Abstract

Nanocrystalline ferrite powders of Ni x Zn1 − x + y Fe2−2y Sn y O4 (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0 and y = 0.1, 0.2) were prepared by oxalate co-precipitation method and characterized by XRD, FT-IR and FE-SEM techniques. The ferrite thick films (FTFs) of all compositions were prepared by screen printing technique and tested for gas sensing behaviour for liquid petroleum gas (LPG), ethanol (C2H5OH) and chlorine (Cl2). For LPG, the sensitivity decreases with an increase in Ni2+ up to x = 0.6. It increases slightly for further increment in Ni2+. For this gas, the sensitivity is higher for higher concentration of Sn4+ (y = 0.2) while the optimum temperatures are smaller than that for lower concentration of Sn4+ (y = 0.1). The response and recovery times increase with the increase in Ni2+ for lower concentration of Sn4+ (y = 0.1), while at higher concentration of Sn4+ (y = 0.2), there is increase (for Ni2+ up to x = 0.6) and decrease (for further increase in Ni2+ up to 1.0) in response and recovery times. For ethanol and Cl2, the sensitivity of Zn FTFs decreases with an increase in Ni2+ and increases with an increase in Sn4+. For these gases, the optimum temperature is found to be higher for higher concentration of Sn4+. The response and recovery times of Zn FTFs for ethanol and Cl2 increase with increasing Ni2+ and Sn4+.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soft ferrites are one of the most important materials used in the fabrication of electronic components. They possess good chemical and thermal stability under operating conditions. Nowadays, researchers have focused their attention on gas sensors of soft ferrites. Among the soft ferrites, Ni-Zn ferrites are particularly useful because of their high resistivity, low loss and high saturation magnetization [1]. By substituting divalent, trivalent and tetravalent impurities, the properties of the soft ferrites can be changed. Kadu et al. [2] synthesized Zn-Mn ferrite sensors and tested for LPG, CH3, CO and C2H5OH. They reported that Zn-Mn ferrite sensor is sensitive to ethanol at an operating temperature of 300 °C. They found improved sensitivity, response and reduced operating temperature to 230 °C with the addition of palladium in Zn-Mn ferrite sensors. Vasambekar et al. [3] studied the gas sensing properties of Nd3+-substituted zinc ferrites for ethanol, Cl2 and LPG. They reported that response and recovery decrease with an increase in Nd3+ content in zinc ferrite. Rezlescu et al. [4] reported the influence of partial replacement of Mg and Fe ions by Sn4+ and Mo6+ ions and studied their structural, electrical and gas sensing properties. These ferrites were more sensitive to acetone than ethanol. Doroftei et al. [5] studied the influence of Sn4+ and/or Mo6+ ions on the structure and the humidity sensitivity of Mg ferrite prepared by self-combustion method. The role of Sn4+ substitution in Mg ferrite is to enhance the humidity sensitivity. The improvement of resistivity, density and permeability with the addition of Sb in Ni-Zn ferrite is reported by Praveena and Srinath [6].

The study of gas sensing properties of ferrites showed very good surface reactivity. The ferrites have temperature-dependent surface morphologies [7–10]. Reddy et al. [7] prepared nanocrystalline nickel ferrite by micro-emulsion and hydrothermal methods and studied its gas sensing properties for LPG. They found that nickel ferrite prepared by the hydrothermal method shows high sensitivity at lower operating temperatures compared to that prepared by mitcelle technique. They also observed the significant reduction in operating temperature and faster response for palladium-substituted nickel ferrite. Gopal Reddy et al. [8] reported the gas sensing properties at lower concentrations of chlorine gas for nickel ferrite. Gadkari et al. [9] studied the gas sensing properties of Sm3+-added Mg-Cd ferrites. They reported lower response and recovery times for Sm3+-added Mg-Cd ferrites than that for Mg-Cd ferrites. They also observed that response-recovery times of Mg-Cd ferrites decrease with an increase in Cd2+ content.

