Abstract

Objectives

The aims of this study were to evaluate the radiopacity, compressive strength, setting time, and porosity of white Portland cement (PC) with the addition of bismuth oxide (Bi2O3), zirconium dioxide (ZrO2), and ytterbium trifluoride (YbF3) after immersion at 37 °C for 7 days in distilled water or phosphate buffer saline.

Materials and methods

Specimens measuring 8 mm in diameter and 1 mm in thickness were fabricated from PC with the addition of 10, 20, and 30 wt% Bi2O3, ZrO2 or YbF3. ProRoot MTA (Dentsply, Tulsa, OK, USA) and pure PC were used as controls. For radiopacity assessments, specimens were radiographed alongside a tooth slices and an aluminum stepwedge on Extraspeed occlusal dental films (Insight Kodak, Rochester, New York). Mean optical density of each specimen was calculated and used to express radiopacity of the material as an equivalent thickness of aluminum. Compressive strength was measured by using 4-mm diameter and 6-mm high specimens and Universal testing machine. High-pressure mercury intrusion porosimeter (Carlo Erba Porosimeter 2000) was employed to measure the porosity of the specimens. The setting time was measured by using a needle of 100 g in weight. The morphology of specimens was evaluated using a scanning electron microscope (TESCAN Mira3 XMU, USA Inc.). Data were analyzed by one-way ANOVA and post hoc Tukey test (P < 0.05).

Results

The PC with the addition of at least 10 wt% Bi2O3 and 20 wt% ZrO2 or YbF3 demonstrated greater radiopacity value than the recommended 3 mmAl cut-off. ZrO2 and YbF3 increased the compressive strength of PC, but it was not statistically significant (P > 0.05), while Bi2O3 decreased it (P < 0.05). All radiopacifiers significantly increased the porosity of the experimental cements (P < 0.05). Bi2O3 extended the setting time of PC (P < 0.05), whilst ZrO2 and YbF3 did not significantly affect it (P > 0.05).

Conclusions

ZrO2 and YbF3 may be used as a suitable alternative to replace Bi2O3 in MTA without influencing its physical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mineral trioxide aggregate (MTA) is a cement-type material, developed in the 1990s at Loma Linda University. Originally developed for retrograde filling [1], MTA has since been indicated in root perforation repairs [2], pulp-capping [3], pulpotomy [4], and the treatment of traumatized teeth with incomplete apexification [5]. The success of MTA arises from its superior biological properties [6], excellent sealing ability [7], and low solubility [8].

Both MTA and Portland cement (PC) are silicate-based cements; a comparative analysis reported the similarities between MTA and PC in respect to biocompatibility [6], pulp protection [9], and sealing ability [10]. However, PC itself has insufficient radiopacity, and thus, in MTA, bismuth oxide (Bi2O3) is added to PC as a radiopacifier in 4:1 proportion [11]. Furthermore, a shortcoming of both MTA and PC is their long setting time which has been reported to be about 3 h [12].

The ideal radiopacifier should be inert, non-toxic, and contaminant-free. The addition of radiopacifying agent to calcium silicate-based cement should be sufficient to enable its visualization on radiograph without compromising other properties [11]. However, the addition of Bi2O3 seems to be deleterious to the physical properties of the material. Bi2O3 is not inert and does not act as filler but actively takes part in hydration mechanism of the cement and displace silicon in hydrated paste. After 28 days of hydration, only 8 % of Bi2O3 remains in the form of oxide; the rest leaches out or is incorporated in the cement [13]. Moreover, PC with Bi2O3 experiences extended setting time and reduced compressive strength [14]. Yet, bismuth affects the microstructure of MTA inducing creation of dense rims with central voids and diminishes the release of calcium ions by the cement making up for the lack of cell proliferation [15]. Also, Bi2O3 increases the water uptake of the cement; high water to cement ratio increases the susceptibility of the cement to leaching [13]. High water uptake causes an extensive expansion leading to higher risk of root fracture [16]. Finally, Bi2O3 is soluble in acid media additionally increasing its leaching from the cement and thus the degradation of the material [15, 17].

