Abstract

Light supplying to luting resin cements is impeded in several clinical situations, causing us to question whether materials can properly be cured to achieve adequately (or adequate) mechanical properties. The aim of this study was therefore to analyse the effect of light on the micro-mechanical properties of eight popular dual-cured self-adhesive resin cements by comparing them with two conventional, also dual-cured, resin cements. Four different curing procedures were applied: auto-polymerisation (dark curing) and light curing (LED unit, Freelight 2, 20 s) by applying the unit directly on the samples’ surface, at a distance of 5 and 10 mm. Twenty minutes after curing, the samples were stored for 1 week at 37°C in a water-saturated atmosphere. The micro-mechanical properties–Vickers hardness, modulus of elasticity, creep and elastic/plastic deformation–were measured. Data were analysed with multivariate ANOVA followed by Tukey’s test and partial eta-squared statistics (p < 0.05). A very strong influence of the material as well as filler volume and weight on the micro-mechanical properties was measured, whereas the influence of the curing procedure and type of cement–conventional or self-adhesive–was generally low. The influence of light on the polymerisation process was material dependent, with four different behaviour patterns to be distinguished. As a material category, significantly higher micro-mechanical properties were measured for the conventional compared to the self-adhesive resin cements, although this difference was low. Within the self-adhesive resin cements group, the variation in micro-mechanical properties was high. The selection of suitable resin cements should be done by considering, besides its adhesive properties, its micro-mechanical properties and curing behaviour also.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

An important requirement for an ideal luting agent is its ability to provide superior mechanical properties to resist functional forces over the lifetime of a restoration. A multitude of studies were initiated to assess the mechanical behaviour of luting agents, comprising fatigue analysis [1], measurements of flexural strength [2], diametral tensile strength [3, 4], modulus of elasticity [5], fracture toughness [6] and hardness [3], generally showing that filled resin cements exhibit higher values in comparison to conventional luting agents. A correlation between high strength and low margin wear of resin cements in vitro has also been demonstrated [7].

Parallel to trials to enhance the mechanical properties of luting resin cements, improved handling properties and reduced procedure time led to substantial modifications in chemical composition. The self-adhesive luting resin cements were thus designed to adhere by themselves to tooth structure, eliminating the need for separate etchants and primers for bonding to tooth, metal alloy or ceramics and reducing concomitantly both procedure time and postoperative sensitivity [8]. The self-adhesive luting resin cements are generally composed of phosphoric and/or carboxylic acid methacrylate monomers that are thought to bond chemically to tooth apatite and to the superficial oxides of the restoration, being usually dual-cured resins that can be light activated and can self-cure as well.

The majority of the studies with self-adhesive luting resin cements were performed in vitro. A comparison of different luting cement categories proved that self-adhesive resin cements achieved lower flexural and compressive strengths than conventional resin cements, both material categories being however statistically stronger than resin-modified glass ionomer cements, glass ionomer cements or zinc phosphate cements [9]. The wear resistance to toothbrush abrasion of self-adhesive cements was found to be similar to conventional resin cements and light-cured composite resins [10]. However, most of the self-adhesive cements wear more rapidly in an ACTA abrasive test under higher loads, when compared to conventional resin cements and flowable composites [10]. In view of an effective bonding to enamel and dentin, self-adhesive luting cements were shown to perform in a micro-tensile bond strength test equally as using etch-and-rinse and self-etch adhesives [11]; others authors however limit this statement to a good adhesion only to dentin [12]. Self-adhesive luting cements interact only superficially with mineralised tissues as they do not lead to the formation of a dentin hybrid layer nor resin tags [13, 14]. The marginal integrity by luting glass ceramic inlays in vitro using self-etch resin cements was shown to be inferior to classical luting approaches using etch-and-rinse adhesives combined with conventional luting resin composites [15]. On the other side, it was shown that the type of cementation of all-ceramic crowns–being zinc phosphate cement, glass ionomer cement or self-adhesive resin cement–have no impact on the load capability of endodontically treated teeth restored with glass fibre-reinforced composite posts and composite core build-ups [16].

