Abstract

An electrochemical non-enzymatic glucose sensor was fabricated by electrodeposition of copper nanoparticles (CuNPs) onto a poly(o-phenylenediamine) (PoPD) film-modified glassy carbon electrode (CuNPs/PoPD/GCE). We had studied some factors such as the pH value of supporting electrolyte, the amount of PoPD and applied potentials and optimize the experiment conditions. Under the optimum conditions, the as-obtained sensor for glucose sensing had achieved a wide linear range, low detection limit, and fast response time. The current response of the as-obtained sensor towards electrochemical oxidation of glucose was linear with the concentration of glucose in the range of 5.0 μM to 1.6 mM (R = 0.998) in the solution of 0.1 M NaOH at the applied potential of 0.5 V. The detection limit is 0.25 μM and the fast response achieves within 1 s. The sensor exhibits good sensitivity, selectivity, and reproducibility. The proposed non-enzymatic glucose was successfully employed to determine glucose in blood samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Diabetes mellitus is a metabolic diseases and a major public health problem affecting millions of people. In order to achieve accurate diagnosis and good management of diabetes mellitus, tremendous efforts have been devoted into seeking an efficient, sensitive, and reliable method to determine glucose. Glucose sensing also plays an important role in food industries [1] Owing to good sensitivity, selectivity, and simplicity, electrochemical methods have become the main technique in glucose sensing. Most studies had focused on glucose oxidase (GOx)-based and glucose dehydrogenase (GDH)-based electrochemical glucose sensors [2–4] so as to cater to the demand of reliable blood glucose monitoring in clinical practice. However, due to the natural instability of enzymes, strict experimental conditions, and complicated immobilization procedures [4, 5], enzyme-based sensors usually obtain unsatisfactory results such as unsatisfactory reproducibility and insufficient long-term stability [6]. Another drawback of enzyme-based electrochemical glucose biosensor is the serious interference induced by other electroactives species in blood samples such as ascorbic acid and uric acid [7]. Therefore, the development of non-enzymatic glucose biosensors is of great significance and has attracted considerable attention.

The good performance of non-enzymatic glucose sensor is attributed to the efficient electron transfer electrode and excellent catalytic material [8, 9]. In recent years, nanotechnology has offered many research opportunities on fabrication nanostructured materials and multi-component nanomaterials. There had been many studies that improve the performance of non-enzymatic glucose sensors by incorporating various nanostructured metals or metal oxides [7, 8, 10–15]. Recent advances indicate that nanostructured copper and copper oxides (Cu/CuOx) is very promising [8, 10–14, 16–20] due to their excellent property of high electrocatalytic activity and some advantages, which are inexpensive, non-toxic, and easily produced. Copper NPs can efficiently enhance the electron transfer process and decrease the overpotentials of the investigated electrochemical reaction, which is attributed to its properties such as excellent conductivity and catalytic properties [21, 22]. Multi-component nanomaterials have a synergistic effect that takes advantage of their hybrid properties [23]. The synergistic effects of the composite nanomaterials lead to broad applications in different analytical fields, especially in fabrication of sensor. Electrodeposition is a particularly simple and effective approach that consists in introducing nanoparticles (NPs) into polymer matrices or mixing them with the polymer [24]. Cu NPs-based nanocomposites in the electrochemical enzymeless glucose detection have attracted interest. As for polymers, conducting polymers are used as a coating or encapsulating material on an electrode surface and are developed towards interdisciplinarity [25]. Whereas a majority of polymers are unable to conduct electricity, a non-conducting polymer is being used for the immobilization of specific receptor agents on the sensor device, and their insulating properties are utilized in the electronic industry [26]. o-Phenylenediamine (o-PD), a non-conducting polymer, is usually electropolymerized over electrodes, which widely act as a support for immobilizing enzymes and a charge-transfer mediator or as a barrier to interference. Because the film is permselective, o-PD polymer film is being increasingly electrosynthesized over enzyme electrodes in order to avoid or minimize interferences from endogenous electroactive species in biological samples [27].

