, hence loosening of the slope veneer occurs.

The correction suggested by Marinos and Hoek (2000, 2001) regarding “wet conditions” is ignored by the present system (Pantelidis 2009).

Landslide–precipitation height relationship

It is commonly appreciated that the stability of slopes is affected by the intensity and/or the duration of precipitation and numerous researchers worldwide have proposed threshold precipitation values as criteria for slope failure. These usually refer to the mean annual, bi-monthly, monthly, daily, hourly or seasonal precipitation (Anagnostopoulos and Georgiadis 1997; Chau et al. 2003; Crozier 1999; Frayssines and Hantz 2006; Guzzetti et al. 2007; Komac 2005; Koukis and Ziourkas 1991; Rapp 1960; Wieczorek and Jäger 1996).

As a database for precipitation periods (e.g. daily, hourly) is not often available, the mean annual precipitation height is used by the proposed system. Based on the study of 802 landslide incidents, Koukis and Ziourkas (1991) concluded that the landslide frequency is related to the mean annual precipitation height with an exponential relationship. Seven examples taken from the international literature (five referring to Europe, one to America and one to Africa) indicate that the critical annual precipitation height above which most landslides occur is in the order of 850 ± 150 mm (Table 3).

Landslide triggering mechanism factor (f TM)

The influence of water on the stability of rock cuttings is taken into account in the proposed system by the Triggering Mechanism Factor (f TM) which is given as the product of the critical precipitation ratio I m /I cr times the drainage factor f D:

where, I m is the mean annual precipitation height, I cr the critical annual precipitation height (I cr = 700 mm, fixed conservative value) and f D the drainage factor of the cutting.

The drainage factor (f D) which was structured in a form of rating table (Table 4) is inferred through in situ observations relative to the potential of underground or surface water to trigger instabilities. The most unfavorable of the three cases listed in Table 4 (i.e. that with the highest score) is chosen:

where, f D,1a , f D,1b , f D,2 and f D,3 drainage sub-factors (Table 4).

Critical precipitation ratio The dimensionless site-specific coefficient Im/Icr is used to reduce the influence of the drainage factor fD on the system in areas where the mean annual precipitation is below the threshold value. The reduction in fD is linear, following the approximately linear relation between the landslide frequency and the mean annual precipitation height suggested by Koukis and Ziourkas (1991). If the mean annual precipitation height is greater than the relevant critical value, the ratio equals unity (that is, if Im > Icr then Im/Icr = 1).

Hazard index of rock cuttings

The Hazard Index is obtained from factors f NC and f TM through Eq. 18. The product “f NC × f TM ” is raised to the power of ½ such that the Hazard Index score ranges between 1 and 10.

Two cases are excluded from this step:

-

a.

Where individual blocks topple due to their weight exceeding the ultimate bearing capacity of the base of the block and HI = f 1

-

b.

Where the safety factor of the cutting is >2, climatic conditions are unlikely to trigger a failure incident and HI = 1.

Classification of rock cuttings

Depending on the Hazard Index value, rock cuttings are classified in one of the four categories: good (HI = 1–4), fair (HI = 4–6), poor (HI = 6–8) and very poor (HI = 8–10).

Summary and conclusions

Since 1979, when Bieniawski presented the modified version of the RMR system able to deal with both tunnels and cuttings, several other rock mass classification systems for the stability assessment of rock cuttings have been proposed. These systems have serious drawbacks and limitations related to the parameters involved and the types of failure considered. Furthermore, they attempt to describe quantitatively the condition of the rock cuttings rather than their failure hazard.

The proposed classification system is an innovative approach to hazard assessment, still based on the concept of rating and taking into account normal (drained) conditions and the impact of climatic conditions. It is considered that this new system is applicable to all of the most common types of failure of rock cuttings: planar and wedge sliding, the topple of individual rock block, block and flexural toppling, the non-structurally controlled failures and differential weathering. Each type of failure is examined independently and its associated instability factors are introduced into the system.

Given the degree of uncertainty in the relationship between the slope stability factors and rating values (a flaw of all systems that use the concept of rating), where possible the parameters were amalgamated to reduce the number of rating elements.

