Abstract

Layered LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds with interconnected spherical particles are synthesized using a novel surfactant-coassisted sol–gel process. A combination of cetyltrimethyl ammonium bromide as surfactant and citric acid as chelating agent results in the formation of hydrophobically nucleated transparent gel, which upon furnace calcination yields phase pure and growth-controlled spherical particles of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds. The compounds containing Co3+ ions, viz., LiNi0.45Mn0.45 C0.1O2 and LiNi0.4Mn0.4Co0.2O2 cathodes, exhibit good cation ordering and better electrochemical performance than LiNi0.5Mn0.5O2 cathode. The study demonstrates the superiority and suitability of LiNi0.4Mn0.4Co0.2O2 cathode over LiNi0.5Mn0.5O2 and LiNi0.45Mn0.45Co0.1O2 cathodes at 1 C rate and up to 4.6 V limit.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Majority of the commercialized cathode materials for lithium ion batteries are based on LiCoO2, but cobalt has environment-related problems that leave the door open to exploit alternative cathode materials [1]. Over the past several years, there have been concerted efforts to design Mn- or Ni-based layered LiMO2 compounds with a view to find a less expensive and safer cathode material than LiCoO2. However, LiMnO2 and LiNiO2 of LiMO2 family have hampering issues like difficulty in the synthesis of stoichiometric and stable compounds and thus remain unsuitable for practical applications.

In an electronic stabilization approach, when Mn is partially substituted by Ni in equal concentration such as 1:1 in LiMn0.5Ni0.5O2 compound, Ni is found to be in +2 state and Mn in +4 state, thus eliminating the adverse effects of Jahn–Teller distortion prone Mn3+ ions and becomes a successful cathode [2–4]. Basically, LiNi0.5Mn0.5O2 cathode offers all the advantages of LiCoO2 and a higher discharge capacity of 250 mA h g−1 (when charged up to 4.8 V) along with an apparently better chemical stability resulting from the electrochemical redox process of Ni2+/Ni4+ via Ni3+ [2–6]. It also reduces the nickel content of LiNiO2 electrode by 50 % without compromising its theoretical capacity (274 mA h g−1).

However, the major drawback of LiMn0.5Ni0.5O2 compound is that ~0.1Li+ per formula unit is found in the transition metal layer of the O3-layered structure, which displaces an equivalent amount of Ni2+ to Li+ layer [7, 8]. Such a disorder or mixing of Li+ and Ni2+ in alternative layers may also result from the fact that they have similar ionic radii (Li+ = 0.76 Å and Ni2+ = 0.69 Å). On the other hand, presence of cobalt plays a critical role in minimizing the transition metal content in the lithium layer and enhances the electronic conductivity [9, 10]. Hence, lithium–nickel–manganese compounds with smaller amount of cobalt would be a better choice to prepare tailored cathode materials with better physical and electrochemical properties. Since the charge compensation in LiNi0.5Mn0.5O2 proceeds via Ni2+ and Mn4+ in the transition metal layers, replacement of Ni2+ with an equal amount of M3+ (Co3+) and Mn4+ will maintain the charge neutrality. Based on this simple concept, two solid solutions, viz., LiNi0.45Mn0.45Co0.1O2 and LiNi0.4Mn0.4Co0.2O2, were chosen for the present study along with the parent LiNi0.5Mn0.5O2 cathode.

It is well known that the electrochemical performance of any electrode material is highly sensitive to the synthesis procedure, which strongly affects the cationic distribution in lithium-transition metal oxides [11–13]. Towards this direction, literature is replete with results of this research group [14, 15] and other groups [16–19] on the citric acid-assisted sol–gel method, where the citric acid acts as a chelating agent to produce a transparent gel and to form the desired cathode materials. Quite different from such an approach, cetyltrimethyl ammonium bromide (CTAB), a known quaternary ammonium salt, has been exploited in the present study along with the chelating citric acid in order to obtain interconnected spherical morphology.

