Abstract

A binary nanocomposite of polyaniline/tin oxide nanorod array (PANI/SnO2 NRA) was developed as an electrode material for energy storage. SnO2 NRA supported on the substrate of carbon fibers was prepared by the seed-assisted hydrothermal synthesis method. PANI/SnO2 NRA was then obtained by depositing PANI nanowires onto SnO2 NRA through an electro-polymerization process. SnO2 NRA presents quadrangular prism shape with a side length of 50~60 nm. PANI nanolayer is loaded into the interspace of the neighboring SnO2 nanorods to form the core-shell-structured PANI/SnO2 NRA. Additional PANI nanowires with a diameter of 100~150 nm are formed on the top surface of PANI/SnO2 NRA. Well-designed PANI/SnO2 NRA benefited a directional electron transfer along with highly ordered SnO2 nanorods during an electrochemical reaction process. The interface layer between SnO2 nanorods and PANI could act as the buffer space to restrain the volumetric change of PANI during the cycling charge-discharge process. Considering electroactive PANI, PANI/SnO2 NRA exhibited higher specific capacitance of 367.5 F g−1 at 0.5 A g−1 than that of 232.4 F g−1 for bare PANI film. The capacitance retention ratio was enhanced from 60.4% for PANI film to 88.3% for PANI/SnO2 NRA after 2000 cycles even at a high current density of 5 A g−1. All-solid-state PANI/SnO2 supercapacitor was also constructed using symmetric PANI/SnO2 NRA electrodes and sulfuric acid-polyvinyl alcohol gel electrode, presenting the specific capacitance of 44.9 F g−1, the energy density of 20.2 Wh Kg−1, and the output voltage of 1.8 V at 0.2 A g−1 when both PANI and SnO2 were considered as electroactive materials. PANI/SnO2 NRA with high capacitance performance presents the promising supercapacitor applications for the electrochemical energy storage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Supercapacitors as high-efficient energy storage devices have gained extensive attention in recent years, due to their fast charge-discharge capability, long cycle life, and high power density [1]. Polyaniline (PANI) acting as pseudo-capacitive electrode material has attracted significant attention because of its high theoretical capacitance, low cost, and environmental safety [2, 3]. However, PANI suffers from the poor cycling stability due to the volumetric swelling, shrinking, and even cracking during a proton doping/dedoping process [4–6]. To overcome this drawback, some approaches have been proposed by hybridizing PANI with transition metal oxides or carbon materials [7–10]. The graphene, carbon quantum dot, and titanium nitride acting as highly conductive materials have been widely investigated for various electrochemical applications [11–16]. The tin oxide (SnO2) and graphene are used as the supporting materials to promote the electrochemical performance of PANI [17, 18]. Particularly, PANI/SnO2 with various microstructures have been prepared for supercapacitor electrode materials [19–22]. PANI/SnO2 nanocomposite was prepared through chemical polymerization of aniline monomer in the solution containing SnO2 particles, hydrochloric acid, and ammonium persulfate, showing the specific capacitance of 175.5 F g−1 at a current density of 1 A g−1. However, its capacitance loss reached 27.9% after 100 cycles [23]. Usually, SnO2 particles were deposited on the surface of PANI. The inhomogeneous dispersion of SnO2 particles could lead to the inefficient loading of PANI, lowering the electrochemical performance of PANI/SnO2 composites [24]. PANI/SnO2 nanocomposite with an embedment structure was prepared through the polymerization of aniline monomer in the suspension of SnO2 nanoparticles, showing a high specific capacitance of 305.3 F g−1 at a current density of 1 A g−1. The capacitance retention ratio also reached 95.5% after 500 cycles [25]. The intensified interaction between SnO2 and PANI could promote the capacitance performance and the cycling stability of PANI. It has been reported that SnO2 nanorod array (NRA) could be grown on graphite substrate by a catalyst-assisted hydrothermal synthesis method and used as the electrode material of lithium ion batteries [26]. So, it is reasonable that the ordered SnO2 nanoarray supported on the carbon material can be used for loading PANI in the application of supercapacitor electrode material.

In this study, a facile approach has been proposed to prepare a binary nanocomposite of PANI/SnO2 NRA supported on carbon fibers. An electro-polymerization process was adopted to deposit PANI nanolayer on SnO2 NRA which was initially grown on carbon fibers by the seed-assisted hydrothermal method. Carbon fibers acted as the current collector and the scaffold for loading SnO2 NRA. The binary nanocomposite of PANI/SnO2 NRA is expected to achieve high electrochemical capacitance and reasonable cycling stability as well.

Experimental section

Electrode material preparation

Fig. 1 shows the preparation procedure of PANI/SnO2 NRA. Firstly, well-ordered SnO2 NRA was formed on the surface of carbon fibers by the seed-assisted hydrothermal process. Herein, SnCl4 was converted into the SnO2 seeds through a hydrolysis process. SnO2 NRA was then formed by the crystal growth of SnO2 seeds in SnCl4 and NaOH aqueous solution through a hydrothermal process. The as-described procedure included the following equations [26].

