Abstract

We have synthesized cobalt metal-organic framework (Co-MOF) at different temperatures through solvothermal route as metal-organic frameworks which can be used for supercapacitors. The effect of synthesizing temperature on Co-MOF’s structure and porous behavior were analyzed with various characterization techniques like X-ray diffraction, Brunauer-Emmett-Teller surface analyzer, scanning electron microscope, and transmission electron microscope. The charge storage performance of the as-prepared Co-MOF’s was carried out in 3 M KOH. The results proved the excellent redox behavior of Co-MOFs, and a maximum specific capacitance of 952.5 F g−1 was obtained for Co-MOF/150 (synthesized at 150 °C) at a current density of 0.25 A g−1. The higher specific surface area and micropore of Co-MOF/150 significantly heightened the electrolyte ion transport during the electrochemical performance.

ᅟ

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Caused by fossil fuel-based energy sources, global warming, and environmental pollution problems have brought a few crucial issues, which drives many recent research attempts on exploring new materials for energy storage and energy conversion devices [1, 2]. The development of energy storage devices with high energy and power output, long lifetime, and short charging time is essential for many applications which include electric vehicles, energy storage for wind and large industrial equipment. Supercapacitors, also called electrochemical capacitors or ultracapacitors had attracted much attention in recent decades due to their characteristics of high-power density (> 10 kW kg−1), long-term stabilities (> 105 cycles), high reliability, fast charge/discharge rate, and safe operation mode compared to traditional batteries [3, 4]. Depending on the charge storage processes, supercapacitors can be divided into the electrical double layer capacitors (EDLCs) and pseudocapacitors. EDLCs can store charges from electrostatic charge accumulation at electrode/electrolyte interface. The capacitive behavior of EDLCs mainly depends on the specific surface area and the structure of the electrode materials. Generally, carbon-based materials such as carbon nanotubes, activated carbon, graphene, and recently graphdiyne have been used for EDLCs due to their high surface area and excellent conductivity [5,6,7,8,9]. Pseudocapacitors can store charges due to the reversible faradic reactions involving charge transfer between electrode and electrolyte. Metal oxides, transition metal chalcogenides, and conducting polymers have been employed for pseudocapacitors thanks to their excellent redox activities and multiple available oxidation states [10,11,12]. In recent years, metal-organic frameworks (MOFs) have received much research interest in pseudocapacitors as a result of their high accessible surface area and porosity, tunable pore size, and ordered crystalline structures [13,14,15,16,17,18].

Metal-organic frameworks are a kind of porous materials connected with metal-containing units and organic linkers, and possess large surface area [13]. In recent years, several studies have been focused on MOF-based applications such as gas storage [19,20,21,22], separations [23,24,25,26], and catalysis [27,28,29]. Since metal cations (ions) inside the MOF can offer more active sites for redox behavior towards charge storage phenomena, many metals such as Cu [30, 31], Co [32,33,34], Ni [35,36,37], Fe [38], Cr [39], and Zr [40] have been used for MOFs as supercapacitor electrode materials. Among various MOFs, Co-MOF has received much attention in electrochemical energy storage devices such as lithium-ion batteries and supercapacitors due to its excellent redox performance. Cobalt, as a transition metal, can provide redox-active sites and is suitable to construct MOFs of good electrochemical performance. Furthermore, different oxidation states of cobalt could be involved in surface faradic redox reactions and delivered higher electrochemical activities than other MOF materials. Diaz et al. reported the electrochemical behavior of a Co-based MOF as electrode material firstly [33]. Lee et al. reported a Co-MOF synthesis and the electrode exhibited a specific capacitance of 179.2 F g−1, an energy density of 31.4 Wh kg−1 and a power density of 5.64 kW kg−1 [41]. In some previous works, Co-MOFs showed good capacitive behavior with comparable specific capacitance and good cycling stability [34, 42]. It has been remarked that the electrochemical capacitance performance of the electrodes not only depends on the type of electrode, also it depends on the several factors such as morphology, porosity, size, and composition. The morphology, phase, and porous features of MOF can be controlled with synthesis conditions, including temperature, metal precursor, organic linker, molar concentration, and solvents.