Dual-cured self-adhesive resin cements cover nowadays a wide range of indications including luting indirect restorations, like cementation of metal, metal–ceramic and all-ceramic crowns, bridges, inlays and onlays, but are more frequently used also for cementation of root posts. The light supplying to the resin cement’s surface is, in most of these cases, impeded, causing us to question whether the materials can properly be cured to achieve adequately (or adequate) mechanical properties. The aim of this study was therefore to analyse the effect of light on the micro-mechanical properties of eight popular dual-cured self-adhesive resin cements by comparing them with two conventional dual-cured resin cements.

The null hypotheses tested were: (a) the micro-mechanical properties–Vickers hardness, modulus of elasticity, creep and elastic/plastic deformation–of the measured luting cements will not be influenced by the way of curing; b) there would be no differences in the micro-mechanical properties of conventional and self-adhesive dual-cured resin cements.

Materials and methods

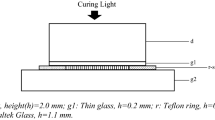

Eight dual-cured self-adhesive resin cements were analysed in comparison to two conventional dual-cured resin cements (Table 1). Two hundred-forty thin samples of cement were made in total by compressing the materials to a ca. 200-μm thin film. The time frame elapsed between specimen fabrication and light activation was 30 s. For each material, four different curing procedures were applied. The cement specimens were cured for 20 s with the LED curing unit Freelight 2 (3M-ESPE, 1,226 mW/cm2; Seefeld, Germany) by applying the unit directly on the samples’ surface, at a distance of 5 and 10 mm. To determine the effect of auto-curing, samples were dark stored with the intention that no light reaches the samples. The thin films were stored 20 min after curing for 1 week at 37°C in a water-saturated atmosphere. The effect of curing mode and the differences between the materials were assessed by evaluating the micro-mechanical properties—Vickers hardness, modulus of elasticity, creep and elastic/plastic deformation.

Micro-mechanical properties

Measurements were made on thin cement films (n = 6, 10 measurements/sample) with a micro-hardness indenter (Fischerscope H100C, Fischer, Sindelfingen, Germany) according to DIN 50359-1:1997-10 [17]. The test procedure was carried out force controlled; the test load increased and decreased with constant speed between 0.4 and 500 mN. The load and the penetration depth of the indenter were continuously measured during the load–unload hysteresis. Universal hardness is defined as the test force divided by the apparent area of the indentation under the applied test force. From a multiplicity of measurements, a conversion factor between universal hardness and Vickers hardness was calculated and implemented in the software, so that the measurement results were indicated in the more familiar Vickers hardness units. The indentation modulus was calculated from the slope of the tangent of indentation depth-curve at maximum force and is comparable with the modulus of elasticity of the material. By measuring the change in indentation depth with constant test force, a relative change in the indentation depth can be calculated. This is a value for the creep of the materials. The mechanical work W tot indicated during the indentation procedure is only partly consumed as plastic deformation work W plast. During the removal of the test force, the remaining part is set free as work of the elastic reverse deformation W elast.. The mechanical work is defined as W = ⌠Fdh, with W tot = W elast + W plast. The parameter W elas/W tot (percent) representing the percentage of elastic work reported to the total mechanical work is indicated in the results data [17].

Results were statistically compared using one-way ANOVA and Tukey’s HSD post hoc test (α = 0.05). A multivariate analysis (general linear model with partial eta-squared statistics) tested the influence of the parameters cement, cement type, curing mode as well as filler volume and weight on the measured micro-mechanical properties (SPSS Inc.,version 17.0, Chicago, IL, USA).

