Abstract

The interest in the determination of critical micelle concentrations (CMC) has been growing for decades. The measurement of CMC is fundamental in many fields because surfactants are widely used in biology, pharmaceutical chemistry, and materials science. The properties and characteristics of surfactants, including CMC determination are also of major importance in drug delivery. There is no updated review that covers the developed methods to assess the CMC of surfactants. This review aims to survey and discuss various physicochemical and electrochemical approaches for the determination of the CMC. The principle, limitations, and remarks about the difficulties that may arise in the process of CMC determination are also elaborated. Methods that can be used for CMC determination of different types of surfactants (anionic, cationic, non-ionic, and zwitterionic), and methods for low CMC levels are highlighted. The deviations in certain methods from the actual CMC values have also been discussed.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

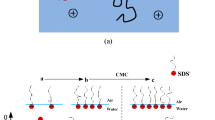

Surface active agents (surfactants) are substances with characteristic amphipathic molecular structure, including hydrophilic heads and hydrophobic tails. The hydrophobic region is usually a long hydrocarbon chain, while the hydrophilic region is composed of ionic or non-ionic polar groups. Accordingly, surfactants are classified into four types depending on the nature of the hydrophilic head group, including anionic, cationic, zwitterionic, and nonionic [1]. Surfactants have been applied in different analytical techniques including UV/Vis spectrophotometry [2], spectrofluorometry [3], flow injection analysis [4], and chromatography [5,6,7,8]. The association of monomers of amphiphiles in aqueous solutions results in the formation of spherical aggregates, which are known as micelles [9]. The dynamic process of the formation of micelles is termed micellization, which is one of the most important properties of surfactants. The presence of micelles in the solution facilitates solubilization of insoluble substances by incorporation either in the core or in the palisade layer of surfactants. Micellization enables the usage of surfactants in detergency, emulsion stabilization, and as drug-delivery vehicle [10]. The minimum concentration of surfactant at which micelles are formed is called the critical micellar concentration (CMC). Below CMC, surfactant monomers are dispersed in the solution, while at the CMC, monomers gather and form micelles. CMC can be determined by different techniques. The methods used for the determination of CMC were discussed in previous reviews [11] and the CMC values of several surfactants in aqueous media estimated by different methods can be found in other reports [11,12,13].

Determination of CMC is fundamental in many fields, including pharmaceutical chemistry, synthetic chemistry, materials science, biology [14], in addition to their importance in analytical chemistry [4, 7]. CMC estimation is important for analytical separation with micellar chromatography and micellar electrokinetic chromatography, besides the use of surfactants as ion pairing agents in high performance liquid chromatography [15]. Further applications with the aid of micelles in analytical chemistry were reported [16]. The properties and characteristics of surfactants are also of major importance in drug delivery, a number of different kinds of surfactants have been used because of their capacity to improve the permeability of drugs across biological membranes [9].

There is a diversity of methods that can be used for the determination of CMC. The methods employed can be divided into two major categories, direct and indirect methods depending on whether or not a probe or a tracer is added to the surfactant solution to aid the measurement. These methods can be also classified according to the technique of measurement into five categories; methods based on measurement of physicochemical properties of surfactants, electrochemical, capillary electrophoresis-based, spectroscopic, and miscellaneous methods (Fig. 1). The spectroscopic methods for determination of CMC have been recently reviewed [17].

The CMC can be measured by tracing a physicochemical property of surfactant solution that changes upon micelles formation. A variety of physical properties have been studied such as viscosity, density, conductivity, osmotic pressure, surface and interfacial tension, refractive index, and light scattering (Fig. 2) [18].

Other techniques that could be employed include nuclear magnetic resonance spectroscopy [19], calorimetry [20,21,22,23], chromatography [24], electrophoresis [12], sound velocity [25,26,27,28,29,30,31,32,33,34], fluorescence spectroscopy [22, 35], and UV/Vis absorption spectroscopy [36,37,38,39,40,41,42]. The readings obtained from these methods were represented in a graph as a function of surfactant concentration, and the CMC was then deduced as a breakpoint between the two lines with varying slopes. To the best of our knowledge, there is no updated review that discusses the physicochemical and the electrochemical methods for CMC determination of surfactants. The drawbacks, limitations, and remarks for the difficulties that may arise during the CMC determination process are also addressed.

