Abstract

High specific capacitance and low cost are the critical requirements for a practical supercapacitor. In this paper, a new activated carbon with high specific capacitance and low cost was prepared, employing cotton stalk as the raw material, by using the phosphoric acid (H3PO4) chemical activation method. The optimized conditions were as follows: the cotton stalk and activating agent with a mass ratio of 1:4 at an activation temperature of 800 °C for 2 h. The samples were characterized by nitrogen adsorption isotherms at 77 K. The specific surface area and pore volume of activated carbon were calculated by Brunauer–Emmett–Teller (BET) and t-plot methods. With these experimental conditions, an activated carbon with a BET surface area of 1,481 cm2 g−1 and micropore volume of 0.0377 cm3 g−1 was obtained. The capacitance of the prepared activated carbon was as high as 114 F g−1.The results indicate that cotton stalk can produce activated carbon electrode materials with low cost and high performance for electric double-layer capacitor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is well known that fossil fuel-based energy causes lots of economic and environment problems in the world. Growing energy demand, depleting resources of fossil fuel, and increasing environmental concerns, including the emission of greenhouse gases and local air pollutants, have driven the search for developing alternative energy storage with high power and energy density. Supercapacitor is the most promising electrochemical energy storage device because of its higher power density and longer cycle life compared with the secondary battery. It has been widely used in the information technology industry, such as electronic devices, electric vehicles, military equipment, and high power energy storage devices with an ever decreasing size [1–4].

One of the most important components of a supercapacitor is the electrode. For electric double-layer capacitor (EDLC) electrodes, the common materials are metal oxides, polymers, and porous materials such as activated carbon and carbon aerogel. Moreover, new carbon materials, such as carbon nanotube, have been developed as electrode material, but there are difficulties in practical application due to their complicated preparation and high cost [5]. Compared with other carbon materials, activated carbon is more suitable as supercapacitor electrode material because of its high specific surface area and low cost. In addition, using biomass waste materials to prepare activated carbons is becoming a trend in the preparation of electrode materials for EDLC. Many carbon electrodes of EDLC obtained from biomass materials, such as nutshell [6], banana fiber [7], firewood [8, 9], corn grain [10], bamboo [11], rice husk [12], sunflower seed shell [13], cherry stone [14], and fluff of chinar [15] have been reported.

Cotton is known as one of the most important agricultural commodities in China, which is used to make a number of textile products. As the largest cotton-planting nation in the world, China has an average of 533,300 ha2 of cotton. Cotton stalks are discarded by cotton planters after picking the cotton, weighing 3,375 to 3,750 kg ha−2 and amounting to 1.53 million tons in China every year [16, 17]. As a kind of agricultural wastes, they are directly burned as fuels in the countryside. The rest is dumped in the field, which causes great waste. The discarded cotton stalks are rich in lignin so that it can be made into activated carbon that has a wide range of use and high additional value. This is an efficient way to utilize discarded cotton stalk resources.

Activated carbons with a wide variety of pore size distribution are obtained by modifying the preparation conditions of either a physical or chemical activation process. In both methods, there is a reaction of the precursor with the activating agent (H3PO4, ZnCl2, KOH, etc.) to develop porosity, but they differ not only in practical procedure but also in the mechanism by which the activating agent develops such porosity [18, 19]. Previous investigations proved its effectiveness in producing excellent activated carbon from cotton stalks [20–23]. As is well known, the chemical constitution of the H3PO4 solution used with preparative purposes is a very sensitive property to the increase in its concentration [24]. The activation temperature is one of the factors that affect the performance of active carbon. Figure 1 illustrates the changes in weight as a function of heat for both the cotton stalk precursor and its H3PO4-treated sample. A comparison between the two tracks indicates that the impregnation of phosphoric acid delayed the main thermal degradation of the raw material. The whole pyrolysis process could be divided into three stages. The first stage occurs between ambient temperature and 600 °C, and a minor weight loss observed is mainly due to H2O release by evaporation and the sample decomposed to uncondensable gas (CO, CO2, CH4, H2) [25]. The second stage is in the temperature range of 600–800 °C and the strongest weight loss observed is attributed to the thermal decomposition of the raw material; these reactions are accompanied by further chemical transformations that include dehydration, degradation, and condensation with a loss of aliphatic character and a corresponding increase in aromaticity and simultaneous release of gases [20].The third stage appears over a wide temperature range from 800 °C to the final temperature and a slight weight loss. It is indicated that the active sites on the carbons had reacted completely and H3PO4 on the botanical structure through the penetration and dissolving of some components by breaking chemical bonds; it is followed by recombination to form more thermally stable new polymeric and aromatic structures. So, the activation temperature of 800 °C is more perfect than others for the preparation of activated carbon from cotton stalk [21–23].