In this paper, we developed a non-enzymatic glucose sensor based on CuNPs/poly(o-phenylenediamine) (PoPD) film that was obtained from electrodepositing CuNPs onto PoPD film electropolymerized on glassy carbon electrode (GCE). The CuNPs/PoPD/GCE exhibited remarkable catalytic activity for glucose oxidation with a fast amperometric response, a low detection limit, and a wide linear range in alkaline solution.

Experimental

Materials

Glucose, o-phenylenediamine (o-PD) and other chemicals were obtained from the Chemical Reagent Company of Shanghai (Shanghai, China). All the reagents were of analytical grade and used without further purification. The water used in this study was deionized by milli-Q Plus system (Millipore, France) having 18.2-MΩ electrical resistivity.

Apparatus

Electrochemical experiments were performed with a CHI 1232 electrochemical workstation (Chenhua Instruments Company, Shanghai, China) with a conventional three-electrode system. A modified electrode, an Ag/AgCl, and a platinum electrode were used as the working electrode, reference, and the auxiliary electrode respectively. Atomic force microscopy (AFM) images were carried out in the AFM (Nanoscope III, Waeco, USA). Scanning electron microscope (SEM) measurements were conducted on an S-4800 II FESEM (Hitachi High-Technologies Corporation, Japan) and energy-dispersive X-ray spectroscopy (EDS) was performed on an EDAX instrument (Genesis XM2, USA). The accelerating voltage and working distance were 20.0 kV and 15 mm, respectively. Magnetic stirrers (85–1; Keeler Instruments Company, Nanjing, China) and a Mettler-Toledo FE20 pH meter (Shanghai, China) were adopted. All experiments were carried out at room temperature (25 °C).

Cu NPs/PoPD composite sensor preparation

GCE (Φ 3 mm) was polished with alumina paste (0.3 and 0.05 μm) on a soft polishing cloth, and then GCE was cycled in the potential range of −0.2 to 0.8 V at a scan rate of 100 mV/s in 0.1 M H2SO4 until the stable cyclic voltammograms (CVs) were obtained. Thereafter, the PoPD film was fabricated on a GCE surface by electropolymerizing o-PD in an aqueous solution of 80 mM o-PD solutions with 0.1 M H2SO4. Figure 1 shows the cyclic voltammograms (CVs) of GCE in 0.1 M H2SO4 solution containing 80 mM o-PD. This is the process that o-PD electropolymerization onto the surface of GCE. In the first anodic scan, there were two irreversible anodic peaks at 0.55 V (O1) and 1.08 V (O2), respectively, which were ascribed to the oxidation of o-PD that resulted in the polymerization of o-PD [25, 28].

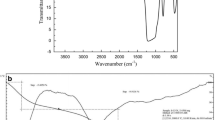

Next, Cu-NPs were electrodeposited onto the PoPD film in 0.1 M H2SO4 solution containing 0.01 M CuSO4 under a fixed applied potential of 0.5 V (vs. Ag/AgCl) for 400 s. Figure 2 shows an obvious Cu peak is detected by energy-dispersive X-ray spectroscopy (EDS), which indicated that Cu had been successfully electrodeposited onto PoPD film-modified electrode.

Electrochemical test

The electrochemical characterization of the modified electrode was evaluated using cyclic voltammetry (CV) in 0.1 M NaOH. The current response measurements were performed in NaOH with a potential of 0.50 V, and then detected glucose concentration in human blood under the same conditions.

Results and discussion

Characterization of the CuNPs/PoPD-modified electrode

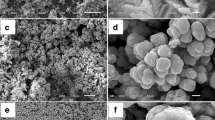

Figure 3 shows the AFM and SEM images of a bare GCE (a), a PoPD/GCE (b), and a CuNPs/PoPD/GCE (c) composite-modified electrode. In the AFM image (b), there are PoPD films covered on the electrode surface, and Cu nanoparticles are dispersed onto the PoPD films uniformly. The SEM images clearly indicated that Cu NPs were uniformly attached to the electrode surface, with an average diameter in the range of 5 to 30 nm. From AFM and SEM images, it was confirmed that PoPD films and CuNPs were attached to the electrode surface.

