Abstract

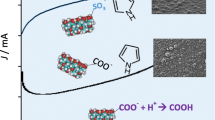

Conducting polypyrrole (PPy) and poly(pyrrole-2,6-dimethyl-β-cyclodextrin) [poly(Py-β-DMCD)] films were prepared by electrode potential cycling on a gold electrode in aqueous and nonaqueous (acetonitrile) electrolyte solutions containing lithium perchlorate. The resulting products were characterized with cyclic voltammetry, in situ UV–Vis spectroscopy, and in situ conductivity measurements. For the electrosynthesis of poly(Py-β-DMCD), a (1:1) (mole–mole) (Py-β-DMCD) supramolecular cyclodextrin complex of pyrrole previously characterized with proton NMR spectroscopy was used as starting material. A different cyclic voltammetric behavior was observed for pyrrole and the poly(Py-β-DMCD) complex in aqueous and nonaqueous solutions during electrosynthesis. The results show that in both solutions in the presence of cyclodextrin, the oxidation potential of pyrrole monomers increases. However, the difference of oxidation potentials for films prepared in aqueous solution is larger than for the films prepared in nonaqueous solution. In situ conductivity measurements of the films show that films prepared in acetonitrile solution are more conductive than those synthesized in aqueous solutions. Maximum conductivity can be observed for PPy and poly(Py-β-DMCD) films prepared in nonaqueous solution in the range of 0.10 < E Ag/AgCl < 0.90 V and 0.30 < E Ag/AgCl < 0.90 V, respectively. In situ UV–Vis spectroelectrochemical data for both films prepared potentiodynamically by cycling the potentials from −0.40 < E Ag/AgCl < 0.90 V in nonaqueous solutions are reported.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Intrinsically conducting polymers (ICPs) and conjugated polymers have attracted a lot of attention during the last decades. ICPs possess high electrical conductivity, excellent electroactivity, and relatively high environmental stability [1]. They have been investigated for application in different electronic devices [2]. PPy and ICPs prepared from substituted pyrroles are of particular interest owing to their conductivity, stability in the oxidized state, and interesting redox properties [3–5]. They have been synthesized electrochemically both in aqueous and nonaqueous solutions [6–8]. A better understanding of differences in the electrochemical behavior of PPy synthesized in different solvents is important for its applications [9]. In recent years, oxidation reactions of host–guest compounds have attracted enormous research interest by several authors [10–13]. Cyclodextrins (CDs) are cyclic glucopyranose oligomers having a toroidal shape. The α-, β-, and γ-cyclodextrins contain six, seven, and eight glucose units, respectively, and exhibit conical structures with a hydrophobic internal cavity and a hydrophilic exterior due to the presence of hydroxyl groups. These compounds have the ability to form inclusion complexes with guest molecules of the proper size [14]. This has led to considerable interest in the role of the reactions of guest molecules. In particular, complexation by CDs influences the electrochemical response of the electroactive guest [15]. Cavity diameters of α-, β-, and γ-cyclodextrins are 5.70, 7.80, and 9.50 Å, respectively, which are large enough to serve as host sites for monomer molecules such as pyrrole and some substituted pyrroles [16]. Such inclusion complexes have shown high potential both in theory and in application. Firstly, studying encapsulated conducting polymers may help to understand the mechanisms of electronic conduction when the macromolecular chains are isolated by CDs. Secondly, the conducting polymer strands are protected from chemical attack, and thermal and mechanical properties may be improved. Thirdly, if nanowires can be obtained this way, molecular electronics may become feasible. If the polymer is housed in a regular array of voids such as provided by CD, this offers a way of addressing individual molecules [17]. Several reports have focused on polymerizing aniline within the cavity of clay [18] and zeolithes [19]. The structural configuration of polyaniline in β-cyclodextrin has been investigated [20]. Yuan et al. [21] have reported the preparation of an inclusion complex of poly(aniline-β-cyclodextrin) by in situ polymerization. Lagrost et al. [22] have reported that the use of host–guest complexation makes it possible to grow polybithiophene in aqueous medium by anodic oxidation of a bithiophene-hydroxypropyl-β-cyclodextrin inclusion compound. The anodic electropolymerization of the BT-HPβCD complex has been performed in aqueous medium under galvanostatic or potentiodynamic conditions [23]. Temsamami et al. [24] have reported the synthesis of stable polymer films from pyrrole and sulfonated β-cyclodextrin complex. The synthesis and characterization of a polypyrrole/β-cyclodextrin (PPy/β-CD) film at a glassy carbon electrode surface have also been reported [25]. Bouchta et al. [26] have reported the synthesis and characterization of PPY/γ-CD at a gold electrode by simple electropolymerization of a 1:1 mixture of γ-cyclodextrin and pyrrole monomer in aqueous solutions with cyclic voltammetry (CV) and electrochemical impedance spectroscopy methods. The aim of the present work was to analyze the role of β-DMCD molecules in the polymerization process and in the optical absorption and the conductivity of PPy films in two different solvents. The results show significantly different CVs and conductivities as well as spectral characteristics as a function of applied potential.

