Abstract

Global cycling of environmental manganese requires catalysis by bacteria and fungi for MnO2 formation, since abiotic Mn(II) oxidation is slow under ambient conditions. Genetic evidence from several bacteria indicates that multicopper oxidases (MCOs) are required for MnO2 formation. However, MCOs catalyze one-electron oxidations, whereas the conversion of Mn(II) to MnO2 is a two-electron process. Trapping experiments with pyrophosphate (PP), a Mn(III) chelator, have demonstrated that Mn(III) is an intermediate in Mn(II) oxidation when mediated by exosporium from the Mn-oxidizing bacterium Bacillus SG-1. The reaction of Mn(II) depends on O2 and is inhibited by azide, consistent with MCO catalysis. We show that the subsequent conversion of Mn(III) to MnO2 also depends on O2 and is inhibited by azide. Thus, both oxidation steps appear to be MCO-mediated, likely by the same enzyme, which is indicated by genetic evidence to be the MnxG gene product. We propose a model of how the manganese oxidase active site may be organized to couple successive electron transfers to the formation of polynuclear Mn(IV) complexes as precursors to MnO2 formation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The redox cycling of manganese is a key chemical process in the natural environment. MnO2 is widespread in soils and sediments, and serves as an electron sink for microbial metabolism when O2 and nitrate are absent. In addition, MnO2 adsorbs other metal ions avidly [1, 2], including pollutants like Pb2+, and thereby plays a role in controlling their mobility in the environment.

MnO2 and Mn(II) are the thermodynamically stable forms of manganese under aerobic and anaerobic conditions, respectively, but the uncatalyzed oxidation of Mn(II) is very slow [3, 4]. The stability of its half-filled (d 5) electronic shell makes the extraction of an electron from Mn(II) a highly endothermic process (\( E_{{{\text{Mn}}^{3 + } /{\text{Mn}}^{2 + } }}^{0} \) ~1.5 V) unless strong chelating agents are available to stabilize the Mn(III). The lattice energy of MnO2 drives the two-electron oxidation, but the high initial barrier to electron transfer greatly slows the process.

However, a variety of bacteria and fungi can catalyze the conversion of Mn(II) to MnO2, increasing the rate by three to five orders of magnitude [2, 5]. Thus, most of the MnO2 present in the environment has been processed by these organisms. Why they do so is uncertain. A number of functions have been suggested [2, 6], including protection from toxic metals, or from UV light, or from predation or viruses. MnO2 can also break down natural organic matter into metabolizable substrates, thereby enhancing the bacterial food source [7]. An intriguing possibility is that the MnO2 deposits that bacteria coat themselves in (Fig. 1) may serve as a reservoir of Mn(II), which can protect them from oxidative damage [2, 6]. A combination of benefits may have driven the evolution of Mn-oxidizing ability in these organisms.

TEM of MnO2-coated spores from Bacillus sp. SG-1 [9]

Of considerable bioinorganic interest is the finding that the enzymes responsible for bacterial MnO2 formation are likely to be multicopper oxidases (MCOs). In three well-studied bacteria, Mn-oxidizing ability is lost upon the disruption of a gene whose sequence identifies it as a MCO [8–11]. Cell homogenates of these and related organisms display Mn-oxidizing protein bands on acrylamide gels [12–14]; in one case, the sequence analysis of peptides derived from the band confirmed that the protein is a MCO gene product [15]. In another bacterium, antibodies raised to the protein in a Mn-oxidizing band were found to cross-react with a MCO gene product from an expression library [16].

However, the finding that bacterial Mn oxidases are likely to be MCOs raises a mechanistic conundrum. MCOs are one-electron catalysts. How can they catalyze a two-electron oxidation? In MCOs, single electrons are transferred from substrates to the type 1 Cu, from which they are relayed to O2 at the type 3 Cu site [17]. Thus, Mn(III), not MnO2, should be the product of MCO-mediated Mn(II) oxidation. Indeed, fungal laccase has been shown to convert Mn(II) to Mn(III) in the presence of the strong Mn(III) chelator pyrophosphate (PP) [18, 19].