Methods based on measurements of physicochemical properties

Surface tension and interfacial tension measurement

Surface tension is the primary physical property of a solution that is affected by the presence of surfactants. In an aqueous solution containing surfactant, the surface tension decreases with increasing the surfactant concentration until reaching a certain point where the surface tension becomes constant; this concentration is the CMC. The CMC can be obtained by plotting the surface tension values against the logarithm of surfactant concentration. In this case, the CMC is the concentration corresponding to the point of the intersection between two lines. On the other hand, when the data are plotted against the surfactant concentration, the CMC is the concentration corresponding to the inflection point of the curve, and in that case, the CMC value is less sharply detected [11, 43].

There are two types of surface tensions known as dynamic and equilibrium surface tensions. As aforementioned, the surface tension of aqueous solutions is reduced upon the addition of surfactant. When adding a surfactant to the solution, its molecules start to migrate to the interface, subsequently, the surface tension of the solution begins to decrease with time; this type of surface tension is termed dynamic surface tension. After a certain time, the value of surface tension will continue to reduce until reaching equilibrium or static surface tension. At a fixed concentration of surfactant, the dynamic surface tension is generally higher than the equilibrium surface tension [44]. Further increases in surfactant concentration reduces the surface tension until the interface becomes saturated with the surfactant monomers. Beyond that point, surface tension does not change significantly; this value is the CMC [45].

The surface tension can be measured using a device called a tensiometer. Some tensiometers measure both types of surface tension, such as drop volume tensiometer [46] or bubble pressure tensiometer [47, 48]. Other tensiometers such as the Wilhelmy plate tensiometer [24, 49], measure only the equilibrium surface tension. Surface tension can be measured in a variety of ways depending on the mechanism of measurement, including: capillary rise, drop volume, growing drop/bubble, inclined plate, maximum bubble pressure, oscillating jet, drop/bubble shape, plate tensiometer, ring tensiometer, sessile drop, pendant drop, spinning drop, static drop volume, transient drop/bubble relaxation, capillary waves, longitudinal waves, elastic ring, oscillating bubble, and oscillating drop [50,51,52,53]. The stalagmometer is a well-known device for measuring surface tension. However, it consumes more time and volumes than other surface tension measuring devices [54], therefore, some modifications on the stalagmometric method were conducted and other devices have been constructed to overcome these limitations [55,56,57]. Table 1 summarizes the CMC values of several surfactants determined using the measurement of surface tension.

In addition to the variation in surface tension in correspondence with surfactant concentration, the spreading behavior is also probable to change across the CMC. To investigate this theory, a method was developed based on oil drops spreading on aqueous solutions of cationic, anionic, or non-ionic surfactants. On the surfactant-loaded surface, changes in the maximum area occupied by oil drops were detected. To measure the spreading behavior, the maximum spreading area was estimated in response to the surfactant concentration using a software [58]. The experiment involved putting the drop of oil in a Petri dish filled with surfactant solution, and held within a box. A lamp was fixed from the top to visualize the spreading with a diffuser sheet to control the intensity of the light beam. A camera was placed underneath the diffuser to document the oil droplet spreading. After that, the area of diffusion was extracted from the pictures and recorded with quantitative image analysis tool using a software. To cancel the effect of vibration resulted from the outside, the experiment was vibration isolated on a table. The setup for the spreading experiments is depicted in the diagram (Fig. 3a). To identify the CMC, the change in the maximum area occupied by the droplet of oil was recorded and related to the surfactant concentration. It was found that below the CMC the slope of the straight line was small, while with increasing surfactant concentration, the area and the slope increased. The spreading behavior of the oil drop on cetyltrimethyl ammonium bromide (CTAB) and the plot between the area and CTAB concentration are illustrated in Fig. 3b and c, respectively. This approach was found to be easy, accurate, and can be applied to determine the CMC of both ionic and non-ionic surfactants, regardless of the purity [58].

a The setup of the spreading experiment. b The spreading of oil drop on aqueous CTAB, the maximum area occupied is surrounded by a dashed line. c Plot between the maximum spreading area on CTAB surface against concentration of CTAB (with permission from [58])

Viscosity measurement

The first attempt to measure viscosity to determine the CMC was in 1939 [59]. Unlike surface tension, the viscosity of the solution is directly proportional to surfactant concentration. The viscosity of a solution containing surfactant increases sharply after reaching the CMC. This is because the presence of micelles in the solution leads to a more compact solution structure, hence it becomes more viscous. If the viscosity of the solution was plotted against surfactant concentration, a change of slope will be observed at the CMC indicating that a sharp increase in viscosity occurred after micelles formation [10, 11]. The viscosity can be correlated with surfactant concentration as relative viscosity [60], specific viscosity, or reduced viscosity [11].