Results

One-way ANOVA analysis of the micro-mechanical properties results is listed in Table 2. Homogenous subgroups can be identified by the same superscript. Post hoc multiple pair-wise comparisons with Tukey’s HSD test revealed significant differences (p < 0.05) in micro-mechanical properties among the tested materials and within the curing methods. The highest modulus of elasticity was reached by G-Cem and RelyX Unicem, the last material achieving also the significantly highest Vickers hardness.

The effect of light activation was proven to be material dependent. Except for Dentin Build, a significant decrease in micro-mechanical properties was measured additionally between light activation and auto-curing.

The total influence of the parameters cement, cement type–self-adhesive vs. conventional–curing mode and filler volume and weight was analysed in a general linear model test. The micro-mechanical properties–modulus of elasticity, Vickers hardness, creep and elastic/plastic deformation–were selected as dependent variables. The significance values of the first main effects were less than 0.05, indicating that they contribute all to the model. The results of the test are summarised in Table 3, showing a very strong influence of the material as well as filler volume and weight (high partial eta-squared values), whereas the influence of curing mode and type of cement was low. Significantly higher micro-mechanical properties were measured for the conventional resin cements compared to the self-adhesive, although this difference was low.

From the measured micro-mechanical properties, the modulus of elasticity and Vickers hardness proved to be the most sensitive parameters (higher partial eta-squared values).

Discussion

To analyse the mechanical properties of dual-curing cements as a function of the curing mode, a depth-sensing hardness measurement device was used in this study, with the intention of assessing not only the plastic but also the elastic part of deformation. In comparison to traditional hardness measurement methods, in which only the plastic part of indentation can be measured (Brinell, Knoop, Rokwell or Vickers hardness), the dynamic measuring principle applied in this study recorded simultaneously the load and the corresponding penetration depth of the indenter [18]. The low indentation force, which varied between 0 and 500 mN, generated indentation depth values in the range of only a few micrometres (<10 μm). This allowed to be measured thin cement films of ca. 200 μm and to assure thus the clinical relevance of the measurements. Another aspect to be considered is the light attenuation caused by the presence of an indirect restoration. Parameters like restoration thickness [19], colour, chemical composition [20] and structure, number, size and distribution of defects, porosity or pigments strongly determine the attenuation of light. Due to the great variety of all the above-mentioned parameters in a clinical situation, we choose to standardize the amount of light reaching the luting cement by varying the distance between the curing unit tip and sample’s surface. It was previously shown that the light attenuation caused by increasing the distance between the curing unit tip and sample’s surface is consistent, achieving for Freelight 2, the curing unit used also in our study, no more than 57% of the total irradiance at a distance of 5 mm and only 22% of the total irradiance at a distance of 10 mm [21].

The measured data demonstrate a great variability in the micro-mechanical performance of the analysed materials as a function of their chemical composition and way of cure. When the curing unit was applied directly on the cement’s surface, the Vickers hardness varied between 65.87 N/mm2 (RelyX Unicem) and 14.77 N/mm2, (Clearfil SA), whereas in case of auto-polymerisation, the hardness was consistently lower (50.99 N/mm2 for Dentin Build and 1.79 N/mm2 for i-CEM).

The influence of light on the polymerisation process seems to be material dependent. Four different behaviour patterns as functions of polymerisation procedure could be differentiated (Fig. 1 and Table 2):

Vickers hardness as function of polymerisation way—light curing with an application of the curing unit directly (0 mm), in a distance of 5 and 10 mm from the sample’s surface as well as auto-curing in darkness–exemplified for four materials, corresponding to the four types of behaviour described above

-

1.

less sensitivity to the way of cure, be it only auto-cured or additionally cured with light of different intensity (Dentin Build, Breeze)

-

2.

less sensitivity to the amount of light used for curing, but significant differences between dual-curing and auto-curing (max-cem Elite, i-CEM, Clearfil SA)

-

3.

high sensitivity to the way of cure, with significant differences not only between dual-curing and auto-curing, but also between the different modes of light curing (RelyX Unicem, Multilink Automix, G-Cem)