In this paper, we have conducted a systematic study of temperature influence on Co-MOF synthesis using ethanol as solvent. The structure and porosity features of the as-prepared Co-MOF’s were characterized, and their electrochemical performance was evaluated towards an electrode material of supercapacitors. The results suggested that the Co-MOF synthesized at 150 °C showed remarkable electrochemical performance with the specific capacitance of 956 F g−1 at a current density of 0.25 A g−1, respectively. The large specific surface area and micropore structure of Co-MOF/150 lead to superior electrochemical performance towards supercapacitor applications.

Experimental methods

Materials

AR grade of cobalt (II) nitrate hexahydrate (Co(NO3)2·6H2O), 1,3,5-tricarboxylic acid (H3BTC), was purchased from Sigma-Aldrich. Ethanol (99.8% assay) and potassium hydroxide (KOH) were purchased from Shanghai Lingfeng Chemical Reagent Co., LTD, China. The purchased chemicals were utilized without additional purification. Milli-Q water with pH 7.2 was used for all the solution preparation.

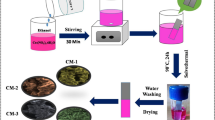

Preparation of Co-MOF

Different structures of Co-MOF’s were synthesized at various temperatures by the following procedure. In the beginning, 0.9 g of H3BTC and 48 ml of ethanol solution were added together and agitated with a magnetic stirrer for 10 min. Following that, 1.8 g of Co(NO3)2·6H2O was added to the previous solution and continued mixing for an additional 10 min. Later, the mixed solution was shifted into a Teflon-lined stainless steel autoclave (70 ml capacity) and heated at 120 °C for 12 h. After being cooled to room temperature naturally, the obtained purple color precipitate was thoroughly washed and centrifuged with ethanol several times. Finally, the collected sample was placed in a vacuum oven at 60 °C and dried for 24 h. As the prepared sample was marked as Co-MOF/120. The synthesis of Co-MOF/150, Co-MOF/180, and Co-MOF/210 was similar to that illustrated above with different temperatures at 150 °C, 180 °C, and 210 °C, respectively.

Material characterization

Powder X-ray diffraction pattern of Co-MOF samples was obtained by Rigaku Smartlab diffractometer with Cu-Kα radiation (λ = 1.540 Å). The surface morphologies and structures of the samples were observed using scanning electron microscope (Zeiss Merlin). In addition, the morphology of Co-MOF/150 was characterized with transmission electron microscope (FEI Tecnai F30). The textural porosity and specific surface area were analyzed with BET analyzer (Model: ASAP 2020).

Electrochemical measurements

Electrochemical workstation (CHI 660 E) was used for all the electrochemical measurements such as cyclic voltammetry (CV), galvanostatic charge-discharge (GCD) and electrochemical impedance spectroscopy (EIS) in 3 M KOH electrolyte. Active material (Co-MOF)-coated Ni foam was used as a working electrode with respect to a reference electrode of Ag/AgCl. Platinum (Pt) wire was employed as a counter electrode. The slurry-coated working electrode was fabricated as follows: In brief, active material and carbon black (conductive agent) with a mass ratio of 85:10 was mixed with 5 wt% of Nafion solution to form a homogeneous slurry. Afterward, the slurry was coated on Ni foam electrode (2 cm × 1 cm × 0.1 cm). The total mass of the active material of electrode was 2 mg cm−2 and the total coated surface area was 1 × 1 cm2. Finally, the electrode was allowed to dry at room temperature for 3 h. All the electrochemical studies were carried out under ambient conditions. The EIS spectrum of Co-MOF samples was fitted with ECLab software.

