Abstract

In the present work we investigate, through DFT calculations, the mechanism of formation of a molecular imprinted polymer for the acetamiprid (ACT) insecticide, using four different functional monomers, four molar ratios attempts, and considering eight distinct solvents. As the main result we obtain the following theoretical protocol for the MIP synthesis: methacrylic acid (MMA) as functional monomer, 1:4 M ratio, i.e., one ACT to four MMAs, and chloroform as solvent. This DFT calculated condition shows more favorable energies for the formed complexes. We consider this work quite relevant since it can be used by experimentalists in order to reach an efficient MIP synthesis for ACT, avoiding wasted time and laboratory resources.

Best MIP Synthesis Protocol for Acetamiprid

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Molecularly imprinted polymers (MIPs) have often been employed in separation science as a sorbent phase in the extraction methods aiming to improve the selectivity and cleaning of complex matrices [1]. MIP is a type of polymer formed from a functional monomer (FM) and a crosslinking agent in the presence of a template molecule (TM), which is the analyte to be extracted. The macromolecular system obtained after the washing step, subsequent to the synthesis, is characterized by the formation of selective sites with favorable size, shape, and electronic structure, which is capable of retaining the TM in new extractions [2, 3]. In simple terms, MIP is a polymer with a memory of the shape and functional groups of a TM. In this sense, MIP can molecularly and selectively recognize the TM in various types of complex samples, such as food, plasma, urine, etc., thus contributing to its efficient extraction [4].

Recently, MIPs have received special attention in the separation and purification processes of analytes [5]. In this sense, they have presented remarkable benefits as separation agents in capillary electrophoresis and chromatography [6,7,8,9], as chemical sensors [10, 11] and drug delivery systems [12, 13].

Regarding the MIP synthesis, the standard experimental procedure is expensive, time-consuming, and tedious. Usually, the choice of the best imprinting conditions has been done empirically based on chemical intuition and trial-and-error method leading to the waste of large quantities of synthesis reactants. In this context, seeking to obtain the best molecular properties for an MIP, computational studies have proved to be a fast, rational, and efficient tool in the search for the ideal imprinting conditions, thus avoiding the waste of laboratory resources [14, 15]. In this way, computer-aided studies have enabled the adequate preparation of more efficient MIPs by a rational design procedure [16].

With the development of more powerful computers at the beginning of the twenty-first century, the use of theoretical methodologies on MIP design has grown substantially [17]. In this sense, several works concerning the molecular modeling of MIPs have been reported since then emphasizing the applicability of the density functional theory (DFT) [18,19,20,21,22,23,24]. The DFT method provides an accurate study of molecular systems at a lower computational effort when compared to pure ab initio methods such as post-Hartree-Fock. In recent works [23, 24], our research group has investigated the MIP formation process for tramadol (TRM), an analgesic opioid [23], and dinotefuran (DNF), a neonicotinoid insecticide [24]. The binding process for both molecules with different FMs and solvents was performed by DFT calculations at the B3LYP/6-31G(d,p) level of theory. From this theoretical analysis it was possible to establish the best synthesis conditions for the MIPs involving the TRM and DNF template molecules.

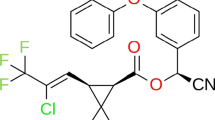

In this context, in order to continue the studies of MIPs for neonicotinoid insecticides, the present work reports a DFT-based investigation aiming to obtain the ideal synthesis protocol of an MIP for acetamiprid (ACT), whose chemical structure is shown in Fig. 1. ACT is a chloropyridine neonicotinoid insecticide frequently employed to control a wide range of household pests, such as flies, ants, cockroaches, bugs, gnats, crickets, etc. [25]. The main goal is to find theoretically an adequate FM, a more stable stoichiometry established between FM and TM, and the best solvent.

It is worth emphasizing that to the best of our knowledge, there are no computer-aided studies reported in the literature involving MIP having ACT as template molecule.

Methods

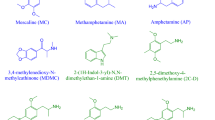

DFT/B3LYP/6-31G(d,p) calculations were carried out aiming to optimize the following species: the template molecule (ACT), the four FMs tested, acid p-vinyl benzoic (APV), acrylic acid (AA), 2-(trifluoromethyl)-arylic acid (TFMAA), methacrylic acid (MAA), and all FM/template complexes in distinct molar ratios. These respective FMs were selected since they are the most used in the MIPs studies [26]. Over the processes of geometry optimization no symmetry constraints were determined. B3LYP/6-31G(d,p) harmonic frequency calculations were performed for the equilibrium structures, characterizing them as true minima on the potential energy surface (all frequencies were real).