To measure viscosity, capillary viscometers have been widely employed because they are cost-effective and relatively simple to use [61]. Good results are usually obtained with the help of an Ostwald viscometer [43, 62], however, it consumes more time and volumes than other viscometers. Man-Singh Survismeter could be used instead of the simple Ostwald viscometer, and the time required by a given volume of surfactant solution to pass through the Survismeter was determined [56, 63]. Another device for measuring viscosity is the automated microviscometer, which is based on the rolling ball/falling ball principle. Automated microviscometers were used in the determination of CMC in several studies [64, 65]. Additionally, capillary electrophoresis (CE) device attached to a precise system that provides pressure was utilized for measuring viscosity to determine the CMC values. This instrumentation was found reliable for measuring CMC, by detecting the variation of viscosity between monomeric surfactant molecules and the micellar state [60, 61].

The CMC of sodium dodecyl sulfate (SDS) and bis(2-ethylhexyl) sulfosuccinate sodium salt were determined using viscometry. A capillary viscometer fitted with an automated timer was used to measure viscosity. The flow time increases as small quantities of surfactants were added to the solution, which increased the viscosity. Then, the flow time increased sharply after a certain concentration. A plot between the estimated viscosity and surfactant concentration was constructed. The point at which the slope changed indicated that the micelles were formed at that concentration [66]. Using the viscosity measurement method for CMC determination offered a varied range of applications in studying factors affecting surfactants and surfactants characterization [54, 62, 64, 65].

Refractive index measurement

The refractive index (RI) is a number that represents how much ray of light is bent or refracted when passing from one medium to another (Fig. S1). The RI can be calculated from the following equation:

where i is the angle of incidence; r is the angle of refraction; n is the refractive index.

The formation of micelles results in high turbidity of the solution, consequently, large fluctuations in the RI of the solution between surfactant monomers and micellar forms are observed. The CMC can be obtained from the change of slope of the curve, when the RI is plotted against surfactant concentration [11].

The RI technique has been extensively used for the determination of CMC [67,68,69]. The traditional RI measurement has undergone some changes such as, the combination between two-channel Fresnel reflection-based fiber-optic RI sensor with partially automated mixing system. The determination of CMC using this instrument relied on two factors; the fact that micelles have higher RI than monomers and the adsorption of surfactant molecules on the sensing part. The cores of the fiber are hydrophilic, because they are made of silica [67]. To determine the CMC of a solution, the sensing (bare core) was immersed in the solution of the surfactant. Surfactant monomers were propagated in the solution when the concentration was below the CMC. With increasing surfactant concentration, the monomers started to gather at the interface between air and solution. When the CMC was reached, the hydrophilic heads of the surfactant were found to interact with the hydrophilic part of the sensor. The combined impacts of micelle assembly and surfactant adsorption caused the RI to rapidly increase with the concentration at this point, indicating the CMC (Fig. S2) [70]. The CMC determined for some surfactants are summarized in Table 1.

In addition to the fiber-optic RI sensor, terahertz time-domain spectroscopy (THz) is a technique that depends on measuring the RI or absorption coefficients of the surfactant. THz waves are a type of electromagnetic waves with a frequency range of 0.1–10 THz. This technique was found in a number of applications [69], as it was used in the measurement of the CMC of SDS and nonaethylene glycol monododecyl ether. The CMCs of surfactants under investigation were determined by correlating the refractive index or the absorption coefficient of the surfactant solution and the concentration. The determined CMCs of surfactants were in good agreement with the existing reported data.

Light scattering measurement

In an aqueous solution of surfactant, the formation of micelle contributes to the turbidity of the solution. The turbidity can be measured using light scattering; the intensity of the scattered light depends on surfactant concentration. At low concentration of surfactant, the turbidity is minimum, while upon approaching the CMC, the formation of micellar aggregates will be reflected in the increase of scattered light [10]. The CMC can be determined by co-relating the intensity with surfactant concentration. A plot of the intensity or the turbidity of the solution shows a low slope for dilute solutions (monomer phase) and a steeper slope above the CMC (micellar phase). The intersection of the two lines on a turbidity graph gives the CMC [11].

The light scattering technique offers information about particles in solutions, e.g., molecular weight, diffusion, and interaction strength. Most importantly, it gives information about the size of the solutes, because the intensity of scattered light is very sensitive to variations in particle size; this feature is advantageous to investigate the aggregation in solution. Light scattering measurements could be static or dynamic. Dynamic light scattering (DLS) measures the variations in the intensity of scattered light with time, while the absolute mean intensity is measured by static light scattering.

