Abstract

In the present study, we investigate the relationship between the aging of a barium coating solution used in the synthesis of the precursors for YBa2Cu3O7−x -coated conductors or any oxide compound containing BaO and the transverse relaxation time measured in a nuclear magnetic resonance (NMR) experiment. The barium propionate precursor solution sample was prepared by the stepwise addition of an excess of propionic acid and ammonia to a barium acetate dispersion in methanol. All NMR relaxation experiments were performed at 20°C and a proton resonance frequency of 20 MHz. The experimental results are compared with a proposed model that assumes the reduction of the relaxation centers during the aging process. The model allows us the extraction of a characteristic aging time for the monitored sample.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The chemical solution deposition (CSD) methods for oxide thin films fabrication have gathered continuous scientific and practical interest due to their compositional versatility, wide flexibility even on large-scale processing conditions, precise stoichiometry control, relative simplicity and low cost, especially when used for the development of advanced functional materials, such as ferroelectrics, magnetoelectronic or superconducting materials [1–4]. In the metalorganic deposition (MOD) approach, several carboxylates (acetates, trifluoroacetates (TFA), citrates, naphthenates, neodecanoates) and acetylacetonates have been used for the preparation of the precursor coating solution [2, 4]. Among them, the MOD-TFA method has been extensively used for the deposition of YBa2Cu3O7−x (YBCO) superconducting thin films [5, 6]. High critical temperature T C and high critical current density J C are reported, even for the deposition of YBCO on textured metal tapes, according to the coated conductor concept [6]. In the TFA method, a stoichiometric mixture of Y, Ba and Cu trifluoroacetates obtained by the reaction of the corresponding acetates with trifluoroacetic acid decomposes to oxifluorides and, finally, to oxides at a low pyrolysis temperature in humid oxygen atmosphere. The YBCO epitaxial thin films are obtained by the subsequent crystallization thermal treatment at 800°C under a humid oxygen–nitrogen mixture. Until now, the long reaction times [7] and the high rate of hydrofluoric acid elimination [8] were considered to be the major drawbacks of this method. Modified TFA approaches have envisaged the replacement of the trifluoroacetates with non-fluorine precursors, e.g., metal propionates obtained by the reaction of the alcoholic dispersions of metal acetates with propionic acid and the further addition of ammonia [9]. Due to the complexity of the liquid phase interactions, individual precursor chemistry studies are necessary. One such study refers to the aging of a barium propionate coating solution that can itself be used for the deposition of BaO-based thin films, which are attractive due to their catalytic and optical properties [10, 11].

Owing to its completely non-destructive character, nuclear magnetic resonance (NMR) is widely used to investigate both the structure and the dynamics of molecules in different states of aggregation. If the structure of molecules is usually revealed in the frame of the so-called high-field NMR spectroscopy with the magnetic field generated by expensive superconducting magnets, the dynamics of molecules can be investigated with much more inexpensive equipment operating at low magnetic fields [12]. The experimental parameters, mostly measured in a low-field experiment, are the transverse relaxation time T 2, the longitudinal relaxation time T 1 and the diffusion coefficient D [12–15]. These parameters characterize the attenuation of the transverse and longitudinal components of the magnetization during a specific NMR experiment in the presence of molecular motion. They provide information on the translational or rotational motion of the tagged molecules, the viscosity of their environment, geometrical restrictions, as well as the influence of different external parameters.

In the present study, it will be shown that the low-field transverse relaxation measurements can be implemented to study the aging of precursor solutions, e.g., of a barium propionate precursor solution used in the preparation of the YBCO coating solution for the deposition of high-temperature superconducting YBCO thin films by CSD method. The technique relies on the effect introduced by the barium propionate relaxation centers on the effective relaxation time of the observed sample. In spite of the fact that the measurements are performed in low fields and, consequently, without spectral resolution, it is shown that they can be used as a valuable tool in monitoring the aging process of the coating solutions for oxide thin films deposition by chemical methods.

2 Experimental

2.1 The Pulse Sequence

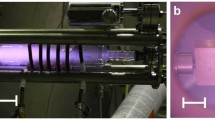

The Carr–Purcell–Meiboom–Gill (CPMG) technique has been proven to be a useful method for transverse relaxation measurements [13]. The radio-frequency pulse sequence and the echoes train recorded during such an experiment are indicated in Fig. 1. The main advantage of such a multiple echo technique is its fastness as compared with other techniques based on single echoes. Consequently, it allows multiple accumulations of the echoes train signal, which is an important issue in low-field experiments where the detection sensitivity is strongly reduced relative to the high-field experiments.

If the recorded CPMG envelope, shown in Fig. 1, exhibits mono-exponential decay and diffusion effects can be neglected during the time intervals 2τ, then the transverse relaxation time T 2 of the sample can be extracted by fitting the data with the formula:

Here, A n is the amplitude of the n-th echo in the echo train and A 0 is a constant that depends on the sample magnetization and other experimental parameters. Note that the diffusion effects on the echoes’ decay can be tested by performing experiments with different τ intervals.

