Abstract

Existing methods have been applied to estimate the uncertainty of measurement, caused by both sampling and analysis, and fitness-for-purpose of these measurements. A new approach has been taken to modify the measurement uncertainty by changing the contribution made by the sampling process. A case study on nitrate in lettuce has been used to demonstrate the applicability of this new generic approach. The sampling theory of Gy was used to predict the alterations in the sampling protocol required to achieve the necessary change in sampling uncertainty. An experimental application of this altered sampling protocol demonstrated that the predicted change in sampling uncertainty was achieved in practice. For the lettuce case study, this approach showed that composite samples containing 40 heads, rather than the usual ten heads, produced measurements of nitrate that where more fit-for-purpose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sampling has been recognised as part of the measurement process, when the measurand (or true value to be determined) is defined in terms of the sampling target (e.g., a batch of material) rather than in terms of the laboratory sample [1]. Several methods have been proposed therefore to estimate measurement uncertainty arising from all steps in the measurement process, including the primary sampling [2–5]. Once an estimate of the uncertainty has been made, the next question to address is whether that level of uncertainty is acceptable in order to decide whether the measurements are fit for the purpose for which they are intended. One approach to this question has been to designate this optimal value of uncertainty, as the point that minimises the overall financial loss to the user of the measurements [6, 7]. The next step in this line of research is to find procedures to modify the uncertainty of a measurement system, in order to achieve this optimal value, if the actual value is initially sub-optimal.

In this paper, a case study of nitrate (NO3) in lettuce is used to demonstrate how sampling theory can be employed to modify the sampling procedure undertaken to the point where the uncertainty due to sampling is indicated as being cost-effective, using the optimised uncertainty (OU) method [7]. The OU method balances the uncertainty of measurements on food against the costs of both the measurements and the other expenditure that may arise as a consequence of the possible misclassification of the food. Measurement uncertainty from the sources of primary sampling and chemical analysis (but excluding sampling bias) is estimated using an existing technique, which is based on the taking of duplicated samples and duplicated analyses (i.e. the duplicate method [2]). The way in which the duplicate sample is taken may vary from case to case [8, 9]. The input information required for the OU method is the actual costs of sampling and analysis, and the expected costs that could arise from either the ‘false-positive’ or ‘false-negative’ classification of batches of food (also called ‘false non-compliance’ and ‘false compliance’, respectively). A loss function is then constructed that calculates the ‘expectation of loss’, which will arise for a given uncertainty of measurement [6]. This function has a minimum value of cost at an optimal value of uncertainty, which can be estimated numerically. Below the optimum value of uncertainty the costs typically increase due to higher measurement costs. Above the optimum value, the costs increase due to increasing probability of expenditure on consequences such as unnecessary rejection of the batch, potential litigation or loss of corporate reputation because of undetected contamination. A second stage of the OU method optimises the division of the expenditure on the measurement between that on sampling and that on analysis. The technique has been demonstrated as a useful approach for judging the fitness-for-purpose of chemical measurements [7]. By matching the expenditure on the measurement against that caused by the misclassification of the food, the OU method has the potential to reduce overall expenditure whilst ensuring an appropriate reliability of measurement. Typically, if sampling contributes the greatest source of uncertainty, then the OU method will indicate that increased expenditure is required for this process. Where improvements are indicated in the measurement process, steps should be taken to update the protocols in order to improve the quality of the resultant data, in line with reducing the financial losses. Sampling theory, such as that proposed by Gy [10] is one approach that can be employed for predicting the appropriate sample mass needed to achieve the desired modification of uncertainty.

This paper uses a real case study for determining nitrate in lettuce to explain the general principles for modifying uncertainty. Nitrate is present in all vegetables naturally via the nitrogen cycle. Leafy green vegetables, in particular lettuce and spinach, contain relatively high concentrations of nitrate compared to other foods, and constitute a significant source of nitrate to the consumer. Nitrate levels are also affected by factors such as climate, soil characteristics, fertilisation regime, growth rates and in particular, light levels. Cloudy conditions have been observed to lead to high levels of nitrate in lettuce and spinach, which is a concern for several northern European Member States. Much work has been undertaken in the general area concerned with controlling the levels of nitrate in lettuce (e.g., by Burns et al. 2002) [11].