Results and discussion

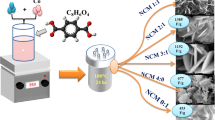

The morphology of as-prepared Co-MOFs at different temperatures is shown in Fig. 1. From the SEM images, it could be seen that the hierarchical hollow microspheres of Co-MOFs are densely composed of one-dimensional nanorods, and the size of the obtained urchin-like Co-MOF spheres is about 2 μm. It is unusual that some of nanosheets structure has been noticed in Co-MOF/120 sample, and the obtained nanosheets might be the reason to reduce the porous feature of MOF as discussed later in BET analysis. The sheet-like structure disappears in Co-MOF/150, indicating a different nucleation rate due to the higher temperature, which suggests that temperature could play an essential role in the formation of various MOF structures. The hollow structures of Co-MOF and the size of holes in the microspheres were expanded at the temperature 180 °C i.e., almost all the Co-MOF spheres became hollow structures compared with Co-MOF/120 and Co-MOF/150. At very high temperature (210 °C), most of the hollow microspheres disappear, and irregular shapes of MOF have been observed. As the evidence of the SEM analysis, the synthesis temperature plays a crucial role on the structure of Co-MOF concerning initial nucleation rates. TEM analysis further characterized the architectures of Co-MOF nanorod. Uniform sized nanorods was observed from TEM images of Co-MOF/150 sample (Fig. 2a–c), and the length and width of the nanorods are about 100 nm and 40 nm, respectively. It can be seen that the mesoporous of voids between the nanorods, and these voids can improve the electron transport and enhance the active sites for electrochemical reactions.

The crystallinity of the Co-MOF was investigated by X-ray diffraction (XRD), as shown in Fig. 3. The obtained diffraction peaks agree well with the previously reported Co-MOF [43]. It is noticed that there was no apparent difference in the diffraction peaks among the Co-MOFs except the diffraction intensities. The difference in their intensities was mainly attributed to the presence of water or solvent molecules in MOF pores.

The textural characteristic such as porosity and specific surface area of as-prepared Co-MOFs were analyzed with BET analyzer. The N2 adsorption-desorption isotherms of Co-MOF samples at 77 K in the relative pressure P/P0 ranging from 0 to 1 are shown in Fig. 4a. The presence of the mesoporous structure in as-prepared Co-MOF samples was validated from type IV hysteresis isotherm loop at the relative pressure between 0.8 and 1.0 [44]. In addition, the mesoporous structure in the Co-MOF hollow spheres was further confirmed with BJH size distribution (Fig. 4b) and the curves show the centered peak in between 20 to 35 nm for all the synthesized Co-MOFs. Since the real pores were not discerned in the nanorods, we assume that the mesoporous behavior may come from the voids among the nanorods (indicated in Fig. 2c) [45]. The textural characteristics of the Co-MOFs are listed in the Table 1. The presence of nanosheets in Co-MOF/120 could reduce the voids between the nanorods, and lower its surface area and porous behavior. The large BET surface area (93.6 m2 g−1) and micropore area (2.60 m2 g−1) of Co-MOF/150 could promote the electrolyte ion migration between the electrode/electrolyte interface and boost the electrochemical redox reactions [46].

In order to evaluate the electrochemical supercapacitance performance of as-synthesized Co-MOFs electrodes, electrochemical measurements were investigated in 3 M KOH electrolyte from 0 to 0.5 V potential window. The cyclic voltammetry performance of the Co-MOF electrodes is shown in Fig. 5. A couple of redox peaks is observed in the curves, suggesting the pseudocapacitance behavior of Co-MOF electrodes which comes from the faradic redox reactions of various cobalt oxidation states and the possible cobalt conversion involved in the electrochemical reactions can be described by the following expression [47].