Figure S1 and Table S1 found in the Supplementary information shows a comparison between the B3LYP/6-31G(d,p) optimized geometry for ACT with its crystallographic structure obtained from X-ray data [27]. As can be seen, the theoretical and experimental molecular structures are quite similar, validating the methodology used in the present work.

Initially, the goal was to establish the most adequate FM molecule (among the four tested) and the best complex molar ratio (among the four tested: 1:1, 1:2, 1:3, and 1:4). The complexation energy (∆E) and Gibbs free energy (∆G) related to the formation process of the pre-polymerization complexes were calculated from the following Eqs. (1) and (2):

n varies from 1 to 4 providing the 1:1, 1:2, 1:3, and 1:4 stoichiometries.

Once the best FM and the complex stoichiometry were obtained, posteriorly the solvent effect was considered on the stability of pre-polymerization complexes using the universal solvent model (SMD). The solvents tested were: acetone, acetonitrile, chloroform, dimethyl sulfoxide, methanol, and water.

All DFT calculations were performed with the Gaussian 2009 quantum mechanical package [28]. From the optimized geometries obtained from Gaussian, the molecular models were generated on the GaussView 5.0 program.

Results and discussion

The ACT molecule (Fig. 1) presents a chemical structure containing distinct interaction sites capable of forming hydrogen bonds with the FMs. Therefore, aiming to obtain the higher affinity interaction sites, the electrostatic density map of ACT was calculated at the B3LYP/6-31G(d,p) level of theory.

The ACT electrostatic charge distribution as well as its optimized geometry is depicted in Fig. 2. One can clearly verify that the attractive affinity sites between template molecule and FMs will be established at the moieties highlighted in Fig. 2 as N-1, N-2, N-3, and Cl-1. Therefore, each of the four FMs was sequentially hydrogen bonded in the four regions of interaction (based on quantitative data provided by the electrostatic density map), forming different pre-polymerization complexes in 1:1, 1:2, 1:3, and 1:4 M ratios.

The calculated energies, ∆E and ∆G, considering different molar ratios in gas phase for complexes are shown in Table 1. The optimized geometries for the 1:4 pre-polymerization complexes are depicted in Fig. 3.

Observing Table 1, one can readily check that the most stable complexes are those found in the 1:4 M ratio. This specific stoichiometry presents the most favorable (negatives) ΔE and ΔG values. Furthermore, the hydrogen bonds formed between the ACT and FMs play a key role in the stability of such complexes. From Fig. 3, one can notice the formation of four hydrogen bonds for each pre-polymerization complex. It is worth mentioning that the DFT methods afford a computationally viable way to consider the effects of electron correlation in the theoretical calculations, which is essential for the accurate description of hydrogen bonds.

In Table 1, one can verify that the ACT-(AA), ACT-(APV), and ACT-(TFMAA) species presented small energy differences among them (about 3.0 kcal mol−1 for ΔE and 2.0 kcal mol−1 for ΔG). In contrast, the most stable species in all stoicheometries is found with the MAA functional monomer. The ACT-(MAA) is always more favorable in comparison to the other complexes, as can be checked from both ΔE and ΔG values in Table 1. Therefore, in the first part of the present work, based on energetic and structural analyses, we could determine the MMA as being the best FM for ACT. Moreover, 1:4 was found to be the most adequate molar ratio.

A further step of the present work was to establish the most suitable solvent for the complexation process of FM and TM. The choice of solvent is a crucial step for MIP synthesis, since it needs to solubilize all the species present on synthesis without interfering in the interactions between reactants. Table 2 shows the complexation energies, ΔE and ΔG, in each solvent tested, for the ACT-(MAA)4 species (previously found as the best pre-polymerization complex in gas phase).

As can be noticed in Table 2, the most favorable values of ∆G (−16.8 kcal mol−1) and ΔE (−63.7 kcal mol−1) are found for ACT-(MAA)4 in chloroform. Since the chemical interaction between TM and FM is established by hydrogen bonds, chloroform, which is a nonpolar solvent with low dielectric constant, provides a more appropriated medium for such intermolecular forces. Moreover, solvents such as acetonitrile, which presents a higher dielectric constant, may eventually be used; however, the generated polymer may present lower affinity in rebinding to the TM. For protic solvents, such as methanol, hydrogen atoms will be released in the medium, which may compete with the formation of hydrogen bonds between FM and TM, thus giving rise to a polymer with damaged functionality.