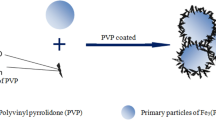

Initially, CTAB gets absorbed on the surface of precursor particles with its hydrophobic head inside and hydrophilic tail oriented away from the surface and thereby minimizes the friction between individual metal particles. Further, formation of metastable chelating complex in the form of a transparent gel is aided by the addition of citric acid and by adjusting the pH with NH4OH. Herein, the selective capping effect of CTAB by its hydrophobic regions nucleating the surface plays a vital role in forming spherical particles without agglomeration via strong surface interaction and controls the growth of the same even upon high-temperature calcinations. The chelating citric acid forms a transparent gel at an alkaline pH (consisting of CTAB-facilitated spherical particles) and renders interconnectivity between the nano spherical particles to result in the formation of spherically interconnected surface morphology with a porous structure (Scheme 1). Such a formation of desired morphology with porosity will facilitate easy penetration of electrolyte and facile lithium ion transport, which is the significance of the study.

To sum up, the present study deals with the exploration of CTAB-coassisted sol–gel method in synthesizing phase pure and tailored cathodes of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] family, wherein synergistic effect of synthesis method and the select concentration of Co3+ ions in improving the electrochemical performance has been investigated. Particularly, cycleability at extended voltage limits (4.5–4.8 V) and at different rates (0.1–1 C) has been studied.

Materials and methods

Synthesis procedure

The LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] active materials planned for the study were synthesized by adopting surfactant (CTAB) coassisted sol–gel method. Stoichiometric ratios of high purity starting materials, viz., LiCOOCH3, (CH3COO)2Co, (CH3COO)2Mn, and (CH3COO)2Ni (Alfa Aesar), were dissolved in water with stirring to get a homogeneous solution. To the solution, 0.01 M of CTAB surfactant was added dropwise and the stirring was continued for 1 h. Followed by this, an optimized amount of 1 M of citric acid as chelating agent was added. Further, ammonia solution was added drop wise to adjust the pH value of the solution between 8.5 and 9 and the process of stirring and heating (80 °C) was continued to get a transparent gel. The gel thus obtained was aged for 24 h in an oven and furnace-heated to 350 °C for about 12 h followed by calcination at 900 °C for about 5 h in air using alumina crucibles. Ultrafine LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] powders obtained after 900 °C were ground and subjected to characterization studies.

Details pertaining to electrode fabrication and the subsequent 2032 coin cell assembly are reported elsewhere [20]. Electrochemical characterizations were carried out on freshly fabricated 2032 coin cells consisting of lithium anode, synthesized LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes individually, and a nonaqueous electrolyte consisting of 1 M LiPF6 dissolved in 1:1 v/v EC/PC with a Celgard separator.

Physical and electrochemical characterizations

Phase characterization was done by powder X-ray diffraction technique on a PANalytical X'pert PRO X-ray diffractometer using Ni-filtered Cu Kα radiation (=1.5406 Å) in the 2θ range 15–70° at a scan rate of 0.04° s−1. The lattice parameters were determined using the HighScore Plus software package. Surface chemical compositions of individual cathode materials were measured using X-ray photoelectron spectroscopy on a Physical Electronics model 5400 X-ray photoelectron spectrometer using an Mg Kα excitation source. The surface morphology and particle size of synthesized samples were examined by scanning electron microscopy (SEM, HITACHI S–3000 H, and Japan) and transmission electron microscopy (TEM, FEI-Tecnai-20 G2). Electrochemical cycling behavior (CV) was performed using an AutoLab electrochemical workstation and the charge–discharge studies were carried out on ARBIN charge–discharge cycle life tester.

Result and discussion

Powder diffraction studies—structural characterization

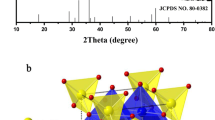

Powder diffraction pattern recorded for LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds are depicted in Fig. 1a–c. All the diffraction peaks could be indexed to α-NaFeO2-type of structure (space group R-3 m) that forms an fcc lattice with a distortion in the c direction, as indicated by the clear splitting of the (006)/(102) and (108)/(110) peaks. It is well known that a good resolution of (006)/(102) and (108)/(110) diffraction pairs is typical of an ideal layered structure with superior crystallinity, good hexagonal ordering, and better intercalation characteristics [21, 22]. Figure 1 evidences the presence of distinct splitting of (006) and (102) doublets at 2θ = 38.5° and those of (108) and (110) at 2θ = 65° for LiNi y Mn y Co1 − 2y O2 [y = 0.45 and 0.4] compounds, which is in favor of the formation of good layered structure. It is further understood from the cell parameters and the degree of cation ordering derived from XRD (Table 1), i.e., the increasing c/3a ratio from 1.637 to 1.652 with the increase in cobalt content substantiated the presence of perfectly formed layered lattice [23, 24]. Similarly, the I (003)/I (104) ratio increases from 1.15 to 1.38 which is greater than unity with an increase in the concentration of cobalt and the same is an indication of lowering the degree of cation mixing [25, 26]. Hence the role of Co3+ in minimizing the cation mixing of pristine LiNi0.5Mn0.5O2 lattice could be understood. The R value refers to the ratio of the sum of diffraction intensity of (006) and (102) to the diffraction intensity of (101) which measures the cation disorder. This is found to be the lowest for LiNi y Mn y Co1 − 2y O2 [y = 0.45 and 0.4] compounds and suggests that the hexagonal ordering is better.