-

4.

sensitivity to the amount of light used for curing, but no differences between auto-curing and dual-curing with lower intensity (G-Cem automix, SmartCem2)

The above-mentioned data confirm the cements’ behaviour in previous studies, showing a significant influence of the mode of cure on the bond strength by using dual-curing resin cements in combination with dental ceramics (aluminium oxide, leucit-reinforced, lithium disilicate and zirconia ceramics) [22, 23]. For RelyX Unicem, significantly increased bond strength after light polymerisation in comparison to auto-polymerisation was reported [22–24]. This behaviour can be explained by our results, as the modulus of elasticity measured for RelyX Unicem with additional light curing (12.08–13.07 GPa) was double as high compared to auto-polymerisation (5.77 GPa).

The limited information concerning especially the initiator systems used in the analysed materials hampers a clear interpretation of the four material behaviour patterns after curing. As a general observation, the materials showing less sensitivity to the way of cure, be it dual or only auto-cured (Dentin Build, Breeze) approach both the chemical composition of conventional resin-based composites, containing besides other compounds also a mixture of Bis-GMA and UDMA monomers (Table 1). As for the two above-mentioned materials, the mechanical properties of Dentin Build, a conventional resin cement, were proved to be superior compared to Breez, a self-adhesive resin cement. However, this difference should not be attributed to the type of resin cement the materials belong, but to the differences in filler amount, since both filler volume and weight were consistently higher in Dentin Build. Besides the filer amount, the way of cure is influencing significantly the materials’ properties. Caution should be consequently taken by choosing luting materials for indications with restricted light access.

When considered as a material group, superior micro-mechanical properties were measured for the conventional resin cements in comparison to the self-adhesive resin cements, even though these differences were small. These results are in agreement with those of other studies [9] but must be seen differentiated, since the variation in micro-mechanical properties within the self-adhesive resin cements was high. If the self-adhesive resin cements G-Cem and RelyX Unicem are directly compared with the conventional resin cements–Dentin Build and Multilink Automix–the former performed comparably or even better. Self-adhesive cements proved also to have good wear resistance to toothbrush abrasion [10] but wear more rapidly under higher loads in the ACTA test than conventional resin cements or flowable composites [10]. Six of the self-adhesive cements considered in the above-mentioned study were also included in our study. However, there seems to be no correlation between the in vitro measured wear behaviour of the materials and the measured micro-mechanical properties.

It was previously shown that the modulus of elasticity measured in our test correlates well with the flexural strength and the modulus of elasticity measured in the more familiar flexural strength test [25], the last parameter being regarded as a fundamental material property, since a material with a low modulus will more readily elastically deform under functional stresses. A correlation between high strength and low margin wear of resin cements has also been demonstrated in vitro [7], leading to a positive clinical prognosis for the cements with high micro-mechanical properties. Besides that, the ranking of the modulus of elasticity measured in our test seems to correlate well with the micro-tensile bond strength tests, which showed a significantly higher strength for RelyX Unicem compared to Multilink [26] or Maxcem [27].

Poor clinical performance may also be a consequence of a material that exhibits high creep, a time-dependent deformation under load. When subjected to a constant force (in our study, 500 mN for 5 s), the cements experience a time-dependent plastic deformation. Lower light intensity, as a consequence of increasing distance between the curing unit and sample surface, but also plasticizers like water, saliva and alcohol, or a temperature above the glass transition point, are able to reduce the cements’ capacity to resist deformational change under load [28]. A reduced amount of resin matrix, on account not only of high filler content, but also a homogeneous filler distribution, has been found to provide for a higher creep resistance [29]. Auto-polymerisation induced in the most analysed cements a significant higher creep, when compared to the dual-cured polymerisation conditions. With creep values varying between 3.72% and 5.9%, performed luting cements inferior to conventional resin-based composites (internal data) and dental hard tissue [30], but were comparable to glass ionomer cements, flowable composites or adhesives [30].