Cyclic voltammogram (CV) curves of a Co-MOF/120, b Co-MOF/150, c Co-MOF/180, and d Co-MOF/210 at different scan rates. e Comparison of galvanostatic charge-discharge curve of Co-MOF/120, Co-MOF/150, Co-MOF/180, and Co-MOF/210 at 5 mV s−1 (f). Specific capacitance plot of Co-MOF electrodes at different scan rates (i) Co-MOF/120, (ii) Co-MOF/150, (iii) Co-MOF/180, and (iv) Co-MOF/210

The area of CV curve represents the capacitance behavior of the electrodes. As shown in the Fig. 5e, both the measured current level and the area of the curve from Co-MOF/150 electrode were higher than those of all the other electrodes which indicates the best capacitive behavior. The specific capacitance of the electrodes from CV curves was calculated according to the following formula [48],

where v is the scan rate; m is the mass of the active material of the electrode; Va is the anodic potential; Vc is the cathodic potential; I(V) is the response current density versus potential and V is the potential. As compared in Fig. 5f, a maximum specific capacitance of 1240.4 F g −1 has been attained for the Co-MOF/150 electrode at a scan rate of 5 mV s−1 which is higher compared to other electrodes due to the better ion transport within the mesoporous voids structures [49]. The specific capacitance of electrode decreases with the increase of scan rate, which is due to the insufficient redox reactions at high scan rates.

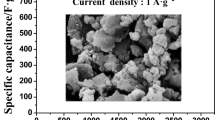

In addition, the specific capacitance behavior of the electrodes was characterized by galvanostatic charge-discharge (GCD) technique, and the GCD curves of the electrodes are shown in Fig. 6. The non-linear changes in charge and discharge curves (indicated in Fig. 6b) are attributed to the good pseudocapacitance behavior of the electrodes which is consistent with the CV results [50]. The following expression is used for electrodes specific capacitance calculation from GCD measurement [51, 52],

where Δt is the discharge time (s), I is the applied current (A), m is the total mass of the active material of the electrode (g), ΔV is the potential window (V). A maximum specific capacitance of 952.5 F g−1 has been achieved for the Co-MOF/150 electrode at a current density of 0.25 A g−1. With the same current density, however, the other electrodes exhibit a lower specific capacitance of 649.8, 322.1 and 495.6 F g−1 for Co-MOF/120, Co-MOF/180, Co-MOF/210, respectively (Fig. 6f). The larger specific surface area and higher micro-pore area of Co-MOF/150 enhance the electrolyte ion transportation to the electrode and deliver better redox behavior. Table 2 shows a comparison of the current work with previously reported electrodes based on MOF materials. The cyclic stability of the electrodes was investigated by GCD endurance test at 5 A g−1 current density for 2000 cycles (Fig. 7). It can be seen that the specific capacitance retains to be over 85% after 2000 cycles for all the Co-MOF electrodes which suggesting the good electrochemical reversibility during charge/discharge process. The changes in the morphology of Co-MOF/150 electrode was analyzed before and after 2000 cycles and shown in Fig. S1. As the evidence of the figure, the tiny change in the morphology is remarked which suggests that the Co-MOF microspheres undergo considerable aggregation during the long cyclic process.

Galvanostatic charge-discharge profile of a Co-MOF/120, b Co-MOF/150, c Co-MOF/180, and d Co-MOF/210 at different current densities. e Comparison of galvanostatic charge-discharge curve of Co-MOF electrodes at a current density of 0.25 A g−1 (f) specific capacitance plot of Co-MOF/120, Co-MOF/150, Co-MOF/180, and Co-MOF/210 at different current densities

