Abstract

The electro-oxidation of methanol at supported tungsten carbide (WC) nanoparticles in sulfuric acid solution was studied using cyclic voltammetry, potentiostatic measurements, and differential electrochemical mass spectroscopy (DEMS). The catalyst was prepared by a sonochemical method and characterized by X-ray diffraction. Over the WC catalyst, the oxidation of methanol (1 M in a sulfuric acid electrolyte) begins at a potential below 0.5 V/RHE during the anodic sweep. During potentiostatic measurements, a maximum current of 0.8 mA mg−1 was obtained at 0.4 V. Measurements of DEMS showed that the methanol oxidation reaction over tungsten carbide produces CO2 (m/z = 44); no methylformate (m/z = 60) was detected. These results are discussed in the context of the continued search for alternative materials for the anode catalyst of direct methanol fuel cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since Levy and Boudart [1] suggested that tungsten carbide (WC) displays Pt-like behavior in several catalytic reactions, there has been growing interest in investigating this material. Because platinum has been used as a catalyst in fuel cells since the 1950s, it is worthwhile to explore whether tungsten carbide can perform as well as platinum in reactions relevant to fuel cells. These reactions include the oxidation of hydrogen and small organic molecules like methanol and formic acid, as well as the reduction of oxygen.

Today, one focus of fuel cell research is the direct methanol fuel cell (DMFC). This fuel cell uses the oxidation of methanol as the anode reaction responsible for providing the electrons. There are many studies in the field of DMFC catalysis, and the majority uses platinum with other metals (Rh [2], Sn [3], Ru [4], Mo [5, 6], W [7], Os [8]) to oxidize methanol. To date, PtRu alloys are the most effective anode catalysts for low temperature operation of the DMFCs. The efficiency of these materials is attributed to their ability to decompose water for oxidation and subsequent removal of intermediates produced during the dissociation of methanol [9]. While the PtRu anode catalyst is effective, both Pt and Ru are expensive metals. Thus, the high price of the anode catalyst prevents the DMFC from being commercially viable for large-scale application. Finding a cheaper catalyst with activities and selectivities similar to platinum would then be one way to improve the commercial viability of the DMFC.

Indeed, many previous studies have provided evidence that tungsten carbides may perform well as alternative fuel cell catalysts. Ross and Stoneheart [10] used tungsten carbide to oxidize hydrogen and showed that the most active forms of WC are more active than Au and other coinage metals like Cu, Ag, Al, etc., but significantly less active than Pt group metals like Pt, Ir Pd, Rh, and Ru. In reactions that utilize methanol, Kawamura et al. [11–13] showed that double carbides of tungsten and molybdenum (WMoC) have a fairly high activity for methanol electro-oxidation. More recently, Hwu et al. [14, 15] used temperature-programmed desorption and high-resolution electron energy loss spectroscopy in ultrahigh vacuum to show the potential effectiveness of tungsten carbide as a methanol decomposition catalyst. Also, based on ultrahigh vacuum studies, Zellner and Chen [16] predicted that platinum and tungsten carbide could act synergistically as methanol fuel cell catalysts. Recent work investigating WC combined with platinum has shown that the effectiveness predicted by Chen's ultrahigh vacuum studies is in fact observable in the electrochemical environment. Specifically, the oxygen reduction reaction was seen to occur at lower overpotentials on Pt/WC than on Pt/C [17]. Simultaneously, the current density associated with the anodic oxidation of methanol was greater on Pt/WO3 than on Pt/C [18]. The effect of CO poisoning during the anodic oxidation of hydrogen over tungsten carbide in acidic media was also investigated [19, 20]. This study showed that carbon monoxide (CO) has little influence on the anodic current density, presumably because of its weak adsorption strength on tungsten carbide. Taken together, the early electrochemical studies, the ultrahigh vacuum studies, and the more recent electrochemical studies all suggest that it is worthwhile to continue to investigate the application of tungsten carbide catalysts to fuel cell reactions.