In this paper, cotton stalks were used as the raw material for preparing the supercapacitor’s electrode material. The cotton stalk activated carbons (ACs) were modified by H3PO4 to improve their surface chemistry performances and pore structures. The influence of chemical activation on the capacitance of activated carbon electrode was observed, and the relationship between the surface chemistry characteristics, pore structures of modified ACs, and the capacitance were researched in order to obtain the highest capacitance.

Experiments

Preparation of activated carbon-based cotton stalk

The dried cotton stalk was pulverized to 200 μm after the powder samples were treated with an aqueous solution of H3PO4 (50 wt.%) for 12 h at a mass ratio of cotton stalk to activating agent (H3PO4) ranging from 1:2 to 1:5. Then, the mixture was dried, heated up to 800 °C under nitrogen atmosphere with a heating rate of 5 °C min−1, and allowed to dwell in that temperature for 2 h, followed by cooling down to room temperature. The activated carbon products were washed sequentially with 0.5 mol L−1 NH3·H2O to neutralize the excess H3PO4 compounds. The samples were washed repeatedly with distilled water until the pH of the washing solution reached 7. The final activated carbon samples were dried at 90 °C in a vacuum oven for 12 h and stored in desiccators. The samples were labeled as AC-x, (AC1, AC2, AC3, and AC4 are H3PO4-to-carbon mass impregnation ratios 1:2, 1:3, 1:4, and 1:5, respectively). All chemicals were of analytical grade and used as received.

Preparation of electrode and supercapacitor

The electrochemical performances of all carbon samples were investigated by using CR2025 coin cell without a reference electrode. The electrodes were composed of activated carbon, carbon black as an electronic conductor, and polyvinylidene fluoride as a binder in a weight ratio of 80:15:5. They were blended in distilled water to form a slurry. The mixed slurry was pressed onto aluminum foil current collectors (Φ 1.2 cm) and dried at 120 °C for 8 h to fabricate electrodes in vacuum oven. The cells (CR2025) were assembled in an argon-filled glove box. Two electrodes with identical or very close masses were selected and then assembled as supercapacitor. All of the measurements were carried out in 1.0 mol L−1 Et4NBF4 electrolyte. The supercapacitor was charged and discharged from 0 to 3.5 V on the charge/discharge apparatus (BTS-51, Neware, China). Cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) were tested using a CHI660 electrochemical working station.

Results and discussion

Raw material analysis

The proximate analysis of cotton stalk indicated that this raw material contained 44.47 % of fixed carbon, 5.60 % of hydrogen, 0.53 % of nitrogen, and 49.47 % of oxygen [16, 23]. The proximate analysis result shows that the carbon content of cotton stalk is higher than the other biomass resources. As comparison, the fixed carbon content of several raw materials for activated carbon production is as follows: cassava peel waste—28.7 % [26], bamboo—16.60 % [27], rubber wood sawdust—23.38 % [28], and palm shell—18.70 % [29].

Compared with other materials, cotton stalk has a higher density of carbon and a larger weight ratio of active material to the capacitor with a certain volume. From the view of practical application, it is a potential raw material for the preparation of activated carbon.