Finally, PANI layer was deposited on the surface of SnO2 NRA to form PANI/SnO2 NRA through electro-polymerization process.

In detail, an ultrasonic treatment in anhydrous ethanol solution for 30 min and then an activation treatment in aqua regia solution for 20 h were conducted on the carbon fibers. The pretreated carbon fibers were immersed in 30 mL of 0.055 M SnCl4 aqueous solution. Thirty milliliters of 0.11 M NaOH aqueous solution was added dropwise into above solution and then maintained for 3 h at room temperature. As-formed SnO2 colloidal particles could adsorb on the surface of carbon fibers to act as SnO2 seeds. Subsequently, carbon fibers with SnO2 seeds were placed in a Teflon-lined stainless steel autoclave containing 0.0125 M SnCl4 and 0.25 M NaOH aqueous solution. The sealed autoclave was heated to 200 °C, maintained at this temperature for 12 h, and then cooled to room temperature. Carbon fibers were washed sufficiently with distilled water and then dried at 60 °C. Accordingly, SnO2 NRA was obtained through the seed-assisted hydrothermal synthesis method, which was grown on the surface of carbon fibers. PANI/SnO2 NRA was prepared by the electrodeposition process in a three-electrode system, consisting of SnO2 NRA/carbon fibers as the working electrode, Pt plate as the counter electrode, and the saturated calomel electrode as the reference electrode. Typically, the precursor solution was prepared by mixing 2.67 mL sulfuric acid (98%, AR) and 0.455 mL aniline monomer (99.5%, AR) with 50 mL distilled water under magnetic stirring condition. Electrodeposition reaction was carried out through a cyclic voltammetry process with a scan rate of 25 mV s−1 and a potential window of −0.2~1.0 V for 15 cycles. PANI was deposited on SnO2 NRA to obtain the binary composite of PANI/SnO2 NRA. For a comparison, pure PANI film was electrodeposited directly onto the surface of carbon fibers under the same condition.

Supercapacitor construction

Fig. 2 shows the schematic of the construction structure of all-solid-state symmetrical PANI/SnO2 supercapacitor. The PANI/SnO2 supercapacitor was assembled using the two symmetrical PANI/SnO2 NRA electrodes, the sulfuric acid-phosphate-polyvinyl alcohol (H2SO4-PVA) gel electrolyte, the separator material of non-woven fabric, and the packing material of poly(ethylene terephthalate) (PET) film. In detail, the H2SO4-PVA gel electrolyte was obtained through the following process. H2SO4 and PVA with a mass ratio of 2:1 were dissolved in the deionized water and continuously stirred at 80 °C until a homogeneous solution was form. Then, H2SO4-PVA aqueous solution was placed in a vacuum oven at 60 °C to evaporate excess water. Subsequently, PANI/SnO2 NRA electrodes were uniformly coated with H2SO4-PVA gel electrolyte, separated with the non-woven fabric and packaged with ultrathin plastic PET film. The as-prepared supercapacitor was denoted as PANI/SnO2 supercapacitor. The total amount of electroactive materials on the PANI/SnO2 supercapacitor was 11 mg, including the loading mass of electroactive PANI and SnO2 of the two electrodes.

Characterization and measurements

Raman spectrum was measured using Raman spectrometer (Renishaw inVia Reflex Raman microscope) equipped with a He-Ne laser at an excitation wavelength of 532 nm. X-ray diffraction (XRD) patterns were recorded using an X-ray diffractometer (Rigaku, Dmax-2500) operating at Cu K α = 1.54056 Å, 40 kV, and 40 mA. The morphology was characterized by a scanning electron microscope (SEM, Zeiss Ultra-Plus).

The electrochemical performance of PANI/SnO2 NRA was evaluated by cyclic voltammetry (CV), galvanostatic charge-discharge (GCD), and electrochemical impedance spectrum (EIS) measurements using CHI 760C and IMe6x electrochemical workstations. The CV measurements were conducted at different sweep rates of 5, 10, 20, 50, 80, 100, and 150 mV s−1, and the GCD measurements were conducted at different current densities of 0.5, 1, 2, 3, and 5 A g−1. EIS measurements were carried out at the frequency range of 10−2~105 Hz and the potential amplitude of 5 mV. The impedance data was fitted with the equivalent circuits using Zview software. Cycling stability measurements were conducted using LAND CT2001A battery testing system. The 1.0 M H2SO4 aqueous solution was used as electrolyte solution in all measurements.