Among other properties, porosity of an endodontic material is an important property to consider because it is related to the solubility, degradation, and longevity of the cement. It is documented that the addition of Bi2O3 increases the porosity of PC and consequently decreases its compressive strength [18]. Alternative radiopacifiers, such as barium sulfate, zirconium oxide, iodoform, gold powder, titanium dioxide, lead oxide, calcium subnitrate, calcium tungstate, bismuth carbonate, and bismuth subnitrate have been proposed to overcome disadvantages of Bi2O3 [11, 19, 20]. However, little is known about the interference of alternative radiopacifiers with the porosity of PC. Thus, the aim of this study was to evaluate the influence of Bi2O3, zirconium oxide (ZrO2), and ytterbium trifluoride (YbF3) on the radiopacity, compressive strength, setting time, and porosity of PC.

Materials and methods

Specimen preparation

Radiopacifiers were added to PC (Italcementi SPA, Bergamo, Italy) by replacing 10, 20, and 30 % of the cement powder by weight. Each portion of the cement was weighted on an electronic analytic balance (Mettler, Zurich, Switzerland). All specimens were hand-mixed at a powder to liquid ratio of 1 g cement per 0.37 ml distilled water. A glass mixing pad and stainless steel spatula were used for hand mixing.

For radiopacity assessments, cements were placed in the molds 8 mm in diameter and 1 mm thick. After removal from the mold, thickness of the specimens was checked with a digital caliper. If necessary, specimens were ground wet with 600-grit silicon carbide paper to reach the thickness of 1 ± 0.1 mm. Specimens were randomly divided in two groups and immersed for 10 days whether in distilled water at 37 °C and 95 % humidity or in phosphate buffer saline solution (PBS). Five specimens were prepared for each cement. For setting time measurements, at 120 ± 10 s after the onset of mixtures, the assembly was stored in an incubator at 37 °C and 95 % humidity. Three specimens of each of the investigated cements were analyzed. For compressive strength testing the materials were mixed and compacted into metal molds (4 mm diameter and 6 mm high) and allowed to set for 24 h in an incubator at 37 °C and 95 % humidity before the specimens were removed from the molds and cured in distilled water or in PBS at 37 °C for 10 days. Seven specimens were prepared for each material tested. For porosity measurements, five specimens of each cement measuring 8 mm in diameter and 1 mm in thickness were prepared in a similar way as described for radiopacity assessments. The specimens were cured in an incubator in distilled water or in PBS at 37 °C for 10 days. White ProRoot MTA (Dentsply, Tulsa Dental Products, Tulsa, OK, USA) and pure PC were used as a positive and negative controls, respectively.

Radiopacity assessments

Each specimen of the material was placed alongside a tooth slice specimen and an aluminum stepwedge (99.6 % pure) varying in thickness from 1 to 10 mm in increments of 1 mm each on Extraspeed occlusal film (Insight Kodak, Rochester, NY, USA) and radiographed by using X-ray unit (Trophy Radiology, Cedex, France) operating at 65 kV, 7 mA, for 0.32 s and at a focus to target distance of 35 cm. The optical densities of the specimens were calculated by using transmission densitometer (X Rite 341, Grand Rapids, MI). Care was taken to analyze only regions free of air bubbles or other irregularities. Three readings were taken for each specimen, and the mean optical density was calculated. The mean optical densities were plotted against the number of aluminum steps; the plots were linearly regressed, and regressions were used to convert mean optical densities into millimeters of aluminum.

Determination of compressive strength

The wet comprehensive strength was determined in accordance to International Standard Organization (ISO) 6876 by dividing the breaking load (unit: Newton) of every specimen on a Universal testing machine (Instron, Norwood, USA, loading rate 50 N/min) by the cross-sectional area (Newton per square millimeter).