Kamble and Mathe [10] showed that the nickel ferrite thick film (FTF) is an efficient gas sensor for chlorine compared to LPG and NH3 at room temperature. Gawas et al. [11] prepared Mn0.3Ni0.3Zn0.4Fe2O4 powder by autocatalytic thermal decomposition technique. They deposited thick films by the screen printing method. The sensors showed high sensitivity to NH3 gas at room temperature and also high selectivity at 10 ppm against other toxic gases at higher concentrations. Bangale and Bamane [12] prepared Mg ferrite powders by solution combustion method and thick films by the screen printing method. They showed that these ferrites have high sensitivity and good selectivity to ethanol gas at 30 ppm compared to acetone, H2S, CO2 and LPG. By the similar method, zinc FTF was prepared. This nanocrystalline zinc FTF has high sensitivity and good selectivity to Cl2 at 300 ppm compared to acetone, NH3, H2, H2S and LPG [13]. They also found that zinc FTF has high sensitivity and good selectivity to H2S gas at 1000 ppm [14].

NiO/TiO2-added zinc ferrite gas sensor was tested by Arshak and Gaidan [15] for alcohols like ethanol, pentanol, propanol, butanol and hexanol. The sensor showed highest sensitivity to hexanol. It is observed that the addition of NiO/TiO2 improved the response and recovery times. They also found that the response and recovery times are temperature dependent and decrease with an increase in operating temperature. Rezlescu et al. [16] prepared zinc ferrite by self-combustion method and tested its sensing properties for LPG, C2H5OH and CH3COOH. They found that zinc ferrite is sensitive and selective to ethanol. Xiangfeng and Chenmou [17] prepared MFe2O4 (M = Zn, Cd, Mg and Cu) thick films by co-precipitation method and tested their sensing properties for H2S, CH3SH and (CH3)2S. They reported that CdFe2O4 is sensitive, even at 0.01 ppm concentration of CH3SH.

Current status and future trends on solid-state potentiometric gas sensors have been reported by Pasierb and Rekas [18]. They reported that the potentiometric gas sensors may be used in a variety of areas including domestic applications, agriculture, industries, medicine, automobiles, mines, control of gas emissions, leak and fire. Mobius and Hartung [19] carried further research on potentiometric gas sensors by adding some oxygen sensors in reducing gases. Bahteeva et al. [20], Shalaeva et al. [21], Markov et al. [22] and Kharton et al. [23] synthesized strontium-substituted ferrites. They revealed that the variation in accepter doping level and oxygen vacancy concentration results in structural modifications that develop simultaneously with changes in ionic conductivity.

We reported the gas sensing properties of Y3+-added nanocrystallite Mg-Cd ferrite [24] and Ni-Zn ferrite thick films [25] for LPG, ethanol and chlorine. It is clear that thick films show good sensitivity as compared to the bulk material. No literature is found for the gas sensing properties of Sn4+-substituted Ni-Zn ferrites and Sn4+-substituted Ni-Zn FTFs. Therefore, it was decided to prepare Ni-Zn-Sn FTFs and study their gas sensing properties for LPG, ethanol and chlorine at various operating temperatures.

Experimental

Preparation of Ni-Zn-Sn ferrite powder

The nanosize ferrite powders of Ni x Zn1 − x + y Fe2 − 2y Sn y O4 (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0 and y = 0.1, 0.2) system were prepared by oxalate co-precipitation method. The AR-grade ZnSO4.6H2O (Thomas Baker), NiSO4 .6H2O (Molychem), FeSO4.7H2O (Thomas Baker) and SnSO4 (Thomas Baker) were dissolved in double-glass-distilled water in the required proportion. The pH of the solution was maintained at 4.0 by adding conc. H2SO4. The mixture was heated at 80 °C for 1 h to optimize the complete ionization of metal sulphates. AR-grade ammonium oxalate solution (Sd Fine-Chem. Ltd) was added with stirring until complete precipitation was obtained. The precipitate was filtered and washed several times with double-glass-distilled water in order to remove sulphate ions. The removal of sulphate ions was confirmed by barium chloride test [9, 24]. The precipitate was dried on a hot plate and pre-sintered at 200 °C for 1 h. The pre-sintered powders were milled in an agate mortar with acetone as a base and finally sintered at 450 °C for 2 h.