Mn oxidases have yet to be purified in amounts sufficient to permit mechanistic studies. However, Webb et al. [20] utilized a Mn-oxidizing preparation of exosporium (the loose outer part of the spore coat) from Bacillus sp. SG-1 [9, 13] to show, via PP trapping, that Mn(III) is an intermediate in the production of MnO2. In this bacterium, disruption of the MCO gene MnxG abolishes Mn-oxidizing activity [9]. Following the addition of Mn(II) and PP to the exosporium, the concentration of Mn(III)PP rose to a peak and then fell again, while MnO2 particles were observed to form. In addition, exogenous Mn(III)PP was shown to be a substrate for the exosporium, the Mn(III)PP concentration falling at about the same rate when Mn(III) instead of Mn(II) was added to the exosporium in the presence of PP. Thus, MnO2 formation occurred in two steps, both of which required exosporium. Mn(II) oxidation required O2, as expected, and was abolished by azide, a known inhibitor of MCOs [21, 22]. However, since the protein organization of exosporium is unknown, it was unclear whether both oxidation steps were MCO mediated or whether only the initial oxidation of Mn(II) was. Conceivably, Mn(III) oxidation to MnO2 took place at a different site, either through further reaction with O2 or via a disproportionation mechanism. The present study was undertaken to answer this question and to consider how the second step of the two-step oxidation might proceed.

Methods

UV–vis absorption spectra were monitored with an Agilent (Santa Clara, CA, USA) 8453 UV–vis spectrophotometer using a thermostattable multicell transport configuration with an automated kinetic scan capability. Spectra were recorded at room temperature every 15 min during the 24–36 h, using a 10 mm path length cuvette with a magnetic stirrer. The samples were stirred continuously during the UV–vis time courses using a Spinette cell stirrer (Starna Cells, Atascadero, CA, USA). Typically, several reaction mixtures and a control were monitored in a parallel configuration.

Bacillus sp. SG-1 spores were harvested [23] and exosporium was prepared as previously described [13]. All experiments were carried out at pH 7.5 in a 10 mM HEPES/50 mM NaCl buffer. For the UV–vis absorption time courses, 1 mL samples contained 50 μL aliquots of exosporium suspension, 0.1 mM Mn(II) chloride or Mn(III) acetate and 500 μM NaPP, added as a trapping agent for the Mn(III) ions. For experiments performed under anaerobic conditions, O2 was eliminated from the reaction mixture by continuously blowing Ar over the solution for 1 h; after that, the cuvette was sealed and transferred to the spectrophotometer. For inhibition experiments, sodium azide was added to the reaction mixture at a concentration of 10 mM.

Time-dependent absorption spectra were modeled with pure component spectra using a linear least squares fit. Three basis spectra were used (Fig. 2): (1) exosporium (50 μL in 1 mL of HEPES), (2) Mn(III)-PP (0.1 mM in HEPES), and (3) MnO2 in water (obtained as the supernatant after centrifuging a “Mn(II) + PP + exosporium” mixture that had reacted for 26 h). The 231–650 nm spectral region was used for fitting. The exosporium component was kept fixed during the fitting.

UV–vis absorption spectra of exosporium (50 μL in 1 mL of HEPES buffer) (black), Mn(III)–pyrophosphate complex (100 μM in HEPES buffer) (red), and MnO2 suspension in water (blue), all of which were used as basis spectra for a linear squares fit analysis of the UV–vis absorption spectra taken over 30 h of experiments investigating Mn oxidation catalyzed by exosporium

Results

The experiments were much the same as those reported by Webb et al. [20], with the crucial addition of experiments to test the effects of oxygen exclusion and azide inhibition on Mn(III) oxidation. Also, instead of simply monitoring the Mn(III)PP absorption intensity at 258 nm, we performed a full analysis of the absorption spectra by fitting them to three-component spectra (Fig. 2): (1) exosporium in HEPES buffer plus PP, (2) Mn(III)PP, and (3) MnO2. A fourth component, Mn(II)PP, was present in the reaction mixtures, but contributed negligibly to the spectra at the concentrations in use. Since exosporium + PP is unaltered throughout the course of the reaction, the first component was held constant when fitting the Mn(III)PP and MnO2 contributions.