Results and discussion

Morphology characterization

Fig. 3 shows photographs of SnO2 NRA, PANI film, and PANI/SnO2 NRA supported on carbon fibers. SnO2 NRA grown on carbon fibers exhibits colorful appearance. Comparatively, due to the formation of PANI, PANI film and PANI/SnO2 NRA present the green appearance. It indicates that PANI can be well electrodeposited onto bare carbon fibers and SnO2 NRA.

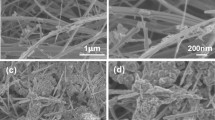

Fig. 4 exhibits SEM images of SnO2 NRA, PANI film, and PANI/SnO2 NRA supported on carbon fibers. Concerning SEM images of SnO2 NRA, SnO2 exhibits a uniform and close-packing nanorod array with quadrangular prism shape. The side length of SnO2 nanorods was 50~60 nm. SnO2 nanorods are separated from each other, showing independent structure characteristic. The interspaces can be obviously observed between the neighboring SnO2 nanorods. These interspaces can be used for loading the electroactive material of PANI (Fig. 4a–c). Concerning SEM images of PANI film, PANI is fully covered on the surface of carbon fibers forming a compact film. In addition, some scattered PANI patches are dispersed on the surface of PANI film. PANI film is directly formed on the surface of carbon fibers by electropolymerizing aniline monomer, keeping a relatively smooth surface (Fig. 4d, e). Concerning SEM images of PANI/SnO2 NRA, SnO2 nanorods become a more compact structure and their interspaces are highly narrowed. It implies that PANI is able to be loaded into these interspaces of neighboring SnO2 nanorods. As-synthesized PANI nanolayer is covered on the external surface of SnO2 nanorods to form the core-shell-structured PANI/SnO2 NRA. In addition, some PANI nanowires have been also formed on the top-surface of PANI/SnO2 NRA. PANI nanowires keep a cross-linked porous structure. The diameter of PANI nanowires is 100~150 nm (Fig. 4f, g).

PANI/SnO2 NRA was prepared by the seed-assisted hydrothermal synthesis method. The interspaces of SnO2 nanorods are highly related to the density of SnO2 seeds, which is dependent on the hydrolysis reaction of SnCl4. The growth of SnO2 nanorods is associated with the concentration of SnCl4 and NaOH in hydrothermal precursor solution. Usually, the hydrolysis reaction of SnCl4 in low-concentration NaOH solution leads to insufficient formation of SnO2 seeds. The hydrothermal reaction in low-concentration SnCl4 solution leads to the insufficient growth of SnO2 nanorods. So, the density of SnO2 nanorods is highly relied on the number and growth of SnO2 seeds. The interspaces of SnO2 nanorods can be increased by reducing SnO2 seeds and limiting the growth of SnO2 nanorods in the seed-assisted hydrothermal reaction process.

Crystal structure

The X-ray diffraction measurement is carried out to identify the crystallinity and crystal phase of the prepared samples. Fig. 5a shows XRD patterns of SnO2 NRA, PANI film, and PANI/SnO2 NRA supported on carbon fibers. The XRD patterns of SnO2 NRA and PANI/SnO2 NRA show the characteristic diffraction peaks at 26.5°, 34.1°, and 52.2°, corresponding to the (110), (101), and (211) crystal planes of the tetragonal rutile SnO2 according to the JCPDS card no. 41-1445 [27]. The XRD pattern of PANI film shows the characteristic diffraction peak of PANI at about 25.5° and the characteristic diffraction peak of the carbon fibers at about 24.5° [31, 32]. The overlapping of the neighboring characteristic diffraction peaks of PANI and carbon fibers leads to the formation of the broad diffraction peak at about 25° [33]. In comparison with the sharp and strong diffraction peak of crystal SnO2 at 26.5°, the relatively weak characteristic diffraction peak of PANI and carbon fibers at about 25° becomes insignificant in the XRD patterns of PANI/SnO2 NRA and SnO2 NRA. This result is in well agreement with other research work [34].

Fig. 5b shows Raman spectra of SnO2 NRA, PANI film, and PANI/SnO2 NRA. In view of Raman spectrum of SnO2 NRA, the characteristic Raman peaks at 633 and 776 cm−1 are corresponding to A1g and B2g vibration modes of Sn-O, respectively [27, 28]. The Raman peak at 581 cm−1 may be ascribed to small granule size of SnO2 [27]. In view of Raman spectrum of PANI film, the characteristic Raman peaks at 581, 810, and 1167 cm−1 are corresponding to out-of-plane C-H deformation vibration of the quinonoid ring, C-H bending vibration of the quinonoid ring, and C-H bending vibration of the benzenoid ring, respectively [29]. The additional characteristic Raman peaks at 1322 and 1586 cm−1 are related to the vibration of the semiquinone radical and C=C stretching vibration of the quinonoid ring or the oxidized state of PANI [29, 30]. Comparatively, in view of Raman spectrum of PANI/SnO2 NRA, the characteristic Raman peaks of PANI are observed at 818, 1172, 1341, and 1567 cm−1. The obvious Raman peak at 581 cm−1 is the overlapped characteristic peak of SnO2 and PANI in PANI/SnO2 NRA. Accordingly, both XRD and Raman spectrum characterization analysis confirm that PANI has been well deposited on SnO2 NRA to form PANI/SnO2 nanocomposite.