The EU Scientific Committee for Food (SCF) reviewed the available data in 1995 [12] and recommended an acceptable daily intake (ADI) for nitrates of 3.65 mg kg−1 bodyweight per day. This is equivalent to a safety guideline of 219 mg day−1 nitrate for a 60-kg person. An ADI is an estimate of the amount of a substance, expressed on a bodyweight basis, which can be ingested daily over a lifetime without appreciable health risks. In this case, the safety guideline was set to protect against possible harmful effects of nitrate in the diet, such as a form of anaemia that is most likely to occur in young children. Many studies have investigated the possibility of a link between nitrate intake and its conversion to cancer-causing compounds, but so far these have failed to provide convincing evidence that nitrate intake in the UK causes cancer.

EU Regulation 1822/2005 [13] sets maximum levels for nitrate in lettuce and spinach and requires that all Member States carry out monitoring annually. The limits set down vary according to season with higher nitrate levels permitted in crops grown in winter in comparison with those grown in the summer. For lettuce, there are also different limits for glasshouse-grown and outdoor crops. The regulation also allows for an optional derogation from the limits for nitrate in lettuce and spinach. This means that during the derogation period, Member States are permitted to produce lettuce and spinach that is exempt from the maximum limits. However, it should be noted that maximum permitted levels do apply to imported produce. The derogation period allows growers time to implement a code of Good Agricultural Practice (GAP), which is another requirement of the regulation. Amongst other suggestions, this code of GAP [14–16] requires the alteration of fertiliser application regimes with the aim of reducing the level of nitrogen in crops.

By way of derogation from Article 1(1) of EU Regulation 1822/2005, the UK and Ireland are authorised until 31 December 2008 to place on the market fresh lettuce grown and intended for consumption in their territory and harvested throughout the year with nitrate levels higher than the maximum levels laid down in this Regulation. Most lettuce and spinach grown in the UK is grown under codes of GAP and meets the EC maximum limits for nitrate. This case study provides all of the characteristics needed to apply the methodologies for the estimation, optimisation and modification of uncertainty, from both the scientific and contextual points of view.

In this paper, measurement uncertainties (from both sampling and chemical analysis) were estimated in the first instance, and subsequently assessed in terms of fitness for purpose using the OU methodology. Recommendations for improvements in this measurement system are made on the basis of the sampling theory of Gy [10], and the overall benefit of the methodologies for optimising and modifying uncertainty in measurement systems in general will be considered.

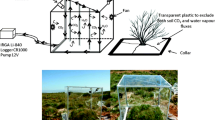

Estimation of measurement uncertainty in routine procedures

Sampling was conducted during February 2004 (known later as round 1, R1). The particular sampling methods employed were adapted from those laid down in Commission Directive 2002/63/EC [17]. Within this study a sample is taken to represent a bay of lettuce (i.e. the sampling target). Ten heads of lettuce, selected whilst walking either a ‘W’ or ‘X’ (5-point die) shaped pattern through each bay, were cut from each bay selected. The ten lettuce heads formed a primary sample [17]. For the purpose of estimating the measurement uncertainty associated with routine methods, eight bays were selected for inclusion within this study. All eight bays were housed within glasshouses, however they did range in size and the level of agricultural technology applied. The lettuce sampled were either curly or round-head varieties grown from a number of different cultivars. Since legislation (i.e. EU Regulation 1822/2005 [13]) does not set different thresholds of maximum nitrate concentration according to lettuce cultivar or variety (except Iceberg lettuce), and the routine sampling procedures are applied indiscriminately for all lettuce, the inclusion of a range of different lettuce cultivars was justified. The resultant uncertainty estimates are therefore broadly applicable for the routine sampling and analyses of lettuce.

