Abstract

The aim of this in vitro study was to investigate the two-body wear of different ceramics. Two-body wear tests were performed in a chewing simulator with steatite and enamel antagonists, respectively. Specimens were loaded in a pin-on-block design with a vertical load of 50 N for 1.2 × 105 cycles; (f = 1.6 Hz; lateral movement, 1 mm; mouth opening: 2 mm). Human enamel was used as a reference. Three zirconia ceramics, three veneering porcelains, two glass-infiltrated and one lithium disilicate ceramic were investigated. Veneering and lithium disilicate ceramics were glazed before testing. Surface roughness Ra (SP6, Perthen-Feinprüf, G) and wear depth were determined using a 3D scanner (Laserscan 3D, Willytec, G). SEM (Quanta FEG 400, FEI, USA) pictures of the worn specimens and antagonists were made for evaluating wear performance. Veneering porcelain provided wear traces between 71.2 and 124.1 μm (enamel antagonist) and 117.4 and 274.1 μm (steatite). Wear of the steatite antagonists varied between 0.618 and 2.85 mm². No wear was found for zirconia and glass-infiltrated substructure ceramics. Also, no wear was found for the corresponding antagonists. Wear of specimens and antagonists was strongly material dependent. No visible wear was found on zirconia and glass-infiltrated ceramics. Porcelain and lithium disilicate ceramic showed a comparable or lower wear than the enamel reference. Antagonist wear was found to be lower when specimens were made of substructure oxide ceramics instead of veneering porcelain. From the point of wear testing, zirconia may be used for the fabrication of fixed dental prosthesis without veneering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Different types of all-ceramic restorations are available as alternatives for metal-supported fixed dental prosthesis. All-ceramic restorations consist entirely of porcelain or, alternatively, a high-strength ceramic substructure, which is veneered with porcelain. Mechanical properties such as hardness, frictional resistance or fracture toughness [1] strongly vary between substructure and veneering ceramics and are supposed to show strong influence on wear performance [2, 3]. Especially substructures that are made of partially stabilized zirconia provide high hardness, fracture strength and structural reliability combined with a small range of strength variation compared to porcelain [1, 4, 5]. With new milling methods, full-zirconia restorations with occlusal design, but without veneering (Prettau, Zirkonzahn, I), are made available for dental application.

Occlusal contact between antagonist’s surfaces is a reason for wear and gradual removal of material [6]. Wear is the result of a complex process that depends on the abrasive nature of food, properties of the antagonistic material, thickness and hardness of enamel, chewing behaviour along with parafunctional habits and neuromuscular forces [6–9]. Abrasive wear describes the ploughing of hard asperities into softer surfaces [10], and can be further classified as abrasion and attrition. Abrasion occurs during mastication in the presence of food serving as a third body medium [11, 12], whereas attrition is the result of antagonist contacts during mastication, swallowing or occlusal movements [13, 14]. Further on, fatigue wear is caused by subsurface cracks that proceed due to repeated load cycles, and corrosive wear is a result of chemical reactions [10, 15]. Chewing, clenching and moisture might cause wear on the ceramic surface, which is supposed to be a reason for cracking or chipping, especially of the veneering porcelain [16–18]. Ideal dental materials therefore are supposed to yield low wear or wear resistance similar to that of tooth tissues.

The clinical evaluation of wear is expensive and time-consuming, and various variables such as chewing forces or environmental factors cannot be controlled sufficiently [19]. Thus, despite of the complexity of the clinical wear processes, laboratory mastication simulation allows for the investigation of single parameters of the wear processes, but it has to be borne in mind that even in vitro wear simulations show considerable variability [20].

The aim of this in vitro study was to investigate the two-body wear behaviour of different ceramics versus steatite and human enamel antagonists, respectively. The hypothesis of this study was that high-strength zirconia ceramics show higher wear resistance than porcelains, but higher antagonistic wear.