Electrochemical properties

The electrochemical properties of as-prepared electrode materials were investigated through CV and GCD measurements. Fig. 6a shows the CV curves of SnO2 NRA, PANI film, and PANI/SnO2 NRA electrodes at a scan rate of 10 mV s−1. The shape of CV curve for SnO2 NRA is quasi-rectangular, implying the ideal electrical double-layer capacitance behavior and fast charge-discharge characteristic. A pair of redox peaks (the oxidation peak at about 0.30 V and the reduction peak at about 0.03 V) can be observed in the CV curves of PANI film and PANI/SnO2 NRA, which are ascribed to the leucoemeraldine/emeraldine transition of PANI caused by a reversible doping/dedoping of reactive protons [35]. Differently, PANI/SnO2 NRA shows larger integral area of the CV curve when compared with PANI film, indicating the increased specific capacitance. Thus, it is reasonable to conclude that the capacitive contribution of PANI/SnO2 NRA benefits from the large accessible active area of PANI supported on SnO2 NRA. Fig. 6b shows GCD curves of SnO2 NRA, PANI film, and PANI/SnO2 NRA electrodes at a current density of 0.5 A g−1. The specific capacitance of as-prepared electrode materials can be calculated using the following equation on the base of GCD curves.

where C m (F g−1) is the specific capacitance, I (mA) is the charge-discharge current, t is the discharge time (s), ΔV (V) is the potential window, and m (mg) is the loading mass of active material. The charge curves of all electrodes symmetrically mirrored their discharge counterparts, implying relatively reversible electrochemical process. Usually, the capacitance of electrode materials is proportional to the discharge time. In view of the GCD curve of SnO2 NRA, it shows the shortest discharge time, and the specific capacitance of SnO2 NRA is calculated to be 33.4 F g−1 at 0.5 A g−1. Comparatively, the shapes of GCD curves of PANI film and PANI/SnO2 NRA present the charge-discharge platform. It is mostly corresponding to the redox reaction of the leucoemeraldine/emeraldine transition of electroactive PANI. The discharge time of PANI/SnO2 NRA is much longer than that of PANI film, indicating the enhanced electrochemical capacitance. The specific capacitance is 367.5 F g−1 for PAN I/SnO2 NRA electrode and 232.7 F g−1 for PANI film electrode when only PANI is acted as the electroactive material. This result of the GCD curves is also consistent with the above result of the CV curves. Additionally, the internal resistance (IR) drop of PANI/SnO2 NRA (22.5 mV) is higher than that of PANI (10.7 mV), which may be ascribed to the additional contact resistance between PANI and SnO2 NRA in PANI/SnO2 NRA. PANI film is electrodeposited directly and densely on the surface of carbon fibers. The electrolyte solution hardly reaches the internal space of PANI, leading to the lowered Faradaic reaction efficiency of compact PANI film. Comparatively, PANI/SnO2 NRA involves a large amount of accessible interface of PANI nanolayer and nanowires. The electrolyte ions can feasibly penetrate into the inner surface of PANI, causing a higher specific capacitance of PANI/SnO2 NRA. In addition, well-designed PANI/SnO2 NRA benefits a directional electron transfer along with highly ordered SnO2 nanorods during an electrochemical reaction process, contributing to the improved capacitance performance.

The EIS is usually used to estimate the kinetic behavior of electrode materials during the electrochemical reaction process, such as charge transfer and ion diffusion properties. Fig. 7 shows EIS Nyquist plots and the corresponding fitting curves of SnO2 NRA, PANI film, and PANI/SnO2 NRA electrode materials. The inset patterns are the enlarged Nyquist plots at high-frequency region and the equivalent circuit diagram. Nyquist plots of all electrodes present approximate semicircles in the high-frequency region corresponding to the dominant charge transfer process and an oblique line in the low frequency section corresponding to the dominant ionic diffusion process. The equivalent circuit diagram is composed of equivalent elements including the ohmic resistance (R o), the charge transfer resistance (R ct), the constant phase element (CPE), and the Warburg element (W o ). The impedance of constant phase element (Z CPE) and Warburg diffusion impedance (Z Wo ) can be expressed as the following formulas.

where ω is the angular frequency and i is the imaginary number, CPE T is the capacitance when CPE P = 1, CPE P is the constant phase element exponent, W R is the Warburg diffusion resistance, W T is the diffusion time constant, and W P is a fractional exponent between 0 and 1.