Electrocatalytic activity of CuNPs/PoPD/GCE towards glucose oxidation

To understand electrocatalytic activity of the Cu NPs/PoPD-modified GCE towards glucose oxidation, cyclic voltammograms (CVs) of the bare GCE (curve a), PoPD/GCE (curve b), and Cu NPs/PoPD/GCE (curve c) in 0.10 M NaOH containing 0.65 mM glucose were investigated, and the result was shown in Fig. 4. As can be seen in Fig. 4, compared with other two electrodes, the Cu NPs/PoPD/GCE led a dramatic increase of current response at 0.5 V, which indicated that the Cu NPs/PoPD modified electrode caused an increased electrocatalytic activity towards the oxidation of glucose. Meanwhile, we can also observe that the Cu NPs/PoPD/GCE produced an evident increase of current signal at 0.2 V compared with the bare GCE and PoPD/GCE, which is attributed to the oxidation of Cu. The possible mechanism for the oxidation of glucose in alkaline media at Cu NPs/PoPD/GCE is that Cu (III) species such as CuOOH or Cu (OH)4 − are considered as the strong oxidizing agent for electrocatalyzing glucose [8, 29, 30]. The first is that Cu is electrochemical oxidized into CuO in NaOH solution. And then CuO is electrochemically oxidized into strong oxidizing agent of Cu(III) species such as CuOOH or Cu(OH)4 −. Finally, glucose is catalytically oxidized by the Cu(III) species and forms hydrolyzate gluconic acid.

Figure 5 shows the CVs of the Cu NPs/PoPD modified electrode in 0.1 M NaOH in the absence and the presence of glucose by sweeping the potential between −0.8 and 0.5 V at a scan rate of 100 mV/s. The CVs shows that the CuNPs/PoPD modified electrode led an increasing current response with the concentration of glucose at around 0.5 V, which also indicated that glucose could be irreversibly oxidized at the CuNPs/PoPD modified electrode. In the case of the CuNPs electrodeposited onto PoPD layer, CuNPs grown on the surface of the non-conducting polymer film, through the inert polymer matrix, remained in electronic contact with the underlying substrate and acted as an electrocatalytic center for glucose oxidation.

Effect of the applied potential on the current response

Applied potential is an important parameter in chronoamperometry. Figure 6 shows the effect of the applied potential on the amperometric response to 60 μM glucose. From Fig. 6, it can be seen that the glucose oxidation exhibited strong electrocatalytic activity at an applied potential of 0.50 V. It was evident that Cu NPs electrodeposited on PoPD film showed strong electrocatalytic activity towards glucose oxidation. So the potential of 0.50 V was chosen as the optimum applied potential in our experiments.

Selection of the optimal operation conditions

Figure 7 shows the effect of the amount of PoPD on the response current for glucose oxidation in 0.1 M NaOH containing glucose of 60 μM. Firstly, we had investigated that the CuNPs/PoPD/GCE was constructed by electropolymerizing o-PD in a solution with different concentrations of o-PD and then electrodepositing Cu NPs onto the PoPD film surface. From Fig. 7a, we could see an obvious rise in the response current with the increase of o-PD concentration, and reaching the maximum value at 80 mM. This can be explained that lower o-PD concentration resulted in few PoPD electropolymerized on the electrode surface and prevented more CuNPs from depositing on the PoPD film, which reduced the electrocatalytic activity [29]. With the continuous increase of o-PD, the current decreased gradually, which produced compact PoPD film on the electrode surface and decreased the active area of CuNPs. So 80 mM o-PD was selected as the optimal concentration. The number of scanning cycles affects the uniformity, porosity, permeability, and thickness of the PoPD film on GCE [26]. Figure 7b shows the effect of the PoPD scanning cycles on the response current. With the increase of scanning cycles, the response currents of glucose rose. This is because less scanning cycles formed a smaller amount of thin PoPD film on the GCE surface, which reduced the deposition of CuNPs on the films and produced a poor catalytic activity to glucose. While the number of scanning cycles increased the thickness of PoPD film, the porosity decreased accordingly, diminishing the exposed copper particles surface available for the glucose molecules. As shown in Fig. 7b, 25 cycles was chosen as the optimal number of scanning cycles.