Exosporium and Mn(III)PP both have absorption bands at 220 and 255–260 nm, but their shapes and relative intensities differ, allowing for discrimination between them. The spectrum of MnO2 is variable; it depends on particle size. We took the product spectrum to be that of the MnO2 colloid in the reaction mixture supernatant after 26 h of incubation. Beyond this time, the absorption spectrum of the reaction mixture did not change significantly, except for alterations due to aging of the MnO2, which formed larger particles. The MnO2 colloid displays broad UV–vis absorption, with a weak maximum at ~420 nm (Fig. 2).

Exosporium converts Mn(II) to Mn(III) and then MnO2

When Mn(II) was added to exosporium in the presence of excess PP, the absorption spectra evolved with time (Fig. 3a), showing increased absorption in both the UV and visible regions. Component fitting revealed a rise and fall in the Mn(III)PP fraction, with a maximum at around 10 h (Fig. 3b). In addition, we see that MnO2 production commenced after only 10 h, when Mn(III)PP had reached its peak. The MnO2 fraction then rose steadily as the Mn(III)PP fraction fell. Thus, there is a clear two-stage reaction sequence, with Mn(II)PP first being converted to Mn(III)PP and then to MnO2.

Time-resolved UV–vis absorption spectral measurements of Mn(II) oxidation by exosporium at room temperature. a Selected UV–vis absorption spectra of the reaction mixture taken at the indicated time points during the course of Mn(II) oxidation. The growth of the 265 nm band indicates the formation of the Mn(III) intermediate trapped by pyrophosphate; the 400 nm band is due to the formation of particulate Mn oxides. b Time courses followed by Mn(III)–pyrophosphate and MnO2 species during the 30 h UV–vis absorption experiment and obtained from the fit of the absorption spectrum at each time point to a linear combination of the component spectra depicted in Fig. 2

When Mn(III) was added to exosporium instead of Mn(II), the absorption spectra showed little change in the UV region and a rise in the visible region (Fig. 4a). Component fitting (Fig. 4b) revealed a steady decline in the Mn(III)PP fraction, while the MnO2 fraction rose from the beginning. Thus, the second stage in the reaction sequence proceeds independently of the first.

Time-resolved UV–vis absorption spectral measurements of Mn(III) oxidation by exosporium at room temperature. a Selected UV–vis absorption spectra of the reaction mixture taken at the indicated time points during Mn(III) oxidation. The growth of the 400 nm band indicates the formation of the particulate Mn oxides. b Time courses followed by Mn(III)-pyrophosphate and MnO2 species during the 30 h UV–vis absorption experiment and obtained from the fit of the absorption spectrum at each time point to a linear combination of the component spectra depicted in Fig. 2

Eliminating O2 or adding azide blocks the oxidation of both Mn(II) and Mn(III)

When O2 was eliminated from the reaction mixture (see the “Methods” section), no reaction with Mn(II) was observed. Likewise, there was no reaction when 10 mM sodium azide was added in the presence of O2 (data not shown). In both cases, the Mn(II) + exosporium UV–vis absorption spectrum remained essentially unchanged. Crucially, there was likewise no reaction of Mn(III) if the reaction mixture was de-aerated (Fig. 5a) or if 10 mM sodium azide was added (Fig. 5b). Again, the initial UV–vis absorption spectrum remained essentially unchanged (Fig. 5) over the time course of the reaction with O2 (Fig. 4).

Discussion

Our results corroborate those of Webb et al. [20], showing that the oxidation of Mn(II) by SG-1 exosporium produces chelatable Mn(III), and that this reaction requires O2 and is blocked by azide. These results are consistent with Mn(II) oxidation by a MCO, since MCOs couple O2 reduction to the one-electron oxidation of substrates, and are inhibited by azide binding. These findings corroborate the genetic and biochemical evidence that the manganese oxidase in SG-1 exosporium, MnxG, is an MCO.