Table 1 lists the fitting values of equivalent elements of SnO2 NRA, PANI film, and PANI/SnO2 NRA. The R o values are determined to be 2.78, 2.35, and 2.60 Ω for SnO2 NRA, PANI film, and PANI/SnO2 NRA, respectively. These values include the total resistance of the ionic resistance of electrolyte, intrinsic resistance of active materials, and the contact resistance at the active materials/current collector interface and active materials/active materials interface [36]. The R o value of PANI/SnO2 NRA is slightly higher than that of PANI film, which is probably attributed to the additional contact resistance between PANI and SnO2 NRA in PANI/SnO2 NRA. The R ct value can be estimated according to the diameter of semicircle in the high-frequency range. SnO2 NRA as typical semiconductor material has the highest R ct value (1.75 Ω). PANI/SnO2 NRA exhibits lower R ct value (1.17 Ω) than that of PANI film (1.30 Ω). It is believed that a large amount of accessible surface area of PANI nanolayer and nanowires is more beneficial to promote the interfacial charge transfer in PANI/SnO2 NRA. CPE is normally used to compensate for the non-homogeneity of electrode materials. It illustrates a non-ideal capacitance that deviates from the ideal capacitance due to the non-homogeneity of the electrode system. PANI/SnO2 NRA shows relatively lower CPE P (0.962) than PANI film (0.959). It implies PANI/SnO2 NRA has more porous structure and interspace than PANI film. This is well consistent with the microstructure characterization result. The W o is used to characterize the ionic diffusion impedance during the process of ionic diffusion from the bulk phase of electrolyte solution to the surface of electrode. It consists of three parameters of W R , W T , and W P . The W R represents Warburg resistance. The W R values of PANI film and PANI/SnO2 NRA are 2.681 and 2.239 Ω, respectively. Comparatively, lower Warburg resistance of PANI/SnO2 NRA is more beneficial for ionic diffusion. In addition, the W T can be expressed as the formula of W T = L 2 /D. Herein, L is the effective diffusion distance and D is the effective diffusion coefficient. The W T values of PANI film and PANI/SnO2 NRA are 0.233 and 0.215, respectively. It implies that PANI/SnO2 NRA has a relatively higher diffusion coefficient. Overall, in comparison with PANI film, PANI/SnO2 NRA has superior capability of charge transfer and ion diffusion during the electrochemical process.

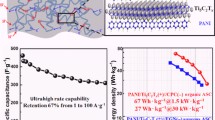

The electrochemical capacitance performance of PANI/SnO2 NRA has been investigated through CV and GCD measurements. Fig. 8a, b shows CV curves at different scan rates and GCD curves at different current densities of carbon fibers. CV curves of carbon fibers show the obvious rectangle-like shape, presenting the typical double-layer capacitance performance. The specific capacitance of carbon fibers is declined from 0.02956 F g−1 at 0.5 A g−1 to 0.01244 F g−1 at 5.0 A g−1. Comparatively, the capacitance performance of carbon fibers is much lower than that of SnO2, PANI, and PANI/SnO2. So, its capacitance contribution can be ignored in the whole electrode materials. So, the carbon fibers can reasonably act as the substrate material. Fig. 8c shows CV curves of PANI/SnO2 NRA at different scan rates of 5, 10, 20, 50, 80, 100, and 150 mV s−1. A couple of apparent redox peaks is observed at scan rates below 50 mV s−1, corresponding to the redox reaction the leucoemeraldine/emeraldine transition of PANI. The current response has been obviously enhanced as the scan rate has been increased. This indicates that PANI/SnO2 NRA has good electrochemical reversibility. However, CV curves reveal the sloping rectangle-like shapes and redox peaks become insignificant at relatively high scan rates above 80 mV s−1. The increase of response current becomes more and more insignificant at relatively high scan rates. It is believed that the reactive protons are insufficient to diffuse into the inner of active electrode materials at high scan rates. The reversible Faradaic reaction mostly occurs on the external surface of PANI/SnO2 NRA. Due to the lack of capacitive contribution of the internal PANI, PANI/SnO2 NRA suffers from a capacitive loss at higher scan rates. Fig. 8d shows GCD curves of PANI/SnO2 NRA at different current densities of 0.5, 1, 2, 3, and 5 A g−1. Apparently, all charge-discharge curves have good symmetric characteristic, implying the excellent electrochemical reversibility of PANI/SnO2 NRA electrode. Fig. 8e exhibits the specific capacitance of SnO2 NRA, PANI film, and PANI/SnO2 NRA electrodes in terms of current density. Table 2 lists the corresponding specific capacitance on the base of different electroactive materials. Usually, the specific capacitance of electrode materials gradually declines when the current density increases. High current density usually leads to the deficiency of electroactive materials during the redox reaction process. Apparently, the specific capacitance of PANI/SnO2 NRA electrode is 376.5 F g−1 at 0.5 A g−1, which is far higher than 232.4 F g−1 for PANI film electrode and 33.4 F g−1 for SnO2 NRA electrode. Even at comparatively high current density of 5 A g−1, PANI/SnO2 NRA still keeps the reasonable capacitance of 231.9 F g−1, presenting higher capacitance of 201.4 F g−1 for PANI film and 13.4 F g−1 for SnO2 NRA. It should be noted that the specific capacitance of PANI/SnO2 NRA electrode exhibits the obviously low level of 108.0 F g−1 at 0.5 A g−1 when both PANI and SnO2 are considered as electroactive materials. PANI/SnO2 NRA also exhibits the capacitance retention ratio of 61.6% when GCD current density increases from 0.5 to 5.0 A g−1, presenting a good rate capability. Herein, as-formed PANI nanolayer and nanowires coated on SnO2 NRA provide high accessible surface area, contributing to high reaction efficiency. SnO2 NRA could induce directional charge transfer and also shorten ionic diffusion distance during the charge-discharge process. So, PANI/SnO2 NRA exhibits a higher capacitive performance than SnO2 NRA and PANI film alone.