As regards to the quantitative attribution of the triggering mechanism for failure, the potential for underground or surface water is considered in terms of the critical precipitation ratio and drainage. The former is a dimensionless site-specific coefficient related to the mean and critical precipitation height, such that the influence of drainage can be modified for less wet climates. The drainage factor quantitatively expresses the potential for the development of unfavorable conditions (e.g. hydrostatic pressures, wedging forces due to frozen water, wash-out of infilling material).

A major advantage of the system is that it takes into account the different degree of hazard in two cuttings with similar rock mass condition but subjected to different climatic conditions, as may occur over long linear structures such as highways.

References

Anagnostopoulos C, Georgiadis M (1997) Analysis of rainfall data and correlation to landslides: the case of Sykia-Pieria, Greece. In: Proceedings of the International Symposium of the IAEG on engineering geology and the environment 1:483–487

Ayalew L (1999) The effect of seasonal rainfall on landslides in the highlands of Ethiopia. Bull Eng Geol Environ 58:9–19. doi:10.1007/s100640050065

Barton NR, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech Rock Eng 6(4):189–239. doi:10.1007/BF01239496

Bieniawski ZT (1979) The geomechanics classification in rock engineering applications. In: Proceedings of 4th international congress for rock mechanics, ISRM 2:41–48

Brown ET (1981) Rock characterization, testing and monitoring, ISRM suggested methods. Pergamon Press, Oxford

Cardinali M, Galli M, Guzzetti F, Ardizzone F, Reichenbach P, Bartoccini P (2006) Rainfall induced landslides in December 2004 in South-Western Umbria, Central Italy. Nat Hazards Earth Syst Sci 6:237–260

Chau KT, Wong RHC, Liu J, Lee CF (2003) Rockfall hazard analysis for Hong Kong based on rockfall inventory. Rock Mech Rock Eng 36(5):383–408. doi:10.1007/s00603-002-0035-z

Chleborad AF, Baum RL, Godt JW (2006) Rainfall thresholds for forecasting landslides in the Seattle, Washington, area—exceedance and probability. US Geological Survey Open-File Report 2006–1064 (available from: http://pubs.usgs.gov/of/2006/1064/pdf/of2006-1064.pdf)

Crozier MJ (1999) Prediction of rainfall-triggered landslides: a test of the antecedent water status model. Earth Surf Process Landf 24:825–833

Flageollet JC, Maquaire O, Martin B, Weber D (1999) Landslides and climatic conditions in the Barcelonnette and Vars Basins (Southern French Alps, France). Geomorphology 30:65–78. doi:10.1016/S0169-555X(99)00045-8

Frayssines M, Hantz D (2006) Failure mechanisms and triggering factors in calcareous cliffs of the Subalpine Ranges (French Alps). Eng Geol 86:256–270. doi:10.1016/j.enggeo.2006.05.009

Goodman RE (1989) Introduction to rock mechanics, 2nd edn. Wiley, New York

Goodman RE, Bray JW (1977) Toppling of rock slopes. In: Proceedings of a Specialty Conference on rock engineering for foundations and slopes 2:201–234

Guzzetti F, Reichenbach P, Cardinali M, Ardizzone F, Galli M (2003a) The impact of landslides in the Umbria Region, Central Italy. Nat Hazards Earth Syst Sci 3(5):469–486

Guzzetti F, Reichenbach P, Wieczorek GF (2003b) Rockfall hazard and risk assessment in the Yosemite Valley, California, USA. Nat Hazards Earth Syst Sci 3(6):491–503

Guzzetti F, Peruccacci S, Rossi M, Stark CP (2007) Rainfall thresholds for the initiation of landslides in central and southern Europe. Meteorol Atmos Phys 98:239–267. doi:10.1007/s00703-007-0262-7

Hack HRGK (1996) Slope stability probability classification (SSPC). ITC Publication, Netherlands ISBN 90 6164 125 X. 258 pp (thesis, book, online)

Hoek E (2007) Practical rock engineering. Internet site: Hoek’s corner (available from: http://www.rocscience.com/hoek/Hoek.asp)