Electron microscopy studies—particle size

Presence of 200 nm secondary particles of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds prepared by surfactant-coassisted sol–gel method are evidenced by transmission electron microscopy (Fig. 2). Particularly, homogeneous distribution of spherical particles with interconnected crystals is seen from the TEM images (Fig. 2a–c). Figure 2d shows the representative SEM image of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds, wherein spherical particles with interconnected morphology is found to get maintained even after furnace calcination at 900 °C. Unlike citric acid-assisted sol–gel method (inset of Fig. 2d), wherein presence of crystalline particles is seen without any desired spherical or interconnected morphology, the currently adopted CTAB-coassisted sol–gel method has produced interconnected spherical particles and the same could be attributed to the selective capping (or) nucleation effect of CTAB as a surfactant. Further, LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds synthesized with CTAB surfactant shows uniformly distributed and size reduced (200 nm) primary particles that are properly interconnected to form a porous network, which in turn would facilate better penetration of electrolyte and improve the electrochemical performance. Hence, it is learnt from the current study that the newly adopted surfactant-coassisted sol–gel method is advantageous over the conventional solid state [27], mixed hydroxide [28], and solution-assisted combustion [29] methods in synthesizing layered LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds with desired morphology.

X-ray photoelectron spectroscopy-elemental composition of cathode material

X-ray photoelectron spectroscopy (XPS) was employed to confirm the oxidation state of metal ions present in LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds. From Fig. 3, it is evident that the binding energy (BE) values of Ni 2p3/2, Co 2p3/2, and Mn 2p3/2 of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds are in good agreement with the reported values [30, 31]. The curve fitting of LiNi0.5Mn0.5O2 Ni 2p3/2 signal at 855 eV indicates [30, 31] a slight shift in energy towards higher side compared to those of LiNi0.45Mn0.45Co0.1O2 and LiNi0.4Mn0.4Co0.2O2 compounds, which may be correlated to the effect of cationic mixing. However, the presence of an additional and a characteristic satellite peak noted with the Ni 2p3/2 signal, corresponding to the multi-electron excitation behavior, confirms the oxidation state of Ni as +2 in all the LiNi y Mn y Co1 − 2y O2 compounds. The best fit for the Co 2p3/2 spectrum gives a BE value, which is matching with the value reported by Shaju et al. [32] for Co3+ ions. Similarly, the Mn XPS spectra that has a major peak located at a binding energy value of 642.2 eV for LiNi0.45Mn0.45Co0.1O2 and LiNi0.4Mn0.4Co0.2O2 compounds matches with the BE reported for Mn4+ ions [33]. Here again, a small shift towards higher energy side is observed for LiNi0.5Mn0.5O2 compounds, which may also be correlated to the possible presence of cation mixing. Based on these results, the individual oxidation state of Ni, Mn, and Co atoms in the currently synthesized LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds has been confirmed as +2, +4, and +3, respectively, and the charge neutrality of synthesized compounds is thus understood.