a CV curves of carbon fibers at different scan rates and b GCD curves of carbon fibers at different current densities. c CV curves of PANI/SnO2 NRA electrode at different scan rates. d GCD curves of PANI/SnO2 NRA at different current densities. e Capacitance performance of PANI film and PANI/SnO2 NRA electrodes at different current densities of 0.5, 1, 2, 3, and 5.0 A g−1. f Capacitance and capacitance retention curves of PANI film and PANI/SnO2 NRA at a current density of 5.0 A g−1

The cycling stability is an important factor to evaluate the electrochemical performance of supercapacitor electrode materials. SnO2 NRA, PANI film, and PANI/SnO2 NRA electrodes have been conducted long-term cycling charge-discharge process over 2000 cycles at 5 A g−1. Fig. 8f shows the specific capacitance and capacitance retention ratio of SnO2 NRA, PANI film, and PANI/SnO2 NRA in terms of cycle number. SnO2 NRA keeps the capacitance retention ratio of nearly 100% after 2000 cycles, presenting the outstanding cycling stability. Its ideal electrical double-layer capacitance behavior contributes to high electrochemical stability. PANI film keeps the capacitance retention ratio of 80.9% after 100 cycles and 60.4% after 2000 cycles, indicating an obvious capacitive loss. Herein, the reversible proton doping/dedoping must have occurred on PANI during the cycling charge-discharge process. PANI suffers from the acute volumetric swelling and shrinkage, leading to the obvious capacitance decay during the cycling GCD process. Comparatively, PANI/SnO2 NRA keeps the higher capacitance retention ratio of 88.3% after 2000 cycles. Concerning PANI/SnO2 NRA, the ultrathin interface layer between SnO2 nanorods and PANI could act as the buffer space to restrain the volumetric change of PANI during the cycling charge-discharge process. The feasible electron transfer along with highly ordered SnO2 nanorods also could promote the reversible proton doping/dedoping reaction. PANI/SnO2 NRA shows highly improved cycling stability in comparison with PANI film. Accordingly, PANI/SnO2 NRA with PANI nanolayer and highly ordered SnO2 NRA keeps reasonable cycling stability and Faradaic capacitive performance, indicating the potential application as the electrode material of supercapacitors.

In view of the application of PANI/SnO2 supercapacitor, it seems reasonable that both PANI and SnO2 are regarded as electroactive materials. The electrochemical capacitance performance of PANI/SnO2 supercapacitor is evaluated through the CV and GCD measurements. Fig. 9 shows CV curves at different scan rates, GCD curves at different current densities, corresponding capacitance curve, and Ragone plot of PANI/SnO2 supercapacitor. The CV curve exhibits the redox peaks at low scan rate, presenting the good reversibility in Faradaic process (Fig. 9a). The gel electrolyte used in PANI/SnO2 supercapacitor is well applied to expand the potential window, providing the enlarged output voltage of 1.8 V (Fig. 9b). The specific capacitance of PANI/SnO2 supercapacitor is decreased from 44.9 F g−1 at 0.2 A g−1 to 25.7 F g−1 at 2.0 A g−1, presenting the capacitance retention ratio of 57.2% (Fig. 9c). The power density is enhanced to from 180 to 1800 W Kg−1 when the current density is increased from 0.2 to 2.0 A g−1. Meanwhile, the energy density is declined from 11.6 to 20.2 Wh Kg−1 (Fig. 9d).

Fig. 10 shows photographs of the prototype of all-solid-state symmetric PANI/SnO2 supercapacitor and its lighting LED with a rated voltage of 1.8 V. The overall dimension of this supercapacitor is approximately 40 × 12 × 0.85 mm. Such one unit of PANI/SnO2 supercapacitor with an output voltage of 1.8 V can well operate a LED with a rated voltage of 1.8 V, presenting the promising application for the electrochemical energy storage.