Electrochemical impedance analysis was investigated to understand the ion transfer phenomenon of the electrode/electrolyte interface. Nyquist plot of the Co-MOF electrodes is shown in Fig. 8. The intercept at the real axis in the high-frequency region corresponds to the solution resistance (Rs) of the electrode/electrolyte interface. [53]. It could be seen that the Rs value of Co-MOF/150 electrode shows a minor value (inset picture of Fig. 8) than others which suggesting better conductivity and better electrolyte ion transportation in the electrode/electrolyte interfaces [54]. The Nyquist plot of Co-MOF/150 electrode before and after 2000 cycles is shown in Fig. S2. As the evidence from the figure, the solution resistance at the high-frequency region is increased after cycles, suggesting that the decreased ion mobilities during the long cyclic process. However, the straight line at lower frequency region is closer to the imaginary axis which indicates that better pseudocapacitive nature and good stability even after cycles. The bode phase angle of Co-MOF the electrodes (Fig. 9) is obtained in the range of 50°–70° at low-frequency region (< 100 Hz) which is attributed to the perfect pseudocapacitance function of electrodes [55]. The higher phase angle of Co-MOF/150 demonstrates better transportation of electrolyte ions and hence achieved greater pseudocapacitance response. The plot of total impedance versus frequency shows three different slopes at different frequency regions. The slope at higher frequency region (105–103 Hz) of all the Co-MOF electrodes exhibited almost zero suggesting that the electrode and electrolyte ions interactions became weaker, and a resistive component is dominant. Whereas, at the low-frequency (< 100 Hz) and the mid-frequency regions (103–102 Hz), the value of the slopes are higher and these can be associated to the greater adsorption of the electrolyte ions onto the electrode surface, thus confirmed the pseudocapacitive nature of Co-MOF electrodes.

Overall, the higher specific capacitance of the Co-MOF/150 electrode can be attributed to the subsequent reasons: (1) the large surface area of the Co-MOF/150 from hollow microspheres guarantees excellent redox-active sites for charge storage, which ends up in high electrochemical performance; (2) a larger micropore area and also the mesoporous voids could reduce the ion diffusion path to the electrode, which often makes sure good rate capability.

Conclusion

In summary, we have synthesized Co-MOF at different temperatures and characterized their performance with various tools. Based on the structure and porous analysis, we have optimized the temperature for obtaining large surface area of Co-MOF. The electrochemical properties of as-prepared Co-MOFs were examined towards electrode material of supercapacitor in 3 M KOH electrolyte. A maximum specific capacitance of 952.5 F g−1 has been obtained for Co-MOF/150 at a current density of 0.25 A g−1. This excellent electrochemical characteristics of Co-MOF/150 may lead to a promising electrode for high-performance supercapacitors.

References

Krishnamoorthy K, Pazhamalai P, Kim SJ (2017) Ruthenium sulfide nanoparticles as a new pseudocapacitive material for supercapacitor. Electrochim Acta 227:85–94

Saranya M, Ramachandran R, Wang F (2016) Graphene-zinc oxide (G-ZnO) nanocomposite for electrochemical supercapacitor applications. J Sci Adv Mater Devices 1(4):454–460

Pu J, Wang X, Xu R, Komvopoulos K (2016) Highly stretchable microsupercapacitor arrays with honeycomb structures for integrated wearable electronic systems. ACS Nano 10(10):9306–9315

Sahoo S, Pazhamalai P, Krishnamoorthy K, Kim SJ (2018) Hydrothermally prepared α-MnSe nanoparticles as a new pseudocapacitive electrode material for supercapacitor. Electrochim Acta 268:403–410

Zhu Y, Murali S, Stoller MD, Ganesh KJ, Cai W, Ferreira PJ, Pirkle A, Wallace RM, Cychosz KA, Thommes M (2011) Carbon-based supercapacitors produced by activation of graphene. Science 332(6037):1537–1541

Zhang LL, Zhao X (2009) Carbon-based materials as supercapacitor electrodes. Chem Soc Rev 38(9):2520–2531

Wang X, Liu L, Wang X, Bai L, Wu H, Zhang X, Yi L, Chen Q (2011) Preparation and performances of carbon aerogel microspheres for the application of supercapacitor. J Solid State Electrochem 15(4):643–648

Pu J, Wang X, Zhang T, Li S, Liu J, Komnopoulos K (2016) High-energy-density, all-solid-state microsupercapacitors with three-dimensional interdigital electrodes of carbon/polymer electrolyte composite. Nanotechnol 27(4):045701

Krishnamoorthy K, Thangavel S, Veetil JC, Raju N, Venugopal G, Kim SJ (2016) Graphdiyne nanostructures as a new electrode material for electrochemical supercapacitors. Int J Hydrog Energy 41(3):1672–1678