Electrochemical characterizations

The electrochemical behavior of synthesized cathodes was evaluated using 2032 coin cells containing lithium foil as anode and the synthesized compounds as cathode individually, wherein the investigation was carried out initially at C/10 rate in the potential range between 2.5 and 4.6 V. Figure 4 shows the charge and discharge profile of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes, wherein the first discharge capacity of LiNi0.5Mn0.5O2, LiNi0.45Mn0.45Co0.1O2, and LiNi0.4Mn0.4Co0.2O2 is found to be 210, 222, and 206 mA h g−1, respectively. Subsequently, an initial irreversible capacity loss of 30, 22, and 16 mA h g−1 has been exhibited by LiNi0.5Mn0.5O2, LiNi0.45Mn0.45Co0.1O2, and LiNi0.4Mn0.4Co0.2O2 cathodes, which is not unusual. Further, such a reduced irreversible capacity loss of 16 mA h g−1 exhibited by the currently synthesized LiNi0.4Mn0.4Co0.2O2 cathode indicates the superiority of the same, based on the reported behavior [10, 26] in the literature. On the other hand, progressive discharge capacity values of 140, 172, 179 mA h g−1 have been observed for LiNi0.5Mn0.5O2, LiNi0.45Mn0.45Co0.1O2, and LiNi0.4Mn0.4Co0.2O2 cathodes at the end of the 50th cycle (Fig. 4), thus suggesting that 20 % cobalt addition is beneficial in minimizing the capacity fade of native LiNi0.5Mn0.5O2 cathode, via hexagonal ordering of lithium and nickel ions. Further, maintenance of discharge plateau at 3.8 V and the absence of plateau around 4.0 V exhibited up to 50 cycles confirm the absence of possible structural changes of layered LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes into spinel-related phases [34]. Such an improved structural stabilization is attributed to the presence of Mn4+ that maintains the oxide network favorable for facile lithium intercalation/de-intercalation upon extended cycling.

The cycling behavior of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes at 0.1 and 0.2 C rate is furnished in Fig. 5. As mentioned already, an initial discharge capacity of 210, 222, and 206 mA h g−1 has been exhibited by LiNi0.5Mn0.5O2, LiNi0.45Mn0.45Co0.1O2, and LiNi0.4Mn0.4Co0.2O2 cathodes at 0.1 C rate with reduced second cycle discharge capacity values such as 176, 213, and 192 mA h g−1, respectively. Interestingly, LiNi0.4Mn0.4Co0.2O2 cathode with 192 mA h g−1 of second cycle discharge capacity exhibited better capacity retention (93 %) and lesser capacity fade (7 %) up to 50 cycles. In other words, the overall capacity retention of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes calculated for 50 cycles (with respect to second cycle discharge capacity value) is found to be 78, 82, and 93 %, respectively. Similarly, when charge–discharge cycling was performed at 0.2 C rate, LiNi0.4Mn0.4Co0.2O2 cathode exhibited a capacity as high as 160 mA h g−1 along with a capacity retention of 98 %, compared to those of LiNi0.5Mn0.5O2 (142 mA h g−1) and LiNi0.45Mn0.45Co0.1O2 (150 mA h g−1) with a capacity retention of 89 and 95 %, respectively. Such an improved electrochemical behavior of LiNi0.4Mn0.4Co0.2O2 cathode has been endorsed to the synergistic effect of spherically formed interconnected particles obtained from CTAB-coassisted sol–gel method and the optimum cobalt substitution (20 %) that minimizes the cation disorder.

Further, with a view to investigate the rate capability behavior of LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] cathodes, electrodes of synthesized compounds were subjected to charge–discharge cycling with different C rates and the observed capacity values are depicted in Fig. 6. The discharge capacity of LiNi0.5Mn0.5O2 is 210 mA h g−1 at a 0.1-C rate and the same gets decreased to 70 mA h g−1 at 1 C rate. Interestingly, 10 % of cobalt-doped LiNi0.45Mn0.45Co0.1O2 cathode exhibits the highest discharge capacity of 222 mA h g−1 (compared to the rest of the cathodes at 0.1 C rate) but suffers from significant capacity fade, as evident from the reduced capacity value of 94 mA h g−1 exhibited observed at 1 C rate. On the other hand, LiNi0.4Mn0.4Co0.2O2 cathode exhibits a nominal discharge capacity of 206 mA h g−1 at 0.1 C rate and an appreciable capacity value of 163, 131, and 109 mA h g−1 at higher discharge rates such as 0.2, 0.5, and 1 C rate, respectively. As mentioned earlier, such an improved rate capability behavior of LiNi0.4Mn0.4Co0.2O2 cathode is also attributed to the optimum addition of cobalt (20 %) that minimizes the cation disorder in the pristine LiNi0.5Mn0.5O2 lattice and the formation of interconnected spherical grains obtained from CTAB-coassisted sol–gel method.