Figure 8 shows the effect of the electrodeposition time of CuNPs on the response current. The glucose oxidation signal rises with the increase in the amount of deposited copper, which is due to the increase of the exposed metal surface [31]. When the electrodeposition time increased to 400 s, the response current reached maximum value. Then the response current began to decrease when the electrodeposition time increased further, which might obtain bigger CuNPs and decrease the electrocatalytic ability. Thus, 400 s was chosen as the optimal electrodeposition time.

Amperometric determination of glucose

The amperometric response measurements of Cu-NPs/PoPD modified electrode were performed for the successive addition of 1.0 μM glucose in 0.1 M NaOH at 0.50 V under gently stirring. Figure 9a shows a typical current–time plot for the CuNPs/PoPD/GCE upon the consecutive addition of glucose. The response current increased with the successive addition of glucose. The response currents reached a steady-state current signal within 1 s, indicating a fast response of the sensor. Figure 9b displays the corresponding calibration curve for glucose. The linear response range of the biosensor to glucose was from 5.0 μM to 1.6 mM and the corresponding linearity (R) was 0.998, and the detection limit was 0.25 μM. The response speed, detection limit, and linear range of the proposed glucose sensor were compared with non-enzymatic glucose sensors based on nanostructured Cu that had reported in recent two years, as summarized in Table 1. From the presented data in Table 1, our proposed sensor exhibits relatively fast response speed, low detection limits, and wide linear range.

Anti-interference study

Ascorbic acid (AA) and uric acid (UA) are well-known main interferents on the amperometric response of glucose. To evaluate the selectivity of the proposed biosensor, AA and UA were examined. Considering that the concentration of glucose in the healthy human blood is more 30 times that of AA and UA [32], 60 μM glucose, 6 μM DA, 6 μM AA, and 6 μM UA were successively added to 0.1 M NaOH for the amperometric response measurement of the CuNPs/PoPD/GCE, and the results were shown in Fig. 10. As can be seen in Fig. 10, insignificant responses were observed for interfering electroactive species. These small responses for DA, AA, and UA can be neglected. In other words, the CuNPs/PoPD/GCE shows good selectivity for glucose detection. Furthermore, some main coexist ions in human blood (Na+, K+, NH3 +, Ca2+, Fe2+, Cl−, PO4 3−), maltose, icodextrin, galactose, and xylose were also examined, and all the effects could be ignored. The results indicated our electrode has high selectivity. Therefore, the sensor can be used for blood glucose detection effectively.

Reproducibility, repeatability, and stability of the sensor

The response reproducibility of six electrodes, prepared under the same optimum conditions, was estimated in 0.1 M NaOH at 0.50 V by the response to 60 μM glucose. A mean current response of 4.89 μA and a relative standard deviation (R.S.D.) of 3.8 % were yielded. The repeatability of the determination was investigated at 0.50 V and 25 °C in 0.10 M NaOH containing 60 μM glucose, which yielded a relative standard deviation of 3.5 % for ten continuous determinations of the same sample by using one proposed electrode. The results indicated that the proposed electrode has good reproducibility and repeatability. The proposed electrodes were stored at room temperature, and their long-term stability was tested over 4 months. The measurements were taken under the same conditions, which yielded a relative standard deviation of 3.7 %. The measurement results indicated that the response current did not show obvious decrease, thereby exhibiting long-term stability.

Determination of glucose in human blood samples

The sensor was used to determine the glucose in human blood samples. Blood samples were obtained from healthy humans who complied with fasting blood test requirements. Human blood samples were mixed and diluted in NaOH, and the amperometric response measurements were performed under the optimum conditions at an applied potential of 0.50 V. The results of glucose concentrations in blood samples are listed in Table 2. Recoveries in blood samples were from 96.3 to 102.8 %.