In a single bay, one primary sample consisting of ten heads of lettuce was taken by professional samplers. A second ‘duplicate primary sample’ was then taken under instruction from the researchers. This was repeated for a further seven bays. For logistical reasons it was not always possible to implement the protocol exactly as described (e.g. the starting point, orientation and exact locations of sampling in a ‘W’ design are not explicit). However, this situation is frequently encountered in practice; consequently the results obtained from all sampled targets were used in the uncertainty calculations.

Each ten-head primary sample was transported to the analytical laboratory in ice-packed cool boxes, to ensure that the samples were kept at the prescribed temperature (<10°C). Primary samples were routinely presented at the analytical laboratory no later than 24 h after the sampling event. Physical preparation of the analytical test sample from the ten-head primary sample required each individual lettuce head to be cut into quarters [17]. Two (opposite) quarters were retained for analysis and the remaining quarters discarded. The 20 quarters (per ten-head primary sample) were blended in a Hobart macerator. Subsequently, two analytical test portions [17] were taken directly from the Hobart bowl for the purpose of duplicate analysis. The analytical test portions were extracted using hot water and the nitrate concentration was determined by HPLC with ultra-violet detector [18, 19]. Quality control samples (spike recovery experiments) were analysed concurrently with the analytical portions of the samples. No significant analytical bias was detected and so, in this instance, bias correction was considered unnecessary for the resultant data.

As described, each ten-head primary sample was analysed twice to produce a fully balanced experimental design [20]. The full data set, comprising eight sets of four data points, was treated with robust analysis of variance (ANOVA) [2]. This statistical technique calculates the variance arising between-bays, from sampling (\(s_{{\rm samp}}^2\)) and from the chemical analysis (\( s_{{\rm anal}}^2\)). The estimates of sampling standard deviation (\(s_{{\rm samp}} = 319\) mg kg−1 of nitrate in the lettuce material) and analytical standard deviation (\(s_{{\rm anal}} = 168\) mg kg−1) were combined \(\left({s_{{\rm meas}} = \sqrt {s^2 _{{\rm samp}} + s^2 _{{\rm anal}}}} \right)\) to produce an estimate of the standard measurement uncertainty (\(u = s_{{\rm meas}} = 360.5\) mg kg−1). The mean nitrate mass fraction across the eight targets was 4,408 mg kg−1. In this study most of the variability (71% of total variance) arose due to differences between the eight target bays. Sampling contributed 23% of the total variability and was, as expected, the dominant source of measurement uncertainty (78% of \(s_{{\rm meas}}^{\rm 2}\)), when compared to the analytical uncertainty (22% of \(s_{{\rm meas}}^{\rm 2}\)).

Having estimated the measurement uncertainty and its component parts, the OU methodology was applied to assess the fitness for purpose using financial considerations.

Application of the OU method for fitness for purpose assessment

The OU method requires the quantification of a number of input parameters [8]. Parameters such as the regulatory maximum level or threshold (T=4,500 mg kg−1 of nitrates per kilo of fresh product) and uncertainty estimates, including those for sampling (319 mg kg−1) and for analysis (168 mg kg−1), were already known. The costs per sample and per analysis were equivalent to the costs paid to the professional samplers for each ten-head primary sample (£40) and the cost paid to the laboratory for each nitrate analysis (£40). The concentration at which the system was to be optimised (c m) was selected so that there was an appreciable probability of misclassification. Previous applications of the OU method have utilised a range of criteria for the setting of c m (e.g. 1.1T=4,950 mg kg−1) [8]. For this investigation, the level of c m was set at a hypothetical enforcement limit of nitrate in lettuce. The relative expanded analytical uncertainty was already estimated to be 7.62% at 95% confidence \(({U_{{\rm anal}} \ \% = {{200s_{{\rm anal}}} \mathord{/ {\vphantom {{200s_{{\rm anal}}} {\overline x}}} \kern-\nulldelimiterspace} {\overline x}}})\). The minimum mass fraction that would indicate that the nitrate mass fraction was greater than the threshold was calculated to be 4,871 mg kg−1 (c m–U anal=T=4,500 mg kg−1). Interestingly, this value is similar to the median value of non-compliant measurements (4,891 mg kg−1) and also the value of 1.1T (4,950 mg kg−1).

