Abstract

To evaluate the influence of exposure time on speckle noise for laser displays, speckle contrast measurement method was developed observable at a human eye response time using a high-sensitivity camera which has a signal multiplying function. The nonlinearity of camera light sensitivity was calibrated to measure accurate speckle contrasts, and the measuring lower limit noise of speckle contrast was improved by applying spatial-frequency low pass filter to the captured images. Three commercially available laser displays were measured over a wide range of exposure times from tens of milliseconds to several seconds without adjusting the brightness of laser displays. The speckle contrast of raster-scanned mobile projector without any speckle-reduction device was nearly constant over various exposure times. On the contrary to this, in full-frame projection type laser displays equipped with a temporally-averaging speckle-reduction device, some of their speckle contrasts close to the lower limits noise were slightly increased at the shorter exposure time due to the noise. As a result, the exposure-time effect of speckle contrast could not be observed in our measurements, although it is more reasonable to think that the speckle contrasts of laser displays, which are equipped with the temporally-averaging speckle-reduction device, are dependent on the exposure time. This discrepancy may be attributed to the underestimation of temporal averaging factor. We expected that this method is useful for evaluating various laser displays and clarify the relationship between the speckle noise and the exposure time for a further verification of speckle reduction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, the study of speckle noise has been greatly advanced for practical use in laser displays, because the speckle phenomenon is a fundamental issue in coherent light applications and markedly affects the image quality of laser displays. Quantitative measurement and reduction of speckle noise are urgent tasks.

Since the speckle noise is a laser interference pattern formed and perceived on a human eye retina, it is essential to construct an optical system to simulate the human eye with a camera. The speckle noise used to be measured by the camera with its aperture of about 3 mm which is the same size as the average human eye pupil [1, 2]. However, the camera is not equivalent to the human eye, because the camera has no aberration, while the human eye has a large amount of aberration. Therefore, in order to bring the camera close to the point spread function (PSF) of human eye, we optimized the pinhole to 1.2 mm in diameter which is mounted in front of the camera using a diffraction-limited PSF [3]. Based on this theory, we established a quantitative speckle measurement method which measures speckle contrast, and released some commercial speckle contrast measurement instruments [4,5,6,7,8].

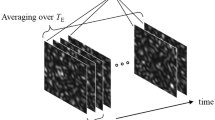

The current model (model SM01VS09 manufactured by Oxide Corporation) can measure the speckle contrast at arbitrary observer’s position by setting the observation distance arbitrarily [7], and the exposure time is optimized to match the brightness of samples with high repeatability over wide dynamic range in speckle contrast. However, the exposure time of several seconds is required in measuring commercially available laser displays since small portion of light can pass through the pinhole. We consider that the exposure time of camera will be important factor in the evaluation of laser displays in which a speckle-reduction device temporally averages independent speckle noise patterns. If the exposure time is largely different from the human eye response time which is estimated to be about 80 ms [9], the number of speckle noise pattern in superposition will be greatly different. Therefore, the captured speckle noise pattern will be deviated from the pattern perceived by the human eye, even if the PSF of camera is close to the human eye. We call this phenomenon an ‘exposure-time effect’, in which the speckle contrast is dependent on the exposure time because the averaging time becomes short. In [10], the influence of the exposure time on a fully-developed speckle noise of a solid-state laser was measured using a charge-coupled device (CCD) camera, in which the speckle contrast was almost constant at the exposure time from 9 to 56 ms. In [11], the influence on a speckle suppression of a laser in a rotating diffuser was measured using a CCD camera, in which the speckle contrast was measured at the exposure time from 0.2 to 10 ms and largely increased at the exposure time less than 0.5 ms.

In this paper, we will report the development of speckle contrast measurement method which can observe commercially available laser displays in the human eye response time using a high-sensitivity camera and the optical system close to the PSF of human eye, and we will show the measurement results of laser displays over a wide range of exposure times.

2 Improvement of measurement equipment

2.1 High-sensitivity camera

For the purpose to increase the sensitivity of camera, we replaced the CCD camera with an electron multiplying charge-coupled device (EMCCD) camera which is added by a signal multiplying function in the readout register of CCD. We used an image sensor model CCD97-00 manufactured by e2v technologies which has 262 thousand pixels (512 × 512) and can amplify its signal by nearly one thousand times. The EMCCD camera equipped with the CCD97-00 can control its light sensitivity by setting an EMCCD gain parameter which is set between 0 and 100. Multiplication gain was measured at various cooling temperatures shown in Fig. 1. When the camera was operated at the cooling temperature of −30 °C which is recommended by the camera manufacturer, the multiplication gain was about 380 at the EMCCD gain parameter of 100.