Physical characterization

The physical characterization of activated carbon was conducted by using nitrogen adsorption method and scanning electron microscopy (SEM). Nitrogen desorption was carried out to determine the pore structure of the carbon and SEM analysis was conducted to observe the surface morphology of activated carbon samples. The pore characteristics of the obtained carbon were measured by a Micromeritics (ASAP2010) instrument in nitrogen at 77 K. Mesopore size distributions were determined by Brunauer–Emmett–Teller (BET) method. The micropore volume (V mic) and the total pore volume (V tot) were calculated from the amount of N2 adsorbed at a relative pressure (p/p 0) of 10−5 and 0.95, respectively. Carbon was degassed at 473 K in a vacuum condition for a period of at least 24 h.

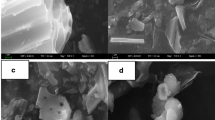

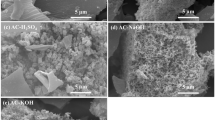

The SEM image of the samples demonstrated in Fig. 2 depicts the surface morphology of the activated carbons. It can be seen that a different surface morphology was observed for all activated carbons studied. They were changed by the addition of H3PO4 as a chemical activation agent. The surface modifications have a significant effect on the surface area and pore distribution of the activated carbons.

The effect of activation on pore characteristic

As known, the specific capacitance of electrode materials is related to the BET surface area and the pore structure. The pore characteristics of these samples are given in Table 1. It can be seen that the BET surface area of activated carbon derived from cotton stalk was higher than peanut shell-based microporous carbon (726 m2 g−1) [30] and commercial activated carbons available in Indonesia (500–700 m2 g−1) [26]. These pore structures are the combination of micropore and mesopore volumes, which is supported by the pore distribution of activated carbons determined by BET and t-plot method. Figure 3a shows the nitrogen adsorption isotherms of these samples at 77 K. This result indicates that H3PO4 activation greatly enhanced the pore development during the chemistry activation process. Compared with other samples, the nitrogen adsorption isotherms of AC3 have an evident type IV isotherm; a hysteresis loop can be observed in the adsorption/desorption isotherms, indicating the existence of mesopore size in modified activated carbons after H3PO4 activation. For comparison, the pore size of AC3 is shown in Fig. 3b, and it is clearly indicated that the pore volume of AC3 is the larger among all of the samples.

The electrochemical capacitance has a close correlation with the pore diameter distribution based on the “double electric layer” energy storage mechanism [30, 31]. We can draw the conclusion that the pores with their diameter distribution from 2 to 3 nm have the most important contribution to the electrochemical characteristic of samples in our system.

AC3 has the highest total pore volume and mesopore volume among all the ACs investigated. The peak pore size of AC3 centered at 3 nm. Comparing with other sample contents of mesopores, AC3 has a larger specific surface area and micropore volume, which are the main factors for higher specific capacitance.

Electrochemical measurements

The charge–discharge curves of ACs between 0 and 3.5 V at the current density of 0.5 A g−1 are shown in Fig. 4. It can be seen that no obvious voltage drop can be observed at the beginning of the discharge process for the electrode, and the charge–discharge curves at the current density of 0.5 A g−1 were regularly of triangular shapes, showing better capacitor behavior for this material. The initial voltage drop observed in the charge–discharge profiles indicated that the electrochemical impedance is relatively small. It was also found that the specific capacitance of AC3 is significantly larger than those of other samples at the same current densities, and it is the best electrode material in the samples. Besides, it can be seen that a drastic change in the capacitance value occurred when the current density increased from 0.5 to 2 A g−1 (shown in Fig. 5). This can be easily understood as follows [32]: at a low current density, the ion can be transported and diffused into the pores easily. Hence, the capacitance is higher. However, when the current density increases, the ion cannot be easily diffused into the pores, which results in such a way that the effective ion attachment occurred only at the surface of the electrode. As a result, the capacitance decreases. Based on the evaluation in the entire experimental result, the highest capacitance value that can be obtained was AC3. Its capacitance value is as high as 114 and 98 F g−1 at a current density of 0.5 and 2 A g−1 from Fig. 6, respectively. Actually, this capacitance value is relatively higher than those of other electrode materials for supercapacitor application from a biomass precursor [33, 34]. Owing to its simple preparation process and the availability of the simple source in a large scale, activated carbon from cotton stalk exhibits excellent electrochemical performance especially at high current density.