Conclusions

The binary nanocomposite of PANI/SnO2 NRA was synthesized by electrodepositing PANI on the surface of SnO2 NRA which was initially supported on the substrate of carbon fibers. Considering electroactive PANI, PANI/SnO2 NRA exhibited a high specific capacitance of 376.5 F g−1 at 0.5 A g−1 and good cycling stability with the capacitance retention ratio of 88.3% after 2000 cycles, which was higher than that of the pure PANI film directly deposited on carbon fibers. PANI/SnO2 NRA involves large accessible interface for the reversible proton doping/dedoping reaction, contributing to the pseudo-capacitance. The feasible electron transfer along with highly ordered SnO2 nanorods could promote the electrochemical reactivity of PANI, leading to the improved capacitance performance. The interconnection between SnO2 NRA and PANI could promote the mechanical stability of PANI. The ultrathin interface layer between SnO2 nanorods and PANI could act as the buffer space to effectively restrain the volumetric change of PANI caused by the proton doping/dedoping process, leading to the improved cycling stability. All-solid-state symmetric PANI/SnO2 supercapacitor was also constructed using two PANI/SnO2 NRA electrodes and H2SO4-PVA gel electrode, presenting the specific capacitance of 44.9 F g−1, the energy density of 20.2 Wh Kg−1, and the output voltage of 1.8 V at 0.2 A g−1 when both PANI and SnO2 were considered as electroactive materials. PANI/SnO2 NRA with high capacitance performance presents the promising supercapacitor applications for the electrochemical energy storage.

References

Wang G, Zhang L, Zhang J (2012) A review of electrode materials for electrochemical supercapacitors. Chem Soc Rev 41:797–828

Deshmukh PR, Shinde NM, Patil SV, Bulakhe RN, Lokhande CD (2013) Supercapacitive behavior of polyaniline thin films deposited on fluorine doped tin oxide (FTO) substrates by microwave-assisted chemical route. Chem Eng J 223:572–577

Xie Y, Wang D (2016) Supercapacitance performance of polypyrrole/titanium nitride/polyaniline coaxial nanotube hybrid. J Alloys Compd 665:323–332

Wang K, Wu H, Meng Y, Wei Z (2014) Conducting polymer nanowire arrays for high performance supercapacitors. Small 10:14–31. doi:10.1007/s10008-017-3525-3

Xie Y, Xia C, Du H, Wang W (2015) Enhanced electrochemical performance of polyaniline/carbon/titanium nitride nanowire array for flexible supercapacitor. J Power Sources 286:561–570

Xie Y, Wang D, Ji J (2016) Preparation and supercapacitance performance of free-standing polypyrrole/polyaniline coaxial nanoarray. Energy Technol 4:714–721

Mao L, Zhang K, On Chan HS, Wu J (2012) Surfactant-stabilized graphene/polyaniline nanofiber composites for high performance supercapacitor electrode. J Mater Chem 22:80–85

Nguyen VH, Lamiel C, Kharismadewi D, Tran VC, Shim J-J (2015) Covalently bonded reduced graphene oxide/polyaniline composite for electrochemical sensors and capacitors. J Electroanal Chem 758:148–155

Zhao Z, Xie Y (2017) Enhanced electrochemical performance of carbon quantum dots-polyaniline hybrid. J Power Sources 337:54–64

Lu L, Xie Y (2017) Fabrication and supercapacitor behavior of phosphomolybdic acid/polyaniline/titanium nitride core-shell nanowire array. New J Chem 59:1508–1512

Xie Y, Song F (2016) Preparation and capacitance performance of nitrided lithium titanate nanoarrays. Ceram Int 42:9717–9727

Xie Y, Meng Y, Wu M (2016) Visible-light-driven self-cleaning SERS substrate of silver nanoparticles and graphene oxide decorated nitrogen-doped titania nanotube array. Surf Interface Anal 48:334–340

Xie Y (2016) Photoelectrochemical performance of cadmium sulfide quantum dots modified titania nanotube arrays. Thin Solid Films 598:115–125

Xie Y (2017) Overview of supercapacitance performance of graphene supported on porous substrates. Mater Tech. doi:10.1080/10667857.10662016.11242198

Xie Y, Wang W (2016) Bioelectrocatalytic performance of glucose oxidase/nitrogen-doped titania nanotube array enzyme electrode. J Chem Technol Biotechnol 91:1403–1412

Xie Y, Tian F (2017) Capacitive performance of molybdenum nitride/titanium nitride nanotube array for supercapacitor. Mater Sci Eng B 215:64–70

Pedrós J, Boscá A, Martínez J, Ruiz-Gómez S, Pérez L, Barranco V, Calle F (2016) Polyaniline nanofiber sponge filled graphene foam as high gravimetric and volumetric capacitance electrode. J Power Sources 317:35–42