Lang JW, Kong LB, Wu WJ, Luo YC, Kang L (2008) Facile approach to prepare loose-packed NiO nano-flakes materials for supercapacitors. Chem Commun 0(35):4213–4215

Abouali S, Garakani MA, Zhang B, Xu ZL, Heidari EK, Huang JQ, Huang J, Kim JK (2015) Electrospun carbon nanofibers with in situ encapsulated Co3O4 nanoparticles as electrodes for high-performance supercapacitors. ACS Appl Mater Interfaces 7(24):13503–13511

Pazhamalai P, Krishnamoorthy K, Mariappan VK, Sahoo S, Manoharan S, Kim SJ (2018) A high efficacy self-charging MoSe2 solid-state supercapacitor using electrospun nanofibrous piezoelectric separator with ionogel electrolyte. Adv Mater Interfaces 5(12):1800055

Furukawa H, Cordova KE, O’Keeffe M, Yaghi OM (2013) The chemistry and applications of metal-organic frameworks. Science 341(6149):1230444

Xia W, Mahmood A, Zou R, Xu Q (2015) Metal-organic frameworks and their derived nanostructures for electrochemical energy storage and conversion. Energy Environ Sci 8(7):1837–1866

Salunkhe RR, Kaneti YV, Kim J, Kim JH, Yamauchi Y (2016) Nanoarchitectures for metal–organic framework-derived nanoporous carbons toward supercapacitor applications. Acc Chem Res 49(12):2796–2806

Gao W, Chen D, Quan H, Zou R, Wang W, Luo X, Guo L (2017) Fabrication of hierarchical porous metal-organic framework electrode for aqueous asymmetric supercapacitor. ACS Sustain Chem Eng 5(5):4144–4153

Shi C, Wang X, Gao Y, Rong H, Song Y, Liu H-J, Liu (2017) Nickel metal-organic framework nanoparticles as electrode materials for Li-ion batteries and supercapacitors. J Solid State Electrochem 21(8):2415–2423

Ramachandran R, Zhao C, Luo D, Wang K, Wang F (2017) Synthesis of copper benzene-1, 3, 5-tricarboxylate metal organic frameworks with mixed phases as the electrode material for supercapacitor applications. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2017.11.271

Tsivion E, Mason JA, Gonzalez MI, Long JR, Head-Gordon M (2016) A computational study of CH4 storage in porous framework materials with metalated linkers: connecting the atomistic character of CH4 binding sites to usable capacity. Chem Sci 7(7):4503–4518

Rosi NL, Eckert J, Eddaoudi M, Vodak DT, Kim J, O'keeffe M, Yaghi OM (2003) Hydrogen storage in microporous metal-organic frameworks. Science 300(5622):1127–1129

Gao CY, Tian HR, Ai J, Li LJ, Dang S, Lan YQ, Sun ZM (2016) A microporous Cu-MOF with optimized open metal sites and pore spaces for high gas storage and active chemical fixation of CO2. Chem Commun 52(74):11147–11150

Alezi D, Belmabkhout Y, Suyetin M, Bhatt PM, Weseliński ŁJ, Solovyeva V, Adil K, Spanopoulos I, Trikalitis PN, Emwas AH, Eddaoudi M (2015) MOF crystal chemistry paving the way to gas storage needs: aluminum-based soc-MOF for CH4, O2, and CO2 storage. J Am Chem Soc 137(41):13308–13318

Bárcia PS, Zapata F, Silva JA, Rodrigues AE, Chen B (2007) Kinetic separation of hexane isomers by fixed-bed adsorption with a microporous metal−organic framework. J Phys Chem B 111(22):6101–6103

Li K, Olson DH, Lee JY, Bi W, Wu K, Yuen T, Xu Q, Li J (2008) Multifunctional microporous MOFs exhibiting gas/hydrocarbon adsorption selectivity, separation capability and three-dimensional magnetic ordering. Adv Funct Mater 18(15):2205–2214