The specific capacitance C of the electrode can be calculated by the following equation [35–37]:

where ∆t is the discharge time, ∆V is the voltage change during discharge, I is the discharge current, and m is the mass of active material on one electrode.

For further understanding of the electrochemical performances, the cyclic charge–discharge tests were performed at a fair current density of 2 A g−1 in 1 mol L−1 Et4NBF4 electrolytes, and the corresponding results are shown in Fig. 7. As shown in Fig. 7, the specific capacitance of AC3 in 1 mol L−1 Et4NBF4 electrolyte is up to 98 F g−1 at 2 A g−1 and keeps remarkably stable over 500 cycles, which shows that the high capacitance retention ratio is 95.3 %. These results demonstrate that the activated carbons derived from cotton stalk exhibit better cycle stability and a very high degree of reversibility during repetitive charge/discharge cycles in organic electrolytes. Figure 8 demonstrates that the AC materials have long-term electrochemical stability, but the AC3 electrode has higher capacitance and better electrochemical stability than the other materials, which proves again that AC3 can be used as electrode material.

The CV measurement was performed from 0 to 3.5 V with a scanning rate at 50 mV s−1. As shown in Fig. 9, all curves have similar and symmetric rectangular shapes between positive and negative scanning rate, indicating the good reversibility characteristic of EDLC during charge and discharge process of carbon electrode. The cyclic voltammogram of AC3 had a broader area compared with other electrode materials, indicating that the capacitance of the sample AC3 is higher than those of others. This evidence supports the result of the galvanostatic charge–discharge experiment.

The EIS analysis has been one of the effective methods in examining the fundamental behavior of electrode materials for supercapacitor. It was performed by Nyquist plots at an applied potential of 3.5 V and frequency range between 10−2 and 105 Hz. As shown in Fig. 10, all the impedance spectra of these samples are almost similar, which contain a distorted semicircle in the high frequency region due to porosity of the electrode and a linear part at the low frequency region due to diffusion-controlled doping and undoping of anions that result from Warburg behavior. The high-frequency intercept in the semicircle with the real axis gives the internal resistance value of these cell capacitors. It is the sum of the resistance of the electrolyte solution, the intrinsic resistance of the active material, and the contact resistance at the interface active material/current collector. The internal resistance of AC electrode is estimated to be about 3 Ω, which is the same for all samples. From the point of intersecting with the real axis in the range of low frequency, the AC3 resistance was estimated to be 30 Ω for the activated carbon electrode, which is a little bit lower than those of other electrode materials, and the vertical line exhibits the domination of the capacitance behavior at the electrolyte/carbon interface. It can be deduced that the high electrochemical performance of the AC3 in our work can be attributed to the predominant production of porosity material with high electrical conductivity.

Conclusions

Activated carbon has been prepared from cotton stalk. The H3PO4 activation processes on the samples have improved the physical and electrochemical properties of the active carbon, such as BET surface area, micropore volume, electrical conductivity, and specific capacitance. The sample AC3 has the highest BET surface area and micropore volume at a temperature of 800 °C with its value of 1,481 m2 g−1 and 0.0377 cm3 g−1, respectively. The capacitances of the samples were found to cause the electrical conductivity to increase linearly with increased activation mass ratio. The sample AC3 showed a supercapacitive effect with a capacitance value as high as 114 F g−1 at 0.5 A g−1 and 98 F g−1 at 2 A g−1. Besides, it also displays a high-rate long-cycle electrochemical performance even at a current density of 2 A g−1 and a capacitance retention ratio of 95.3 %. Owing to the unique characteristic, the simple preparation, and the large availability of material, the cotton stalk will become one kind of potential material for supercapacitor electrode.