Experimental

Cyclodextrin (Wacker Chemie, Burghausen, Germany) was used as received. Pyrrole (Aldrich, 99%) was distilled under vacuum. LiClO4 used as electrolyte (Heraeus, Germany) was dried under vacuum. Acetonitrile (Merck LiChrosolv, water content, as determined by Karl Fischer method, of <0.05%) was used as received and kept over a molecular sieve. Cyclic voltammograms were recorded with a custom-built potentiostat interfaced with a standard PC via an ADDA-converter card operating with custom-developed software. The following working electrodes were used: for CV, it was a gold electrode (99.99%, Schiefer, Hamburg, area ∼0.4 cm2) embedded in epoxy ARALDIT D/HY 956 (Ciba Special Chemicals); for UV–Vis spectroscopy, it was an ITO-coated glass sheet (Merck, R = 20 Ω cm−2), and for in situ conductivity measurements, it was a two-band gold electrode setup described elsewhere [27]. A gold sheet served as counter electrode. A silver/silver chloride and a saturated calomel were used as reference electrodes for nonaqueous and aqueous solutions, respectively. The potential of the Ag/AgCl reference electrode was verified frequently with respect to the aqueous saturated calomel electrode because the employed nonaqueous reference electrode system was prone to potential drifts [28]. UV–Vis spectra were recorded with the polymer films deposited on an optically transparent ITO glass electrode in the supporting electrolyte solution (acetonitrile + 0.1 M LiClO4) in a standard 10 mm cuvette using a Shimadzu UV 2101-PC instrument; a cuvette with the same solution and an uncoated ITO glass was placed in the reference beam. Spectra were recorded at increasingly positive potentials; in a few cases, spectra were recorded in the negative-going potential direction to test reversibility (as indicated in selected figures). All experiments were performed at room temperature with nitrogen-purged solutions.

Preparation of (pyrrole–cyclodextrin) complex

A (1:1) (mole–mole) poly(Py-β-DMCD) complex was prepared by mixing 69.1 μl (1 mmol) of pyrrole and 1.33 g (1 mmol) β-DMCD in 5 ml methanol solution. The formed (Py-β-DMCD) complex was isolated by removing the methanol in a rotary evaporator.

Polypyrrole and poly(pyrrole–cyclodextrin) film electrosynthesis in aqueous solution

A 0.05-M (Py-β-DMCD) complex solution was prepared by dissolving 1.74 g (1.25 mmol) solid (Py-β-DMCD) complex in 25 ml of a 0.1-M LiClO4 aqueous solution. After vigorous mixing and nitrogen purging (10 min), electropolymerization was performed by electrode potential cycling starting initially toward the positive potentials from −0.20 < E SCE < 1.80 V at a scan rate of 50 mV·s−1. At lower anodic potential limits, no differences between pyrrole and pyrrole–cyclodextrin could be detected during oxidation, electropolymerization, and with the films. The electrosynthesis was stopped after 40 cycles. The PPy film was prepared in a similar way. The electropolymerization medium was 69.1 μl (1 mmol) of the monomer in 25 ml of 0.1 M LiClO4 aqueous solution.