As for W e/W tot, being the percentage of the elastic part of the indentation work, decreased values were measured in all materials after auto-polymerisation, except for Dentin Build. This fact confirms that an additional light curing in dual-cured resin cements results in more elastic, and consequently, less plastic materials, which are therefore able to sustain a higher stress without a permanent (= plastic) deformation.

A strong influence of the filler volume and weight on the micro-mechanical properties was measured. A direct comparison of the effect of fillers on the measured properties offers the two materials of the same company–G-CEM and G-CEM Automix–showing that the reduced filler weight and volume% in G-CEM Automix were also reflected in significantly lower mechanical properties. Since the influence of filler on mechanical properties is considerable (Table 3), it would be advisable to estimate resin luting materials preferential with regard to their filer amount and less by considering their belonging to a material category.

Regarding the adhesion ability of self-adhesive cements to enamel and dentin aroused concerns, since self-adhesive cements were proven to be unable to demineralise or dissolve the smear layer completely, and no decalcification/infiltration of dentin was observed [14]. The bond strengths produced by the self-adhesive cements were shown, however, to be comparable to the conventional multi-step luting agents using etch-and-rinse and self-etch adhesives [11, 31].

Therefore, both parts of the null hypothesis tested in this study are rejected.

Conclusions

The selection of the suitable resin cements should be done by considering, besides their adhesive properties, also the micro-mechanical properties and their curing behaviour, since the differences between the measured materials were high. Whereas some of the self-adhesive cements performed better than conventional cements, the properties of others were consistently lower. Furthermore, for indications where light supplying is difficult, cements with less sensitivity to the way of cure, be it dual-cured with different light intensities or only chemical cured, should be considered (Dentin Build, Breeze).

References

Kamposiora P, Papavasilious G, Bayne SC, Felton DA (1994) Finite element analysis estimates of cement microfracture under complete veneer crowns. J Prosthet Dent 71:435–441

Ban S, Hasegawa J, Anusavice KJ (1992) Effect of loading conditions on bi-axial flexure strength of dental cements. Dent Mater 8:100–104

White SN, Yu Z (1993) Physical properties of fixed prosthodontic, resin composite luting agents. Int J Prosthodont 6:384–389

Canay S, Hersek N, Akca K, Ciftci Y (1996) The effect of weight loss of liquid on the diametral tensile strengths of various kinds of luting cements. Int Dent J 46:52–58

Scherrer SS, de Rijk WG, Belser UC, Meyer JM (1994) Effect of cement film thickness on the fracture resistance of a machinable glass-ceramic. Dent Mater 10:172–177

Mueller HJ (1990) Fracture toughness and fractography of dental cements, lining, build-up, and filling materials. Scan Microsc 4:297–307

Peutzfeldt A (1995) Dual-cure resin cements: in vitro wear and effect of quantity of remaining double bonds, filler volume, and light curing. Acta Odontol Scand 53:29–34

Sensat ML, Brackett WW, Meinberg TA, Beatty MW (2002) Clinical evaluation of two adhesive composite cements for the suppression of dentinal cold sensitivity. J Prosthet Dent 88:50–53

Piwowarczyk A, Lauer HC (2003) Mechanical properties of luting cements after water storage. Oper Dent 28:535–542

Belli R, Pelka M, Petschelt A, Lohbauer U (2009) In vitro wear gap formation of self-adhesive resin cements: a CLSM evaluation. J Dent 37:984–993

Hikita K, Van Meerbeek B, De Munck J, Ikeda T, Van Landuyt K, Maida T et al (2007) Bonding effectiveness of adhesive luting agents to enamel and dentin. Dent Mater 23:71–80

Radovic I, Monticelli F, Goracci C, Vulicevic ZR, Ferrari M (2008) Self-adhesive resin cements: a literature review. J Adhes Dent 10:251–258