The glucose concentrations in fresh human blood samples obtained from our experiments were compared with those measured by the hospital with an YSI Model 2300 Glucose Analyzer (Yellow Springs Instruments, Yellow Springs, OH). The YSI analyzer uses a GO based method to measure glucose. The results are listed in Table 3. The bias for each sample is less than 0.3 mM. This comparison clearly shows that our results satisfactorily agree with those obtained in the hospital.

Conclusions

In conclusion, a non-enzymatic glucose sensor based on Cu-NPs and PoPD was developed. The response of the proposed electrode to glucose concentrations presented a good linearity over the range of 5.0 μM to 1.6 mM. The study provided an easy way for the determination of glucose in human blood. The current response time for steady-state current was within 1 s. The applicability of the method to the determination of glucose in human blood was demonstrated. As a non-enzymatic sensor, the analytical results were satisfactory for the detection of glucose in human blood. The newly developed non-enzymatic glucose sensor shows various excellent characteristics such as low cost, fast response, acceptable sensitivity, reproducibility, selectivity, and long-time stability.

References

Liu Y, Javvaji V, Raghavan SR, Bentley WE, Payne GF (2012) Glucose oxidase-mediated gelation: a simple test to detect glucose in food products. J Agric Food Chem 60:8963–8967

Yoo EH, Lee SY (2010) Glucose biosensors an overview of use in clinical practice. Sensors 10:4558–4576

Chen C, Xie QJ, Yang DW, Xiao HL, Fu YC, Tan YM, Yao SZ (2013) Recent advances in electrochemical glucose biosensors: a review. RSC Adv 3:4473–4491

Zhang YC, Liu YX, Su L, Zhang ZH, Huo DQ, Hou CJ, Lei Y (2014) CuO nanowires based sensitive and selective non-enzymatic glucose detection. Sensors Actuators B 191:86–93

Heller A, Feldman B (2008) Electrochemical glucose sensors and their applications in diabetes management. Chem Rev 108:2482–2505

Park S, Boo H, Chung TD (2006) Electrochemical non-enzymatic glucose sensors. Anal Chim Acta 556:46–57

Choi T, Kim SH, Lee CW, Kim H, Choi SK, Kim SH, Kim E, Park J, Kim H (2015) Synthesis of carbon nanotube–nickel nanocomposites using atomic layer deposition for high-performance non-enzymatic glucose sensing. Biosens Bioelectron 63:325–330

Fan Z, Liu B, Liu X, Li Z, Wang H, Yang S, Wang J (2013) A flexible and disposable hybrid electrode based on Cu nanowires modified graphene transparent electrode for non-enzymatic glucose sensor. Electrochim Acta 109:602–608

Veerappan G, Bojan K, Rhee SH (2011) Sub-micrometer-sized graphite as a conducting and catalytic counter electrode for dye-sensitized solar cells. ACS Appl Mater Interfaces 3:857–862

Zhao Y, Zhao J, Ma D, Li Y, Hao X, Li L, Yu C, Zhang L, Wang Z (2012) Synthesis, growth mechanism of different Cu nanostructures and their application for non-enzymatic glucose sensing. Colloids Surf A Physicochem Eng Asp 409:105–111

Ensafi AA, Abarghoui MM, Rezaei B (2014) A new non-enzymatic glucose sensor based on copper/porous silicon nanocomposite. Electrochim Acta 123:219–226

Zhao J, Wei L, Peng C, Su Y, Yang Z, Zhang L, Wei H, Zhang Y (2013) A non-enzymatic glucose sensor based on the composite of cubic Cu nanoparticles and arc-synthesized multi-walled carbon nanotubes. Biosens Bioelectron 47:86–91

Li Y, Fu J, Chen R, Huang M, Gao B, Huo K, Wang L, Chu PK (2014) Core–shell TiC/C nanofiber arrays decorated with copper nanoparticles for high performance non-enzymatic glucose sensing. Sensors Actuators B 192:474–479

Jiang D, Liu Q, Wang K, Qian J, Dong X, Yang Z, Du X, Qiu B (2014) Enhanced non-enzymatic glucose sensing based on copper nanoparticles decorated nitrogen-doped graphene. Biosens Bioelectron 54:273–278