DLS technique was used for the determination of CMC for amphiphilic diblock copolymer polybutadiene-block-polyethylene oxide in aqueous media. The scattered light intensity of the solution was examined and the values of scattered light were plotted as a function of the concentration of polybutadiene-block-poly(ethyleneoxide) as shown in Fig. S3. DLS was found to be capable of determining both the CMC and the hydrodynamic diameter of micelles in micellar solution, which is critical for the application of di- or tri-block copolymer micelles in controlled nanoparticle synthesis as nanoreactors. The DLS was proven to be a sensitive and convenient method to determine low CMC values down to 10−7 mol/dm3 [71]. The CMC of N-decanoyl-N-methylglucamide sugar-based surfactant in the presence of increasing glycine concentrations was investigated using the light-scattering measurement method [72]. Time-dependent static light scattering was applied in the measurements of the self-aggregation of an ionic liquid, didecyl-dimethylammonium nitrate, CTAB and the mixtures of these two salts in an aqueous solution [73].

An automated method has been developed to make the light scattering technique more accurate, less tedious with less sample preparation. The automated method combined measurement of static light scattering with continuous automatic mixing. This instrument considerably speeded up the processes of data collection and analysis, enhanced the precision, sensitivity, range of application, and reduced the amount of manual intervention required [74]. The obtained CMC values of anionic, cationic, non-ionic, and zwitterionic surfactants are presented in Table 1.

Resonance Rayleigh Scattering (RRS) is an interesting analytical technology that has been applied successfully to determine the CMC values of surfactants [79, 80]. RRS involves measuring the variation in of Rayleigh scattered visible light in terms of energy or direction. The electromagnetic wave is absorbed by electrons, when the frequency of the wave is equal to the electrons scattering frequency. This will result in an absorption band corresponds to the wavelength of the incident light on the scattering molecules [81]. The advantage of this method is its sensitivity and suitability for all kinds of surfactants without the use of any reporter. In addition, it can be employed to investigate the aggregation behavior of the surfactant molecules in aqueous solution [82]. RRS was applied for the determination of the CMC of bile salts [80]. Further developments in light scattering techniques include coupling DLS with laser Doppler electrophoresis. This combined technique was applied to characterize properties of the CTAB micellar solutions while α-tocopherol (vitamin E) and NaCl are present in the solution. DLS was used to determine the particle size, while laser Doppler electrophoresis was used to measure the electrolytic conductivity and electrophoretic mobility. The physicochemical properties of CTAB were found to be affected by vitamin E according to its position within CTAB micelles. Enhanced electrophoretic mobilities of micelles were noticed when α-tocopherol was located in the palisade layer. On the other hand, when α-tocopherol molecules were positioned in the core, no alteration in the micellar size or aggregation number was remarked [83].

Limitations and remarks

Measurement of the surface tension of surfactant solutions is the most common method of CMC determination. The main advantage of this method is that it is direct and applicable to all types of surfactants. Currently, the applications of the surface tension method for CMC determination are still going, although it is one of the oldest methods for the determination of CMC. The surface tension method can be applied to determine CMC in various matrices, e.g., in protein formulation [84]. The surface tension method despite being direct and universal is a tedious, time-consuming procedure and the results are not of high accuracy nor precision. This method is very sensitive to impurities since it does not detect the presence of micelles in the bulk and only measures the surface concentration of all surface-active species present in solution. The presence of other highly surface-active impurities may affect the readings and result in that the inflection in the surface tension versus concentration plot becomes more ambiguous [43]. Furthermore, the surface tension is very sensitive to temperature variation, a certain degree of error can be expected, while using the instruments [85]. Since there are many limitations to measure the CMC with the surface tension method, it is recommended to implement other methods to obtain an accurate CMC value. The viscosity measurement method for CMC determination offers a wide range of applications in studying factors affecting surfactants and surfactants characterization [54, 62, 64, 65]. In general, the viscosity measurement method offers the advantages of direct determination of CMC, it can also be applied to all types of surfactants, especially for nonionic surfactants, where no electroviscous effect arises [1]. Although it is a successful method for first CMC determination, it was reported that viscosity measurement is not a good method for the determination of second CMC, where micelles change from spherical to rod shape [86].

Although terahertz time-domain spectroscopy is not the most accurate among the traditional methods for the determination of the CMC of surfactants, it is fast, convenient, and label-free [69]. Furthermore, it is universal, it can be applied on all types of surfactants. Since this method does not involve the addition of a probe or the application of a strong external field, no change in the CMC can occur throughout the experiments, however, it is necessary to ensure very careful temperature control [45].