Based on the encouraging results obtained for LiNi0.4Mn0.4Co0.2O2 cathode, an explorative attempt to investigate the CV behavior of the same at different voltages such as 4.4, 4.5, 4.6, 4.7, 4.8, and 4.85 V has been made with the scan rate of 0.1 mV s−1 (Fig. 7), mainly to understand the effect and extent of individual transition metals in imparting the specific capacity. The CV recorded with 4.4 V cutoff voltage limit consists of a redox couple at 3.81 and 3.68 V corresponding to Ni2+/Ni4+ pair, and Mn4+, being an electrochemically inactive species, gives rise to no CV signal throughout the study, which is justifiable. Alternatively, CV recorded up to 4.6 V and at higher cutoff voltage limits (4.7 to 4.85 V) consists of another redox pair at 4.58 and 4.51 V, corresponding to the presence of Co3+/Co4+ redox pair. Hence, apart from an understanding on the facile intercalation and de-intercalation behavior of Li+ ions in LiNi0.4Mn0.4Co0.2O2 cathode and the respective oxidation states of Ni+2, Co+3, and Mn+4 ions, significant role of Co+3 ions in improving the electrochemical behavior of the same has also been substantiated from CV studies.

The charge–discharge behavior of LiNi0.4Mn0.4Co0.2O2 cathode synthesized using surfactant-coassisted sol–gel method at different cutoff voltages (0.1 C rate) has been furnished in Fig. 8 and the observed capacity fade values are given in Table 2. An increasing capacity value from 194 to 228 mA h g−1 has been observed with an increase in the upper cutoff voltage from 4.5 to 4.8 V. Simultaneously, an increasing capacity fade of about 15 and 17 % has been observed up to 30 cycles, when the cell was charged to 4.7 and 4.8 V limits, respectively. This could be correlated to the slight shift in redox peaks observed in CV exhibited by LiNi0.4Mn0.4Co0.2O2 cathode, especially when cycled beyond 4.6 V. Interestingly, LiNi0.4Mn0.4Co0.2O2 cathode exhibited reduced capacity fade behavior (7 %) and an enhanced capacity value (192 mA h g−1), especially when cycled up to 4.6 V compared to those of 4.7 and 4.8 V limits. On the other hand, cycling up to 4.5 V renders much reduced capacity fade behavior (5 %) but at the expense of highly reduced initial and progressive capacity values (180 mA h g−1). Therefore, it is evident from the present study that LiNi0.4Mn0.4Co0.2O2 cathode synthesized by CTAB-coassisted sol–gel method exhibits lesser capacity fade (7 %) and higher capacity value (192 mA h g−1) at 4.6 V limit, compared to those reported at reduced potential windows such as 4.3 and 4.5 V [11, 26]. Such an improved electrochemical behavior of LiNi0.4Mn0.4Co0.2O2 cathode has been endorsed to the synergistic effect of interconnected and spherically shaped particles (~200 nm) derived from surfactant-coassisted sol–gel method and the perfect layeredness obtained by using an optimum (20 %) amount of cobalt in the solid solution.

Conclusions

LiNi0.5Mn0.5O2, LiNi0.45Mn0.45Co0.1O2, and LiNi0.4Mn0.4Co0.2O2 compounds were prepared at 900 °C using CTAB-coassisted sol–gel method. The Co+3 introduction in LiNi0.5Mn0.5O2 compound helps in increasing the reversible capacity and rate capability. Among the LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds, LiNi0.4Mn0.4Co0.2O2 cathode exhibited superior discharge capacity (192 mA h g−1) and with an excellent capacity retention (93 %) for 50 cycles, and its rate capability at 1 C rate and cycling behavior up to 4.6 V are found to be satisfactory compared to those of LiNi0.5Mn0.5O2 and LiNi0.45Mn0.45Co0.1O2 cathodes. The study recommends that the currently adopted surfactant-coassisted sol–gel method is yet another potential approach to synthesize LiNi y Mn y Co1 − 2y O2 [y = 0.5, 0.45, and 0.4] compounds with interconnected spherical grains which are responsible for the improved electrochemical properties. Further, the suitability of LiNi0.4Mn0.4Co0.2O2 cathode for high-rate (1 C) lithium battery applications is believed to result from the synergistic effect of synthesis method and the selection of optimum amount of (20 %) Co3+ concentration that renders required cation ordering.