References

Ding LL, Wang ZC, Li YN, Du YL, Liu HQ, Guo YP (2012) A novel hydrochar and nickel composite for the electrochemical supercapacitor electrode material. Mater Lett 74:111–114

Ragupathy P, Vasan HN, Munichandraiah N (2008) Synthesis and characterization of nano-MnO2 for electrochemical supercapacitor studies. J Electrochem Soc 155:A34–A40

Liu EH, Meng XY, Ding R, Zhou JC, Tan ST (2007) Potentiodynamical co-deposited manganese oxide/carbon composite for high capacitance electrochemical capacitors. Mater Lett 61:3486–3489

Cao GF, Zhang LY, Chen XH, Jin H (2011) Preparation and characterization of peasecod-based activated carbons as electrode materials for electrochemical double-layer capacitors. Acta Phys Chim Sin 27:1679–1684

Liu YF, Hu ZH, Xu K, Zheng XW, Qiang G (2008) Surface modification and performance of activated carbon electrode material. Acta Phys Chim Sin 24:1143–1148

Ahmadpour A, Do DD (1997) The preparation of activated carbon from macadamia nutshell by chemical activation. Carbon 35:1723–1732

Subramanian V, Luo C, Stephan AM, Nahm KS, Thomas S, Wei BJ (2007) Supercapacitors from activated carbon derived from banana fibers. J Phys Chem C 111:7527–7531

Wu FC, Tseng RL, Hu CC, Wang CC (2004) Physical and electrochemical characterization of activated carbons prepared from firwoods for supercapacitors. J Power Sources 138:351–359

Wu FC, Tseng RL, Hu CC, Wang CC (2005) Effects of pore structure and electrolyte on the capacitive characteristics of steam- and KOH-activated carbons for supercapacitors. J Power Sources 144:302–309

Balathanigaimani MS, Wang GS, Lee MJ, Chan K, Lee JW, Hee M (2008) Highly porous electrodes from novel corn grains-based activated carbons for electrical double layer capacitors. Electrochem Commun 8:868–871

Wang XF, Tian Y (2010) Electrochemical performance of bamboo based activated carbon as electrodes in aqueous and organic electrolytes. Int Mater Rev 24:21–27

Guo YP, Qi JR, Jiang YQ, Yang SF, Wang ZC, Xu HD (2003) Performance of electrical double layer capacitors with porous carbons derived from rice husk. Mater Chem Phys 80:704–709

Li X, Xing W, Zhuo S, Zhou J, Li F, Qiao SZ, Lu GQ (2011) Preparation of capacitor's electrode from sunflower seed shell. Bioresour Technol 102:1118–1123

Olivares-Marína M, Fernández JA, Lázaro MJ, Fernández-González C, Macías-García A, Gómez-Serrano V, Stoeckli F, Centenob TA (2009) Cherry stones as precursor of activated carbons for supercapacitors. Mater Chem Phys 114:323–327

Ma YW, Xiong CY, Huang W, Zhao J, Li XA, Fan QL, Huang W (2012) Preparation of carbon microtubes by carbonizing the fluff of chinar tree and their application as supercapacitor electrodes. Chin J Inorg Chem 28:546–550

Akdeniz RC, Acaroglu M, Arif H (2004) Cotton stalk as a potential energy source. Energ Source 26:65–75

Prahas D, Kartika Y, Indraswatin N (2008) Activated carbon from jackfruit peel waste by H3PO4 chemical activation: Pore structure and surface chemistry. Chem Eng J 140:32–42

Stoeckli HF (1990) Microporous carbons and their characterization the present state of the art. Carbon 28:1–6

Girgis BS, Ishak MF (1999) Activated carbon from cotton stalks by impregnation with phosphoric acid. Mater Lett 39:107–114

Rufford TE, Hulicova-Jurcakova D, Khosla K, Zhu ZH, Lu GQ (2010) Microstructure and electrochemical double-layer capacitance of carbon electrodes prepared by zinc chloride activation of sugar cane bagasse. J Power Sources 195:912–918

Abdel-Nasser AEH, Andrew JA, Robert JA, Gavin F (2008) Microstructure and electrochemical double-layer capacitance of carbon electrodes prepared by zinc chloride activation of sugar cane bagasse. J Anal Appl Pyrolysis 82:272–278