Materials and methods

Specimens (n = 16 per group; diameter, 5 mm; thickness, 2 mm) were prepared from different ceramics representing different types of materials (Table 1). For fixation whilst two-body wear test, the specimens were embedded in the middle of round aluminium stubs (ALU Stubs, Balzers, Walluf, G) using a light-curing dental resin (Tetric Ceram, Ivoclar Vivadent, Schaan, FL). Veneering porcelains and lithium disilicate ceramic were glazed with the corresponding glazing material. Specimens were smoothed under permanent water cooling using silicone carbide grinding paper (grain 500; Buehler, Lake Bluff, USA). Surface roughness was determined using a profilometer (Perthometer SP6, Perthen-Feinprüf, G; LT = 1.7/0.25, diamond indenter).

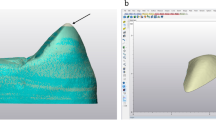

For simulation of a standardized wear, steatite balls (magnesium silicate, n = 8; d = 2 mm, CeramTec, Plochingen, G) were used as antagonists. Human enamel (n = 8) served as reference for simulating the clinical wear situation. For the preparation of enamel antagonists, human molars (stored in 0.5% chloramine solution for no longer than 4 weeks) were separated into individual cusps. Randomly selected cusps or steatite spheres were mounted in the chewing simulator (EGO, Regensburg, G). Specimens were loaded pneumatically in a pin-on-block design [21] with a vertical load of 50 N for 1.2 × 105 cycles at a frequency of 1.6 Hz (lateral movement, 1 mm; mouth opening, 2 mm; Fig. 1) simulating a human chewing cycle. During wear simulation, specimens were subjected to 600 thermal cycles in distilled water at temperatures of 5°C and 55°C, with duration of 2 min for each cycle. Apart from the simulation of temperature changes and permanent humidity in the oral cavity, thermal cycling in a water bath removes abraded particles from the specimen surfaces.

After wear test, vertical substance loss (micrometer) of the different ceramics (with steatite and enamel antagonists) was determined using an optical three-dimensional surface profilometer (Laserscan 3D, Willytec, Munich, G). Wear area of the steatite antagonists (square millimeter) was measured for evaluating antagonist wear. Due to falsification of the wear results and due to individual geometry, we resigned on determining wear values of the enamel antagonists. For characterizing wear patterns, all specimens and antagonists were subjected to scanning electron microscopy after wear simulation (Quanta FEG 400, FEI Company, Hillsboro, USA). The surfaces were examined at a magnification of 30 to 4,000 at 10 keV. Damage, which was caused by wear tests, was characterized on enamel antagonists. Exemplary element analysis (EDX Genesis 2000, Ametek, G) was performed on the worn ceramics for evaluating surface changes or material transfer.

Calculations and statistical analysis were carried out using SPSS 17.0 for Windows (SPSS Inc., IL, USA). Means and standard deviations were calculated and analysed using one-way analysis of variance and the Bonferroni multiple comparison test for post hoc analysis. The level of significance was set to α = 0.05.

Results

Surface roughness

Mean surface roughness Ra of the ceramics (Table 2) varied between 0.1 ± 0.01 μm (Vita In-Ceram YZ) and 0.3 ± 0.02 μm (Empress 2). No significant differences were found between the individual materials (p > 0.687). Only Empress 2 showed significantly higher values than the zirconia ceramics and ICE Keramik veneering porcelain (p < 0.024). The enamel (0.9 ± 0.2 μm) reference provided significantly (p < 0.001) higher roughness than all tested ceramics.

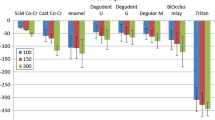

Wear on ceramics

Zirconia, alumina–zirconia and alumina oxide ceramics showed no valuable wear after simulation tests neither with steatite nor enamel. When wear tests were performed with steatite antagonists, porcelains and lithium disilicate ceramic provided no significant different (p < 0.001) wear (VM7, 271 ± 61 μm; VM9, 238 ± 54 μm; E2, 200 ± 36 μm). Significantly lower (p < 0.002) wear was found for the veneering ceramic ICE Keramik (117 ± 44 μm) in comparison to the other veneering ceramics, but not to the lithium disilicate ceramic (p = 0.651). Only ICE Keramik showed significant (p < 0.001) lower wear than the enamel reference (274 ± 187 μm).