DLS is an ideal technique for studying the surfactant-micellar system and it is simple, effective, noninvasive and requires no use of tracers or further sample manipulation [80]. The light scattering technique had a major contribution and offered many applications in the field of studying surfactants [87, 88]. It provided information that has been difficult to be obtained by conventional techniques as the polydispersity of micellar systems, the aggregation number, the dissymmetry of a particle, and the amount of charge on the micelle [45]. However, the presence of very small amounts of impurities will result in significant errors, it is necessary to ensure very careful elimination of dust particles from solutions [43, 45]. Small amounts of organic vapors present in the environment could affect the measurements [45].

Electrochemical methods

There are several types of electrochemical methods; e.g., conductimetry, potentiometry, and voltammetry, that have been used successfully in the determination of the CMC of various surfactants [89].

Conductimetry

Electrical conductivity can be defined as the ability of a substance to carry an electric current when there is an applied potential difference. Strong electrolytes are substances that completely dissociate into ions and produce a solution with high electric conductivity. On the other hand, weak electrolytes are substances that partially dissociate and produce a solution with weak electric conductivity.

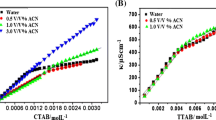

When an ionic surfactant is added to an aqueous solution, its monomers undergo complete ionization and act as strong electrolytes, showing strong electrical conductivity. After the CMC is reached, the formed micelles are larger than monomers in size and undergo partial ionization. The mobility of ions in solution decreases above the CMC and hence, the solution shows a lower extent of electric conductance [27]. The electrical conductivity of a solution is measured using a device called; conductivity-meter (conductimeter). Typically, if the electrical conductivity values are plotted against surfactant concentration, a sharp breakpoint will be observed, and this point is the CMC [90]. Electrical conductivity can be expressed as specific conductivity κ, which can be converted to equivalent conductivity or molar conductivity [11]. Sometimes, the specific conductivity—concentration plot is unable to show a sharp transition from the premicellar to the micellar region, but it rather exhibits a curvature. Therefore, for a precise determination of the CMC, a method of integration should be considered such as Boltzmann-type sigmoidal equation [91,92,93]. Conductimetry has been applied in many studies for the determination of CMC [49, 91, 94, 95] and the investigation of factors and additives effect on CMC values. Common additives include electrolytes [90], amino acid such as glycine [31, 93] and leucine [29], lysozyme [33], and glycyl dipeptides [96]. The cosolvents effect on CMC was also studied using conductimetry or short-chain alcohol [65, 97,98,99], ethylene glycol [98], polyethylene glycol [100], and acetonitrile [91].

Conductimetry is the most commonly used electrochemical method, because it is simple and can be performed with standard instrumentation. [89]. In general, manual pipetting conductivity experiments take time, generating tens of reading points in a matter of hours (point by point procedure). To make the procedures rapid and automated, a method was proposed to obtain conductometric curves with several hundred readings in minutes. This automated method was developed to study surfactants/cell interaction and surfactants alone [101]. The conductimeter was linked to a computer as well as a peristaltic pump, which was in charge of delivering the surfactant solution (Fig. 4a). At a rate of 0.0143 cm3 per second, the surfactant solution was pumped into a measuring chamber. A gravimetric determination of the flow was used to calculate the rate of the pump. The conductivity measurements were taken with a frequency of one per second by the conductimeter and sent to the computer [101]. There were no significant differences between the results obtained from point-by-point method and the automated method (Fig. 4b).

a Graphical representation of the automated method. b Plot between conductivity against the concentration of CTAB obtained with automated method (black dots) and the classical (point by point) method (circles) (with permission from [101])

Zeta potential measurement

The application of conductimetric measurements is more convenient in the case of ionic surfactants [102]. However, the conductimetry techniquecannot determine the polarity of the surfactant. A method for determining the CMC and polarities of ionic surfactants was proposed based on measuring the zeta potentials of electrolyte solution-air interfaces. The method investigated the theory of electrical potential at the liquid–air interface being affected by surfactant aggregation. When the measurement system electrode came into contact with the interface between liquid and air, the electrical potential difference between the electrode surface and the liquid–air interface produced an electrical current that flowed through an electrical circuit. The magnitudes of the signals were measured in relation to surfactant concentrations, the measuring system is presented in Fig. 5a. According to the findings, increments in the intensity of the measured signal were observed with increasing surfactant concentration until it approached the CMC. The signal magnitude remained steady after the CMC. This could be because surfactant adsorption at the interface causes an increase in surface charge density as soon as surfactant molecules begin to form micelles in the bulk of the solution. More counter ions are drawn to the interface in the electrolyte solution, forming an electrical double layer (Fig. 6) [103]. The CMC value obtained shows good agreement with replicates, which demonstrates the reliability of this method (Fig. 5b) [103].