Puziy AM, Poddubnaya OI, Alonso AM, Garcıa FS, Tascon JMD (2002) Synthetic carbons activate with phosphoric acid II. Porous structure. Carbon 40:1507–1519

Nahil MA, Williams PT (2012) Pore characteristics of activated carbons from the phosphoric acid chemical activation of cotton stalks. Biomass Bionerg 37:142–149

Marina MO, Fernandez GC, Macias GA, Gomez SV (2006) Thermal behavior of lignocellulosic material in the presence of phosphoric acid. Influence of the acid content in the initial solution. Carbon 44:2330–2356

Fu P, Hu S, Xiang J, Sun LS, Su S, An SM (2012) Study on the gas evolution and char structural change during pyrolysis of cotton stalk. J Anal Appl Pyrolysis 97:130–136

Andrian EI, Steven W (2010) Preparation of capacitor’s electrode from cassava peel waste. Bioresour Technol 101:3534–3540

Choy KKH, Barford JP, McKay G (2005) Production of activated carbon from bamboo scaffolding waste-process design, evaluation and sensitivity analysis. Chin J Chem Eng 109:147–165

Ganan J, González-Garcia CM, Gonzáleza JF, Sabioa E, Macias-Garciab A, Diaz-Diez MA (2004) Preparation of activated carbons from bituminous coal pitches. Appl Surf Sci 238:347–354

Daud WMAW, Ali WSW (2004) Comparison on pore development of activated carbon produced from palm shell and coconut shell. Bioresour Technol 93:63–69

Guo PZ, Ji QQ, Zhang LL, Zhao SY, Zhao XS (2011) Preparation and characterization of peanut-shell-based microporous carbons as electrode materials for supercapacitors. Acta Phys Chim Sin 27:0001–0009

Liang HC, Chen F, Li RG, Wang L, Deng ZH (2004) Electrochemical study of activated carbonsemiconducting oxide composites as electrode materials of double-layer capacitors. Electrochim Acta 49:3463–3467

Jiang Q, Zhao XF, Huang B, Du B, Zhao Y (2009) Effect of the activated carbon reactivation on its electrochemical capacitance. Acta Phys Chim Sin 25:757–761

Stoller MD, Park SJ, Zhu YW, An JH, Ruoff RS (2008) Graphene-based ultracapacitors. Nano Lett 10:3498–3502

Hao GP, Mi J, Li D, Qu WH, Wu TJ, Li WC, Lu AH (2011) A comparative study of nitrogen-doped hierarchical porous carbon monoliths as electrodes for supercapacitors. New Carbon Mater 26:197–203

Xu B, Chen YF, Wei G, Cao GP, Zhang H, Yang YS (2010) Activated carbon with high capacitance prepared by NaOH activation for supercapacitors. Mater Chem Phys 124:504–509

Wang MX, Wang CY, Chen MM, Wang YS, Shi ZQ, Du X, Li TQ, Hu ZJ (2010) Preparation of high-performance activated carbons for electric double layer capacitors by KOH activation of mesophase pitches. New Carbon Mater 25:285–290

Kim C, Lee JW, Kim JH, Yang KS (2006) Feasibility of bamboo-based activated carbons for an electrochemical supercapacitor electrode. Korean J Chem Eng 24:592–594

Acknowledgments

The authors are grateful for support from Advanced Carbon Materials Research Laboratory, College of Materials Science and Engineering, Beijing University of Chemical Technology. This work was supported by the “West Light” Talents Cultivation Program of the Chinese Academy of Sciences (No. XBBS200919), the Main Direction Program of the Knowledge Innovation Program of the Chinese Academy of Sciences (Grant No. KGCX2-YW-359), and the science and technology projects of Urumqi (No. K111410005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Kang, X., Wumaier, T. et al. Preparation of activated carbon from cotton stalk and its application in supercapacitor. J Solid State Electrochem 17, 1005–1012 (2013). https://doi.org/10.1007/s10008-012-1946-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-012-1946-6