Setting time

To determine setting time, a needle having a mass of 100 ± 1 g with a needle attachment having a flat end 2 ± 0.1 mm in diameter was vertically placed on the cement surface every 2 min. The needle was cleaned between each test. Setting time was considered as the time when needle failed to create an indentation onto the surface of the material after being allowed to settle for 5 s.

Density and porosity measurements

Density of the specimens was calculated using a pycnometer with benzene as the displacement fluid. The high-pressure mercury intrusion porosimeter (Carlo Erba Porosimeter 2000) operating in the interval 0.1–200 MPa and using Milestone 100 Software System was employed to estimate the pores in interval 7.5–15,000 nm. Preparation of the samples was performed at room temperature and a pressure of 0.5 kPa.

Microstructural examination

The morphology of cements was evaluated using a scanning electron microscope (SEM) (TESCAN Mira3 XMU, USA Inc.) at 20 kV. The specimens used for compressive strength testing were attached to aluminum stubs using carbon double-sided tape and carbon-coated. SEM analysis was carried out to analyze the microstructure of selected regions within each specimen.

Statistical analysis

The data were tested for normality of distribution by Kolmogorov–Smirnov test (P < 0.05). A one-way analysis of variance (ANOVA), followed by Tukey’s test, was used for comparison of the differences between the groups (P < 0.05). The Statistica 8.0 (Stat Soft, Inc., Tulsa, OK, USA) was used for all statistical analysis.

Results

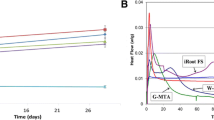

The evaluators of the results were same as those who performed the study. The results for the radiopacity are present in Fig. 1. The ANOVA revealed statistically significant differences between the mean radiopacity values of the specimens tested. The PC with the addition of 30 wt% Bi2O3 immersed in PBS experienced the greatest, whereas pure PC soaked in PBS presented the lowest radiopacity value of all cements. The PC with 20 and 30 wt% of ZrO2 or YbF3, all mixtures of Bi2O3, and ProRoot MTA (Dentsply) met the ISO guideline of 3 mmAl. None of the investigated materials reached significance in radiopacity when immersed in PBS in comparison with distilled water (P > 0.05). The addition of 20 % and 30 % of ZrO2 and YbF3 at all concentrations resulted in increased compressive strength (P < 0.05) of PC while the addition of Bi2O3 decreased its compressive strength (P < 0.05). The addition of 10 % ZrO2 did not influence the material’s compressive strength (P > 0.05) (Fig. 2). ProRoot MTA (Dentsply) has demonstrated marked difference in compressive strength when cured in water and PBS (P < 0.05), while other cements did not show statistical significance (P > 0.05).

Bi2O3 significantly increased the setting time of PC (P < 0.05), while the addition of ZrO2 and YbF3 did not significantly affect it (P > 0.05) (Fig. 3).

Some textural properties, such as porosity and total pore volume per mass (the specific pore volume), the specific surface area, S Hg, and the most dominant diameter, d max, of the investigated specimens were calculated, and the results are in Table 1, together with the results obtained from the pycnometer density measurements. According to these results, total pore volume for PC was 0.042 cm3/g in interval 15,000 < d < 7.5 nm, with 60 % of total pore volume in interval 7.5 < d < 30 nm, with d max of 15 nm and S HG of 11 m2/g. The addition of Bi2O3 resulted in increased the total pore volume from 0.076 cm3/g in water and 0.082 cm3/g in PBS for 10 % addition to 0.125 cm3/g in water and 0.088 cm3/g in PBS for 30 % addition. Also, d max increased from 20 nm for 10 % addition to 100 nm for 30 % addition of Bi2O3, while the porosity increased from 18 % to 28 % in distilled water and 15 % to 23 % in PBS. The addition of ZrO2 resulted in increased S HG, porosity, and d max. The specimens with the YbF3 present similar S HG and porosity while the d max varied from 70 to 100 nm. The porosity of ProRoot MTA was statistically insignificant to the porosity of PC with 20 % addition of Bi2O3 (P < 0.05).

