Abstract

In-house reference materials (IHRMs) for determination of inorganic polysulfides in water have been developed. The determination is based on the polysulfides’ derivatization with a methylation agent followed by GC/MS or HPLC analysis of the difunctionalized polysulfides. Therefore, the IHRMs are synthesized in the form of dimethylated polysulfides containing from four to eight atoms of sulfur. The composition of the compounds is confirmed by NMR and by the dependence of the HPLC retention time of the dimethyl polysulfides on the number of sulfur atoms in the molecule. Stability of the IHRMs is studied by HPLC with UV detection at 230 nm. Carbon tetrachloride solutions of the dimethyl polysulfides are stable at −20°C for 2 weeks, while their solutions in a mixture of acetonitrile and formic acid, 1:1, are stable even at +5°C for 3 weeks. The total sulfur content is controlled by the IHRMs’ oxidation with perchloric acid in high-pressure vessels (bombes) followed by determination of the formed sulfate using ICP-AES. Certified values of the dimethyl polysulfide concentrations are in the range of 416–3,327 ppm.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Inorganic polysulfides are not infrequent contaminants of anoxic ground water, especially when hydrogen sulfide and sulfur coexist, and are also known as products of hydrogen sulfide oxidation during treatment of drinking water [1]. For example, over 150 water wells in Israel are contaminated with hydrogen sulfide and, therefore, are prone to formation of inorganic polysulfides during the oxidative treatment for hydrogen sulfide removal. In some cases, inorganic polysulfides lead to the formation of organic polysulfides, such as dimethyl polysulfides and dipropylpolysulfides, which are notorious for their odor. The aroma of cooked onion and garlic is dominated by these compounds [2]. Development of analytical methods allowing the study of the polysulfides’ distribution in water is important for understanding the hydrogen sulfide oxidative patterns and for control of water treatment. Besides, these methods may be beneficial for the quantitative determination of food aroma.

The analytical method proposed for speciation of the inorganic polysulfides in water as semi-volatile compounds is based on their derivatization by methylating agents, followed by gas chromatography with mass spectromtery (GC/MS) analysis of the difunctionalized polysulfides [3]. However, high difunctionalized polysulfides (with four and more sulfur atoms) are temperature sensitive and are destroyed during GC/MS analysis, therefore, high performance liquid chromatography (HPLC) is preferable for their determination. The most effective methylation agent is methyl iodide, since the polysulfides, being strong nucleophiles, react stochiometrically with it to yield dimethyl polysulfides [4, 5]. Dimethyl disulfide (Me2S2) and dimethyl trisulfide (Me2S3) are relatively stable and commercially available [6], but more complex dimethyl polysulfides with four to eight sulfur atoms (Me2S n , where n=4–8) are less stable and not available commercially.

The purpose of the present work is to synthesize the dimethyl polysulfides with four to eight sulfur atoms and to study their stability for development of in-house reference materials (IHRMs) to be used for determination of inorganic polysulfides and naturally occurring dimethyl polysulfides in water.

Experimental

Reagents

The following reagents were used in the experiment: hydrazine sulfate and sodium phosphate dodecahydrate, for analysis, from Riedel-de-Haëne, Germany; sulfur, extra pure (>99%), from Riedel-de-Haëne, France; sodium hydroxide in pellets, dichloromethane and carbon tetrachloride, chemically pure, from Frutarom, Israel; perchloric acid, pro-analysis, and methyl iodide (>99%), stabilized with silver for synthesis, from Merck, Germany; methanol, acetonitrile and formic acid (>98%), HPLC analyzed, from Baker, Holland; chloroform-D (99.8%, atom D content 0.03%) and 1,2,5,6-dibenzanthracene (97%) from Aldrich, UK; dimethyl trisulfide (>98%), from Acros Organics, UK.

Equipment

The following equipment was used: 300 kHz H1 NMR spectrometer, model AMX-400 from Bruker, Germany; HPLC AS 3000 from Finnigan, USA, equipped with a diode array with UV–Vis detector and Spherex 5 ODS-2 column of 250×3.2 mm and 5-μ reverse phase C18; high-pressure decomposition vessels (bombs) from Parr, USA; and ICP Optima 3000 XL from Perkin Elmer, USA.