Yoon SS, Ramadoss A, Saravanakumar B, Kim SJ (2014) Novel Cu/CuO/ZnO hybrid hierarchical nanostructures for non-enzymatic glucose sensor application. J Electroanal Chem 717–718:90–95

Wang B, Li S, Liu J, Yu M (2014) Preparation of nickel nanoparticle/graphene composites for non-enzymatic electrochemical glucose biosensor applications. Mater Res Bull 49:521–524

Sun CL, Cheng WL, Hsu TK, Chang CW, Chang JL, Zen JM (2013) CuO/graphene-modified screen-printed carbon electrode integrated with flow-injection analysis. Electrochem Commun 30:91–94

Sun F, Li L, Liu P, Lian YF (2011) Nonenzymatic electrochemical glucose sensor based on novel copper film. Electroanalysis 23:395–401

Li CL, Su Y, Zhang SW, Lv XY, Xia HL, Wang YJ (2010) An improved sensitivity nonenzymatic glucose biosensor based on a CuOx modified electrode. Biosens Bioelectron 26:903–907

Liu GY, Zheng BZ, Jiang YS, Cai YQ, Du J, Yuan HY, Xiao D (2012) Improvement of sensitive CuO NFs-ITO nonenzymatic glucose sensor based on in situ electrospun fiber. Talanta 101:24–31

Rassaei L, Amiri M, Cirtiu CM, Sillanpaa M, Marken F, Sillanpaa M (2011) Nanoparticles in electrochemical sensors for environmental monitoring. TrAC Trends Anal Chem 30:1705–1715

Kalita G, Matsushima M, Uchida H, Wakita K, Umeno M (2010) Graphene constructed carbon thin films as transparent electrodes for solar cell applications. J Electroanal Chem 20:9713–9717

Xiao Y, Li CM (2008) Nanocomposites: from fabrications to electrochemical bioapplications. Electroanalysis 20:648–662

Malitesta C, Guascito MR, Mazzotta E, Siciliano T, Tepore A (2013) Copper nanoparticles/poly-3-methylthiophene composite: synthesis, characterization and catalytic application to enzyme-less glucose detecting. Sensors Actuators B 184:70–77

Bilal S, Holze R (2006) Electrochemical copolymerization of o-toluidine and o-pheny-lenediamine. J Electroanal Chem 592:1–13

Adhikari B, Majumdar S (2004) Polymers in sensor applications. Prog Polym Sci 29:699–766

Vidal JC, Méndez S, Castillo JR (1999) Electropolymerization of pyrrole and phenylenediamine over an organic conducting salt based amperometric sensor of increased selectivity for glucose determination. Anal Chim Acta 385:203–211

Losito I, Palmisano F, Zambonin PG (2003) O-Phenylenediamine electropoly-merization by cyclic voltammetry combined with electrospray ionization-ion trap mass spectrometry. Anal Chem 75:4988–4995

Luo L, Zhu L, Wang Z (2012) Nonenzymatic amperometric determination of glucose by CuO nanocubes-graphene nanocomposite modified electrode. Bioelectrochemistry 88:156–163

Wang J, Zhang WD (2011) Fabrication of CuO nanoplatelets for highly sensitive enzyme-free determination of glucose. Electrochim Acta 56:7510–7516

Stoyanova AR, Tsakova VT (2008) Electrooxidation of glucose on copper-modified polyaniline layers in alkaline solution. Bulg Chem Commun 40:286–290

Kumar SA, Cheng HW, Chen SM, Wang SF (2010) Preparation and characterization of copper nanoparticles/zinc oxide composite modified electrode and its application to glucose sensing. Mater Sci Eng C 30:86–91

Acknowledgments

The work was supported by the National Natural Science Foundation of China (grant nos. 20975091 and 21375116). FESEM and EDS provided by Test Center of Yangzhou University were employed in the experiment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Chen, Y., Lv, H. et al. Construction of a non-enzymatic glucose sensor based on copper nanoparticles/poly(o-phenylenediamine) nanocomposites. J Solid State Electrochem 19, 731–738 (2015). https://doi.org/10.1007/s10008-014-2659-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2659-9