Materials and methods

Catalyst preparation

The carbon-supported tungsten carbide catalysts were prepared by reduction of W(CO)6 using a method described elsewhere [21]. Briefly, a slurry of 20 wt.% tungsten hexacarbonyl (AlfaAesar) and 80 wt.% carbon (Vulcan XC72) was sonicated in hexadecane with a high-intensity ultrasonic horn. The sonication process was carried out at 90 °C for 3 h under flowing argon using a sonication frequency of 25 kHz and a power of 80 W/cm2. The material was filtered and then washed several times with purified, degassed pentane. After washing, the material was dried via heating to 80 °C. The powder was subsequently heated to 400 °C in a CH4/H2 atmosphere to guarantee that all the tungsten was fully carburized.

XRD

The catalyst was examined by X-ray diffraction (XRD) using a URD-6 Carl Zeiss-Jena diffractometer. The X-ray diffractogram was obtained with a scan rate of 0.058 s−1 for 2θ values between 20° and 90°. The average catalyst particle size was determined by Scherer's equation [22] using the peak associated with the (110) face of the hexagonal close packed tungsten carbide structure at 2θ = 62°. The average catalyst particle size obtained was 5 nm. The incident wavelength was 1.5406 Å (KaCu).

Electrochemical measurements

All electrochemical measurements were performed at room temperature with a Solartron model 1285 potentiostat connected to a three-electrode cell. The cell was comprised of two separate compartments: a base which was interfaced with the differential electrochemical mass spectroscopy (DEMS) apparatus and an upper part in which the counter and reference electrodes resided. The base of the cell was made of polytetrafluoroethylene, and the upper part was made of glass. The base of the cell was separated from the mass spectrometry chamber by a porous hydrophobic membrane. The membrane (SCIMAT type with a mean pore size of 0.17 μm and 50% porosity) was supported by a porous glass frit. The counter electrode was a platinized platinum sheet (0.25 cm2). A reversible hydrogen electrode served as the reference electrode, and all potentials are quoted vs this reference potential.

The electrolyte used was 0.5 M H2SO4 (Merck, suprapur grade). Electrolyte solutions were made from ultrapure Milli-Q water. The working electrodes employed in these studies were prepared by mixing the catalyst powder with a Nafion® solution (Nafion perfluorinated ion-exchange powder, 5% by weight, in a mixture of lower aliphatic alcohols and water, Aldrich) and isopropyl alcohol (Merck, p.a. grade) and sonicating for 10 min. The mixture of the dispersed catalyst and Nafion was painted over a carbon cloth with an area of 0.8 cm2. The catalyst loading was 0.5 mg of metal/cm2. The electrode was then left to dry in a furnace for 60 min at 80 °C. The atmosphere of the furnace was air.

Before the measurements, the electrolyte was purged with argon gas (99.99%, White Martins). During the measurements, the atmosphere above the electrolyte was purged with argon. For methanol electro-oxidation (1 mol L−1 Merck p.a.), the electrode potential was held at 0.05 V while the methanol was added to the cell. After methanol addition, the potential scan was started.

DEMS measurements

Differential electrochemical mass spectroscopy experiments have been performed with a computer-controlled quadruple mass spectrometer (MKS Instruments) and with the same working electrode as described in the prior section. This electrode was in direct contact with a porous Teflon membrane. This Teflon membrane separated the electrochemical cell from the ion source of the mass spectrometer. In the DEMS experiment, the current vs potential curves (cyclic voltammograms (CV)) were recorded simultaneously with the mass intensity vs potential curves (mass spectrometric CV (MSCV)) for selected ion signals (m/z = 44 and 60). The details of the method have been presented elsewhere [23].