The technical tasks of speckle contrast measurement using the EMCCD camera are reported in following sections.

2.2 Modification of optical design

A speckle average grain size S was theoretically expressed by

where λ is the wavelength, d is the pinhole diameter and f is the focal length of imaging lens [8]. It was derived from the analysis of coherence area at an observation plane [12].

When the speckle contrast is measured using the current model of which CCD pixel size is 6.45 × 6.45 μm2, focal length of imaging lens is 50 mm and pinhole diameter is 1.2 mm, the measured speckle average grain size on the sensor is about 34, 29 and 25 μm at the wavelengths in red, green and blue, respectively [8]. Since the grain size is sufficiently larger than the pixel size, it is possible to capture the accurate speckle noise pattern. On the other hand, if the same lens is attached to the CCD97-00, which has the pixel size as large as 16 × 16 μm2, it will be impossible to capture the accurate speckle noise pattern since the speckle grain size is close to the pixel size. Therefore, we modified the focal length from 50 to 135 mm to increase the speckle grain size so as to match the larger pixel size of CCD97-00.

2.3 Linearity correction of light sensitivity

When the amplification of EMCCD is applied, the light sensitivity of camera becomes slightly curved similar to a complementary metal oxide semiconductor (CMOS) sensor [13]. To measure the speckle contrast accurately, we calibrated the nonlinearity of camera light sensitivity. Figure 2 shows the schematics of light sensitivity measurement composed of a spectroradiometer model SR-UL1R of Topcon technohouse, a green light emitting diode (LED) light source model MCEP-CG8 of Moritex Corporation and a 12-inch integrating sphere manufactured by SphereOptics GmbH. Using this setting, we obtained the accurate curve of light sensitivity shown in Fig. 3. Based on this result, we corrected the digital number of the image intensity of EMCCD camera.

As a test trial, we measured the speckle contrast of a laser projector. Figure 4 shows the schematics of speckle contrast measurement, in which the pinhole diameter was fixed at 1.2 mm, the observation distance L between the screen and the pinhole was set to 1060 mm, and the projection distance S between the light source and the screen was set to 260 mm. The screen was a standard diffuse reflectance target (model SRT-99-20 of Labsphere). The CCD97-00 was operated at the cooling temperature of −30 °C, the exposure time of 1 s and the EMCCD gain parameter of 46. We prepared a raster-scanned projection type mobile laser projector (model MX10/B of Microvision), which is one of the commercially available laser displays. In the trial, the projection image was a homogeneous green picture. As a result, the speckle contrast was 0.121 when the amplification was not applied. On the other hand, the speckle contrast was 0.140 when the amplification was applied. The slight curve of light sensitivity influences the speckle contrast and it is confirmed that this correction is necessary to obtain the accurate speckle contrast.

2.4 Reduction of electron noise

As the EMCCD gain parameter is increased, the electron noise of captured image also grows. The noise cannot be completely removed by a specific filter since it behaves as a white noise. To reduce the electron noise and improve the measuring lower limit of speckle contrast, we applied a Butterworth filter, which is one of the spatial-frequency low pass filters, with its order of 10th and its cutoff frequency of 128 pixel−1 in the digital image processing using fast Fourier transformation.

As a test trial, we measured the green LED light source (model MCEP-CG8 of Moritex Corporation), as an incoherent light source, with the EMCCD gain parameter of 85 in the setting of Fig. 4. The ratio (σ/I) of the standard deviation (σ) to the average (I) of digital number in the captured image is 0.054 when the low pass filter is not applied. On the other hand, the ratio is 0.020 when the low pass filter is applied. The noise can be reduced to more than half value using the low pass filter.

Using a red LED light source (model MCEP-CR8), a green LED light source (model MCEP-CG8) and a blue LED light source (model MCEP-CB8) of Moritex Corporation, the measuring lower limit of speckle contrast in red, green and blue was measured in the same setting of Fig. 4, respectively. The measured lower limits noise are dependent on the EMCCD gain parameter shown in Fig. 5. Compared with the current model, the lower limits noise becomes higher than the noise level of current model at the larger value of EMCCD gain parameter and slightly lower at the smaller value of EMCCD gain parameter.