The cost of non-compliance can be estimated by considering potential losses to the users of the measurements. Nitrate analyses are regularly performed on behalf of the growers to check the quality of their product and also that the fertilising regime is appropriate. Furthermore, retailers (to whom the growers are contracted) also conduct nitrate analysis of the lettuce. In spite of the derogation status of the UK, retailers set quality standards with which their contractors must conform. The growers are expected to achieve nitrate concentrations below the regulatory maximum level. A non-compliance scenario could (in the worst-case) result in the rejection of a batch of lettuce. If the assessment of non-compliance was later found to be a ‘wrong’ decision, i.e. the true concentration was below the threshold then the financial consequence can be evaluated as the unnecessary loss of revenue from the batch. For the purpose of this study, a false non-compliance scenario was considered, and the cost of the batch of lettuce was used as the consequence cost. This investigation included a range of batch sizes (up to 12,000 heads per bay), and thus the consequence costs will vary also. The variety of lettuce determines the cost per head; curly lettuce (ca. £0.44) is more expensive than round-head lettuce (ca. £0.24). Given that the current protocol is applied indiscriminately between bay size and variety, a worst-case scenario was selected, i.e. £5,280, for around 12,000 curly lettuce heads.

Practical assessment of fitness for purpose and recommendations for improvement

Application of the OU method under the experimental conditions employed and assumptions made indicated the current levels of uncertainty to be sub-optimal in that measurement uncertainty (s meas) is too high (at 361 mg kg−1), with an associated expectation of loss E(L) of £874. The optimal measurement uncertainty, which results in the lowest expectation of loss (£395), was shown to be at an uncertainty value of ca. 184 mg kg−1 (Table 1).

The second stage of the OU process involves the measured (actual) levels of sampling and analytical uncertainty being compared with the corresponding optimal values and gives recommendations on the optimal expenditure for sampling and chemical analysis. A modification (reduction) factor of approximately two (i.e. 319/149=2.13) in s samp is indicated. Furthermore a reduction factor of 1.6 in s anal is also recommended. If the optimal s meas of 184 mg kg−1 is reached, then the expectation of loss will be effectively halved (from £874 to £395 per batch). By reaching the optimal s samp alone and assuming the s anal remains constant as 168 mg kg−1, (i.e. s meas=225 mg kg−1) ca. 95% of the optimal saving in expectation of loss will be achieved.

The application of the OU method to the nitrate data presented has indicated that the cost per sample should ideally be raised to £183, the equivalent of a 45-head primary sample (assuming a linear increase in cost for extra heads). For the purpose of this study, a 40-head primary sample was considered sufficient to achieve the vast majority (85%) of the predicted reduction in E(L), whilst being logistically achievable.

Modifying measurement uncertainty: a pilot study for nitrate in lettuce

Gy’s sampling theory [10] predicts that the sampling uncertainty is inversely proportional to the mass (m) of sample, where \(m \propto {1 / {s_{{\rm samp}}^2 }}\). This theory has been shown to reduce sampling uncertainty when applied to environmental soil sampling [21] and particulate food commodities e.g. coffee beans for mycotoxin analysis [22]. However it has been less successful when applied to other food commodities (e.g. butter for moisture analysis) [23]. In order to support the use of Gy’s sampling theory for informing optimal sampling plans a pilot study was run with the objective of testing whether the relationship between mass and uncertainty (as suggested by the theoretical model) holds for nitrate in lettuce.