Wear was significantly (p < 0.043) lower for wear tests with enamel antagonists in comparison to results with steatite antagonists for the veneering ceramics (76 ± 8 μm (VM7), 71 ± 24 μm (VM9)) and lithium disilicate ceramic E2 (118 ± 73 μm). Only the glass-ceramic (ICE, 124 ± 64 μm) showed higher values in comparison to steatite wear (117 ± 44 μm). Enamel reference provided wear results with extreme standard deviations 123 ± 131 μm (Table 2).

Scanning electron microscopy (SEM) pictures of the specimens after wear testing revealed smooth zirconia and glass-infiltrated surfaces, whereas porcelain and lithium disilicate provided rough surface with ploughing and wear traces in the sliding direction (Fig. 2). On the surface of most porcelain specimens, circular defects were found (Figs. 2 and 3). Using energy-dispersive X-ray element analysis (EDAX), a transfer of steatite and enamel components was found onto all ceramic materials.

Wear on antagonists

Wear results on the steatite antagonists can be divided into two groups: for zirconia, alumina–zirconia and alumina oxide ceramics, the results varied between 0.618 ± 0.234 (Prettau) and 1.410 ± 0.282 mm2 (In-Ceram Zirconia) without significant differences between each other and between the enamel reference (1.146 ± 1.203 mm2). All veneering ceramics, as well as the lithium disilicate ceramic provided significantly higher results with wear of 2.850 ± 0.546 (VM7), 2.556 ± 0.447 (VM9) and 2.457 ± 0.462 mm2 (E2; Table 2). In the veneering section, only for ICE Keramik no significant (p = 0.813) different wear was found in comparison to enamel.

After wear test, flattening of the antagonist (steatite, enamel) surface was found for all materials. Antagonists, which were opposed by Y-TZP and glass-infiltrated systems, showed a smooth surface. All other ceramics caused stress marks and scratches on the antagonist in gliding direction (Fig. 4). The evaluation of the enamel antagonists with SEM showed chipping, cracks, polishing and ploughing/scratches on the worn surfaces (Figs. 5 and 6). Small differences were found between the results of the materials in the individual material groups. Only when opposed with Vita VM 9, a lower number of cracks on the enamel surface were found (Fig. 7).

Discussion

The hypothesis of this study that high-strength ceramics show higher wear resistance than porcelains in combination with higher antagonistic wear could be confirmed only in parts. The results showed that wear was strongly material dependent. Low wear on high-strength substructure ceramics (zirconia, glass-infiltrated alumina and glass-infiltrated alumina–zirconia) was correlated with low wear on the antagonists.

The tested materials represent typical dental ceramics with different composition and strength, which are used for the fabrication of substructures (zirconia, alumina and alumina–zirconia glass-infiltrated, lithium disilicate ceramic) of fixed dental prosthesis. One zirconia system (Prettau) is available on the market for the fabrication of full-zirconia fixed dental prosthesis without veneering. Three different materials were investigated, which are applied for veneering of metal-based (VM7) or zirconia-based (VM9, ICE Keramik) restorations. For simulating the clinical situation, porcelains were investigated with glaze, and substrucutre materials were used without glazing.