We also confirm the observation [20] that in the presence of exosporium, chelated Mn(III) is further converted to MnO2. However, it was uncertain whether this step was also catalyzed by an MCO, since purified enzyme is unavailable. The exosporium might have harbored separate enzymes for Mn(II) oxidation and MnO2 production. Moreover, it was uncertain whether MnO2 production involved a one-electron oxidation of Mn(III). It might instead have resulted from enzyme-catalyzed disproportionation of Mn(III) followed by re-oxidation of the resulting Mn(II). The possible pathways are illustrated in Fig. 6.

The present experiments were designed to address these issues. If MnO2 production resulted from disproportionation, it should have proceeded in the absence of O2, although its production would have been cut in half because the Mn(II) produced in equal amounts by disproportionation would not have been reoxidized. However, de-aeration completely blocked MnO2 production from Mn(III) as well as Mn(II). Thus, Mn(III) conversion to MnO2 requires O2.

There remained the question of whether the oxidations of Mn(II) and of Mn(III) are catalyzed by the same or different enzymes. The observed inhibition by azide is consistent with an MCO being involved with Mn(III) as well as with Mn(II) oxidation. It is possible that azide acts at other enzyme sites than the MCO trinuclear Cu site (known to be the site of MCO inhibition [22, 24–26]). Azide is an inhibitor of manganese catalase [27], whose active site is a dinuclear Mn(III) complex; such a complex is a likely intermediate in Mn(III) oxidation (see below). Azide could bind this intermediate and thereby inhibit oxidation. However, this intermediate is likely formed within the same protein as the MCO Cu centers. The genetic evidence points to MnxG as a single protein associated with MnO2 formation, and a single native gel protein band converts Mn(II) to MnO2 [9, 15].

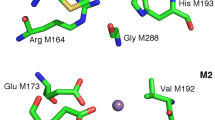

If a single MCO is responsible for both steps of the reaction, how might its active site be organized? The initial reaction, Mn(II) conversion to Mn(III), is straightforward enough. MCO-catalyzed Mn(II) oxidation has previously been observed in Mn(III) trapping experiments with a laccase enzyme [18, 19], and the mechanism is likely similar to MCO-catalyzed Fe(II) oxidation by human ceruloplasmin [28–30] or yeast Fet3p [21, 30–32], or Cu(I) oxidation by CueO from E. coli [33, 34]. Crystallographic studies [28] of the ferroxidase MCO, ceruloplasmin, indicate that Fe(II) binds to a site adjacent to the type 1 Cu, and that, after electron transfer, the product Fe(III) moves several angstroms toward the solvent interface, to a “holding site” (Fig. 7). It seems likely that a similar translocation of Mn(III) in MnxG would provide ready access to chelating agents, accounting for the facile production of Mn(III)PP in solution.

The structure of human ceruloplasmin (pdb #:1KCW), showing a mononuclear type 1 copper site and “substrate” and “holding” cation-binding sites in domain 6. Arrow indicates a movement of sidechain E935 from the substrate site to the holding site upon iron translocation after oxidation. Adapted from [28]

However, MnO2 production from Mn(III) has no precedent in MCO chemistry. Oxidation to mononuclear Mn(IV) is improbable, since Mn(IV) is a powerful oxidant, and it cannot be stabilized by the relatively weak donor ligands available from protein side chains; these are likely to be carboxylates, as seen in ceruloplasmin [28]. In the absence of strong donor ligands (e.g., porphyrin [35, 36]), known Mn(IV) complexes are polynuclear, and are stabilized by oxide bridges [37–39]. We speculate that the MnxG holding site for Mn(III) might accommodate multiple Mn(III) ions, which could then form polynuclear Mn(IV) complexes upon electron transfer. Binuclear binding sites are common in metalloproteins. A pertinent example is Mn catalase [27, 38, 40], in which a pair of Mn ions cycle between Mn(II) and Mn(III) oxidation states during enzymatic turnover. (A “superoxidized” form of the enzyme contains Mn(III) and Mn(IV), but is not in the catalytic cycle [40, 41]).