2.5 Measuring timing of samples

There is a possibility that the camera will capture the image in the middle of displaying in measurements, when the exposure time of camera is nearly equal to the frame rate (about 60 Hz) in a raster-scanned projection type display. We improved the measuring timing of camera to capture the image at the completion of displaying. The shutter timing was adjusted to the display timing using the external trigger function of camera and the measurement software was modified to set the exposure time to an integer multiple of the display frame rate.

3 Experimental methods

We measured the speckle contrasts in Fig. 4, in which the pinhole diameter was fixed at 1.2 mm and the observation distance L was set to about 1 m. The screen was the same as that in Sect. 2.3. The CCD97-00 was operated at the cooling temperature of −30 °C. The exposure time was changed within a range where the EMCCD gain parameter can be set in the measurement software.

We prepared three kinds of commercially available laser displays using different projection schemes. One was a raster-scanned projection type mobile projector (model MX10/B of Microvision) without any speckle-reduction device. The other two displays were equipped with a speckle-reduction device such as a moving diffuser. Another one was a rear-projection type laser TV (model 75-LT1 of Mitsubishi Electric) which was equipped with a digital micromirror device of digital light processing (DLP) manufactured by Texas Instruments. It was set and measured at the position of screen in Fig. 4. The other was a full-frame projection type mobile projector (model FMVNPJ3 manufactured by Panasonic System Networks) which was equipped with a liquid crystal on silicon (LCOS) device. In measurements, the projection image was a uniform circle picture of red, green and blue in color, and the brightness of the projector was kept constant at any exposure time. The new measurement method was compared with the current model (model SM01VS09 of oxide).

4 Results

4.1 Raster-scanned projection type mobile projector

Figure 6 shows the plot of speckle contrasts at various exposure times for each color. The broken lines show the measuring lower limits of speckle contrast which were different in each color. The reason is that the brightness of display and the sensitivity of camera were different for each color, and the EMCCD gain parameters were set to different values. The triangle stands for measurement by the current model. The new measurement tool can measure over a wide range of exposure time, but the current model measurement is limited to one at exposure time shown by triangle. The measured values were nearly constant since the projector was not equipped with temporally-averaging speckle-reduction device.

4.2 Rear-projection type laser TV

The results of the laser TV are shown in Fig. 7. The speckle contrasts were smaller than the raster-scanned mobile projector since it may be equipped with the speckle-reduction device such as a moving diffuser. However, these measured speckle contrasts were also nearly constant over various exposure times although it has the speckle-reduction device. The tendency that the speckle contrast of blue slightly increased at shorter exposure time is attributable to an exposure-time effect by a temporally-averaging speckle-reduction device, but it was close to the measuring lower limit.

4.3 Full-frame projection type mobile projector

The results of the full-frame projection type mobile projector are shown in Fig. 8. The speckle contrasts were smaller than the other displays and slightly increased at shorter exposure time similar to the speckle contrast of blue for the laser TV. These tendencies are attributable to the exposure-time effect, but they were also close to the lower limits.

5 Discussions

5.1 Cross-correlation and speckle average grain size

To verify the exposure-time effect on the speckle contrast, we calculated the cross-correlation between two sequentially captured images from the measurement results. The calculation process of cross-correlation is described in Sect. 7. If the cross-correlation is small, the speckle noise pattern will be temporally changed for each capturing, and the change of speckle contrast will be caused by the exposure-time effect.

In addition, we also calculated the speckle average grain size which was calculated by the auto-covariance function described in the Sect. 7. If the grain size takes a value caused by the speckle noise, the speckle noise pattern will be accurately captured. If not, it will be influenced by the electron noise or something.

5.1.1 Raster-scanned projection type mobile projector

Figure 9 shows the calculation results of the raster-scanned mobile projector. At the longer exposure time, the cross-correlation R CC was close to 1.0, and the speckle average grain size S was separated from each other and grew in order of blue, green and red. We consider that the speckle noise pattern was slightly influenced by the electron noise since the S slightly became small at the shorter exposure time. Although the R CC of blue became smaller than others at the shorter exposure time, we consider that it is not the exposure-time effect because the speckle contrast of blue was nearly constant.