If the relaxation time varies throughout the sample as a result of the sample heterogeneity, then a multi-exponential attenuation of the CPMG envelope should be observed. Assuming a continuous distribution of the relaxation times inside the sample, the amplitude of the n-th echo in the echo train satisfies the formula:

where P(T 2) is the relaxation time probability density. The above formula suggests that the analysis of the experimental data using a Laplace inversion algorithm could provide us the relaxation time distribution. A reliable numerical algorithm for such an analysis has been proven to be CONTIN [16].

2.2 Sample Preparation

The barium propionate solution was prepared at room temperature using the propionate route [9], starting from commercially available (Alfa Aesar) barium acetate (Ba(CH3COO)2·xH2O), methanol (CH3OH), propionic acid (CH3CH2COOH) and ammonia (NH4OH), as follows: (1) the barium acetate was dispersed in methanol; (2) an excess of propionic acid was added; (3) further ammonia was added until the solution became clear; (4) the as-obtained solution was concentrated by distillation under vacuum (42 mbarr; bath temperature, 75°C) for the removal of methanol, propionic acid and water. This precursor solution is moisture insensitive and can be handled in ambient atmosphere. For comparison, as-purchased methanol, ammonia and propionic acid were subjected to NMR relaxation measurements.

2.3 NMR Relaxation Measurements

All the relaxation experiments were performed on a Bruker MINISPEC MQ20 time domain analyzer operating at a proton resonance frequency of 20 MHz. The data were recorded at 20°C using the standard CPMG [13] pulse sequence as indicated in Fig. 1. The length of one hard 90° pulse was set to 2.5 μs and that of a 180° one to 5μs. The time interval between two consecutive echoes (2τ) was chosen between 100 and 300 μs to prevent the appearance of diffusion effects on the echo decay [15]. A maximum number of 2,500 echoes were recorded for each experiment. The repetition delay of one echo train was selected to be 10 s for a full recovery of the longitudinal magnetization. The samples under investigation were the concentrated barium propionate solution at various observation days and the as-purchased liquid reactants: methanol, propionic acid, ammonia and their mixture (CH3OH + CH3CH2COOH + NH4OH). The samples were handled carefully to avoid shaking and placed at the same position inside the radio-frequency coil to ensure a homogeneous excitation.

To test the homogeneity of the barium propionate precursor solution and the role of the barium propionate, formed during the reaction as relaxation centers in this solution, the liquid individual constituents were first investigated using the CPMG technique and the data analyzed using the regularized inversion algorithm (CONTIN) [16]. The obtained relaxation time distributions of the barium propionate sample at the beginning of the aging process, the individual liquid reactants (CH3OH, CH3CH2COOH, NH4OH) and their mixture (CH3OH + CH3CH2COOH + NH4OH) are shown in Fig. 2. One can observe a single peak in the relaxation time distribution of each individual sample. In the precision limit provided by our inverse Laplace transforms, this is an indication for a good homogeneity of all samples. Furthermore, a much shorter relaxation time distribution is observed if the barium acetate is added to produce the barium propionate precursor. This result indicates that the formed barium propionate molecules act in our concentrated precursor solution as relaxation centers, producing enhanced relaxation rates in a similar way with the paramagnetic enhancement [17–19].

To monitor the aging of barium propionate precursor solution, the CPMG envelopes were recorded for different aging times. The results are indicated in Fig. 3. As can be observed, all the curves are mono-exponential with a slope that reduces with the aging time. Consequently, the transverse relaxation time can be extracted by fitting the data with Eq. (1). The values extracted from this fitting are indicated in Fig. 4 (squares) as a function of the aging time.

Transverse relaxation time versus the aging time of a concentrated barium propionate precursor solution. The solid line represents the best fit of the data with Eq. (5)

3 Results and Discussions

The change in the slope of the echo decay curve in Fig. 3 may be associated with the reduction of relaxation centers in the sample as an effect of the observed crystallization–precipitation process. To quantitatively describe the experimental results in Fig. 3, we consider here that the concentrated barium propionate precursor solution contains barium propionate molecules as relaxation centers. The relaxation enhancement induced on the proton spins belonging to the methanol (CH3OH), propionic acid (CH3CH2COOH) and ammonia (NH4OH) molecules can be considered analogous to the paramagnetic enhancement observed in a solution containing paramagnetic centers [17–19]. In such a case, the spins surrounding the paramagnetic centers experience higher relaxation rates due to the magnetic field fluctuations produced by these centers.

The probability for a spin to experience the presence of a relaxation center depends on the number density of such centers and the time scale of the NMR experiment [17–19]. Consequently, the nuclear relaxation rate is proportional to the number density of relaxation centers in the sample and can be written as:

Here, T 2f is the relaxation time of a free solution without the influence of the relaxation centers, N(t) is the number density of paramagnetic centers in the sample after the aging time t and C is a constant that quantifies the strength of the interaction between the considered nuclei and the relaxation centers [17–19].