Various tests (e.g. pin-on-block, pin-on-disk, three-body wear, toothbrush simulation) [2] are available for the investigation of the wear performance of dental materials. It is known that antagonist wear highly depends on the opposing ceramic materials [22] and the testing conditions [2]. Under clinical conditions, enamel antagonistic wear is shown to be higher than ceramic wear [23]. It is easy to understand that with varying force, sliding (roughness) and environmental conditions (e.g. water, food bolus) different wear performance may be achieved. A loading force of 50 N that is applied with a frequency of about 1–1.6 Hz represents average mastication loading [24] and is commonly used for in vitro testing for simulation of the oral situation [25, 26]. To guarantee a clinical relevant surface roughness, specimens were polished under standardized conditions to comparable roughness that was determined in pretests by polishing porcelain surfaces with an intraoral standard polishing set (9749F, Meisinger, Neuss, D, Ra = 0.18 ± 0.04). Permanent thermal cycling with water removed wear debris from the specimen surface kept specimens wet over the whole testing situation and caused additional ageing of the specimens [21]. Enamel antagonists represent clinical relevant situations, whereas steatite antagonists allow for standardization of the wear conditions [27]. Most wear tests provide only limited or no correlation with clinical data [20], although they allow for a comparative evaluation and ranking of different materials under standardized conditions. For zirconia, glass-infiltrated alumina and glass-infiltrated alumina–zirconia ceramics, no wear traces could be found, independent of steatite or enamel antagonist material.

Porcelains and lithium disilicate ceramic provided significantly higher wear up to 124 μm (against enamel), but the results were less or equal than values for enamel reference with values of about 123 μm. Based on wear rates for enamel between 30–40 μm per year [28], the results seem comparable to 3–4 years of clinical service. No wear differences were found for the veneering ceramics VM7 and VM9 from the same manufacturer, although these materials may have different compositions because they are applied for veneering of different substructures (alloy/zirconia). An explanation may be a comparable composition and that identical glaze with a thickness between 80 and 100 μm was used. Therefore, about one third of the wear pattern of these specimens was located only in glaze material. In an actual study, Albashaireh et al. found a similar wear ranking between substructure ceramics and porcelains with zirconia antagonists [3].

Lower wear rates of the third veneering ceramic may be attributed to a different composition (e.g. grain size, share between crystallite and glass) of porcelain and glaze in comparison to the other two porcelains. Glazing may also be required for aesthetic aspects, when substructure ceramics (e.g. zirconia) are used without veneering. In cases where glaze is applied, it is supposed that it is completely worn: wear will be stopped not until the level of the substructure surface is reached.

The evaluation of the enamel antagonists with SEM showed fractures, cracks, polishing/smoothing and ploughing of the worn surfaces. These damages in most cases appear in combination of two or three types of defects. The number of the appearing individual damages showed only small differences between the materials for fractures, polishing and cracks. No different wear pattern was found on steatite or enamel. It was noticeable that polished areas are visible only on enamel/steatite opposing zirconia ceramics. After wear tests with porcelain, provoked wear [29] and ploughing on the antagonist surface could be determined. SEM pictures on porcelain specimens revealed circular defects, which are supposed to be abraded cone cracks [30]. These cone cracks are described as defects that appear on the porcelain surface, which is in direct contact to the antagonist in contact points [31].

As expected, the results, which were obtained with non-standardized human cusps, show high variation, but give an impression on wear pattern on ceramic and enamel antagonists (Fig. 2). Although different wear results were found, either with enamel or steatite as antagonists, wear performances of ceramics, which were opposed by steatite antagonists, allow for a quantitative interpretation of the wear results and a ranking of the materials. In most cases, wear results were higher with steatite, but not on the ICE glass-ceramic veneering. This underlines that wear results are highly dependent on ceramic and the opposing material [2, 22, 23]. Steatite, which is used for standard simulation or wear tests, guarantees identical dimensions and is supposed to be suitable for wear tests [27].