Hu J, Cai H, Ren H, Wei Y, Xu Z, Liu H, Hu Y (2010) Mixed-matrix membrane hollow fibers of Cu3(BTC)2 MOF and polyimide for gas separation and adsorption. Ind Eng Chem Res 49(24):12605–12612

Luo F, Yan C, Dang L, Krishna R, Zhou W, Wu H, Dong X, Han Y, Hu TL, O’Keeffe M, Wang L, Luo M, Lin RB, Chen B (2016) UTSA-74: a MOF-74 isomer with two accessible binding sites per metal center for highly selective gas separation. J Am Chem Soc 138(17):5678–5684

Wang C, DeKrafft KE, Lin W (2012) Pt nanoparticles@ photoactive metal-organic frameworks: efficient hydrogen evolution via synergistic photoexcitation and electron injection. J Am Chem Soc 134(17):7211–7214

Valvekens P, Vandichel M, Waroquier M, Speybroeck VV, Vos DD (2014) Metal dioxidoterephthalate MOFs of the MOF 74 type: microporous basic catalysts with well defined active sites. J Catal 317:1–10

Wu CD, Hu A, Zhang L, Lin W (2005) A homochiral porous metal– organic framework for highly enantioselective heterogeneous asymmetric catalysis. J Am Chem Soc 127(25):8940–8941

Srimuk P, Luanwuthi S, Krittayavathananon A, Sawangphruk M (2015) Solid type supercapacitor of reduced graphene oxide-metal organic framework composite coated on carbon fiber paper. Electrochim Acta 157:69–77

Harvey SD, Eckberg AD, Thallapally PK (2011) Evaluation of copper-1,3,5-benzenetricarboxylate metal–organic framework (Cu MOF) as a selective sorbent for Lewis base analytes. J Sep Sci 34(18):2418–2426

Lee DY, Yoon SJ, Shrestha NK, Lee SH, Ahn H, Han SH (2012) Unusual energy storage and charge retention in Co-based metal-organic frameworks. Microporous Mesoporous Mater 153:163–165

Díaz R, Orcajo MG, Botas JA, Calleja G, Palma J (2012) Co-MOF-5 as electrode for supercapacitors. Mater Lett 68:126–128

Yang J, Ma Z, Gao W, Wei M (2017) Layered structural Co-based MOF with conductive network frames as a new supercapacitor electrode. Chem Eur J 23(3):631–636

Wen P, Gong P, Sun J, Wang J, Yang S (2015) Design and synthesis of Ni-MOF/CNT composites and rGO/carbon nitride composites for an asymmetric supercapacitor with high energy and power density. J Mater Chem A 3(26):13874–13883

Yang J, Zheng C, Xiong P, Li Y, Wei M (2014) Zn-doped Ni-MOF material with a high supercapacitive performance. J Mater Chem A 2(44):19005–19010

Sheberla D, Bachman JC, Elias JS, Sun CJ, Shao-Horn Y, Dincă M (2016) Conductive MOF electrodes for stable supercapacitors with high areal capacitance. Nat Mater 16:220–224

Campagnol N, Romero-Vara R, Deleu W, Stappers L, Binnemans K, De Vos DE, Fransaer J (2014) A hybrid supercapacitor based on porous carbon and the metal-organic framework MIL-100 (Fe). ChemElectroChem 1(7):1182–1188

Jhung SH, Lee JH, Yoon JW, Serre C, Férey G, Chang JS (2007) Microwave synthesis of chromium terephthalate MIL-101 and its benzene sorption ability. Adv Mater 19(1):121–124

Choi KM, Jeong HM, Park JH, Zhang YB, Kang JK, Yaghi OM (2014) Supercapacitors of nanocrystalline metal–organic frameworks. ACS Nano 8(7):7451–7457

Lee DY, Shinde DV, Kim EK, Lee W, Oh IW, Shrestha NK, Lee JK, Han SH (2013) Supercapacitive property of metal–organic-frameworks with different pore dimensions and morphology. Microporous Mesoporous Mater 171:53–57