Polypyrrole and poly(pyrrole–cyclodextrin) film electrosynthesis in nonaqueous solution

A 0.05-M (Py-β-DMCD) complex solution was prepared by dissolving 1.74 g (1.25 mmol) solid (Py-β-DMCD) complex in 25 ml of a solution of acetonitrile + 0.1 M LiClO4. After vigorous mixing and nitrogen purging (10 min), electropolymerization was effected by scanning the electrode potential initially toward the positive potentials and then between −0.40 < E Ag/AgCl < 0.90 V at a scan rate of 50 mV·s−1. The electrosynthesis was stopped after 40 cycles. The PPy film was prepared in a similar way. Electropolymerization medium was 69.1 μl (1 mmol) of the monomer in 25 ml of a nonaqueous solution of acetonitrile + 0.1 M LiClO4.

Results and discussion

Cyclic voltammetry

The electropolymerization of both pyrrole and pyrrole–cyclodextrin complex in aqueous solution was carried out by cycling the potential between E SCE = −0.20 V and different upper potential limits E SCE = 1.00, 1.20, 1.40, 1.60, and 1.80 V. Although polymerization was observed, and films were deposited on the electrode surface when the upper potential limits were E SCE = 1.00, 1.20, 1.40, and 1.60 V, no differences were observed in the characteristics of films prepared either from pyrrole and pyrrole–cyclodextrin. However, when the upper potential was extended to E SCE = 1.80 V, differences were observed both during the electropolymerization and also in the CVs of the deposited films. Therefore, this potential was selected for the electrosynthesis of PPy and poly(Py-β-DMCD) as also reported by several authors for the electrosynthesis of PPy, PPy/sulfated-βCD [24] and PPy, PPy/γCD films [26].

CVs recorded during (PPy) and poly(Py-β-DMCD) electrosynthesis in 0.1 M LiClO4 at a gold electrode in aqueous electrolyte solution are compared in Figs. 1 and 2. The first large oxidation peaks of pyrrole (Fig. 1) and pyrrole–cyclodextrin complex (Fig. 2) were occurring at 0.80 < E SCE < 1.00 V and 0.90 < E SCE < 1.10 V, respectively. This implies that the presence of cyclodextrin has some inhibiting effects on the oxidation potential of pyrrole. This difference in the oxidation behavior may also affect the growth behavior of the polymer on the electrode surface. The oxidation peak for PPy shifted to E SCE = 1.30 V during further oxidative polymerization. In contrast, for poly(Py-β-DMCD) (Fig. 2), the oxidation peak occurred at E SCE = 1.50 V during further oxidative polymerization. The CVs of both films in monomer-free background electrolyte solution are shown in Fig. 3. Apparently, the CVs seem to be of the same nature. Nevertheless, differences can be observed especially in the position of the oxidation peaks. In case of PPy, the oxidation peak is located at E SCE = 1.32 V, while for poly(Py-β-DMCD), the peak can be observed at E SCE = 1.52 V. There is a shift of the oxidation peak by 0.20 V. This means that the presence of cyclodextrin not only increases the oxidation potential of pyrrole (Fig. 1) but also affects the properties of the resulting polymer film in a similar manner (Fig. 3). Electropolymerization was carried out in acetonitrile (with a content of water of <0.05%) to analyze the effect of the solvent on the behavior of both the pyrrole and the pyrrole–cyclodextrin in the polymerization process and on the behavior of the respective polymers. According to our knowledge, the use of acetonitrile with around 1 to 2 wt% of water also results in redox-active and conducting PPy films [11, 29]. Anyway, in our study, the effect of the water content was of no interest; thus, we used a solvent with minimum amount of water. The growth of PPy and poly(Py-β-DMCD) in acetonitrile in the range of −0.40 < E Ag/AgCl < 0.90 V is shown in Figs. 4 and 5. In this system, no clear shift in the oxidation potential can be seen. The only observable difference is in the shape of the oxidation peak. In case of PPy electrosynthesis, the oxidation peak is observed at E Ag/AgCl = 0.30 V. With poly(Py-β-DMCD), there is a plateau extending between 0.30 and 0.60 V (see Fig. 6). These observations clearly demonstrate the interaction of cyclodextrin with pyrrole monomers as well as its interactions in the electropolymerization product. The encapsulation of pyrrole monomers into the cyclodextrin makes the oxidation of pyrrole more difficult conceivably by hindering the electron transfer from the pyrrole unit to the gold electrode. Similarly, the shift of the oxidation peak of poly(Py-β-DMCD) by 0.20 V toward positive potentials as compared to PPy might be attributed to the presence of cyclodextrin units in the form of a shield around PPy chain in poly(Py-β-DMCD). This slight shift of the oxidation peak for poly(Py-β-DMCD) in aqueous and nonaqueous (acetonitrile) solutions compared to PPy may be a result of the hydrophobic pyrrole partly or entirely included in the CD hydrophobic interior cavity [24]. It is clear that the hydrophobic PPy chains have no affinity for the external hydrophilic β-DMCD surface. On the contrary, because of their affinity for the hydrophobic internal β-DMCD surface, the reduced PPy chains could be threaded into these molecules.