a An illustration of the increased surface charges as a result of surfactant adsorption at the interface and b a plot between zeta potential against the logarithm of the surfactant concentration, showing the dependence of zeta potential on concentration (with permission from [103])

Potentiometry

Potentiometry is an electrochemical method that is based on measuring the potential of electrochemical cells. Potentiometric methods of analysis were known for a long time to be used for the location of endpoints in titrations. Lately, potentiometry is used to detect and quantify a large number of ions, by measuring the potential of ion-selective electrodes (ISE). The advantage of using ISE is their lack of response to any interferences, rapid measurement, and simplicity [104]. Potentiometry is less common than conductimetry in the determination of CMC [80, 89, 105].

Electrical Impedance Spectroscopy (EIS)

Electrical Impedance Spectroscopy (EIS) is a highly sensitive characterization technique that permits the measurement of the electrical impedance of a substance (an extension of the concept of resistance) as a function of the frequency of an applied electrical current. The micelle formation was investigated using EIS for ionic surfactants, including SDS, and sodium dihexyl sulfosuccinate (Aerosol MA80). The EIS parameters exhibited sharp changes because of the transformations of surfactant particles from monomers to micelles in the emulsion. Accurate determination of the CMC could be achieved at specific ranges of frequencies [106]. The results of this method showed that EIS method was capable of determination of CMC accurately compared with conductimetry. The conductimetric method, for example, failed to detect the CMC of Aerosol MA80 [106].

Voltammetry

In the CMC detection methods domain, polarography and voltammetry can be classified as indirect electrochemical methods, since they involve measuring the change in an electrical property of an electroactive probe material.

When an electroactive substance is added into a surfactant solution, the formation of micelles will lead to changes in the diffusion coefficient of the probe. Consequently, a change in the limiting current is observed corresponding to the CMC. The CMC value is attained from the point at which discontinuity is observed in the plot of limiting current against surfactant concentration. The main advantage of voltammetry over other electrochemical methods is that it allows the measurement of the CMC of ionic and nonionic surfactants. However, the presence of electroactive reporter molecules may contribute to discrepancies in the CMC values obtained by this method [89].

Development of voltammetric methods that avoid the use of a reporter substance was considered, such as using a boron-doped diamond anode, which is characterized by having a large electrochemical window. Because of the ability of boron-doped diamond of surfactants oxidation in aqueous solutions, it was found to be a good material as an anode. The anodic current decreases abruptly above the CMC of the surfactants in a concentration-dependent manner. The results were in good agreement with reported CMC values determined using the surface tensiometry technique [107].

One of the most common voltammetric methods used for CMC determination is cyclic voltammetry [89]. Cyclic voltammetry involves cycling a working electrode potential and measuring the resulting current. An application of using cyclic voltammetry with a rotating sample system was proposed for the determination of the CMC of surfactants [108]. An example of this method is the use of potassium ferrocyanide to detect the air/water interface of Triton X-100 solutions. In the rotating sample system experiments, the sample size is in microliter drops, where the drop undergoes vigorous rotation through mechanical air/liquid coupling. As a result, changes in the surface properties of aqueous samples generate equivalent changes in the rotating sample system’s hydrodynamic performance, which can be utilized to explore interfacial phenomena. The CMC value estimated using this method matches well with reported values from much larger samples collected using conventional methods [108].

As an application of the polarography technique, the typical fused-silica capillary was utilized to create a mercury electrode with a long drop time. This electrode produced consistent mercury drops that last 40–120 s and it was designed to determine the CMCs of anionic surfactants using a drop-time technique, which was convection-controlled. It had the benefits of being readily available, inexpensive, and a viable alternative in electrocapillary measurements to the spindle-shaped electrode [94].

Limitations and remarks

The electrochemical techniques serve as a powerful tool for the determination of CMC values by measuring different electrical properties, e.g., conductance, potential, and current. Generally, the main disadvantage of these methods is the limited application for ionic surfactants or the need for an electrochemically active probe. The conductance-measuring method is simple, however, for surfactants with a low aggregation number determining the crossing point in the conductance-concentration curves is difficult, and the CMC values determined by such method show great uncertainty [92]. Furthermore, the results obtained in the presence of high electrolyte concentrations are not accurate, because of the residual conductance by the electrolyte [72].