Results and discussion

XRD analysis

The XRD pattern of the catalyst used in this study is shown in Fig. 1. The indexed peaks show that the sample is a mixture of tungsten carbide and di-tungsten carbide (W2C). While WC is the predominant phase, providing a quantitative estimate of the relative abundance of the two phases would be inaccurate without a complementary technique. The presence of the W2C is probably because of the relatively low temperature during the CH4/H2 treatment [24]. The present XRD result is in agreement with the published literature [25, 26]. This is important to note given that the carburizing procedure employed in this study is different from the procedure employed in previous works [21]. The broad peaks denote a very small crystallite size, which is caused by the high dispersion of the catalyst on carbon. The expected particle size, as calculated by the Scherrer equation, is 5 nm.

Electrochemical and DEMS measurements

Cyclic voltammetry was employed to study the stability of tungsten carbide in acidic media in the absence of methanol. The CV recorded at 10 mV s−1 in 0.5 mol L−1 H2SO4 is shown in Fig. 2. The result shows that the electrode presents only capacitive charge, providing no evidence of any reduction or oxidation peaks. Above 0.6 V, a small amount of catalyst oxidation begins. However, using X-ray photoelectron spectroscopy, Zellner and Chen [16] showed that the degree of WC oxidation is relatively minor when the CV experiment is confined to potentials between −0.1 and 1.0 V (vs SHE). Thus, we chose to keep the potential lower than 0.8 V in order to avoid any possible formation of W x O y species. After ten cycles at 10 mV/s, there was no decrease in current, indicating that the material exhibited stability in this potential range and did not undergo dissolution in the acidic electrolyte.

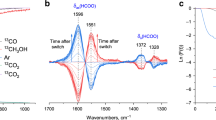

Fig. 3a shows the CV of tungsten carbide in 1 mol L−1 CH3OH + 0.5 mol L−1 H2SO4. During the positive scan until 0.45 V, the electroactivity of WC is low, followed by an oxidation peak current at 0.65 V. This behavior is similar to that observed over Pt electrodes [27]. Notably, the onset potential of the reaction is in the range of onset potentials previously observed for methanol oxidation over porous polycrystalline Pt catalysts, Pt(111), Pt(110) [28]. As such, the overpotential required to initiate the methanol oxidation reaction is similar on W/C as compared to the family of Pt catalysts.

In addition to using cyclic voltammetry to quantify the tungsten carbide catalyst activity, we use DEMS to analyze the products formed during methanol oxidation. It is well known that the oxidation of CH3OH on platinum produces not only CO2 , the methanol oxidation proceeds indeed via a parallel path mechanism, due to a incomplete dehydrogenation or oxidation of methanol. Besides CO2, formaldehyde (HCHO) and formic acid (HCOOH) are formed in solution during methanol dehydrogenation [29]. The formaldehyde and formic acid can react with methanol to form methylal (CH2(OCH3)2) and methylformate (HCOOCH3), respectively [30]. However, the maximum energetic output of the reaction occurs when the methanol is entirely oxidized to CO2, producing six electrons per molecule of methanol. Thus, selectivity for CO2 formation is a highly desired quality of a methanol oxidation catalyst.

Figure 3b presents the results of DEMS analysis for the electro-oxidation of methanol on tungsten carbide. The MSCV were recorded simultaneously with the CV in order to analyze the volatile products formed during the reaction. We monitored the mass signals for CO2 (m/z = 44, [CO2]+) and methylformate (m/z = 60, [HCOOCH3]+). As previously documented, deconvolving the possible formaldehyde and formic acid product signals from the methanol peak is not straightforward under the conditions of differential electrochemical mass spectrometry [29]. As such, m/z = 29 could not be monitored as a proxy for formaldehyde.

The only observable mass signal was m/z = 44, indicating that the only detectable product of methanol oxidation over tungsten carbide is CO2. The onset of CO2 evolution is at 0.45 V. This value follows the profile of the oxidation current observed in the cyclic voltammetry experiments described in Fig. 3a. However, it may be noted that the hysteresis observed in the DEMS curve during the negative scan is much more pronounced than in the voltammetric curve. There are a few possible explanations for this behavior: (a) a delay (because of pumping speed) between the formation of products at the interface (electrode/chamber) and their detection by the quadrupole, (b) contributions to the faradiac current at high potentials because of a small amount of oxidation of tungsten (as noted by Zellner and Chen [16]), and (c) production of comparatively more soluble or otherwise undetectable partial oxidation products in the positive going scan as compared to the negative going scan.