References

Ni JF, Zhou HH, Chen JT, Zhang XX (2005) Mater Lett 59:2361–2365

Yabuuchi N, Ohzuku TJ (2003) Power Sources 119–121:171–174

Ohzuku T, Makimura Y (2001) Chem Lett 30:642–643

Xiao J, Chernova NA, Whittingham MS (2010) Chem Mater 22:1180

Ellis BL, Lee KT, Nazar LF (2010) Chem Mater 22:691–714

Liu Y, Chen B, Cao F, Zhao X, Yuan J (2011) J Mater Chem 21:10437–10441

Kobayashi H, Arachi Y, Kageyama H, Tatsumi K (2004) J Mater Chem 14:40–42

Sakamoto K, Hirayama M, Konishi H, Sonoyama N, Dupre N, Guyomard D, Tamura K, Mizuki J, Kanno R (2010) Phys Chem Chem Phys 12:3815–3823

Whittingham MS (2004) Chem Rev 104:4271–4301

Xiao J, Chernova NA, Whittingham MS (2008) Chem Mater 20:7454–7464

Bruce PG, Scrosati B, Tarascon JM (2008) Angew Chem Int Ed 47:2930–2946

Ahn D, Koo YM, Kim MG, Shin N, Park J, Eom J, Cho J, Shin TJ (2010) J Phys Chem C 114:3655–3680

He P, Wang HR, Qi L, Osaka TJ (2006) Power Sources 160:627–632

Jayaprakash N, Sathiyanarayanan K, Kalaiselvi N (2007) Electrochim Acta 52:2453–2460

Jayaprakash N, Kalaiselvi N, Doh CH, Gangulibabu, Bhuvaneswari D (2010) J Appl Electrochem 40:2193–2202

Huang ZD, Liu XM, Oh SW, Zhang B, Ma BC, Kim JK (2011) J Mater Chem 21:10777–10784

Song WS, Choi HN, Kim YS, Yang H (2010) J Mater Chem 20:6929–6934

Sun YK, Oh IH, Kimc KY (1997) J Mater Chem 7:1481–1485

Brinker CJ, Scherer GW (1990) Sol-gel science: the physics and chemistry of sol-gel processing. Academic Press Inc., San Diego, CA

Gangulibabu, Bhuvaneswari D, Kalaiselvi N, Jayaprakash N, Periasamy P (2009) J Sol Gel Sci Techno 49:137–144

Zhang L, Wang X, Muta T, Li D, Noguchi H, Yoshio M, Ma R, Takada K, Sasaki T (2006) J Power Sources 162:629–625

Wang J, Yao X, Zhou X, Liu Z (2011) J Mater Chem 21:2544–2549

Carley AF, Jackson SD, O’Shea JN, Roberts MW (1999) Surf Sci 440:L868–L864

Ngala JK, Chernova NA, Ma M, Mamak M, Zavalij PY, Whittingham MS (2004) J Mater Chem 14:214–220

Reale P, Privitera D, Panero S, Scrosati B (2007) Solid State Ionics 178:1390–1397

Liu H, Wu YP, Rahm E, Holze R, Wu HQ (2004) J Solid State Chem 8:450–466

Wu Q, Li X, Yan M, Jiang Z (2003) Electrochem Commun 5:878–882

Lu Z, MacNeil DD, Dahn JR (2001) Electrochem Solid State Lett 4:A191–A194

Patoux S, Doeff MM (2004) Electrochem Commun 6:767–772

Casella G, Guascito MR, Sannazzaro MG (1999) J Electroanal Chem 462:202–210

Zhao Y, Fan YEL, Qiu Y, Yang S (2007) Electrochim Acta 52:5873–5878

Shaju KM, Subba Rao GV, Chowdari BVR (2002) Solid State Ionics 69:152–153

Shaju KM, Subba Rao GV, Chowdari BVR (2002) Electrochim Acta 48:145–151

Hwang BJ, Tsai YW, Chen CH, Santhanam R (2003) J Mater Chem 13:1962–1968

Acknowledgments

Among the authors, D. Bhuvaneswari and Gangulibabu are thankful to the Council of Scientific and Industrial Research, India for financial support through senior research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhuvaneswari, D., Gangulibabu & Kalaiselvi, N. Surfactant-coassisted sol–gel synthesis to prepare LiNi y Mn y Co1 − 2y O2 with improved electrochemical behavior. J Solid State Electrochem 16, 3667–3674 (2012). https://doi.org/10.1007/s10008-012-1810-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-012-1810-8