5.1.2 Rear-projection type laser TV

Figure 10 shows the calculation results of the laser TV. At the shorter exposure time, the R CC of blue particularly became small and the grain size of blue decreased to about 50 μm. This size is comparable to the background noise which was measured using the LED light source when the low pass filter was applied to the speckle noise pattern at the large value of EMCCD gain parameter. Therefore, we consider that it is not the exposure-time effect because the speckle noise pattern of blue was greatly influenced by the electron noise at the shorter exposure time, although the speckle contrast of blue slightly increased at the shorter exposure time. In addition, the grain size of blue was comparable to the green at the longer exposure time although the grain size should be dependent on the wavelength. Judging from this fact, we consider that the speckle contrast of blue was not due to the speckle noise itself.

5.1.3 Full-frame projection type mobile projector

Figure 11 shows the calculation results of the full-frame projection type mobile projector. At the shorter exposure time, all R CC became small and all S decreased to the background noise level similar to the grain size of blue for the laser TV. Since the speckle noise patterns were greatly influenced by the electron noise at the shorter exposure time like the laser TV displaying only blue color, we consider that they are not the exposure-time effect although the speckle contrasts were slightly increased at the shorter exposure time.

5.2 Comparison of speckle contrast measurement

The new measurement tool was compared with the current model and the results are summarized in Table 1. Under practical use condition except for the slight increase of speckle contrast due to the lower limit noise, the light sensitivity can be increased up to about twenty times when the EMCCD gain parameter is from 0 to 70. The measuring lower limits of speckle contrast are from 0.006 to 0.014, which are slightly higher than the noise level of current model at the larger value of EMCCD gain parameter. The exposure time for commercially available laser displays can be set from tens of milliseconds to several seconds by controlling the EMCCD gain parameter.

5.3 Consideration of exposure-time effect

The most useful formula for speckle contrast measurement and reduction, which was derived by Goodman, is expressed by [12]

where C S is the speckle contrast, M is the temporal diversity which is related to the exposure time, and K is the spatial diversity which is related to the numerical aperture of lens for the projector and the measurement instrument. Equation (2) is plotted at various K as a function of M in Fig. 12. In the case of M ≫ K, C S can be approximated by [12]

C S converges to a specific value which is dependent on the numerical apertures but independent of the exposure time.

Theoretical function [Eq. (1)] at various K as a function of M

In the previous work, we estimated the M of laser projector which was same as the full-frame projection type mobile projector (model FMVNPJ3) by fitting the experimental data to the theoretical equation of Eq. (2), and the estimated value was M = 761 with the K varied from 104 to 1156 [6]. We assumed that the M will become one twentieth, that is, M = 38 if the exposure time T E of the camera becomes one twentieth. Figure 12 indicates that the speckle contrast must be extremely large when the M is less than 100. Since the projector was measured between T E = 3 s and T E = 18 s in the previous work, it was expected to observe the exposure-time effect by measuring the projector at less than T E = 150 ms in this work. However, the measured speckle contrasts did not increase in such a way as shown in Fig. 12 and were nearly constant over a wide range of exposure time. Therefore, the actual value will be M = 400 or more although the initial expected value was M = 38. We consider that this discrepancy may be attributed to the underestimation of M in the previous work because it was inappropriate to adapt the complex optical system such as laser displays to the theoretical formula of Eq. (2) and the speckle contrast was determined by not only M and K, but also a screen, polarization, wavelength multiplexing, and so on.

In [11], the speckle suppression in a rotating diffuser of 10π rad/s was examined and its speckle contrast was measured as a function of camera’s exposure time. The measured speckle contrast started to increase from the exposure time of about 2 ms. Therefore, if the display has a moving diffuser similar to this speckle suppression, the speckle contrast will not increase at the human eye response time which is much larger than 2 ms. We consider that further experimental verification of speckle-reduction is necessary for prototyping and measuring a customized rotating diffuser with slow rotation control.

6 Conclusion

To evaluate the influence of exposure time on speckle noise for laser displays, the speckle contrast measurement method was developed observable at the human eye response time using the EMCCD camera. Three types of commercially available laser displays were measured over a wide range of exposure times from tens of milliseconds to several seconds without adjusting the brightness of laser displays. Although it is more reasonable to think that the speckle contrasts of laser displays, which are equipped with the temporally-averaging speckle-reduction device, are dependent on the exposure time, the exposure-time effect of speckle contrast could not be observed in our measurements. This discrepancy may be attributed to the underestimation of temporal diversity M. We expect that this method is useful for evaluating various laser displays and clarifying the relationship between the speckle noise and the exposure time for a further verification of speckle reduction.