Ni-Zn-Sn ferrite thick film preparation

The FTFs of Ni x Zn1 − x + y Fe2 − 2y Sn y O4 (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0; y = 0.1, 0.2) powders having an area of 10 × 10 mm2 were prepared by screen printing technique. Ni-Zn-Sn ferrite powders of different compositions were deposited on a glass substrate. For deposition, the mixture of 90 wt% of Ni-Zn-Sn ferrite powders with an organic binder of 5 wt% ethyl cellulose and 5 wt% 2-(2-butoxyethoxy) ethyl acetate was used. The electrical contacts on both the ends of the thick films were made by using a silver conductive adhesive paste (AlfaAesar). The photograph of Ni-Zn-Sn FTFs (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0; y = 0.1) were shown in Fig. 1.

The measurements of FTF thicknesses were carried on surface profiler Ambios Tech. XP-1 and were found in the range of 15–20 μm.

Characterization

The XRD patterns of Ni-Zn-Sn ferrite powder were recorded on (Bruker D2 phaser, USA) desktop X-ray powder diffractometer in the range of 10°–90° (2θ), a step size of 0.02° at 30 kV, 10 mA with CuKα radiation (λ = 1.54184 Å). The FT-IR spectra of ferrite powders were recorded in the range of 300–800 cm−1 using a Perkin Elmer spectrum one spectrometer, USA, by KBr pellet technique. The surface morphology of the FTF was studied with the help of FE-SEM on Hitachi, Model: S-4700, Japan.

Gas sensing

The gas sensing behaviour of Ni x Zn1 − x + y Fe2 − 2y Sn y O4 (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0 and y = 0.1, 0.2) FTFs was measured by using a lab-made gas sensor unit for the gases like chlorine, ethanol and LPG by using a two-probe method. Ohmic contacts of silver paste were made for the 10 × 10 mm2 thick films on glass substrates. A 500-ppm test gas was inserted in the chamber with the help of a syringe. The resistance of the ferrite thick film sensor in air (R a) and in the presence of various test gases (R g) of LPG, C2H5OH and Cl2 was calculated by measuring the current flowing through the film at various temperatures.

The sensitivity of all FTF sensor elements was calculated by using relations [9, 24–25].

Results and discussion

Structural properties

The typical X-ray diffraction patterns of Ni-Zn-Sn (x = 0.8, 1.0; y = 0.1, 0.2) are presented in Fig. 2. The presence of (111), (220), (311), (222), (400), (422), (511), (440) and (533) planes in the figure confirms the formation of a single-phase cubic spinel structure. All the peaks in the diffraction patterns with JCPDS card number-52-0278 are in good agreement. From this figure, it is found that there is no extra peak present in the samples. The typical FE-SEM image of Ni-Zn-Sn (x = 0.6, y = 0.1) FTF is presented in Fig. 3. It is noticed that the average grain size of the samples under investigation lies in the range of 20–60 nm, highly porous nature and located in loosely packed agglomerates. The particle size of the samples decreases with an increase in Sn4+ content. The typical FT-IR spectrum of Ni-Zn-Sn (x = 0.8, 1.0; y = 0.1, 0.2) ferrite is presented in Fig. 4. The figure shows two major absorption bands near the high-frequency absorption band (υ 1) in the range of 596 to 568 cm−1 and low-frequency absorption bands (υ 2) in the range of 481 to 469 cm−1. These are corresponding to intrinsic lattice vibrations of octahedral and tetrahedral sites, respectively [26].

Gas sensing properties

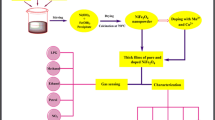

The gas sensing properties of the Ni-Zn-Sn FTFs were measured by laboratory-made gas sensor unit for LPG, ethanol and chlorine at a concentration of 500 ppm. The variation of sensitivity with operating temperature of Ni-Zn-Sn FTFs for LPG, ethanol and chlorine is presented in Figs. 5, 11 and 15. From these figures, it is found that the sensitivity of each FTF initially increases, reaches to a maximum, and then decreases with an increase in temperature for each test gas. This type of behaviour of sensitivity is attributed to the rate of chemical reaction and diffusion of gas molecules. For maximum sensitivity, the rate of chemical reaction and diffusion of gas molecules becomes equal. The temperature at highest sensitivity is referred to as an optimum operating temperature [24]. Such type of behaviour of the sensitivity of FTFs is reported by several researchers [10, 12–17]. The gas sensing mechanism of FTFs under investigation is depicted by the flow diagram presented in Fig. 6.