If there are changes in the number density of relaxation centers due to a precipitation process or crystal formation followed by precipitation (as observed in our samples), the relaxation rate will reduce accordingly. Assuming a constant precipitation rate to an equilibrium number density \( N_{0} \), the density variation as a result of the aging process can be described with an equation of the form:

Here, T age is a characteristic time for the precipitation (aging) process. Substituting in Eq. (3) the solution of the above Eq. (4), the nuclear relaxation rate can be written as:

where \( N\left( 0 \right) \) is the number density of relaxation centers at the beginning of the aging process.

Figure 4 compares the transverse relaxation times measured for different aging intervals with the theoretical model introduced above. It can be observed that the increase in the transverse relaxation time T 2 is more pronounced for earlier aging times, indicating a faster crystallization at the beginning of the aging process. The solid line represents the best fit of the experimental data with the relaxation time given by Eq. (5). This fitting allows the extraction of a characteristic time for the aging process T age = 11.2 days. It can be associated with the shelf life of the coating solution, important especially for the scaling up of the process.

4 Conclusions

The use of the barium propionate precursor solutions represents a robust and efficient method to obtain any barium oxide-based compounds as thin films by solution processing. The characterization of the coating solution is of utmost importance, especially when it is nondestructive, rapid and requires small quantities of samples. The NMR relaxometry method fulfills these requirements and ensures the estimation of the shelf life of any coating solution for the deposition of oxide thin films by chemical solution deposition. Here, we have shown that their aging can be probed in a simple and nonperturbative manner using low-field NMR relaxation. A theoretical model for describing the observed phenomena was suggested. The comparison of the experimental data with the proposed model allowed us to extract the characteristic times of the aging process. Further investigations, based on NMR diffusometry measurements, are envisaged to extract information on the viscosity of the coating solutions.

References

F.F. Lange, Science 273, 903 (1996)

M.S. Bhuiyan, M. Paranthaman, K. Salama, Supercond. Sci. Technol. 19, R1 (2006)

R.W. Schwartz, Chem. Mater. 9, 2325 (1997)

D.V. Mitzi (ed.), Solution Processing of Inorganic Materials (Wiley, Hoboken, New Jersey, 2009)

P.C. McIntyre, M.J. Cima, J.J.A. Smith, R.B. Hallock, M.P. Siegal, J.M. Phillips, J. Appl. Phys. 71, 1868 (1991)

A. Goyal, D.P. Norton, J.D. Budai, M. Paranthaman, E.D. Specht, D.M. Kroeger, D.K. Christen, Q. He, B. Saffian, F.A. List, D.F. Lee, P.M. Martin, C.E. Klabunde, E. Hartfield, V.K. Sikka, Appl. Phys. Lett. 69, 1795 (1996)

W.T. Wang, M.H. Pu, W. Wang, H. Zhang, C.H. Cheng, Y. Zhao, J. Supercond. Nov. Magn. 23, 989 (2010)

A. Llordes, K. Zalamova, S. Ricart, A. Palau, A. Pomar, T. Puig, A. Hardy, M.K. Van Bael, X. Obradors, Chem. Mater. 22, 1686 (2010)

L. Ciontea, A. Angrisani, G. Celentano, T. Petrisor Jr., A. Rufoloni, A. Vannozzi, A. Augieri, V. Galuzzi, A. Mancini, T. Petrisor, J. Phys. Conf. Ser. 97, 012302 (2008)

J.L. Wu, Q.F. Zhanga, C.M. Wanga, Y.H. Zou, Appl. Surf. Sci. 183, 80 (2001)

E.I. Firsov, M. Yu. Sinev, P.A. Shafranovsky, J. Electron Spectrosc. Relat. Phenom. 54-55, 489 (1990)

B. Blümich, P. Blümler, G. Eidmann, A. Guthausen, R. Haken, U. Schmitz, K. Saito, G. Zimmer, Magn. Reson. Imaging 16, 479 (1998)

S. Meiboom, D. Gill, Rev. Sci. Instr. 29, 688 (1958)

R. Kimmich, E. Anoardo, Prog. NMR Spectrosc. 44, 257 (2004)

I. Ardelean, R. Kimmich, Annu. Rep. NMR Spectrosc. 49, 43 (2003)

S.W. Provencher, Comp. Phys. Comm. 27, 229 (1982)

L. Helm, Prog. NMR Spectrosc. 49, 45 (2006)

A. Yilmaz, H. Budak, F.S. Ulak, Magn. Reson. Imaging 26, 254 (2008)

D.A. Yablonskiy, E.M. Haacke, Magn. Reson. Med. 32, 749 (1994)

Acknowledgments

Financial support from the Romanian National Authority for Scientific Research (ANCS, PN2-61-002) and European Social Fund (project POSDRU/6/1.5/S/5) is gratefully acknowledged. The solution preparation was supported by National University Research Council - Executive Agency for Higher Education and Research Funding (CNCSIS-UEFISCSU), project number PNII-IDEI nr. 4/2010, code 106/2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Badea, C., Mos, R.B., Ciontea, L. et al. Low-Field Nuclear Magnetic Resonance Relaxometry as a Tool in Monitoring the Aging of Coating Solutions (Case Study: Barium Propionate Precursor Coating Solution). Appl Magn Reson 39, 365–372 (2010). https://doi.org/10.1007/s00723-010-0167-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00723-010-0167-3