CVs (1, 2, 3,..., 40th cycle) during formation of poly(Py-β-DMCD) film in aqueous solution containing 0.1 M LiClO4 and 0.05 M pyrrole-2,6-dimethyl-β-cyclodextrin under the same experimental conditions as in Fig. 1

CVs (1, 2, 3,..., 40th cycle) during formation of poly(Py-β-DMCD) film in acetonitrile containing 0.1 M LiClO4 and 0.05 M pyrrole-2,6-dimethyl-β-cyclodextrin under the same experimental conditions as in Fig. 4

In situ conductivity measurements

For in situ conductivity measurements, PPy and poly(Py-β-DMCD) were deposited potentiodynamically by cycling the potentials from −0.20 < E SCE < 1.80 V in aqueous solution and from −0.20 < E Ag/AgCl < 0.90 V in nonaqueous solution at 50 mV·s−1, respectively, on a gold band-gap electrode. The number of deposition cycles (for details, see above) was the same for all samples enabling comparison between the films based on the assumption that polymer yields are comparable. Figure 7a–d shows the resistance behavior of PPy and poly(Py-β-DMCD) films in different solvent systems. The resistivity vs applied electrode potential plots for PPy films show a single conductivity change with a highly stable conductivity in acetonitrile as well as in aqueous solution (Fig. 7a,b) The resistivity of PPy film decreases sharply by 4 orders of magnitude at E Ag/AgCl = 0.00 V and then remains almost constant up to E Ag/AgCl = 0.90 V in acetonitrile (Fig. 7a). In aqueous solution, the change in resistivity was observed at E SCE = 0.40 V, but the resistivity was generally higher than PPy film in the acetonitrile solution by 1.40 orders of magnitude (Fig. 7b). Maximum conductivity can be observed in the range of 0.10 < E Ag/AgCl < 0.90 V (Fig. 7a) and 0.45 < E SCE < 1.80 V (Fig. 7b), respectively. As with PPy, one change can be observed in the in situ conductivities of poly(Py-β-DMCD). However, the change amounts only to 2.7 and 3.4 orders of magnitude, respectively, as compared to PPy films. Maximum conductivity can be observed in the range of 0.30 < E Ag/AgCl < 0.90 V (Fig. 7c) and 0.20 < E SCE < 1.80 V (Fig. 7d), respectively. According to these observations, the in situ films prepared in acetonitrile solution are more conductive than those synthesized in aqueous solution by approximately an order of magnitude. This might be due to a larger conjugation length of the polymer and a better contact with the metal electrode in the former case [6]. However, the conductivity of poly(Py-β-DMCD) was observed to be lower than of PPy in nonaqueous solvent, which again might be due to the presence of cyclodextrin in the polymer film.