The scanning electron micrographs of the pure PC and PC with addition of Bi2O3, ZrO2, or YbF3 are shown in Figs. 4 and 5. The magnification on SEM images was increased until the individual particles could easily be identified on micrographs. Cement specimens were composed of spherical and angular particles with PC composed of needle-like particles with a wide range of sizes, whereas MTA particles were more homogenous than experimental cements particles. The radiopacifier grains were distinct from the cement grains, and they were evenly distributed in all the specimens analyzed. The grains of Bi2O3 exhibited a cluster formations ranging in size from approximately 5 to 10 μm in diameter. ZrO2 presented particles with a wide distribution of sizes ranging between 2 and 8 μm, while YbF3 particles, similar to Bi2O3, appeared to agglomerate together instead of remaining separate and varied in size from 3 to 10 μm.

Discussion

Over the past decade the uses of MTA have been mostly limited due to its inadequate compressive strength, long setting time, and poor workability [21]. Therefore, research continued to fabricate calcium silicate based cement with even better properties than MTA [22–24]. This study showed that, when formulating such a material, YbF3 and ZrO2 may be preferred over Bi2O3 as a radiopacifying agent.

The radiopacity value of experimental cement at 20 wt% Bi2O3 was found to be 5.13 and 5.36 mmAl when cured in water and PBS, respectively; it was 6.83 [11], 6.81 [25], 6.62 [26], 5.93 [20], 5.88 [19], and 4.48 mmAl [27] in previous studies. The radiopacity of ProRoot MTA (6.44 mmAl) favorably agrees with the results reported previously (5.72 [19], 6.74 [12], 7 [25], 7.5 [23], and 8 mmAl [11]). The variations in the results reported in different studies arise due to several reasons. Method used for evaluation can affect the measured radiopacity: The results obtained by digitization of radiographic films [20, 27] are lower than those obtained with densitometer [11, 28]. Particle size and shape can affect the water absorption of the material; materials composed of very fine particles absorb more water, which causes reduction in radiopacity of the material [29]. Finally, the purity of aluminum stepwedge can vary: Only 60 % of aluminum stepwedges obtained from representative laboratories worldwide meet the requirements specified by ISO protocols [30]. Several studies reported radiopacity values of PC associated with ZrO2 close to those in the present study [11, 19, 20]. The radiopacity of PC with YbF3 has not been mentioned in the literature until now.

Setting time for pure PC was 90 min in this study; in previous studies, it was between 40 [12] and 270 min [14]. The result for the setting time of MTA (105 min) reasonably agrees with previous studies that reported values between 40 [12] and 50 min [31] for initial and 140 [12], 202 [32], and 219 min [33] for final setting time. The differences in results arise from the use of needles with different weights and different time allowed for needle to be settled to create indentation. The ISO 6876 [34] specifies the use intender having a mass of (100 ± 0.5 g), whilst the researchers used rather the intenders weighting 113 g [29] for initial and 300 g [32], 400 g [14, 22, 33], or 453 g [30] for final setting time. Neither the ISO 6876 nor the vast majority of publications clarify the amount of time the needle rests on the surface [32]. Bi2O3 adversely affected the setting time of PC, decreasing it in 20 % at 20 wt%, which is its concentration in MTA. This result corroborates the previous findings [12]. In contrast, absence of significant effect of ZrO2 and YbF3 on the setting time of experimental cements in this study indicates lack of interaction between YbF3 and PC ingredients. Reduced setting time of PC would be useful as it would allow safer placement of restorative material, less time for adverse affect of oral contaminants, shorter time for possible washout of the cement [32], and reduced number of clinical appointments [14].