Eight bays of lettuce were selected for inclusion in this pilot study. Duplicate ten-head primary samples were taken from each of the bays to facilitate uncertainty estimation by the duplicate method. Four of the targets were from the original experiment, in that the portions of lettuce heads usually discarded were retained. This pilot study was undertaken in June and consequently due to seasonal changes in the growing regimes, the four further duplicate samples had to be sourced from lettuce grown outdoors. From the literature it is known that lettuce grown outdoors typically had lower nitrate concentrations than their indoor grown counterparts [11]. However, the inclusion of outdoor lettuce was valid because the principle aim of the study was to model the change in uncertainty caused by increasing the sample mass, and not specifically to estimate the uncertainty value itself.

For each ten-head primary sample, routine nitrate analysis was applied to each individual head of lettuce, rather than just to a composite sample. Estimates of nitrate content for four-head composite samples (for example) were made by randomly selecting (without replacement) four values from the analysis of the ten lettuce heads. The arithmetic mean was used as a simulated composite concentration, i.e. a mathematically combined sample [24]. This method was employed for one-head increment, up to ten-head increment composite samples, for each duplicated sample. Duplicate analyses were not performed when analysing the single lettuce heads. Estimates of s samp therefore included some element of analytical uncertainty. The main case study has already shown that the s anal only contributes 17% to the total measurement uncertainty and therefore will not exert any significant influence on the results of this pilot study. Furthermore, the value of s samp from the mathematically combined ten-head sample (209.57 mg kg−1) was found to be in good agreement with the mechanically prepared composite ten-head samples (200.53 mg kg−1). No statistical difference could be determined (F stat=1.09) and the method of simulating composite concentrations was considered valid.

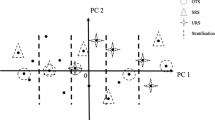

The empirical values of s meas were compared to those predicted by sampling theory. The theoretical values were calculated from a starting point equivalent to the s meas calculated from duplicate samples each comprised of ten lettuce heads (Fig. 1). Visual inspection of the data shows that the empirical relationship appears to fit that predicted by the relationship \(m \propto {1 / {s_{{\rm samp}}^2 }}\).

The observed (−▵−) relationship between sample mass (x= number of lettuce heads) and sampling uncertainty (y = s samp) is described by \(y = 549.76x^{- 0.3998} \;(R^2 = 0.8601)\). The relationship described by sampling theory (solid line, \(y = 634.15^{- 0.5}\)) was calculated using the ten-head s samp value (200.5 mg kg−1) as the initial value. Visual inspection shows the observed data fit the model relatively well (statistical comparison in Table 2)

A more rigorous assessment of the goodness of fit was undertaken using the log-transformed empirical data and application of least-squares regression. The goodness of fit was assessed by comparing the coefficients derived from empirical and theoretical models using the t-test (and standard error estimates for each coefficient) (Table 2). The model derived from empirical data was not found to differ significantly from the theoretical model. This indicates that for the case study of nitrate in lettuce, the sampling uncertainty can be successfully reduced by increasing the number of lettuce heads per samples (i.e. the sample mass) in line with theoretical predictions.

Application of the optimal protocol with the aim of achieving fitness for purpose

A modification was required in s samp, to achieve a reduction by a factor of 2, as determined by the OU method (Table 1). The pilot study provided evidence that this improvement could be achieved by increasing the sample mass by four times (i.e. 22), in line with theoretical predictions. The second round of sampling required a 40-head primary sample (i.e. four times the routine ten-head primary sample).

Two growers were recruited to participate in the second round (R2) of this investigation. In terms of the sample size, the revised protocol was not in line with the routine monitoring program, and as such was conducted independently of it. However, every effort was made to ensure other aspects of the protocol (e.g. sample collection, transportation) were implemented so as to mimic routine procedures. Each grower allowed the researchers to take samples from bays including two of curly lettuce and two of round head lettuce (to reflect the cross-variety sampling performed in R1).

During November, duplicate primary samples, each of 40 lettuce heads, were taken from each of the eight bays where each sample comprised of glasshouse grown lettuce that was considered to be of saleable product. Samples were taken following the routine protocol (i.e. W’s or X’s) and also by imitating the contracted samplers’ interpretation of the sampling protocol as witnessed in R1. As before, samples were transported, by same-day delivery, to the contracted laboratory in industrial sized cool boxes. Similarly to R1, ice packs were used to keep the temperature below the 10°C.