Gao S, Zang P, Dang L, Xu H, Shi F, Liu Z, Lei Z (2016) Extraordinarily high-rate capability of polyaniline nanorod arrays on graphene nanomesh. J Power Sources 304:111–118

Channu VSR, Holze R (2011) Synthesis and characterization of a polyaniline-modified SnO2 nanocomposite. Ionics 18:495–500

Luo Z, Zhu Y, Liu E, Hu T, Li Z, Liu T, Song L (2014) Synthesis of polyaniline/SnO2 nanocomposite and its improved electrochemical performance. Mater Res Bull 60:105–110

Zhu Y, Liu E, Luo Z, Hu T, Liu T, Li Z, Zhao Q (2014) A hydroquinone redox electrolyte for polyaniline/SnO2 supercapacitors. Electrochim Acta 118:106–111

Li X, Chai Y, Zhang H, Wang G, Feng X (2012) Synthesis of polyaniline/tin oxide hybrid and its improved electrochemical capacitance performance. Electrochim Acta 85:9–15

Shen X, Ma L, Gan M, Li Z, Yan J, Xie S, Yin H, Zhang J (2014) Chemical anchoring of aminobenzoate onto the surface of SnO2 nanoparticles for synthesis of polyaniline/SnO2 composite. Synth Met 196:20–26

Janáky C, Rajeshwar K (2015) The role of (photo)electrochemistry in the rational design of hybrid conducting polymer/semiconductor assemblies: From fundamental concepts to practical applications. Prog Polym Sci 43:96–135

Hu Z-A, Xie Y-L, Wang Y-X, Mo L-P, Yang Y-Y, Zhang Z-Y (2009) Polyaniline/SnO2 nanocomposite for supercapacitor applications. Mater Chem Phys 114:990–995

Kim JG, Nam SH, Lee SH, Choi SM, Kim WB (2011) SnO2 nanorod-planted graphite: an effective nanostructure configuration for reversible lithium ion storage. ACS Appl Mater Interfaces 3:828–835

Liu Y, Jiao Y, Zhang Z, Qu F, Umar A, Wu X (2014) Hierarchical SnO2 nanostructures made of intermingled ultrathin nanosheets for environmental remediation, smart gas sensor, and supercapacitor applications. ACS Appl Mater Interfaces 6:2174–2184

Miao F, Shao C, Li X, Lu N, Wang K, Zhang X, Liu Y (2016) Polyaniline-coated electrospun carbon nanofibers with high mass loading and enhanced capacitive performance as freestanding electrodes for flexible solid-state supercapacitors. Energy 95:233–241

Olad A, Gharekhani H (2015) Preparation and electrochemical investigation of the polyaniline/activated carbon nanocomposite for supercapacitor applications. Prog Org Coat 81:19–26

Lee H, Kwac L, An K, Park S, Kim B (2016) Electrochemical behavior of pitch-based activated carbon fibers for electrochemical capacitors. Energy Convers Manag 125:347–352

Xu W, Zhao K, Niu C, Zhang L, Cai Z, Han C, He L, Shen T, Yan M, Qu L, Mai L (2014) Heterogeneous branched core-shell SnO2-PANI nanorod arrays with mechanical integrity and three dimentional electron transport for lithium batteries. Nano Energy 8:196–204

Wang D, Li X, Wang J, Yang J, Geng D, Li R, Cai M, Sham T-K, Sun X (2012) Defect-Rich Crystalline SnO2 Immobilized on Graphene Nanosheets with Enhanced Cycle Performance for Li Ion Batteries. J Phys Chem C 116:22149–22156

Chen F, Liu P, Zhao Q (2012) Well-defined graphene/polyaniline flake composites for high performance supercapacitors. Electrochim Acta 76:62–68

Jin Y, Jia M (2015) Design and synthesis of nanostructured graphene-SnO2-polyaniline ternary composite and their excellent supercapacitor performance. Colloids Surf A Physicochem Eng Asp 464:17–25

Mao L, Li M, Xue J, Wang J (2016) Bendable graphene/conducting polymer hybrid films for freestanding electrodes with high volumetric capacitances. RSC Adv 6:2951–2957

Xie Y, Ji J (2016) Synthesis and capacitance performance of MnO2/RGO double-shelled hollow microsphere. J Mater Res 31:1423–1432

Acknowledgements

The work was supported by National Natural Science Foundation of China (No. 21373047), Graduate Innovation Program of Jiangsu Province (KYLX15_0126), and Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, Y., Zhu, F. Electrochemical capacitance performance of polyaniline/tin oxide nanorod array for supercapacitor. J Solid State Electrochem 21, 1675–1685 (2017). https://doi.org/10.1007/s10008-017-3525-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3525-3