In sensors, chemisorbed oxygen species like O−, O2 − and O2− appear on the surface and plays an important role in the gas sensing mechanism [24]. Usually, sensing mechanism depends on the operating temperature. Sensing mechanism of oxygen adsorbed on the surface of FTFs is given as [24, 34]

The reaction mechanism for reducing gases on the surface of FTFs with oxygen species is given as [17]

When a reducing gas reacts with chemisorbed oxygen, an electron is released back to the conduction band, resulting in changes in the resistance of a sensor.

The variation of grain size and sensitivity with nickel content for Ni-Zn-Sn FTFs is presented in Fig. 7. From this figure, it is noticed that the inverse relation between grain size and sensitivity of Ni-Zn-Sn FTFs expects the sample (x = 0.8, 0.1) for LPG. For higher concentration of Sn4+ (y = 0.2) content, the sensitivity of Ni-Zn-Sn FTFs becomes higher and grain size becomes lower as compared to lower concentration of Sn4+ content (y = 0.1).

Ni-Zn-Sn FTFs as LPG sensors

When Ni-Zn-Sn FTFs are exposed to LPG, they react with chemisorbed oxygen species and results in the formation of gaseous species and water vapours by removal of adsorbed oxygen due to the interaction of hydrocarbons (CnH2n + 2) of LPG.

The reaction of LPG with chemisorbed oxygen is given as

This reaction shows the increased concentration of electrons in the conduction band, resulting in the increased conductance of Ni-Zn-Sn FTFs. This was reflected in increased current after exposure to the gas as expected [24, 27].

From the plot of temperature versus sensitivity presented in Fig. 5a, b, it is observed that the sensitivity and operating temperature of Ni-Zn-Sn FTFs for LPG varies in the range of 65–84 and 154–208 °C, respectively. The variation of sensitivity and optimum temperature of Ni-Zn-Sn FTFs with nickel for LPG is presented in Fig. 8. It is seen that the sensitivity of Ni-Zn-Sn FTFs decreases with increased nickel content (up to x = 0.6) and slightly increases thereafter for further increment in nickel content (for x = 0.8 and 1.0). This change in the sensitivity may be due to the DC electrical resistivity, and activation energy of Ni-Zn-Sn FTFs decreases with increased nickel content (up to x = 0.6) and slightly increases thereafter for further increment in nickel content (for x = 0.8 and 1.0); these results are presented in Fig. S1 (in Supplementary Information). This is also due to the Yafet-Kittel model for (x = 0.8 and 1.0) the sensitivity increases with an increase in nickel content [27, 28]. From this plot, it can be further noticed that the sensitivity of Ni-Zn-Sn FTFs for higher concentration of Sn4+ (y = 0.2) is higher than that for lower concentration of Sn4+ (y = 0.1). This is attributed to the decreased grain size in these FTFs with increased Sn4+ substitution.

From this figure, it is also noticed that the optimum temperature increases with an increase in nickel content. This is due to the increasing grain size of FTFs with Ni2+ content. For Ni-Zn-Sn0.2 FTFs, optimum temperature is lower than that for Ni-Zn-Sn0.1 FTFs. It is found that there is an inverse relation between operating temperature and sensitivity in Ni-Zn-Sn FTFs till the Neel’s two-sublattice model is observed (up to x = 06). Thereafter, for the Yafet-Kittel model (x = 0.8 and 1.0), the sensitivity is seen to follow the same trend of increment as that of operating temperature with increased nickel content [28, 29].

The response and recovery characteristics of Ni-Zn-Sn FTFs (x = 0, 0.2, 0.4, 0.6, 0.8 and 1.0; y = 0.1 and 0.2) for LPG are presented in Fig. S2 (a-b) (in Supplementary Information). From Fig. S2, it is found that the response and recovery time lies in the range of 10–28 and 20–37 s, respectively, for lower (y = 0.1) and higher (y = 0.2) concentrations of Sn4+.