Several drawbacks appear in potentiometric methods, including poor response of the used electrode, interferences from other substances present in the solution, and sensitivity to temperature variation. Errors in the measurement can be introduced if the temperature was not controlled. This is because the potential response is directly dependent on the temperature of the solution. Limitations of voltammetric methods of analysis are found in the ability to correct residual currents, which affect the accuracy of the results [109].

Capillary electrophoresis-based methods

CE is an effective method for determining the CMC of a surfactant [12, 89]. Numerous methods based on CE instruments were designed for determining surfactant CMC. These methods include using the micellar electrokinetic chromatography technique to examine the relationship between the solute retention factor and surfactant concentration, the relationship was found to be linear [12, 110]. However, when interactions are unpredictable between micelles and charged solutes in the aqueous solution, this approach becomes unreliable.

In addition to the retention factor, the different electrophoretic mobility of a tracer helped the determination of CMC, by correlating the marker mobility with surfactant concentration [12]. Moreover, CMC could be determined by studying the effect of different conductivities of different concentrations of ionic surfactants on the electrical current of the solution, that depends on the surfactants aggregation state as monomers or micelles at a given applied voltage using CE instrumentation [111]. Yet, sometimes when the detected current variation by a CE instrument is minimal, the inflection in the surfactant-current graph could be hard to detect. Among the above mentioned CE methods to aid the CMC determination, the most precise determination of CMC could be achieved using the measurement of tracing compound electrophoretic mobility. The migration of a specific solute in the premicellar and micellar concentration zones would be described using this method by applying mobility equations. Additionally, the evaluation of solute binding constants to micelles and surfactant monomers, it led to a better explanation of the interactions between surfactants and test solutes [12].

Other methods that utilize CE instrumentations include relative viscosity measurements by measuring the migration time of a marker in a pressure-driven flow; mesityl oxide. The relative viscosity values were calculated by means of Poiseuille’s law, then the data were plotted against surfactant concentrations. Four representative surfactants (anionic: SDS, cationic: dodecyltrimethylammonium bromide (DTAB), nonionic: N-decanoyl-N-methylglucamine (DMG), and zwitterionic: 3-[(3-cholamidopropyl)dimethylammonio]-1-propanesulfonate (CHAPS)) were studied. The obtained CMC values were very similar to those published in the literature [60].

Instead of calculating the relative viscosity values, another method was also developed based on the viscosity difference between premicellar and micellar systems. The migration times of the marker; nitromethane were plotted in correlation with examined surfactant concentrations to identify the CMC. The migration times were found to change considerably when the CMC value was reached. Figures S4a and S4b demonstrate the change in migration and the first derivative plots, respectively [61]. This method offered the advantages of fast analysis time, in less than 5 minutes, the experiment was completed with minimum sample preparation, consequently, this approach could be applied for examining biosurfactants and other expensive materials. It should be mentioned that the suggested method can be affected by multiple factors, including the variation in temperature and pressure, changes in the timing of injection, etc. As a result, accurate use of this approach necessitates a well-controlled experimental environment as well as well functioning instrumentation [61].

The diffusion coefficients for monomers and micelles are different due to the difference in sizes. The CMC could be identified by measuring the change of the diffusion coefficient of the surfactant solution. With the aid of CE instrumentation, Taylor dispersion analysis (TDA) could be used as an alternative to capillary liquid chromatography. TDA is a microcapillary flow process for analyzing tiny molecules, peptides, and proteins in solution, as well as samples including combinations of these species. TDA measures the Taylogram, which is the time-evolved concentration profile of a nanoliter-sized sample pulse delivered into a laminar flow of a specific buffer. The hydrodynamic radius and diffusion coefficient of solute molecules can be predicted through the analysis of Taylogram. UV absorption with various wavelengths was used to investigate target molecules at static positions within the microcapillary. The absorbance values are plotted as a function of time to generate the Taylogram. By relating the Taylogram width to the molecular diffusion coefficient of the solute species in the sample, the hydrodynamic radius was calculated. In the experiment for the identification of SDS CMC, UV detection was applied, although SDS does not have any chromophore. In theory, two options were available for the analysis: the first was to use a chromophoric probe in the background mobile phase where the TDA examined negative peaks produced by the surfactant (indirect UV-TDA) (Fig. 7a), the second option is to only use the probe in a tested sample region where the peaks for TDA were produced by the probe (direct UV-TDA) (Fig. 7b) [111]. The Taylogram produced by both methods is presented in Fig. 7c and d.