One of main shortcomings of MTA is its inadequate compressive strength [21]. The results of this study provide evidence, although not conclusive at this time, that ZrO2 has a positive effect on compressive strength of calcium silicate cements [22]. Camilleri et al. also reported that ZrO2 may be a promising alternative to Bi2O3 in MTA; 30 % addition of ZrO2 was declared to be the optimal concentration of this radiopacifier resulting in adequate compressive strength for a material intended for use as a root end filling material [22]. In the present study, compressive strength of ProRoot MTA (Dentsply) was 45.6 MPa which is in accordance with results reported elsewhere (28 [31], 30 [32], 33 [18], 43 [33], and 45 MPa [12]). What deserves to be mentioned is that YbF3 also slightly increased compressive strength of PC, in sharp contrast to Bi2O3 which decreased compressive strength of experimental cements. An intriguing result of the present work is that immersion in PBS led only to the increased compressive strength of ProRoot MTA (Dentsply), while the compressive strength of experimental cements remained unchanged.

Porosity of the cement refers to the amount of water throughout the cement pore system. The pore texture in dental cements arises from two sources: selective dissolution of some components and unreacted water or entrapped air [18]. The pore size is of great importance since it affects the ingrowth of new tissue and the degradation of the materials. Pores are classified in different classes depending on their size: micropores (pore diameter smaller than 2 nm), mesopores (pore diameter 2–50 nm), and macropores (pore diameter larger than 50 nm). Pores may be further classified according to how accessible they are to an external fluid as: closed (not accessible from the external), blind (open at one end), and through (open at both ends). The open porosity includes blind and through pores. Closed pores influence macroscopic properties of the material such as bulk density, elasticity, mechanical strength, and thermal conductivity [35]. The importance of open porosity is in its direct impact on the possibility of penetration of bacteria and bacterial toxins into unprotected dentin [36]. In this study, the porosity of ProRoot MTA (Dentsply) was 30.1 % which is in rough agreement with the results of the previous studies where porosities of 5.5 % [23] and 31 % [18] were reported. Regarding radiopacifier’s effect on the porosity both ZrO2 and YbF3 increased the porosity of PC to the lesser extent than Bi2O3. This is not contaminant with the results of the previous study in which the addition of ZrO2 led to the reduced overall porosity of the cement [22]. This may be due to the use of different methodology for porosity evaluation; mercury intrusion porosimetry was used in this study while in previous it was calculated by measuring the difference in mass between each sample when dried and submerged in solution. With the addition of Bi2O3, the pore volume of the pores range increased to the greater extent than when ZrO2 and YbF3 were added. According to analyzed parameters, the cement with the addition of YbF3 poses the most desired porous structure for endodontic application among the investigated experimental cements.

SEM showed the formation of tricalcium aluminate and calcium sulfate with water which is the characteristic of PC hydration mechanism. There was no reaction neither between the zirconium and ytterbium with the calcium, silicon, and aluminum from PC; on the contrary, it is well documented that bismuth in MTA replaces the silicon forming a complex microstructure with the calcium silicate hydrate which affects physical properties of the cement [15]. In addition, it has been documented in the literature that article shape and size influence significantly the handling characteristics of the material [13]. The fineness of the cement is a major factor influencing its physical properties. The addition of small size particles increases the specific surface area and makes the cement less workable [14]. With a similar particle size, a higher mechanical strength is designed by a reduced spreading in grit size, which could be observed in MTA. Therefore, for the more precise analysis of the influence of various radiopacifier upon cement properties, an optimized tricalcium silicate-based dental material should be manufactured with pure raw materials in controlled conditions in the laboratory to make a mixture of tricalcium silicate and radiopacifiers leading to constant properties. However, the authors of this study believe that PC can be used in investigations as a model system to investigate the effect of alternative radiopacifiers.