The variation of response and recovery times of Ni-Zn-Sn FTFs (x = 0, 0.2, 0.4, 0.6, 0.8,1.0; y = 0.1 and 0.2) with nickel content for LPG is presented in Fig. 9. From this figure, it is noticed that the response and recovery times for lower concentration of Sn4+ (y = 0.1) increase with increasing nickel content. However, for higher concentration of Sn4+ (y = 0.2), the response and recovery times increase with an increase in nickel content (up to x = 0.6, i.e. till the Neel’s two-sublattice is dominant) [28, 29]. Thereafter, there is a decrement in the response and recovery times for further increase in nickel content (x = 0.8 and 1.0, i.e. for the predominance of Yafet-Kittel model) [28, 29] for higher concentration of Sn4+. It is also observed that the response and recovery times of Ni-Zn-Sn FTFs for higher concentration of Sn4+ (y = 0.2) are lower than that for lower concentration of Sn4+ (y = 0.1).

The Ni-Sn FTF sensor shows short response (10 s) and good recovery time (20 s) for LPG.

Ni-Zn-Sn FTFs as an ethanol sensor

When Ni-Zn-Sn FTFs are exposed to ethanol, the reaction with chemisorbed oxygen species on the surface is given as [30, 31]

In these reactions, ethanol is adsorbed by the oxygen species (\( {\mathrm{O}}_{\left(\mathrm{ads}\right)}^{2-} \)) and produces adsorbed gas species (\( {\mathrm{C}}_2{\mathrm{H}}_5{\mathrm{O}}_{\left(\mathrm{ads}\right)}^{-} \)), along with a hydroxide group. Adsorbed gas species further gives gaseous species and an electron. The ethanol gas is exposed to chemisorbed oxygen species and hole to produce carbon dioxide, water molecules and doubly charged oxygen vacancy (\( {\mathrm{V}}_{\mathrm{o}}^{\bullet \bullet}\Big) \). During the sensing mechanism of gas with the surface of FTFs, electrons enters in the conduction band, leading to decrease the resistance of Ni-Zn-Sn FTFs [30, 31].

The variation of sensitivity with operating temperature of Ni-Zn-Sn FTFs (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0; y = 0.1, 0.2) for ethanol is presented in Fig. 10a, b. From these figures, it is revealed that the sensitivity and optimum temperature of Ni-Zn-Sn FTFs lies in the range of 55–91 and 152–183 °C, respectively. The variation of sensitivity and optimum temperature of Ni-Zn-Sn FTFs (x = 0, 0.2, 0.4, 0.6, 0.8, 1.0; y = 0.1, 0.2) with a nickel content for ethanol is presented in Fig. 11. From this figure, it is noticed that the sensitivity and the optimum temperature of Ni-Zn-Sn FTFs decrease with an increase in nickel content. This is due to the increase in grain size of the FTFs with an increase in Ni2+ content (Fig. 7). It is observed that the Zn-Sn FTF has high sensitivity (91 %) to ethanol. It means that the Zn-Sn FTFs strongly interact with ethanol as compared to other FTFs [32]. The Ni-Zn FTFs with higher concentration of Sn4+ (y = 0.2) show lower operating temperature and higher sensitivity to ethanol compared to that with a lower concentration of Sn4+ (y = 0.1). The decrement of operating temperature is due to the decrease in grain size of FTFs (Fig. 7) [24, 33]. Kapse et al. [30] reported that the higher sensitivity and lower operating temperature for Pd (1.0 wt%) doped Ni0.6Zn0.4Fe2O2 as compared to Ni0.6Zn0.4Fe2O2 for ethanol.

The variation of response and recovery characteristics of Ni-Zn-Sn FTFs for ethanol is presented in Fig. S3 (a-b) (in supplementary Information). From these figures, it is found that the response and recovery times lie in the range of 10–25 and 20–40 s, respectively. The variation of response and recovery times of Ni-Zn-Sn FTFs with a nickel content of ethanol is presented in Fig. 12. The response and recovery times of Ni-Zn-Sn FTFs increase with increasing nickel content and decreases with increasing Sn4+ content. This is due to the increment and decrement of grain size with substitution of Ni2+ and Sn4+ in FTFs (Fig. 7).

Ni-Zn-Sn FTFs as a chlorine sensor

Exposure of Ni-Zn-Sn FTFs to chlorine results in the formation of chlorides. The reaction of chlorine with the surface of FTFs is given as [10, 34]

The reactions (9) and (10) represent an electron donation to the conduction band of Ni-Zn-Sn FTF sensor indicating decreased resistance [10].