Hoek E, Bray JW (1981) Rock slope engineering, 3rd edn. Institution of Mining and Metallurgy, London

IUGS (1997) Quantitative risk assessment for slopes and landslides—the state of the art. In: Cruden D, Fell R (eds) Landslide risk assessment. Balkema, Rotterdam, pp 3–12

Komac M (2005) Intenzivne padavine kot sprožilni dejavnik pri pojavljanju plazov v Sloveniji (Rainstorms as a landslide-triggering factor in Slovenia). Geologija 48(2):263–279

Koukis G, Ziourkas C (1991) Slope instability phenomena in Greece—a statistical analysis. Bul Int Assoc Eng Geol 43:47–60. doi:10.1007/BF02590170

Koukis G, Tsiambaos G, Sabatakis N (1997) Landslide movements in Greece: Engineering geological characteristics and environmental consequences. In: Proceedings of the International Symposium on engineering geology and the environment 1:789–792

Koukis G, Sabatakakis N, Nikolaou N, Loupasakis K (2005) Landslide Hazard Zonation in Greece. In: Sassa K, Fukuoka H, Wang F, Wang G (eds) Landslides, risk analysis and sustainable disaster management. Springer, Berlin, pp 291–296. doi:10.1007/3-540-28680-2

Marinos P, Hoek E (2000) GSI: A geologically friendly tool for rock mass strength estimation. In: Proceedings of the International Conference on geotechnical and geological engineering (GeoEng2000), pp 1422–1442

Marinos P, Hoek E (2001) Estimating the geotechnical properties of heterogeneous rock masses such as flysch. Bull Eng Geol Environ (IAEG) 60:85–92. doi:10.1007/s100640000090

Marinos V, Marinos P, Hoek E (2005) The Geological Strength Index: applications and limitations. Bull Eng Geol Environ 64:55–65. doi:10.1007/s10064-004-0270-5

Maurenbrecher PM, Hack HRGK (2007) Toppling mechanism: resolving the question of alignment of slope and discontinuities. In: Proceedings of the 11th Congress of the ISRM. The second half century of rock mechanics 1:725–728

McCauley ML, Works BW, Naramore SA (1985) Rockfall mitigation—final report (FHWA/CA/TL-85/12). FHWA, Washington

Mouratidis A, Pantelidis L (2007) Rock failure risk assessment in highway maintenance management. In: Proceedings of the International Conference on advanced characterisation of pavement and soil engineering materials 2:1145–1154

Palmström A (1995) RMi—a rock mass characterization system for rock engineering purposes. PhD thesis, University of Oslo, Norway p 409

Palmström A (2001) Measurement and characterization of rock mass jointing. In: Sharma VM, Saxena KR (eds) In situ characterization of rocks. Balkema, Tokyo, pp 49–97

Pantelidis L (2009) Rock slope stability assessment through rock mass classification systems. Int J Rock Mech Min Sci 46(2):315–325. doi:10.1016/j.ijrmms.2008.06.003

Rapp A (1960) Recent developments of mountain slopes in Kärkevagge and surroundings, northern Scandanavia. Geografiska Annaler 42(A):71–200

Trigo RM, Zêzere JL, Rodrigues ML, Trigo IF (2005) The influence of the North Atlantic Oscillation on rainfall triggering of landslides near Lisbon. Nat Hazards 36:331–354. doi:10.1007/s11069-005-1709-0

Varnes DJ (1978) Slope movement types and processes. TRB 176:11–33

Wieczorek GF, Jäger S (1996) Triggering mechanisms and depositional rates of postglacial slope-movement processes in the Yosemite Valley, California. Geomorphology 15:17–31. doi:10.1016/0169-555X(95)00112-I

Wieczorek GF, Snyder JB, Alger CS, Isaacson KA (1992) Rock falls in Yosemite Valley, California. US Geological Survey, Open-File Report, pp 92–387

Wyllie DC (1999) Foundation on rock, 2nd edn. Taylor and Francis, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pantelidis, L. An alternative rock mass classification system for rock slopes. Bull Eng Geol Environ 69, 29–39 (2010). https://doi.org/10.1007/s10064-009-0241-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-009-0241-y