Synthesis

Synthesis of dimethyl polysulfides was performed based on the reaction of elemental sulfur with hydrazine sulfate in the presence of sodium hydroxide, producing a mixture of inorganic polysulfides on heating [7] which then react with methyl iodide to form dimethyl polysulfides.

Elemental sulfur (3 g), hydrazine sulfate (1.23 g), sodium hydroxide (2.295 g) and deionized water (30 ml) were introduced into a round-bottom three-neck flask with magnetic stirrer in a dry nitrogen atmosphere. The mixture was heated over boiling water for 2 h with intensive mixing. The obtained solution containing polysulfides was cooled to room temperature and removed quickly in the nitrogen atmosphere into a freshly prepared mixture of methanol (70 ml), methyl iodide (10 ml) and sodium phosphate dodecahydrate (2 g). The mixture reacted for 30 min at room temperature. Methanol was evaporated under vacuum, and then water (50 ml) and dichloromethane (50 ml) were added. The organic layer was separated, dried with magnesium sulfate and evaporated using a vacuum aspirator. The remainder (a yellow, oily liquid, about 1.7 g) was kept at −20°C. Precipitated sulfur crystals were separated by decantation. The remaining oily liquid consisted of a mixture of the dimethyl polysulfides from Me2S2 to Me2S11. A typical HPLC chromatogram of this mixture obtained with UV detector at 230 nm is shown in Fig. 1.

Typical HPLC chromatogram of the mixture of dimethyl polysulfides obtained with C18 column and UV detector at 230 nm. The solvent consisted initially of 70% methanol and 30% water, flow rate 0.5 ml/min, for 10 min the methanol concentration was increased up to 80%, during the next 15 min the conditions were isocratic, then for 10 min the methanol concentration was increased up to 100%, and for the last 15 min the solvent consisted of methanol only. Here peak 1 is Me2S2, 2 - Me2S3, 3 - Me2S4, 4 - Me2S5, 5 - Me2S6, 6 - Me2S7, 7 - sulfur, 8 - Me2S8, 9 - Me2S9, 10 - Me2S10, and 11 - Me2S11. The values of the dimethyl polysulfide retention time R t (min) are shown by the numbers above the corresponding peaks

Separation

Separation of the dimethyl polysulfides was performed chromatographically using a preparative column (height 400 mm, diameter 37 mm) with reverse phase C18, 250 g. The synthesized oily liquid was carried over the upper layer of the column. When the liquid was absorbed, the dimethyl polysulfides’ elution was begun with a mixture of acetonitrile and formic acid, 1:1. The vacuum produced by the aspirator was used for acceleration of the elution. Dimethyl polysulfide rich fractions were collected. The volume of each fraction was 50 ml. Fraction Nos. 9–11 contained Me2S4; fraction Nos. 12–13, Me2S5; fraction Nos. 16–19, Me2S6; fraction Nos. 21–26, Me2S7, and fraction Nos. 30–33, Me2S8.

Each individual dimethyl polysulfide was extracted from the corresponding fraction with 60 ml carbon tetrachloride after dilution of its fraction with water in proportion 1:4. The organic layer was separated, washed thoroughly from residuals of acetonitrile and formic acid by 9 portions of 500 ml water, and then dried with magnesium sulfate. A chromatogram of separated Me2S5 as an example is shown in Fig. 2.

Results and discussion

Identification

Nuclear magnetic resonance (NMR)

A test portion for analysis was prepared by mixing the dimethyl polysulfide (2 g) with the internal standard (dimethyl trisulfide, 10 mg) and chloroform-D (1 g) that was used for adjusting the NMR spectrometer. The spectra were recorded for 6 min. Deviations of the protons in the molecules containing methyl, shown in Table 1 in ppm, practically coincided with those published in the literature [8]. However, there are no significant differences in the proton deviations for the number of sulfur atoms in the molecules n>4, therefore, NMR data are not sufficient for identification.