While the production of partial oxidation products is likely based on the comparison of the DEMS and voltammetric curves, no ionic current was detected for methylformate signifying that no detectable [HCOOCH3]+ was formed during the electro-oxidation of methanol (data not shown). However, the experimental method and our experimental set up are not adequately sensitive to methylformate formation [31]. Thus, while our DEMS studies enable us to definitively assert that the WC catalyst has some selectivity for CO2 formation, we cannot definitively rule out the production of side products nor quantitatively compare its performance to that of the Pt catalysts [28].

It is still difficult to say something about the path mechanism for the methanol oxidation, and for the side products on WC surface, since a poisoning intermediate studies were not performed yet in electrochemical environment. But, we can based on the works of Chen et al. [14–16] that used UHV techniques and tried to shed some light to this subject. The authors showed that decomposition of methanol on carbide-modified W(111) and WC PVD films occurs via three reaction pathways producing C and O (by total decomposition), CO and CH4. The adsorption of methanol results by a cleavage of O-H bond forming metoxy at 200 K, where on Pt(111) this behavior is nearly inert. Furthermore, the water and carbon monoxide adsorb molecularly on this surface with a significant higher activity toward water dissociation and for CO, the temperature of desorption was at least 100 K lower than when compared to clean Pt(111). Should be mentioned that the pathways of methanol dissociation at Pt is different in gasphase and in electrochemical environment [32], maybe some differences will can appear for WC surface too.

We would like to emphasize that the control experiments, DEMS and CV of the carbon support without tungsten carbide in 1 M sulfuric acid in the presence of 0.1 M of methanol (data not shown), showed neither faradaic nor ionic current (m/z = 44). The lack of faradaic and ionic currents in the control experiments indicates that the evolution of CO2 from the WC catalyst is because of the catalytic oxidation of methanol and not to the oxidation of the carbon support.

In contrast to potentiodynamic methods, such as cyclic voltammetry, potentiostatic measurements allow the catalyst activity to be studied under “long-term” conditions relevant to fuel cell operation. This is especially important when studying self-poisoning reactions like methanol oxidation. For this purpose, we performed potentiostatic measurements on the WC catalyst in 0.5 mol L−1 H2SO4 solution containing 1 mol L−1 methanol. The resulting potentiostatic current densities are shown in Fig. 4.

It should be noted that the maximum current density, 0.8 mA mg−1, was reached at 0.4 V, approximately the same potential at which the maximum methanol oxidation current is obtained with the commercial Pt/Vulcan catalyst (E-Tek-Pt; Vulcan) [9]. At higher potentials, the current decays. We believe that this decay is because of the high potential (>0.6 V) formation of W x O y , a phenomenon observed by Zellner and Chen [16]. These W x O y sites may be less active for the catalytic oxidation of methanol.

In a similar potentiostatic experiment, Kawamura et al. [13] reported that the mass activity for WC in methanol was 5 mA g−1 at 0.5 V. This value is about 150 times lower than the value we obtained in the present study. However, in the present study, we use nanoparticle catalysts whereas the previous study did not. As such, the surface area per unit mass in this study is much higher than the surface area per unit mass in the Kawamura experiment. In fact, based on the 5-nm radius estimated from the XRD measurement and on the assumption that our particles are spherical, the surface area per unit mass of our catalyst is 150–200 times greater than the surface area per unit mass of the catalyst used in the Kawamura experiment (4,000 m2/g in this study vs 20–30 m2/g in the Kawamura study).

Conclusion

Cyclic voltammetry and potentiostatic measurements indicate that tungsten carbide nanoparticles are catalytically active towards methanol electro-oxidation. The DEMS experiment definitively shows that tungsten carbide catalyzed the production of CO2. This indicates that WC catalyzes the complete dehydrogenation and subsequent oxidation of methanol at relatively low potentials. Future work will focus on attempts to quantify the selectivity of the WC catalyst for methanol oxidation.