However, if the trivalent ion holding site is displaced from the type 1 Cu, as in ceruloplasmin, then direct electron transfer from Mn(III) to Cu is unlikely. A possible pathway that circumvents this difficulty is sketched in Fig. 8. In this model, a binuclear site is envisioned adjacent to the holding site. If two Mn(III) ions fill the binuclear site, then a third Mn(III) in the holding site could serve as an electron shuttle. It could abstract an electron from the binuclear site then migrate back to the Mn(II) site and deliver its electron to the type 1 Cu, permitting successive oxidations by O2. The driving force for electron abstraction from the binuclear Mn(III) complex would be the formation of oxide bridges from coordinated water or hydroxide ions, concerted with Mn(IV) formation. Two electron shuttle rounds would produce a [Mn(IV)2O2]4+ unit, likely bound to carboxylate side chains, and primed to nucleate MnO2 formation. (A binuclear complex is the minimum structure for oxide bridge formation. Higher-nuclearity complexes are possible. There are many synthetic examples of tri- and tetranuclear Mn complexes [37, 42–44], and the water oxidation complex of photosystem II contains four Mn ions [37, 43, 45, 46]).

A precedent for how oxide mineral nucleation may proceed is offered by ferritin, the iron storage protein [47, 48]. In ferritin, a hollow protein shell is filled with Fe2O3 after the oxidation of Fe(II) at a binuclear ferroxidase site. Recent NMR experiments have revealed details of how the binuclear Fe(III) intermediates that are formed at the ferroxidase site migrate along protein channels to nucleation sites within the core [49]. While bacterially produced MnO2 is not confined to a protein core, it is likely that manganese oxidases likewise offer pathways for polynuclear Mn(IV) complexes to migrate toward nucleation sites.

In this proposed mechanism, Mn can be delivered to the enzymes as either Mn(II) or as Mn(III). A conceptual issue is that the Mn(III) oxidation step is actually a disproportionation, with conversion to Mn(IV) being accompanied by Mn(II) production. Why then is MnO2 not produced from exogenous Mn(III) in the absence of oxygen? The simplest explanation would be that access to the substrate site is restricted to the channel connecting it to the holding site. Mn(II) could enter through this channel, but would be unable to migrate back to solution once the holding site contains Mn(III). Thus, the disproportionation reaction would be blocked unless the resulting Mn(II) is reoxidized by O2.

An alternative possibility is that Mn(III) oxidation involves direct electron transfer to O2. If O2 could react directly with the putative binuclear Mn(III) intermediate, the products would be [Mn(IV)2O2]4+ and peroxide; the peroxide would additionally oxidize Mn(III). This scenario seems unlikely, since Mn(III) is normally unreactive with O2. Literature reports of Mn(III) oxidation by O2 have involved complexes with electron-rich organic ligands [50–53], unlike the potential ligands available in the protein. On the other hand, a mass-spectrometric oxygen isotope study [54] has indicated that about half the O atoms in bacterially produced MnO2 are derived from molecular O2. This observation is inconsistent with a purely MCO mechanism, since MCOs reduce O2 to water without releasing intermediates. The present results do not rule out a direct reaction of Mn(III) with O2, since, as noted above, azide inhibition may result from complexation at the Mn(III) site, as well as at the MCO trinuclear Cu center. Resolution of this important issue will require further experiments to distinguish between the reactivities at the Cu and putative Mn(III) sites. Efforts are underway to produce purified MnxG in order to clarify the features of this intriguing enzyme.

Conclusions

The bacterial oxidation of Mn(II), a process central to the global manganese cycle, appears to be controlled by manganese oxidases that are MCOs. Since MCOs are one-electron oxidants, this finding raises the issue of how they can catalyze the two-electron transformation of Mn(II) to MnO2. Trapping experiments with PP and exosporium from the Mn-oxidizing Bacillus sp. SG-1 have shown that Mn(III) is the initial oxidation product, consistent with its oxidase being an MCO. However, it has not been clear how the subsequent conversion of Mn(III) to MnO2 is catalyzed.