High performance liquid chromatography (HPLC)

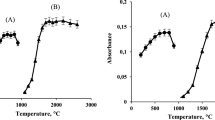

It was reported that the correlation of the logarithm of the chromatographic retention time ln(R t ) with the number n of sulfur atoms in the molecule is very strong for homological lines R–S n –R, where R is an alkyl group [9–11]. In our case, the alkyl is methyl and, therefore, the correlation analysis can be used for the dimethyl polysulfide identification. As one can see from Fig. 1, the HPLC analysis requires about 45 min. The dependence of ln(R t ) on n in the range of R t =5.91–40.68 min is shown in Fig. 3. The experimental data from Fig. 1 are represented here by dots. The regression line in the range of n=2–8 corresponds to the equation \({\text{ln}}{\left( {R_{t} } \right)} = 1.195 + 0.295n\), with square correlation coefficient r 2=0.999. However, one can see in Fig. 3 that at n=9–11 the dependence slope is changed. This can be explained by the solvent gradient: after 35 min of chromatography, when dimethyl polysulfides with n=2–8 have passed the column, the solvent composition was changed from the “methanol–water” mixture to pure methanol. Anyway, widening of the regression for n=2–11 leads to decreasing the square correlation coefficient down to r 2=0.947. Therefore, identification of the dimethyl polysulfides with n=2–8 is acceptable, while identification of the compounds with higher n using such a chromatogram is questionable.

The dependence of the dimethyl polysulfide retention time R t on the number n of sulfur atoms in a molecule. The experimental data from Fig. 1 are shown here by dots. The line is calculated using regression analysis

Stability study and IHRMs characterization

Since dimethyl polysulfides with n=4–8 are not stable, their solutions in organic solvents were studied with the purpose of finding suitable storage conditions. Two types of solvents: (1) carbon tetrachloride and (2) a mixture of acetonitrile with formic acid, 1:1, were used. The solutions were stored in amber glass bottles at −20 and +5°C and analyzed by HPLC using 1,2,5,6-dibenzanthracene as the internal standard. The total sulfur content was determined by oxidation with perchloric acid in high-pressure decomposition vessels at 230°C for 3 h, followed by determination of the sulfate product with inductively coupled plasma-atomic emission spectrometry (ICP-AES). The certified value of the dimethyl polysulfide concentration was calculated taking into account the ratio of its molecular mass and the sulfate ionic mass. The results of the analyses are presented in Tables 2, 3. One can see that the solutions in carbon tetrachloride are less stable: even at −20°C they can be stored for 2 weeks only, after which indications of the degradation process are observed. Such indication is shown, for example, in Fig. 4 for Me2S5, when the Me2S6 peak appears. Later on, the degradation results are similar to the mixture shown in Fig. 1, i.e., shorter and longer dimethyl polysulfides are formed simultaneously. The solutions in acetonitrile and formic acid can be stored for 3 weeks at +5°C (Table 3) even at dimethyl polysulfide concentration levels significantly higher than in carbon tetrachloride.

It is clear that the limited stability of the solutions requires preparation of such IHRMs before every water analysis. On the other hand, 2–3 weeks can be enough for analysis of a season group of environmental samples.

An example of HPLC calibration for determination of the longest studied dimethyl polysulfide Me2S8 using the corresponding IHRM (the carbon tetrachloride solution) is shown in Fig. 5 by curve 1. The ordinate is the ratio of the peak area of the analyte to that of the internal standard (1,2,5,6-dibenzanthracene, 44 μg/ml of the solution), the abscissa is the Me2S8 concentration in the solvent (ppm). For comparison, calibration curve 2 for Me2S3 determination is plotted in this figure for the same conditions using the commercial dimethyl trisulfide. Both of them have square correlation coefficients greater than 0.99.