Wang L, Feng X, Ren L, Piao Q, Zhong J, Wang Y, Li H, Chen Y, Wang B (2015) Flexible solid-state supercapacitor based on a metal–organic framework interwoven by electrochemically-deposited PANI. J Am Chem Soc 137(15):4920–4923

Yu G, Sun J, Muhammad F, Wang P, Zhu G (2014) Cobalt-based metal organic framework as precursor to achieve superior catalytic activity for aerobic epoxidation of styrene. RSC Adv 4(73):38804–38811

Zhou G, Zhu J, Chen Y, Mei L, Duan X, Zhang G, Chen L, Wang T, Lu B (2014) Simple method for the preparation of highly porous ZnCo2O4 nanotubes with enhanced electrochemical property for supercapacitor. Electrochim Acta 123:450–455

An C, Wang Y, Huang Y, Xu Y, Jiao L, Yuan H (2014) Porous NiCo2O4 nanostructures for high performance supercapacitors via a microemulsion technique. Nano Energy 10:125–134

Jiao Y, Pei J, Yan C, Chen D, Hu Y, Chen G (2016) Layered nickel metal-organic framework for high performance alkaline battery-supercapacitor hybrid devices. J Mater Chem A 4(34):13344–13351

Liu X, Shi C, Zhai C, Cheng M, Liu Q, Wang G (2016) Cobalt-based layered metal–organic framework as an ultrahigh capacity supercapacitor electrode material. ACS Appl Mater Interfaces 8(7):4585–4591

Srinivasan V, Weidner JW (2002) Capacitance studies of cobalt oxide films formed via electrochemical precipitation. J Power Sources 108(1-2):15–20

Ramachandran R, Zhao C, Luo D, Wang K, Wang F (2018) Morphology-dependent electrochemical properties of cobalt-based metal organic frameworks for supercapacitor electrode materials. Electrochim Acta 267:170–180

Zhao YQ, Zhao DD, Tang PY, Wang YM, Xu CL, Li HL (2012) MnO2/graphene/nickel foam composite as high performance supercapacitor electrode via a facile electrochemical deposition strategy. Mater Lett 76:127–130

Gao Y, Chen S, Cao D, Wang G, Yin J (2010) Electrochemical capacitance of Co3O4 nanowire arrays supported on nickel foam. J Power Sources 195(6):1757–1760

Liu XM, Zhang XG, Fu SY (2006) Preparation of urchinlike NiO nanostructures and their electrochemical capacitive behaviors. Mater Res Bull 41(3):620–627

Ramachandran R, Saranya M, Kollu P, Raghupathy BP, Jeong SK, Grace AN (2015) Solvothermal synthesis of zinc sulfide decorated graphene (ZnS/G) nanocomposites for novel supercapacitor electrodes. Electrochim Acta 178:647–657

Morozan A, Jaouen F (2012) Metal organic frameworks for electrochemical applications. Energy Environ Sci 5(11):9269–9290

Arul NS, Mangalaraj D, Ramachandran R, Grace AN, Han JI (2015) Fabrication of CeO2/Fe2O3 composite nanospindles for enhanced visible light driven photocatalysts and supercapacitor electrodes. J Mater Chem A 3(29):15248–15258

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Project No. 51505209). We also acknowledge the support from Shenzhen Science and Technology Innovation Committee (Project No. JCYJ20170412154426330 and KQTD2015071710313656). Fei Wang is also supported by Guangdong Natural Science Funds for Distinguished Young Scholar (Project No. 2016A030306042).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 8953 kb)

Rights and permissions

About this article

Cite this article

Xuan, W., Ramachandran, R., Zhao, C. et al. Influence of synthesis temperature on cobalt metal-organic framework (Co-MOF) formation and its electrochemical performance towards supercapacitor electrodes. J Solid State Electrochem 22, 3873–3881 (2018). https://doi.org/10.1007/s10008-018-4096-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-018-4096-7