The present experiments show that this conversion requires O2 and is inhibited by azide. This finding is consistent with the MCO catalysis of Mn(III) as well as Mn(II) oxidation. We present a model of how the MnxG active site might be organized to couple multiple electron transfers to the formation of MnO2-precursor polynuclear Mn(IV) complexes via a Mn(II)/Mn(III) shuttle.

However, our results do not rule out an alternative possibility: that O2 might react directly with a putative polynuclear Mn(III) complex, a process that might also be inhibited by azide. While such a reaction seems chemically unlikely, it would explain the otherwise puzzling observation that O2 is incorporated into bacterially produced MnO2. Further experiments, hopefully with purified protein, will be needed to distinguish these possibilities.

Abbreviations

- HEPES:

-

4-(2-Hydroxyethyl)piperazine-1-ethanesulfonic acid

- MCO:

-

Multicopper oxidase

- PP:

-

Pyrophosphate

- TEM:

-

Transmission electron microscopy

References

Nelson YM, Lion LW (2003) In: Selim HM, Kingerly WL (eds) Geochemical and hydrological reactivity of heavy metals in soils. CRC Press, Boca Raton

Tebo BM, Bargar JR, Clement BG, Dick GJ, Murray KJ, Parker D, Verity R, Webb SM (2004) Annu Rev Earth Planet Sci 32:287–328

Morgan JJ (2000) Metal ions in biological systems. Marcel Dekker, New York

Morgan JJ (2005) Geochim Cosmochim Acta 69:35–48

Spiro TG, Bargar JR, Sposito G, Tebo BM (2010) Acc Chem Res 43:2–9

Brouwers G-J, Vijgenboom E, Corstjens PLAM, de Vrind JPM, de Vrind-de Jong EW (2000) Geomicrobiol J 17:1–24

Sunda WG, Kieber DJ (1994) Nature 367:62–64

Brouwers G-J, de Vrind JPM, Corstjens PLAM, Cornelis P, Baysse C, de Vrind-de Jong EW (1999) Appl Environ Microbiol 65:1762–1768

van Waasbergen LG, Hildebrand M, Tebo BM (1996) J Bacteriol 178:3517–3530

Ridge JP, Lin M, Larsen EI, Fegan M, McEwan AG, Sly LI (2007) Environ Microbiol 9:944–953

Larsen EI, Sly LI, McEwan AG (1999) Arch Microbiol 171:257–264

Francis CA, Tebo BM (2002) Appl Environ Microbiol 68:874–880

Francis CA, Casciotti KL, Tebo BM (2002) Arch Microbiol 178:450–456

Okazaki M, Sugita T, Shimizu M, Ohode Y, Iwamoto K, de Vrind-de Jong EW, de Vrind JPM, Corstjens PLAM (1997) Appl Environ Microbiol 63:4793–4799

Dick GJ, Torpey JW, Beveridge TJ, Tebo BM (2008) Appl Environ Microbiol 74:1527–1534

Corstjens PLAM, de Vrind JPM, Goosen T, de Vrind-de Jong EW (1997) Geomicrobiol J 14:91–108

Solomon EI, Sundaram UM, Machonkin TE (1996) Chem Rev 96:2563–2605

Schlosser D, Hofer C (2002) Appl Environ Microbiol 68:3514–3521

Hofer C, Schlosser D (1999) FEBS Lett 451:186–190

Webb SM, Dick GJ, Bargar JR, Tebo BM (2005) Proc Natl Acad Sci USA 102:5558–5563

de Silva D, Davis-Kaplan S, Fergestad J, Kaplan J (1997) J Biol Chem 272:14208–14213

Allendorf MD, Spira DJ, Solomon EI (1985) Proc Natl Acad Sci USA 82:3063–3067

Dick GJ, Lee YE, Tebo BM (2006) Appl Environ Microbiol 72:3184–3190

Yoon J, Liboiron BD, Sarangi R, Hodgson KO, Hedman B, Solomon EI (2007) Proc Natl Acad Sci USA 104:13609–13614