Uncertainty and traceability

The uncertainty of the IHRM certified value consists of three components caused by the material homogeneity, its stability and its characterization process [12]. Homogeneity is a negligible source in our case at the studied dimethyl polysulfide concentrations in the organic solvents (<0.5%) and the quantity of the substance about 2 g. The relative standard uncertainty of the chromatographic data on the material stability can reach 5% [13, 14]. The relative standard uncertainty of results of the sample preparation for analysis (by their digestion in bombs) is also about 5% [15]. The relative standard uncertainty of the ICP-AES data used for sulfur determination is about 2% [16, 17]. Therefore, the relative standard uncertainty of the IHRM certified values is about \(u = {\left( {5^{2} + 5^{2} + 2^{2} } \right)}^{{0.5}} = 7.3\% \). Obviously, it is only a first approximation, and the uncertainties should be evaluated further in more detail. However, this approximation allows the supposition that the IHRMs will be useable for control of inorganic polysulfides in water.

The IHRM certified values are traceable to SI kg, since all the test portions were weighed, and to NIST SRM 682 through the Anionen Multi-Element Standard II from “Merck” containing sulfate ions of 1,000±5 ppm that was used for the ICP-AES calibration. Note, traceability of the chromatographic data is not important here, as these data were used only for identification of the polysulfide degradation.

Validation of the analytical method using the IHRMs and its applications for analysis of inorganic polysulfides in natural water sources will be reported elsewhere.

Conclusions

-

1.

Reference materials for control of inorganic polysulfides in water can be synthesized and separated as dimethyl polysulfides.

-

2.

The solutions of dimethyl polysulfides in organic solvents can be stored without degradation for 2–3 weeks at temperatures from −20 to +5°C. Such solutions can have the status of IHRMs.

-

3.

The relative standard uncertainty of the material certified value is about u=7.3%, which is acceptable for control ofinorganic polysulfides in water.

References

White GF (1972) Handbook of water chlorination. Van Nostrand Reinhold, New York, USA

Gun J, Goifman A, Shkrob I, Kamyshny A, Ginzburg B, Haadas O, Modestov A, Dor I, Lev O (2000) Environ Sci Technol 34:4741–4746

Korchevin NA, Turchaninova LP, Deryguna, Voronkov MG (1985) J Obschey Himii (in Russ) 5:1785–1787

Ganesh K, Kichore K (1995) Colloid Polym Sci 273:648–652

Nakabayashi T, Tsung J, Yabuta T (1964) J Org Chem 29:1236–1238

Acros Organics (2003) Fine chemicals catalogue, http://www.fisher.co.uk/acros

Rule A, Thomas JS (1914) J Am Chem Soc 105:177–189

Grant D, Van-Wazer JR (1964) J Am Chem Soc 86:3012–3017

Steudel R, Forster S, Aldersen J (1991) Chem Ber 124:2357–2359

Singer E, Mockel HJ (1989) Chromatographia 27:27–30

Steudel R, Shmidt H (1994) Chem Ber 127:1219–1221

Van der Veen AMH, Linsinger TPJ, Schimmel H, Lamberty A, Pauwels J (2001) Accred Qual Assur 6:290–294

Barwick VJ, Ellison SLR, Lucking CL, Burn MJ (2001) J Chromatogr A 918:267–276

Anglov T, Byrialsen K, Carstensen JK, Christensen F, Christensen S, Madsen BS, Sorensen E, Sorensen JN, Toftegard K, Winther H, Heydorn K (2003) Accred Qual Assur 8:225–230

Kingston HM, Jassie LB (eds) (1988) Introduction to microwave sample preparation. Theory and practice. ACS, Washington DC, USA

Bersier PM (1994) Analyst 119:219–232

Boss CB, Fredeen KJ (1989) Concepts, instrumentation, and techniques in inductively coupled plasma atomic emission spectrometry. Perkin Elmer, USA

Acknowledgments

The authors gratefully acknowledge the financial support of the water technology program of the BMBF-Germany and the Israel Ministry of Science. Prof. Ovadia Lev is also grateful for the financial support of the infrastructure program of the Ministry of Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rizkov, D., Lev, O., Gun, J. et al. Development of in-house reference materials for determination of inorganic polysulfides in water. Accred Qual Assur 9, 399–403 (2004). https://doi.org/10.1007/s00769-004-0788-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00769-004-0788-z