The variation of sensitivity with operating temperature of Ni-Zn-Sn FTFs for chlorine is as presented in Fig. 13a, b. The sensitivity and operating temperature of Ni-Zn-Sn FTFs lies in the range of 54–85 and 146–202 °C, respectively.

The variation of sensitivity and optimum temperature of Ni-Zn-Sn FTFs with a nickel content for chlorine is presented in Fig. 14. From this figure, it is revealed that the sensitivity of FTFs decreases, whereas optimum temperature increases with increasing nickel content. The increase in optimal temperature and decrease in sensitivity are mainly affected due to smaller surface area and greater grain size of FTFs under investigation (Fig. 7).

From Fig. 14, it is also observed that the sensitivity of each FTFs is higher whereas the optimum temperature of each FTFs becomes lower for higher concentration of Sn4+ (y = 0.2) in Ni-Zn FTFs than that for lower concentration of Sn4+ (y = 0.1). It is found that the optimum temperature for Ni-Zn-Sn FTFs (x = 0, 0.2; y = 0.1, 0.2) is the same, but the sensitivity is slightly different. This can be attributed to the lattice constant of Sn4+-substituted Zn FTFs [35].

Response and recovery characteristics of Ni-Zn-Sn FTFs for chlorine are presented in Fig. S4 (a-b) (in supplementary Information). From these Fig S4, it is seen that the response and recovery times of Ni-Zn-Sn FTFs lie in the range of 10–30 and 20–35 s, respectively. The variation of response and recovery times of Ni-Zn-Sn FTFs with a nickel content for chlorine is presented in Fig. 15. From this figure, it is clear that the response and recovery times of Ni-Zn-Sn FTFs increase with increasing nickel content. The response and recovery times of Ni-Zn-Sn FTFs for higher concentration of Sn4+ (y = 0.2) are lower than that for lower concentration of Sn4+ (y = 0.1). This is due to decrement in the grain size for increased concentration of Sn4+. The Sn4+-substituted Zn FTF sensor under investigation has a short response (10 s) and good recovery time (15 s) for chlorine compared to other FTFs.

From Figs. 8, 11 and 14, it is clear that the sensitivity of all the ferrites decreases with an increase in Ni2+ content for test gases like LPG, ethanol and Cl2. This is attributed to the increase in grain size of the Ni-Zn-Sn ferrites with the increase in Ni2+ content. From these figures, it is also observed that optimum temperature of the FTFs increases with the increase in Ni2+ content for LPG and chlorine except ethanol.

The compositional variation of sensitivity of Ni-Sn, Ni0.6Zn0.4Sn and Zn-Sn FTFs for test gases is presented in Fig. 16. From this figure, it is confirmed that the sensitivity of Zn-Sn FTF is higher for ethanol gas as compared to the other gases like LPG and ethanol. Response and recovery time of these FTFs is also well as compared to other FTFs (Fig. 12 ). Therefore, Zn-Sn FTFs is highly sensitive as compared to Ni-Sn and Ni0.6Zn0.4Sn FTFs.

Conclusions

Nanosize Ni-Zn-Sn ferrite powders were prepared by oxalate co-precipitation method. The FTFs were deposited on a glass substrate by a screen printing technique. The XRD study confirms the formation of cubic spinel structure. The FT-IR spectra confirm the formation of ferrites. From the gas sensing characteristics of the FTFs under investigation, it can be concluded that

-

1.

The sensitivity of Ni-Zn-Sn FTFs is in the order of ethanol > Cl2 > LPG.

-

2.

The highest response (91 %) is shown by Zn-Sn FTFs to ethanol.

-

3.

The lowest response (61 %) is shown by Ni-Sn FTFs to ethanol.

-

4.

The sensitivity of Ni-Zn-Sn FTFs decreases with increases in Ni2+ content for ethanol and chlorine. It is attributed to increases in grain size to increase in Ni2+ content.

-

5.

The sensitivity of Ni-Zn-Sn FTFs for all test gases is higher for higher concentration of Sn4+ (y = 0.2) in Ni-Zn FTFs than that for lower concentration of Sn4+ (y = 0.1). The high sensitivity is due to its smaller grain size in Sn4+ (y = 0.2) compared to that of Sn4+ (y = 0.1) Ni-Zn FTFs.