ProRoot MTA (Dentsply) that consists of PC and Bi2O3 was introduced in 1998 for both surgical and non-surgical endodontic treatments [7]. Recently, new silicate-based cement Biodentine (Septodont, Cedex, France) has been developed with ZrO2, rendering it sufficiently radiopaque. Also, Bioaggregate (Verio Dental, Vancouver, Canada) has been introduced with tantalum oxide instead of Bi2O3 as a radiopacifier [24]. Coming to a conclusion, this study showed that 20 % addition of ZrO2 is necessitated to reach 3 mmAl radiopacity minimum while the compressive strength of the material slightly increased. Regarding the compressive strength of the material, the results of this study stipulates that YbF3 seems to present even better substitute to Bi2O3 in MTA, since it slightly increased the compressive strength of PC. This concept of using YbF3 as a radiopacifier is further strengthened by the fact that Yb has higher atomic number (Z = 70) than Zr (Z = 40); thus, lower amount of radiopacifier is necessitated to make material distinguishable from anatomical structures on a radiograph without influencing other physical properties. The further systematic investigations are necessary to establish possible interference of ZrO2 and YbF3 with biocompatibility and therapeutic value of calcium silicate-based cements.

References

Al-Kahtani A, Shostad S, Schifferle R, Bhambhani S (2005) In-vitro evaluation of microleakage of an orthograde apical plug of mineral trioxide aggregate in permanent teeth with simulated immature apices. J Endod 31:117–119

Unal GC, Maden M, Isidan T (2010) Repair of furcal iatrogenic perforation with mineral trioxide aggregate: two years follow-up of two cases. Eur J Dent 4:475–481

Lee SK, Lee SI, Park JH, Jang JH, Kim HW, Kim EC (2010) Effect of calcium phosphate cements on growth and odontoblastic differentiation in human dental pulp cells. J Endod 36:1537–1542

Karabucak B, Li D, Lim J, Iqbal M (2005) Vital pulp therapy with mineral trioxide aggregate. Dent Traumatol 21:240–243

Oliveira TM, Sakai VT, Silva TC, Santos CF, Abdo RC, Machado MA (2008) Mineral trioxide aggregate as an alternative treatment for intruded permanent teeth with root resorption and incomplete apex formation. Dent Traumatol 24:565–568

Estrela C, Bammann LL, Estrela CR, Silva RS, Pecora JD (2000) Antimicrobial and chemical study of MTA, Portland cement, calcium hydroxide paste, sealapex and dycal. Braz Dent J 11:3–9

Torabinejad MWT, Pitt Ford TR (1993) Sealing ability of an MTA when used as a root end filling material. J Endod 19:591–595

Fridland M, Rosado R (2005) MTA solubility: a long term study. J Endod 31:376–379

Menezes R, Bramante CM, Letra A, Carvalho VG, Garcia RB (2004) Histologic evaluation of pulpotomies in dog using two types of mineral trioxide aggregate and regular and white Portland cements as wound dressings. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 98:376–379

De-Deus G, Reis C, Brandao C, Fidel S, Fidel RA (2007) The ability of Portland cement, MTA, and MTA Bio to prevent through-and-through fluid movement in repaired furcal perforations. J Endod 33:1374–1377

Camilleri J, Gandolfi MG (2010) Evaluation of the radiopacity of calcium silicate cements containing different radiopacifiers. Int Endod J 43:21–30

Islam I, Chng HK, Yap AU (2006) Comparison of the physical and mechanical properties of MTA and Portland cement. J Endod 32:193–197

Camilleri J (2008) Characterization of hydration products of mineral trioxide aggregate. Int Endod J 41:408–417

Camilleri J (2008) The physical properties of accelerated Portland cement for endodontic use. Int Endod J 41:151–157

Camilleri J (2007) Hydration mechanisms of mineral trioxide aggregate. Int Endod J 40:462–470

Laustsen MH, Munksgaard EC, Reit C, Bjorndal L (2005) A temporary filling material may cause cusp deflection, infractions and fractures in endodontically treated teeth. Int Endod J 38:653–657

Lide DR (1998) CRC handbook of chemistry and physics, 79th edn. CRC Press, Taylor & Francis, Abingdon, pp 1–10

Coomaraswamy KS, Lumley PJ, Hofmann MP (2007) Effect of bismuth oxide radioopacifier content on the material properties of an endodontic Portland cement-based (MTA-like) system. J Endod 33:295–298