A revised procedure was needed to manage the increased sample volume during subsequent preparation of the analytical sample. The 40 heads of lettuce making up each primary sample were randomised and split into one ten-head sub-sample, and a 30-head sub-sample. By splitting the primary samples in this way, the resultant data could be used to estimate uncertainty arising from the procurement of both ten-head and 30-head primary samples. Duplicate analytical test portions were selected from each analytical sample and were analysed for nitrate (as in R1). The uncertainty associated with the 40-head primary sample was calculated using the weighted average of the nitrate concentration determined in the ten-head and 30-head primary samples. This method of sample splitting facilitated a direct comparison to be made between the uncertainty that would have arisen during routine testing (i.e. ten-head primary sample) and that from the optimal sampling protocol suggested following R1 (i.e. 40-head primary sample).

The results for round 2 of the experiment showed that by implementing the revised sampling protocol, s samp was reduced (Table 3) from 553 mg kg−1 (R2, ten-head primary sample) to 306 mg kg−1 (R2, 40-head primary sample). The observed improvement factor (1.8) is in close agreement with the improvement factor predicted by Gy’s sampling theory [10], a difference that was not statistically significant. When comparing the s anal estimates (from R2) obtained from test portions from ten-head primary samples (54 mg kg−1) and 40-head primary samples (42 mg kg−1) no statistically significant difference was determined (F 16/16=1.65).

In addition to this main comparison of uncertainty made between different sample masses within one round, a second comparison was also made between the two different rounds to test the general conformity with the predictions from this model. A comparison between the 40-head primary sample (R2) and the ten-head primary sample (R1), showed that the predicted reduction in uncertainty, expected by increasing the sample mass, was not apparent when the comparison was made in this way. However, a slight arithmetic decrease in sampling uncertainty, following the four-fold mass increase, was observed between R1 (319 mg kg−1) and R2 (306 mg kg−1). It is considered that any changes would have been masked by seasonal variations in nitrate mass fraction in lettuce plants. R2 sampling was undertaken in November (as opposed to February/March for R1) and the mean nitrate composition had decreased by ca. 30% between R1 and R2. Nitrate levels are temporally variable and so, the sampling uncertainty will vary also. A large reduction in analytical uncertainty was observed between R1 (168 mg kg−1) and R2 (54 mg kg−1), when considering ten-head primary samples. The difference in the levels of analytical uncertainty may be explained by changes in ambient or operating conditions that may exert random effects on the test results.

Re-assessment of fitness-for-purpose – has the optimal level of uncertainty really been achieved?

The level of uncertainty achieved using the revised protocol (R2) may also be assessed using the OU methodology. For this application of the OU method, the uncertainty values are not the only input parameters to have changed in value as a result of the new protocol. The increased size of the primary sample limited the number of samples that may practically be taken in one day, and also the number that could be transported to the analytical laboratory in one delivery. Consequently, L samp has increased as a result of, e.g. the additional person-hours necessary to cut the samples, financial reimbursement of the growers and extra courier services. Using the new protocol L samp was calculated as being £215. When the OU method makes recommendations for optimal measurement expenditure it currently assumes that the L samp is directly proportional to the desired decrease in uncertainty. For this study, it was assumed that the L samp would increase by four times in order that the s samp would be reduced by a factor of 2, i.e. increase the mass by a factor of 4. It is seen for the case study of nitrate in lettuce that this assumption is not always justified, and should be used as a general guide and not as an exact instruction. The L samp for a 40-head primary sample was approximately five times that of a ten-head primary sample, rather than the predicted four times. The L anal was also increased in R2 (£120 per analysis), when compared to R1 (£40 per analysis). This increase takes into account the factor that to obtain an estimate of the concentration of a 40-head primary sample, two analyses are required (i.e. of ten- and 30-head primary samples). An additional sum (£40) is added to the expected £80 (i.e. 2×£40) to account for the additional sample preparation and sample handling/storage complications brought about by a 40-head primary sample. Due to seasonal variations in the market value of a single lettuce head, the value of consequence cost was reduced from £5,280 (R1) to £4,200.