a Conductivity vs electrode potential data for PPy prepared potentiodynamically by cycling the potentials from −0.40 < E Ag/AgCl < 0.90 V in LiClO4 nonaqueous solution (from a solution of 0.1 M pyrrole in acetonitrile + 0.1 M LiClO4) in a solution of acetonitrile + 0.1 M LiClO4. b Conductivity vs electrode potential data for PPy prepared potentiodynamically by cycling the potentials from −0.20 < E SCE < 1.80 (from a solution of 0.1 M pyrrole in 0.1 M LiClO4 aqueous solution) in a 0.1-M LiClO4 aqueous solution. c Conductivity vs electrode potential data for poly(Py-β-DMCD) prepared potentiodynamically by cycling the potentials from −0.40 < E Ag/AgCl < 0.90 V in LiClO4 nonaqueous solution (from a solution of 0.05 M pyrrole-2,6-dimethyl-β-cyclodextrin complex in acetonitrile + 0.1 M LiClO4) in a solution of acetonitrile + 0.1 M LiClO4. d Conductivity vs electrode potential data for poly(Py-β-DMCD) prepared potentiodynamically by cycling the potentials from −0.20 < E SCE < 1.80 V in LiClO4 aqueous solution (from a solution of 0.05 M pyrrole-2,6-dimethyl-β-cyclodextrin complex in 0.1 M LiClO4 aqueous solution) in a 0.1 M LiClO4 aqueous solution

In situ UV–Vis spectroelectrochemistry

Thick and adherent PPy films prepared potentiodynamically by cycling the potentials from −0.40 < E Ag/AgCl < 0.90 V on an ITO electrode show reversible color change from violet to black/brown with increasing anodic potentials (see Fig. 8). The film in the reduced state shows an absorption band around 360 nm which is attributed to the π–π* transition of the pyrrole moiety, whereas the fully oxidized black form shows a broad absorption with a maximum around 780 to 880 nm as reported in the literature [30]. Between these limits, the film color is violet due to a third absorption that develops at 460 to 540 nm with maximum absorbance at E Ag/AgCl = 0.00 to 0.20 V. This absorption is assigned to the high-energy polaron transition [31, 32]. The UV–Vis spectra at different electrode potentials for poly(Py-β-DMCD) are shown in Fig. 9. Like PPy, in the reduced state, the poly(Py-β-DMCD) film shows an absorption band at about 380 nm which is attributed to the π–π* transition. The fully oxidized black form shows an absorption with a maximum around 830 nm. By comparison, PPy films show upon oxidation a continuous increase of absorption into the NIR. The absorption band at 520 nm in PPy disappears completely in poly(Py-β-DMCD). This may be due to the absence of the high-energy polaron transition because of interaction between polymer chain and CDs.

The charge in absorbance of bands at 880 (Fig. 8) and 830 nm (Fig. 9) as a function of applied potential both for PPy and poly(Py-β-DMCD) can be correlated to the amount of mobile charge carriers present in the system. It is noteworthy that with increasing applied potential, the absorbance of the both bands increases whereas the conductivity (Fig. 7a,c) increases and attains a nearly constant value.

Conclusions

Poly(Py-β-DMCD) films were synthesized electrochemically after complexation of pyrrole with 2,6-dimethyl-β-cyclodextrin. Slight positive potential shifts are observed for poly(Py-β-DMCD) in aqueous and nonaqueous (acetonitrile) solutions compared to PPy films. The incorporation of CDs in the film causes significant effects. Although cyclodextrins are not electroactive, electrochemical activation is required to trigger significant insertion of β-DMCD. The driving force that makes it possible to insert CDs into the polymer can be seen as electrochemically controlled molecular recognition forces. The possible structures for the polymeric materials are (1) with covalent bonding between the PPy chains and CDs, (2) without covalent bonding but only insertion of CDs between the polymeric chains, or (3) partial encapsulation of the PPy chains with CDs. In fact, from hydrophilic–hydrophobic considerations, we suggest that the most probable conformation of cyclodextrins in the polymer layers is the partial encapsulation of the PPy chains. In addition, we need more structural information to confirm this proposition.