References

Trisnadi, J.I.: Speckle contrast reduction in laser projection displays. Proc. SPIE 4657, 131–137 (2002)

Roelandt, S., Meuret, Y., Craggs, G., Verschaffelt, G., Janssens, P., Thienpont, H.: Standardized speckle measurement method matched to human speckle perception in laser projection systems. Opt. Express 20, 8770–8783 (2012)

Kubota, S.: Simulating the human eye in measurements of speckle from laser-based projection displays. Appl. Opt. 53, 3814–3820 (2014)

Kubota, S., Goodman, J.W.: Very efficient speckle contrast reduction realized by moving diffuser device. Appl. Opt. 49, 4385–4391 (2010)

Fukui, T., Ito, K., Suzuki, K., Tokita, H., Furukawa, Y., Kubota, S.: 1st Laser Display Conf. Dig. Tech. Pap. LDC8-3, Laser Dispay Conference, Yokohama (2012)

Suzuki, K., Fukui, T., Kubota, S., Furukawa, Y.: Verification of Speckle Contrast Measurement Interrelation with Observation Distance. Opt. Rev. 21, 94–97 (2014)

Fukui, T., Suzuki, K., Kubota, S.: Proc. IDW’13, PRJ4-1. The Institute of Image Information and Television Engineers and The Society for Information Display, pp. 1251–1254. Sapporo (2013)

Fukui, T., Suzuki, K., Kubota, S.: Proc. IDW’14, PRJ3-2. The Institute of Image Information and Television Engineers and The Society for Information Display, pp. 1094–1097. Niigata (2014)

Gakkai, S.: Hikari no keisoku manual, p. 404. Tokyo, Nihon Riko Shuppankai (1990). (in Japanese)

Xu, M., Shi, Y., Tang, G., Liu, J., Chen, X.: World academy of science, engineering and technology. Int. J. Math. Comput. Phys. Electr. Comput. Eng. 6(3), 261–264 (2012)

Li, D., Kelly, D.P., Sheridan, J.T.: Speckle suppression by doubly scattering systems. Appl. Opt. 52, 8617–8626 (2013)

Goodman, J.W.: Speckle Phenomena in Optics. Roberts & Company, Colorado (2007)

Ma, Q., Xu, C.: 4th Laser Display and Lighting Conf. Dig. Tech. Pap., LDC 7–2. Laser Display Conference. Yokohama (2015)

Digital-Gazou-Syori Hensyu-iinkai: Digital Image Processing, p. 204. Computer Graphic Arts Society, Tokyo (2004). (in Japanese)

Piederrière, Y., Cariou, J., Guern, Y., Le Jeune, B., Le Brun, G., Lotrian, J.: Scattering through fluids: speckle size measurement and Monte Carlo simulations close to and into the multiple scattering. Opt. Express 12, 176–188 (2004)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Appendix

Appendix

The cross-correlation was calculated by the following method. In [14], a zero-mean normalized cross-correlation is expressed by

where I (i, j) is a digital number of the original image, T (i, j) is a digital number of the template image with the size of M × N pixels, and the position of (i, j) is the address of template image in which the value of i is from 0 to M − 1 and the value of j is from 0 to N − 1. The values of \(\overline{I}\) and \(\overline{T}\) are expressed by

In this work, the maximum value of R ZNCC with the template image size of 128 × 128 was calculated by shifting every one pixel from the perfectly matched position between the original image and the template image to ± 128 pixels, and we plotted the maximum value as the cross-correlation R CC in Figs. 9, 10 and 11. As a result, the value of R CC was the same as the R ZNCC at the perfectly matched position.

We calculated the speckle average grain size defined as an FWHM of the normalized auto-covariance function [15], which is expressed by

where I (x, y) is a digital number of the captured image at the position of (x, y), and FT and FT−1 are Fourier and inverse Fourier Transform, respectively. \(\langle \rangle\) is a spatial average. We plotted the FWHM of Eq. (A4) as S in Figs. 9, 10 and 11.

Rights and permissions

About this article

Cite this article

Suzuki, K., Kubota, S. Understanding the exposure-time effect on speckle contrast measurements for laser displays. Opt Rev 25, 131–139 (2018). https://doi.org/10.1007/s10043-017-0372-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10043-017-0372-5