Bortoluzzi EA, Guerreiro-Tanomaru JM, Tanomaru-Filho M, Duarte MA (2009) Radiographic effect of different radiopacifiers on a potential retrograde filling material. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 108:628–632

Hungaro Duarte MA, de Oliveira El Kadre GD, Vivan RR, Guerreiro Tanomaru JM, Tanomaru Filho M, de Moraes IG (2009) Radiopacity of Portland cement associated with different radiopacifying agents. J Endod 35:737–740

Parirokh M, Torabinejad M (2010) Mineral trioxide aggregate: a comprehensive literature review—part I: chemical, physical, and antibacterial properties. J Endod 36:16–27

Camilleri J, Cutajar A, Mallia B (2011) Hydration characteristics of zirconium oxide replaced Portland cement for use as a root-end filling material. Dent Mater 27:845–854

Cutajar A, Mallia B, Abela S, Camilleri J (2011) Replacement of radiopacifier in mineral trioxide aggregate; characterization and determination of physical properties. Dent Mater 27:879–891

Grech L, Mallia B, Camilleri J (2013) Characterization of set intermediate restorative material, biodentine, bioaggregate and a prototype calcium silicate cement for use as root-end filling materials. Int Endod J 46:632–641

Kim EC, Lee BC, Chang HS, Lee W, Hong CU, Min KS (2008) Evaluation of the radiopacity and cytotoxicity of Portland cements containing bismuth oxide. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 105:e54–e57

Saliba E, Abbassi-Ghadi S, Vowles R, Camilleri J, Hooper S (2009) Evaluation of the strength and radiopacity of Portland cement with varying additions of bismuth oxide. Int Endod J 42:322–328

Vivan RR, Ordinola-Zapata R, Bramante CM, Bernardineli N, Garcia RB, Hungaro Duarte MA, de Moraes IG (2009) Evaluation of the radiopacity of some commercial and experimental root-end filling materials. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 108:e35–e38

Hwang YC, Lee SH, Hwang IN, Kang IC, Kim MS, Kim SH, Son HH, Oh WM (2009) Chemical composition, radiopacity, and biocompatibility of Portland cement with bismuth oxide. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 107:e96–e102

Coomaraswamy KS, Lumney LP, Hofmann MP (2008) Effect of cement paste dilution on the radiopacity of MTA, abstract 0613. Pan European Federation for Dental Research, London

Watts DC, McCabe JF (1999) Aluminium radiopacity standards for dentistry: an international survey. J Dent 27:73–78

Kogan P, He J, Glickman GN, Watanabe I (2006) The effects of various additives on setting properties of MTA. J Endod 32:569–572

Ber BS, Hatton JF, Stewart GP (2007) Chemical modification of proroot MTA to improve handling characteristics and decrease setting time. J Endod 33:1231–1234

Hwang YC, Kim DH, Hwang IN, Song SJ, Park YJ, Koh JT, Son HH, Oh WM (2011) Chemical constitution, physical properties, and biocompatibility of experimentally manufactured Portland cement. J Endod 37:58–62

International Organization for Standardization (2001) Specification for dental root canal sealing materials. ISO 6876, Geneva

du Sart GG, Vukovic I, Vukovic Z, Polushkin E, Hiekkataipale P, Ruokolainen J, Loos K, ten Brinke G (2011) Nanoporous network channels from self-assembled triblock copolymer supramolecules. Macromol Rapid Commun 32:366–370

Milutinović-Nikolić AD, Medić VB, Vuković ZM (2007) Porosity of different dental luting cements. Dent Mater 23:674–678

Acknowledgments

This work was supported by the Ministry of Education and Science of the Republic of Serbia (projects no. III 45001 and III 45005).

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antonijevic, D., Medigovic, I., Zrilic, M. et al. The influence of different radiopacifying agents on the radiopacity, compressive strength, setting time, and porosity of Portland cement. Clin Oral Invest 18, 1597–1604 (2014). https://doi.org/10.1007/s00784-013-1130-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-013-1130-0