Contrary to expectations that hard zirconia ceramics should force antagonist wear, the present results show that high-strength oxide ceramics provided significantly lower wear on steatite antagonists than veneering porcelains do. SEM pictures prove that enamel generally shows wear and deterioration either opposed by substructure ceramics or veneering ceramics. Defects are abrasion, cracks or even fractures at the ridge. Only with veneering ceramic, ploughing and grinding of the enamel surface could be found. Under clinical conditions, ceramic wear is shown to be lower than the enamel antagonistic wear [23]. Grinding of glass and exposing of crystallite structures (e.g. leucite) during wear test may result in roughening of the comparable “soft” veneering ceramic. This deterioration is influenced by materials’ properties such as hardness, fracture toughness or composition [2]. With the ongoing wear process, the roughened ceramic surface causes enduring wear on the antagonist surface. EDAX analysis revealed enamel and steatite transfer from the antagonist to the ceramic surface for all tested ceramics. For improving wear performance and a reduction of subcritical crack growth, polishing of the porcelain surface may therefore be required every now and then [32].

In contrast, sliding of the antagonist on hard zirconia surface caused only flattening of the antagonist surface. These wear results allow for the estimation that zirconia can be used for the fabrication of fixed dental prosthesis without veneering. Then, optimized occlusal fitting and contact is essential because “fitting wear” in these cases is limited to the antagonist surface or a thin glaze layer. Further aspects for the application of zirconia without veneering (aesthetics, acoustics, mandibular jaw situation, ageing due to local phase transition), as well as how zirconia performs in combination with higher abrasive porcelain or enamel in a tooth row, have to be clarified in further investigations and under clinical conditions.

Conclusion

The results of the wear test with steatite or enamel antagonists provided no visible wear on substructure oxide ceramics. Porcelain and lithium disilicate ceramic showed a comparable or lower wear than an enamel reference. Antagonist wear was found to be lower when the specimens were made of substructure oxide ceramics instead of veneering porcelain.

References

Guazzato M, Albakry M, Ringer SP, Swain MV (2004) Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater 20:449–456

Heintze SD, Cavalleri A, Forjanic M, Zellweger G, Rousson V (2008) Wear of ceramic and antagonist—a systematic evaluation of influencing factors in vitro. Dent Mater 24:433–449

Albashaireh ZS, Ghazal M, Kern M (2010) Two-body wear of different ceramic materials opposed to zirconia ceramic. J Prosthet Dent 104:105–113

Fischer J, Stawarczyk B, Hammerle CH (2008) Flexural strength of veneering ceramics for zirconia. J Dent 36:316–321

Shijo Y, Shinya A, Gomi H, Lassila LV, Vallittu PK, Shinya A (2009) Studies on mechanical strength, thermal expansion of layering porcelains to alumina and zirconia ceramic core materials. Dent Mater J 28:352–361

Mair LH, Stolarski TA, Vowles RW, Lloyd CH (1996) Wear: mechanisms, manifestations and measurement. Report of a workshop. J Dent 24:141–148

Johansson A, Haraldson T, Omar R, Kiliaridis S, Carlsson GE (1993) An investigation of some factors associated with occlusal tooth wear in a selected high-wear sample. Eur J Oral Sci 101:407–415

Jung YS, Lee JW, Choi YJ, Ahn JS, Shin SW, Huh JB (2010) A study on the in-vitro wear of the natural tooth structure by opposing zirconia or dental porcelain. J Adv Prosthodont 2:111–115

Kim SK, Kim KN, Chang IT, Heo SJ (2001) A study of the effects of chewing patterns on occlusal wear. J Oral Rehabil 28:1048–1055

Correr GM, Bruschi Alonso RC, Correr Sobrinho L, Puppin-Rontani RM, Ferracane JL (2006) In vitro wear of resin-based materials—simultaneous corrosive and abrasive wear. J Biomed Mater Res B; Appl Biomat 78:105–114

Lambrechts P, Debels E, Van Landuyt K, Peumans M, Van Meerbeek B (2006) How to simulate wear? Overview of existing methods. Dent Mater 22:693–701

DeGee AJ, Davidson CL (1986) Effect of abrasion medium on wear of stress bearing composites and amalgam in vitro. J Dent Res 65:654–658