-

6.

The response and recovery times of Ni-Zn-Sn FTFs increase with increasing Ni2+ content, and response and recovery time decreases with increasing Sn4+ concentrations.

-

7.

The optimum temperature of Ni-Sn-Zn FTFs increases with increases in nickel content for LPG and chlorine. The optimum temperature of Ni-Zn-Sn FTFs for all test gases was decreased with the increase in Sn4+ concentrations.

References

Deka S, Joy PA (2007) Enhanced permeability and dielectric constant of Ni-Zn ferrite synthesized in nanocrystalline form a combustion method. J Am Ceram Soc 90:1494–1499

Kadu AV, Jagtap SV, Chaudhari QN (2009) Studies on the preparation and ethanol gas sensing properties of spinel Zn0.6Mn0.4Fe2O4 nanomaterials. Curr Appl Phys 9:1246–1251

Vasambekar PN, Gadkari AB, Shinde TJ (2013) Nd3+ substituted nanocrystalline zinc ferrite sensors for ethanol, LPG and chlorine. Appl Mech Mater 310:150–153

Rezlescu N, Dorofti C, Rezlescu E, Popa PD (2006) The influence of Sn4+ and/or Mo6+ ions on the structure, electrical and gas sensing properties of Mg-ferrite. Phys Status Solidi 203:306–316

Doroftei C, Reszlescu E, Rezlescu N, Popa PD (2006) Microsturcture and humidity sensitive properties of MgFe2O4 ferrite with Sn and Mo substitutions prepared by self combustion method. J Optoelectron Adv Mater 8:1012–1015

Praveena K, Srinath S (2013) The effect of Sb on the electrical and magnetic properties of Ni-Zn ferrite prepared by so-gel auto combustion method. J Electroceram 31:168–175

Reddy KM, Satyanarayana L, Manorama SV, Misra RDK (2004) A comparative study of the gas sensing behavior of nanostructured nickel ferrite synthesized by hydrothermal and reverse micelle technique. Mater Res Bull 39:1491–1498

Gopal Reddy CV, Manorma SV, Rao VJ (1999) Semiconducting gas sensor for chlorine based on inverse spinel nickel ferrite. Sensors Actuators B Chem 55:90–95

Gadkari AB, Shinde TJ, Vasambekar PN (2013) Effect of Sm3+ ion addition on gas sensing properties of Mg1-xCdxFe2O4. Sensors Actuators B Chem 178:34–39

Kamble RB, Mathe VL (2008) Nanocrystalline nickel ferrite thick film as an efficient gas sensor at room temperature. Sensors Actuators B Chem 131:205–209

Gawas UB, Verenkar VMS, Patil DR (2011) Nanostructured ferrite based electronics nose sensitive to ammonia at room temperature. Sens Transd J 134:45–55

Bangale SV, Bamane SR (2012) Nanostructured MgFe2O4 thick film resistors as ethanol gas sensors operable at room temperature. Sens Transd J 137:176–188

Bangale SV, Patil DR, Bamane SR (2011) Nanostructured spinel ZnFe2O4 for the detection of chlorine gas. Sens Transd J 134:107–119

Bangale SV, Bamane SR (2012) Preparation and study of H2S gas sensing behaviour of ZnFe2O4 thick film resistors. Sens Transd J 137:123–136

Arshak K, Gaidan L (2006) Effect of NiO/TiO2 addition in ZnFe2O4 based gas sensors in the form of polymer thick films. Thin Solid Films 495:292–298

Rezlescu N, Rezlescu E, Tudorache F, Popa PD (2007) Some spinel oxide compounds reducing gas sensors. Sens Transd J 78:1134–1142

Xiangfeng C, Chenmou Z (2003) Sulfide-sensing characteristics of MFe2O4 (M = Zn, Cd, Mg and Cu) thick film prepared by co-precipitation method. Sensors Actuators B Chem 96:504–508

Pasierb P, Rekas M (2009) Solid-state potentiometric gas sensors-current status and future trends. J Solid State Electrochem 13:3–25

Möbius HH, Hartung R (2010) Solid-state potentiometric gas sensors—a supplement. J Solid State Electrochem 14:669–673