References

Nalwa HS (ed) (1997) Handbook of organic conductive molecules and polymers, vols 2 and 3. Wiley, England

Skotheim TA, Elsenbaumer RL, Reynolds JR (eds) (1998) Handbook of conducting polymers, vols 1 and 2. Marcel Dekker, New York

Holze R (2001) In: Nalwa HS (ed) Handbook of advanced electronic and photonic materials and devices, vol 8. Academic, San Diego, CA, p 209

Diaz AF, Bargon J (1986) In: Skotheim TA (ed) Handbook of conducting polymers, vol I. Marcel Dekker, New York, p 81

Vernitskaya TV, Efimov ON (1997) Russ Chem Rev 66:443

Genies EM, Bidan G, Diaz AF (1983) J Electroanal Chem 149:101

Kanazawa KK, Diaz AF, Gill WD, Kwak JF, Logan JA, Rabolt JF, Street GB (1979) Chem Commun 19:854

Qian R, Qiu J, Yan B (1985) Synth Met 11:81

Ko JM, Rhee HW, Park SM, Kim CY (1990) J Electrochem Soc 137:905

Matsue T, Evans DH, Osa T, Kobayashi N (1985) J Am Chem Soc 107:3411

Lee JY, Park SM (2000) J Electrochem Soc 147:4189

Isnin R, Salam C, Kaifer AE (1991) J Org Chem 56:35

Wang Y, Mendoza S, Kaifer AE (1998) J Inorg Chem 37:317

Chen W, Wan X, Xu N, Xue G (2003) Macromolecules 36:276

Ching KIC, Lacroix JC, Jouini M, Lacaze PC (1999) J Mater Chem 9:1065

Chen Q, Pamidi P, Wang J, Kutner W (1995) Anal Chim Acta 306:201

Cardian DJ (2002) Adv Mater 14:553

Wu Q, Xue Z, Qi Z, Wang F (2000) Polymer 41:2029

Enzel P, Bein T (1989) J Phys Chem 93:6270

Belosludov RV, Mizuseki H, Ichinoseki K, Kawazoe Y (2002) Jpn J Appl Phys 41:2739

Yuan GL, Kuramoto N, Takeishi M (2003) Polym Adv Technol 14:428

Lagrost C, Lacroix JC, Aeiyach S, Jouini M, Ching KIC, Lacaze PC (1998) Chem Commun 4:489

Lagrost C, Ching KIC, Lacroix JC, Aeiyach S, Jouini M, Lacaze PC, Tanguy J (1999) J Mater Chem 9:2351

Temsamami KR, Mark HB, Kutner W, Stalcup AM (2002) J Solid State Electrochem 6:391

Izaoumen N, Bouchta D, Zejli H, Kaoutit ME, Stalcup AM, Temsamani KR (2005) Talanta 66:111

Bouchta D, Izaoumen N, Zejli H, Kaoutit M-El, Temsamani KR (2005) Anal Lett 38:1019

Holze R, Lippe J (1990) Synth Met 38:99

Gritzner G, Kuta J (1984) Pure Appl Chem 56:461

Zhou M, Heinze J (1999) J Phys Chem B 103:8451

Yakushi K, Lauchlan LJ, Clarke TC, Street GB (1983) J Chem Phys 79:4774

Breads JL, Scott JC, Yakushi K, Street GB (1983) Phys Rev B 30:102

Zotti G, Schiavon G (1989) Synth Met 30:151

Acknowledgments

One of us (JA) acknowledges the financial support from the Ministry of Science, Research and Technology, Islamic Republic of Iran. Further support from the Fonds der Chemischen Industrie and the Deutsche Forschungsgemeinschaft (Graduiertenkolleg GRK 829/1) is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper is dedicated to Prof. Alan Bond on the occasion of his 65th birthday in recognition of his numerous contributions toward electrochemistry.

Rights and permissions

About this article

Cite this article

Arjomandi, J., Holze, R. Spectroelectrochemistry of conducting polypyrrole and poly(pyrrole–cyclodextrin) prepared in aqueous and nonaqueous solvents. J Solid State Electrochem 11, 1093–1100 (2007). https://doi.org/10.1007/s10008-006-0243-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-006-0243-7