De Munck J, Vargas M, Van Landuyt K, Hikita K, Lambrechts P, Van Meerbeek B (2004) Bonding of an auto-adhesive luting material to enamel and dentin. Dent Mater 20:963–971

Monticelli F, Osorio R, Mazzitelli C, Ferrari M, Toledano M (2008) Limited decalcification/diffusion of self-adhesive cements into dentin. J Dent Res 87:974–979

Frankenberger R, Lohbauer U, Schaible RB, Nikolaenko SA, Naumann M (2008) Luting of ceramic inlays in vitro: marginal quality of self-etch and etch-and-rinse adhesives versus self-etch cements. Dent Mater 24:185–191

Preuss A, Rosentritt M, Frankenberger R, Beuer F, Naumann M (2008) Influence of type of luting cement used with all-ceramic crowns on load capability of post-restored endodontically treated maxillary central incisors. Clin Oral Investig 12:151–156

DIN-50359-1 (1997) Testing of metallic materials-universal hardness test-part 1: test method.

Fischer-Cripps AC (2004) Nanoindentation: dynamic indentation testing. Springer, Berlin

Lee IB, An W, Chang J, Um CM (2008) Influence of ceramic thickness and curing mode on the polymerization shrinkage kinetics of dual-cured resin cements. Dent Mater 24:1141–1147

Valentino TA, Borges GA, Borges LH, Vishal J, Martins LR, Correr-Sobrinho L (2010) Dual resin cement knoop hardness after different activation modes through dental ceramics. Braz Dent J 21:104–110

Rencz A, Hickel R, Ilie N (2011) Curing efficiency of modern LED units. Clin Oral Investig. doi:10.1007/s00784-010-0498-3

Piwowarczyk A, Lauer HC, Sorensen JA (2005) The shear bond strength between luting cements and zirconia ceramics after two pre-treatments. Oper Dent 30:382–388

Piwowarczyk A, Bender R, Ottl P, Lauer HC (2007) Long-term bond between dual-polymerizing cementing agents and human hard dental tissue. Dent Mater 23:211–217

Piwowarczyk A, Lauer HC, Sorensen JA (2004) In vitro shear bond strength of cementing agents to fixed prosthodontic restorative materials. J Prosthet Dent 92:265–273

Ilie N, Hickel R (2009) Macro-, micro- and nano-mechanical investigations on silorane and methacrylate-based composites. Dent Mater 25:810–819

Pisani-Proenca J, Erhardt MC, Valandro LF, Gutierrez-Aceves G, Bolanos-Carmona MV, Del Castillo-Salmeron R et al (2006) Influence of ceramic surface conditioning and resin cements on microtensile bond strength to a glass ceramic. J Prosthet Dent 96:412–417

Goracci C, Cury AH, Cantoro A, Papacchini F, Tay FR, Ferrari M (2006) Microtensile bond strength and interfacial properties of self-etching and self-adhesive resin cements used to lute composite onlays under different seating forces. J Adhes Dent 8:327–335

el Hejazi AA, Watts DC (1999) Creep and visco-elastic recovery of cured and secondary-cured composites and resin-modified glass-ionomers. Dent Mater 15:138–143

Marghalani HY, Al-Jabab AS (2004) Compressive creep and recovery of light-cured packable composite resins. Dent Mater 20:600–610

Magni E, Ferrari M, Hickel R, Ilie N (2010) Evaluation of the mechanical properties of dental adhesives and glass-ionomer cements. Clin Oral Investig 14:79–87

Viotti RG, Kasaz A, Pena CE, Alexandre RS, Arrais CA, Reis AF (2009) Microtensile bond strength of new self-adhesive luting agents and conventional multistep systems. J Prosthet Dent 102:306–312

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ilie, N., Simon, A. Effect of curing mode on the micro-mechanical properties of dual-cured self-adhesive resin cements. Clin Oral Invest 16, 505–512 (2012). https://doi.org/10.1007/s00784-011-0527-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-011-0527-x