References

Levy R, Boudart M (1973) Science 181:547

Detacconi NR, Lezna RO, Beden B, Lamy C (1994) J Electroanal Chem 379:329

Ishikawa Y, Liao MS, Cabrera CR (2000) Surf Sci 463:66

Liu RX, Iddir H, Fan Q, Hou GY, Bo AL, Ley KL, Smotkin ES, Sung YE, Kim H, Thomas S, Wieckowski A (2000) J Phys Chem B. 104:3518

Mukerjee S, Lee SJ, Ticianelli EA, McBreen J, Grgur BN, Markovic NM, Ross PN, Giallombardo JR, De Castro ES (1999) Electrochem Solid-State Lett 2:12

Ioroi T, Fujiwara N, Siroma Z, Yasuda K, Miyazaki Y (2002) Electrochem Commun 4:442

Götz M, Wendt H (1998) Eletrochim Acta 43:3637

Ley KL, Liu RX, Pu C, Fan QB, Leyarovska N, Segre C, Smotkin ES (1997) J Eletrochem Soc 144:1543

Schmidt TJ, Gasteiger HA, Behm RJ (1999) Electrochem Comm 1:1

Ross PN, Stoneheart P (1977) J Catal 48:42

Kudo T, Kawamura G, Okamoto H (1983) Electrochem Soc 130:1491

Okamoto H, Kawamura G, Ishikawa A, Kudo T (1987) J Electrochem Soc 134:1649

Kawamura G, Okamoto H, Ishikawa A, Kudo T (1987) J Electrochem Soc 134:1653

Hwu HH, Chen JGG, Kourtakis K, Lavin JG (2001) J Phys Chem B 105:10037

Hwu HH, Polizzotti BD, Chen JGG (2001) J Phys Chem B 105:10045

Zellner MB, Chen JGG (2005) Catal Today 99:299

Meng H, Shen PK (2005) J Phys Chem B 109:22705

Ganesan R, Lee JS (2005) Angew Chem Int Ed 44:6557

Palanker VSh, Gajyev RA, Sokolsky DV (1977) Electrochim Acta 22:133

McIntyre DR, Burstein GT, Vossen A (2002) J Power Sources 107:67

Hyeon TH, Fang MM, Suslick KS (1996) J Am Chem Soc 118:5492

Cullity BD (1967) Elements of X-ray Diffraction, Addison Wesley

de Souza JPI, Queiroz SL, Nart FC (2000) Quim Nova 23:384

Löfberg A, Frennet A, Leclercq G, Leclercq L, Giraudon JM (2000) J Catal 189:170

Patterson PM, Das TK, Davis BH (2003) Appl Catal A 251:449

Koc R, Kodambaka SK (2000) J Eur Ceram Soc 20:1859

Jusys Z, Kaiser J, Behm RJ (2003) Langmuir 19:6759

Iwasita T (2002) Electrochim Acta 47:3663

Iwasita T, Vielstich W (1986) J Electroanal Chem 201:403

Jusys Z, Behm RJ (2001) J Phys Chem B 105:10874

Jusys Z, Kaiser J, Behm RJ (2002) Electrochim Acta 47:3693

Hwu HH, Chen JGG (2005) Chem Rev 105:185

Acknowledgments

The authors thank Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for financial support. L. J. Deiner thanks FAPESP for a postdoctoral fellowship (Fellowship Process # 04/03051-6). Furthermore, the authors thank Demetrius Profeti for helpful discussions and assistance with the DEMS experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

In memoriam

Rights and permissions

About this article

Cite this article

Angelucci, C.A., Deiner, L.J. & Nart, F.C. On-line mass spectrometry of the electro-oxidation of methanol in acidic media on tungsten carbide. J Solid State Electrochem 12, 1599–1603 (2008). https://doi.org/10.1007/s10008-007-0495-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-007-0495-x