Stober T, Lutz T, Gilde H, Rammelsberg P (2006) Wear of resin denture teeth by two-body contact. Dent Mater 22:243–249

Ghazal M, Yang B, Ludwig K, Kern M (2008) Two-body wear of resin and ceramic denture teeth in comparison to human enamel. Dent Mater 24:502–507

Yap AU, Tan CH, Chung SM (2004) Wear behavior of new composite restoratives. Oper Dent 29:269–274

Kim JW, Kim JH, Janal MN, Zhang Y (2008) Damage maps of veneered zirconia under simulated mastication. J Dent Res 87:1127–1132

Rekow ED, Zhang G, Thompson V, Kim JW, Coehlo P, Zhang Y (2009) Effects of geometry on fracture initiation and propagation in all-ceramic crowns. J Biomed Mater Res B Appl Biomater 88:436–446

Al-Amleh B, Lyons K, Swain M (2010) Clinical trials in zirconia: a systematic review. J Oral Rehabil 37:641–652

Condon JR, Ferracane JL (1997) In vitro wear of composite with varied cure, filler level, and filler treatment. J Dent Res 76:1405–1411

Heintze SD (2006) How to qualify and validate wear simulation devices and methods. Dent Mater 22:712–734

Hahnel S, Behr M, Handel G, Rosentritt M (2009) Two-body wear of artificial acrylic and composite resin teeth in relation to antagonist material. J Prosthet Dent 101:269–278

Esquivel-Upshaw JF, Young H, Jones J, Yang M, Anusavice KJ (2006) In vivo wear of enamel by a lithia disilicate-based core ceramic used for posterior fixed partial dentures: first-year results. Int J Prosthodont 19:391–396

Suputtamongkol K, Anusavice KJ, Suchatlampong C, Sithiamnuai P, Tulapornchai C (2008) Clinical performance and wear characteristics of veneered lithia-disilicate-based ceramic crowns. Dent Mater 24:667–673

Rosentritt M, Behr M, Gebhard R, Handel G (2006) Influence of stress simulation parameters on the fracture strength of all-ceramic fixed-partial dentures. Dent Mater 22:176–182

Rosentritt M, Behr M, van der Zel JM, Feilzer AJ (2009) Approach for valuating the influence of laboratory simulation. Dent Mater 25:348–352

Rosentritt M, Siavikis G, Behr M, Kolbeck C, Handel G (2008) Approach for valuating the significance of laboratory simulation. J Dent 36:1048–1053

Wassell RW, McCabe JF, Walls AW (1994) Wear characteristics in a two-body wear test. Dent Mater 10:269–274

Lambrechts P, Braem M, Vuylsteke-Wauters M, Vanherle G (1989) Quantitative in vivo wear of human enamel. J Dent Res 68:1752–1754

Olivera AB, Marques MM (2008) Esthetic restorative materials and opposing enamel wear. Oper Dent 33:332–337

Bhowmick S, Meléndez-Martínez JJ, Zhang Y, Lawn BR (2007) Design maps for failure of all-ceramic layer structures in concentrated cyclic loading. Acta Mater 55:2479–2488

Lawn BR, Deng Y, Thompson VP (2001) Use of contact testing in the characterization and design of all-ceramic crownlike layer structures: a review. J Prosthet Dent 86:495–510

Rosentritt M, Steiger D, Behr M, Handel G, Kolbeck C (2009) Influence of substructure design and spacer settings on the in vitro performance of molar zirconia crowns. J Dent 37:978–983

Etman MK, Woolford M, Dunne S (2008) Quantitative measurement of tooth and ceramic wear: in vivo study. Inter J Prosthodont 21:245–252

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosentritt, M., Preis, V., Behr, M. et al. Two-body wear of dental porcelain and substructure oxide ceramics. Clin Oral Invest 16, 935–943 (2012). https://doi.org/10.1007/s00784-011-0589-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-011-0589-9