Considering the other input parameters remain as defined for R1 (i.e. T=4,500 mg kg−1 and c m=4,871 mg kg−1) the OU method can be applied for R2 (40-head) uncertainty estimates. It can be seen that implementation of the revised ‘optimal’ sampling protocol has achieved optimal levels of uncertainty (Fig. 2). The value of s meas from R2, (309.1 mg kg−1 for a 40-head primary sample) was found to be effectively fit for purpose when compared to the optimal s meas of 246.0 mg kg−1. If the recommendations of this second iteration of optimisation were implemented, the E(L) is only predicted to decrease by £58 (i.e. from 739 to 681 mg kg−1). No statistically significant difference between the optimal and actual measurement uncertainty could be detected for the 40-head primary samples of R2 (F 24/24=1.58). Conversely, a ten-head primary sample from R2 would still not have been considered fit for purpose, assuming R1 estimates for L samp and L anal costs (i.e. £40 each). An E(L) of >£1,000 per batch was calculated for the level of uncertainty estimated for the ten-head primary sample (556.13 mg kg−1).

The actual level of uncertainty (estimated here using s

meas) computed for a 40-head sample in round 2 of the investigation ( 309 mg kg−1) has an associated expectation of financial loss [E(L)] of £739 per batch. When compared to the E(L) of £681 computed for the optimal value (

309 mg kg−1) has an associated expectation of financial loss [E(L)] of £739 per batch. When compared to the E(L) of £681 computed for the optimal value ( 246 mg kg−1), it can be seen that measurement uncertainty is effectively fit for purpose

246 mg kg−1), it can be seen that measurement uncertainty is effectively fit for purpose

Conclusions

When implementing the routine UK monitoring protocol designed to assess nitrate levels in lettuce heads, sampling proved to be the dominant source of uncertainty of measurement, as it has been found for many other food-analyte combinations [8, 9]. Gy’s sampling theory has successfully been used as a tool in the process of reducing sampling uncertainty where an increased sample mass was found to produce a decrease in sampling uncertainty. Under the experimental conditions employed and cost assumptions made, a 40-head primary sample was considered to be of appropriate size for the estimation of nitrate within a bay of lettuce. The predicted improvement factor (i.e. 2) in sampling uncertainty was achieved following a second round of measurement. The reduction in sampling uncertainty, and the coincidental reduction in analytical uncertainty, produced a measurement uncertainty (308 mg kg−1) that was fit for purpose in terms of expected financial loss. Routine implementation of the optimal sampling protocol (i.e. 40-head primary samples) has the benefit of reducing the expectation of loss by ca. £500 per bay of lettuce.

Currently the OU method assumes a direct relationship between uncertainty and measurement cost. This was found not to be exactly the case for nitrate in lettuce. It is advised that where changes in uncertainty are recommended (in order to reach the optimal level), caution is exercised and the recommendations of expenditure for sampling and analysis are treated as guidance values. In this particular case study, the benefits of applying an optimal protocol only became apparent when the uncertainties associated with the routine and optimal protocols where compared within a single round of measurement (i.e. R2).

Even though this approach has been demonstrated using nitrate analysis in lettuce, Gy’s sampling theory suggests that the general strategy of uncertainty modification should be applicable to the sampling and measurement of a wide range of materials. Verification of this generalization will require further experimental investigations.