Table S2 in the Supplementary information contains hydrogen bond distances in gas and solvent phases for the 1:4 ACT-(MAA)4 complex. As can be seen, the four H-bond distances decrease from the gas to the solvent phases, evidencing that the presence of the solvent, whatever it is, increases the electrostatic character of the H-bonds. Furthermore, among all the solvents, the shortest H-bonds are observed for the 1:4 ACT-(MAA)4 complex in chloroform medium, which is the most stable complex found (ΔG = −16.8 kcal mol−1).

Table S3 shows a relationship between the dipole moments calculated for the 1:4 ACT-(MAA)4 complex and their ΔG complexation energies in distinct solvents. As can be noticed when the dielectric constant is >20, the increase of ε (acetone → water) practically does not affect the ΔG and the values of dipole moments remain close. However, in the presence of chloroform, whose dielectric constant is low (ε = 4.71), the ΔG obtained is the most negative one (most stable). This result shows that the complex stability seems to be directly related to solvent polarity, and nonpolar solvents are a more appropriated medium in this case.

Finally, from the results we obtained the best theoretical protocol (FM/TM-FM molar ratio/solvent) for the MIP synthesis, which is 1:4 M ratio, MAA as FM, and chloroform as solvent. This set of conditions is extremely important since it can be used by experimentalists in order to reach an efficient MIP synthesis for ACT, avoiding the waste of laboratory resources.

Conclusions

In the present study we report a theoretical analysis concerning the complexation process of functional monomers with acetamiprid aiming to estimate the best MIP synthesis protocol. The main conclusions drawn from our results are summarized as follows: (i) the adequate FM/TM ratio was 1:4 based on structural and energetic data; (ii) the most suitable functional monomer was found to be the MAA; (iii) chloroform was estimated as being the best solvent; (iv) the hydrogen bonds established between the ACT and FMs play a key role in the stability of pre-polymerization complexes.

References

Hyotylainen T (2009). Anal Bioanal Chem 394:743

Tabandeh M et al (2012). J Chromatogr B 24:898

Wan W et al (2013). Angew Chem Int Ed 52:7023

Lu CH (2012). Biosens Bioelectron 31:439

Urraca JL (2011). J Am Chem Soc 133:9220

Kulsing C et al (2014). J Chromatogr A 1354:85

Gao B et al (2018). Int J Polym Mater Polym Biomater 67:517

Canfarotta F et al (2016). Nat Protoc 11:443

Poma A et al (2010). Trends Biotechnol 28:629

Storer CS et al (2018). Sensors 18:531

Zhou J et al (2014). Biosens Bioelectron 54:199

Kurczewska J et al (2017). Mater Lett 201:46

Piletska EV et al (2015). Analyst 140:3113

Subrahmanyan S, Piletsky SA (2009) Computational design of molecularly imprinted polymers. Springer, New York

Levi L et al (2011). J Mol Recognit 24:883

Nicholls IA et al (2009). Biosens Bioelectron 25:543

Cowen T et al (2016). Anal Chim Acta 936:62

De Barros LA et al (2014). J Braz Chem Soc 27:2300

Ahmadi F et al (2014). J Chromatogr A 1338:9

Fernandes LS et al (2015). Eur Polym J 71:364

Tadi KK et al (2015). RSC Adv 5:99115

Nezhadali A et al (2016). Talanta 146:525

Fonseca MC et al (2016). Chem Phys Lett 645:174

Silva CF et al (2018). Analyst 143:141

Goulson D (2013). J Appl Ecol 50:977

Karim K et al (2005). Adv Drug Deliv Rev 57:1795

Chopra D et al (2004). Acta Cryst E 60:2374

FRISCH MJ et al (2009) Gaussian 09, revision D.01. Gaussian, Inc., Wallingford

Acknowledgments

The authors would like to thank the financial support of Brazilian funding agencies FAPEMIG (Fundação de Amparo à Pesquisa do Estado de Minas Gerais) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico). This work is also part of the project involving the Rede Mineira de Química (RQ-MG) supported by FAPEMIG.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 116 kb)

Rights and permissions

About this article

Cite this article

Silva, C.F., Borges, K.B. & Nascimento, C.S. Computational study on acetamiprid-molecular imprinted polymer. J Mol Model 25, 104 (2019). https://doi.org/10.1007/s00894-019-3990-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-019-3990-y