Bahteeva JA, Leonidov IA, Patrakeev MV, Mitberg EB, Kozhevnikov VL, Poeppelmeier KR (2004) High-temperature ion transport in La1-xSrxFeO3-δ. J Solid State Electrochem 8:578–584

Shalaeva EV, Patrakeev MV, Markov AA, Tyutyunnik AP, Murzakaev AM, Kharton VV, Tsipis EV, Waerenborgh JC, Leonidov IA, Kozhevnikov VL (2015) Ion transport in dual-phase SrFe1−xТаxO3−δ (x = 0.03 − 0.10): effects of redox cycling. J Solid State Electrochem 19:841–849

Markov AA, Chesnokov KY, Patrakeev MV, Leonidov IA, Chukin AV, Leonidova ON, Kozhevnikov VL (2016) Oxygen non-stoichiometry and mixed conductivity of La0.5Sr0.5Fe1–xMnxO3–δ. J Solid State Electrochem 20:225–234

Kharton VV, Kovalevsky AV, Tsipis EV, Viskup AP, Naumovich EN, Jurado JR, Frade JR (2002) Mixed conductivity and stability of A-site-deficient Sr (Fe,Ti)O3–dperovskites. J Solid State Electrochem 7:30–36

Gadkari AB, Shinde TJ, Vasambekar PN (2012) Y3+ added nanocrystallite Mg-Cd ferrite LPG, Cl2 and C2H5OH sensors. Sens Transd J 146:110–120

Dalawai SP, Shinde TJ, Gadkari AB, Vasambekar PN (2015) Ni-Zn ferrite thick film gas sensors. J Mater Sci Mater Electron 26:9016–9025

Waldron RD (1955) Infrared spectra of ferrites. Phys Rev 99:1727–1735

Gedam NN, Kadu AV, Padole PR, Bodade AB, Chaudhari GN (2009) Structural properties of nanosized NiFe2O4 for LPG sensor. Sens Transd J 110:86–95

Satya Murthy NS, Natera MG, Youssef SI, Begum RJ (1969) Yafet-Kittel angles in zinc-nickel ferrites. Phys Rev 181:969–977

Shinde TJ, Gadkari AB, Vasambekar PN (2013) Magnetic properties and cation distribution study of nanocrystalline Ni-Zn ferrites. J Magn Magn Mater 333:152–155

Kapse VD, Ghosh SA, Raghuwanshi FC, Kapse SD, Khandekar US (2009) Nanocrystalline Ni0.6Zn0.4Fe2O4: a novel semiconducting material for ethanol detection. Talanta 78:19–25

Sun Z, Liu L, Jia DZ, Pan W (2007) Simple synthesis of CuFe2O4 nanoparticles as gas sensing materials. Sensors Actuators B Chem 25:144–148

Rezlescu N, Reszlescu E, Tudirache F, Popa PD (2009) Gas sensing properties of porous Cu-,Cd- and Zn-ferrites. Rom Rep Phys 61:223–234

Gadkari AB, Shinde TJ, Vasambekar PN (2011) Ferrite gas sensors. IEEE Sensors J 11:849–861

Dawson DH, Williams DE (1996) Gas-sensitive resistors: surface interaction of chlorine with semiconducting oxides. J Mater Chem 6:406–414

Lee JY, Lee GJ, Kim HS, Lee SH, Lee DH, Yo CH, Kim KH, Ahn K (1998) Electrical and magnetic properties of the Sn4+ substituted spinel ferrite, ZnSnxFe2-4x/3O4 (0.00 ≤ x ≤ 0.30). Mater Chem Phys 52:267–271

Acknowledgments

S.P. Dalawai thanks the Department of Electronics, Shivaji University, Kolhapur, for giving financial assistance through the ‘Golden Jubilee Research Fellowship’ in 2012–2015.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 198 kb)

Rights and permissions

About this article

Cite this article

Dalawai, S.P., Shinde, T.J., Gadkari, A.B. et al. Influence of Ni2+ and Sn4+ substitution on gas sensing behaviour of zinc ferrite thick films. J Solid State Electrochem 20, 2363–2372 (2016). https://doi.org/10.1007/s10008-016-3254-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3254-z