References

Ramsey MH (2004) When is sampling part of the measurement process? Accred Qual Assur (9)11–12:727–728

Ramsey MH (1998) Sampling as a source of measurement uncertainty: techniques for quantification and comparison with analytical sources. J Anal Atom Spectrom 13:97–104

De Zorzi P, Belli M, Barbizzi S, Menegon S, Deluisa A (2002) A practical approach to assessment of sampling uncertainty. Accred Qual Assur 7:182–188

Kurfurst U, Desaules A, Rehnert A, Muntau H (2004) Estimation of measurement uncertainty by the budget approach for heavy metal content in soils under different land use. Accred Qual Assur 9:64–75

Minkkinen (2004) Practical applications of sampling theory. Chemometrics and Intelligent Lab. Systems 74:85–94

Thompson M, Fearn T (1996) What exactly is fitness-for-purpose in analytical measurement? Analyst 121:275–278

Ramsey MH, Lyn J, Wood R (2001) Optimised uncertainty at minimum overall cost to achieve fitness-for-purpose in food analysis. Analyst 126:1777–1783

Lyn JA, Ramsey MH, Wood R (2003) Multi-analyte optimisation of uncertainty in infant food analysis. Analyst 128:379–388

Lyn JA, Ramsey MH, Wood R (2002) Optimised uncertainty in food analysis: application and comparison between four contrasting ‘analyte-commodity’ combinations. Analyst 127:1252–1260

Gy PM (1979) Sampling particulate material systems, first edition. Elsevier, Amsterdam

Burns I et al (2002) Development of a decision support system for nitrogen fertilizer application in soil-grown glasshouse crops (2000) LINK-Technologies for Sustaining Farming Systems-Final Report, London, Ministry of Agriculture Fisheries and Food

European Commission (2006) http://europa.eu.int/comm/food/ fs/sc/scf/reports/scf_reports_38.pdf

Commission Regulation (EC) No 1822/2005 of 8 November 2005 amending Regulation (EC) No 466/2001 as regards nitrate in certain vegetables. Official Journal L 293:11

National Farmers Union (1999) Industry code of good agricultural practice to minimise nitrate content of lettuce grown under outdoor cropping culture in the UK. Commodities Department, National Farmers Union, Version 2

National Farmers Union (1999) Industry code of good agricultural practice to minimise nitrate content of lettuce grown under protected cropping culture in the UK. Commodities Department, National Farmers Union, Version 2

National Farmers Union (1999) Industry code of good agricultural practice to minimise nitrate content of spinach grown in the UK. Commodities Department, National Farmers Union, Version 2

European Commission (2002) Directive 2002/63/EC. OJ L 187, 16/7/2002, p 30

BS EN 12014-2:1997, Foodstuffs. Determination of nitrate and/or nitrite content. General considerations

Farrington D, Damant AP, Powell K, Ridsdale J, Walker M, Wood R (2006) A comparison of the extraction methods used in the UK nitrate residues monitoring program. J Assoc Public Anal (online) 34:1–11

Ramsey MH, Thompson M, Hale M (1992) Objective evaluation of precision requirements for geochemical analysis using robust analysis of variance. J Geochem Expl 44:23–36

Ramsey MH, Argyraki A (1997) Estimation of measurement uncertainty from field sampling: implications for the classification of contaminated land. Sci Total Environ 198:243–257

Whitaker TB (2003) Standardisation of mycotoxin sampling procedures: an urgent necessity. Food Control 14:233–237

Lyn JA, Ramsey MH, Damant A, Wood R (2005) Two-stage application of the OU method: a practical assessment. Analyst 130:1271–1279

ISO 11074-2:1998 (1993) Soil quality – vocabulary, Part 2: terms and definitions related to sampling. International Organization for Standardization, Geneva, Switzerland, 2.16, p 7

Acknowledgements

This research was funded by the UK Food Standards Agency (E01055). Thanks are extended to the growers who allowed the researchers free access to their glasshouses and crops and also to the contracted laboratory for undertaking the analysis of such a large number of lettuces.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lyn, J.A., Palestra, I.M., Ramsey, M.H. et al. Modifying uncertainty from sampling to achieve fitness for purpose: a case study on nitrate in lettuce. Accred Qual Assur 12, 67–74 (2007). https://doi.org/10.1007/s00769-006-0239-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00769-006-0239-0