Cole JL, Avigliano L, Morpurgo L, Solomon EI (1991) J Am Chem Soc 113:9080–9089

Hirota S, Matsumoto H, Huang H-W, Sakurai T, Kitagawa T, Yamauchi O (1998) Biochem Biophys Res Commun 243:435–437

Whittaker JW (2012) Arch Biochem Biophys. doi:10.1016/j.abb.2011.1012.1008

Lindley PF, Card G, Zaitseva I, Zaitsev V, Reinhammar B, Selin-Lindgren E, Yoshida K (1997) J Biol Inorg Chem 2:454–463

Machonkin TE, Solomon EI (2000) J Am Chem Soc 122:12547–12560

Quintanar L, Gebhard M, Wang T-P, Kosman DJ, Solomon EI (2004) J Am Chem Soc 126:6579–6589

Taylor AB, Stoj CS, Ziegler L, Kosman DJ, Hart PJ (2005) Proc Natl Acad Sci USA 102:15459–15464

Stoj CS, Augustine AJ, Zeigler L, Solomon EI, Kosman DJ (2006) Biochemistry 45:12741–12749

Singh SK, Grass G, Rensing C, Montfort WR (2004) J Bacteriol 186:7815–7817

Djoko KY, Chong LX, Wedd AG, Xiao Z (2010) J Am Chem Soc 132:2005–2015

Weiss R, Gold A, Trautwein AX, Terner J (2000) In: Kadish KM, Smith KM, Guilard R (eds) The porphyrin handbook. Academic, Boston

Groves JT, Stern MK (1988) J Am Chem Soc 110:8628–8638

Manchanda R, Brudvig GW, Crabtree RH (1995) Coord Chem Rev 144:1–38

Wu AJ, Penner-Hahn JE, Pecoraro VL (2004) Chem Rev 104:903–938

Dave BC, Czernuszewicz RS (1994) Inorg Chim Acta 227:33–41

Waldo GS, Penner-Hahn JE (1995) Biochemistry 34:1507–1512

Khangulov SV, Barynin VV, Voevodskaya NV, Grebenko AI (1990) Biochim Biophys Acta 1020:305–310

Mullins CS, Pecoraro VL (2008) Coord Chem Rev 252:416–443

Mukhopadhyay S, Mandal SK, Bhaduri S, Armstrong WH (2004) Chem Rev 104:3981–4026

Bhula R, Gainsford GJ, Weatherburn DC (1988) J Am Chem Soc 110:7550–7552

McEnvoy JP, Brudvig GW (2006) Chem Rev 106:4455–4483

Cady CW, Crabtree RH, Brudvig GW (2008) Coord Chem Rev 252:444–455

Liu X, Theil EC (2005) Acc Chem Res 38:167–175

Ha Y, Shi D, Small GW, Theil EC, Allewell NM (1999) J Biol Inorg Chem 4:243–256

Turano P, Lalli D, Felli IC, Theil EC, Bertini I (2010) Proc Natl Acad Sci USA 107:545–550

MacDonnell FM, Fackler NLP, Stern C, O’Halloran TV (1994) J Am Chem Soc 116:7431–7432

Bossek U, Weyhermuller T, Wieghardt K, Nuber B, Weiss J (1990) J Am Chem Soc 112:6387–6388

Larson E, Soo Lah M, Li X, Bonadies JA, Pecoraro VL (1992) Inorg Chem 31:373–378

Chandra SK, Chakravorty A (1992) Inorg Chem 31:760–765

Mandernack KW, Fogel ML, Tebo BM, Usui A (1995) Geochim Cosmochim Acta 59:4409–4425

Acknowledgments

We thank Radhika Rajendran for developing the linear least squares fitting algorithm in VBA Excel and Satya Chinni for producing some of the exosporium preparations. This work was partially funded by NSF grants OCE-1031200 and OCE-1129553 to BMT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Soldatova, A.V., Butterfield, C., Oyerinde, O.F. et al. Multicopper oxidase involvement in both Mn(II) and Mn(III) oxidation during bacterial formation of MnO2 . J Biol Inorg Chem 17, 1151–1158 (2012). https://doi.org/10.1007/s00775-012-0928-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00775-012-0928-6