a The indirect UV-TDA approach scheme. b Direct UV-TDA approach scheme. c The Taylogram of SDS with indirect UV-TDA approach. d The Taylogram of SDS using direct UV-TDA methodology (with permission from [111])

The TDA estimated the diffusion coefficient of the UV probe, according to the fact that the interaction between the probe and free surfactant molecules differs from the interaction between the probe and micelles. The TDA methodology represents a novel and very fast way for the CMC determination of surfactants, with and without the aid of a probe [111].

Limitations and remarks

As can be perceived, CE can be used to determine the CMC of surfactants in a variety of operating circumstances where traditional approaches such as conductivity and surface tension measurements are ineffective. Furthermore, the technique is not only quick but also simple to implement. The CE method allowed CMC to be determined using as little as nanoliter to microliter quantities of various surfactant concentrations, with no total sample requirements [112]. This technique offered more than one approach for CMC determination, some of the proposed approaches could be applied to determine the CMC values of all types of surfactants; anionic, cationic, zwitterionic, and nonionic. Despite these advantages, the determination of CMC with CE is under influence of many factors. The nature of the micellar buffer electrolyte and the operating parameters of an electrophoretic system, including the nature of the surfactant, the type, and composition of the electrolyte solution, all influence the CMC value of a surfactant. Furthermore, buffer pH, the ionic strength of the electrolyte solution, the type of counter-ion of the electrolyte solution, the type of counter-ion of the surfactant, the presence of various organic modifiers, the presence of various electrolyte additives, temperature, and the nature of solubilized solutes all affect the CMC value [12].

Conclusion

In this review, the physicochemical and electrochemical methods for determining CMC were covered, as well as their limitations. Certain remarks were also addressed to achieve better results. Undoubtedly, approaches in determining CMC are several and extremely diverse, however, the pursuit of the development of new methods still exist because there are methodological variations and notable discrepancies in the values of CMC reported in the literature [49, 113]. The disagreements arise from the complexity of the micellization process, that only allow the CMC to be taken as a range of concentrations because it is difficult to obtain accurate and precise CMC as one pinpoint value [114]. Furthermore, inaccurate results may originate, because many factors affect the method used, for example, the surface tension method is highly sensitive to temperature variation [85]. Moreover, different methods of data analysis and unidentified interferences present with surfactants will also contribute to the inconsistency of CMC obtained by different methods. Because of all of the aforementioned reasons, there is a challenge for developing more methods to overcome the drawbacks of existing alternatives, especially with the recent advances in molecular imaging and electrode materials.

References

Schmitt TM (2001) Analysis of surfactants, 2nd edn. Marcel Dekker, New York

Habib A, Mabrouk MM, Hamed NA, Mansour FR (2020) Microchem J 158:105141

Hammad SF, El-Khateeb BZ, El-Malla SF (2021) Luminescence 36:733

Abdeldaim DT, Mansour FR (2018) Rev Anal Chem 37:20170009

Mansour FR, Arrua RD, Desire CT, Hilder EF (2021) Anal Chem 93:2802

Mansour FR, Kirkpatrick CL, Danielson ND (2013) Chromatographia 76:603

Fasciano JM, Mansour FR, Danielson ND (2016) J Chromatogr Sci 54:1

Mansour FR, Waheed S, Paull B, Maya F (2020) J Sep Sci 43:56

Rana S, Bhattacharjee J, Barick KC, Verma G, Hassan PA, Yakhmi JV (2017). In: Grumezescu A, Ficai A (eds) Nanostructures for cancer therapy. Elsevier Inc, Amsterdam, p 177

Lindman B, Wennerström H (1980) Micelles. Springer, Heidelberg, p 1

Mukerjee P, Mysels KJ (1971) Critical micelle concentrations of aqueous surfactant systems. National Bureau of Standards, Washington

Lin CE (2004) J Chromatogr A 1037:467

Rosen M, Kunjappu J (2012) Surfactants and interfacial phenomena. Wiley, Hoboken

Zhu Q, Huang L, Su J, Liu S (2014) Chem Commun 50:1107

Mansour FR, Kirkpatrick CL, Danielson ND (2013) J Chromatogr Sci 51:655

Mclntire GL, Dorsey JG (1990) Crit Rev Anal Chem 21:257

Mabrouk MM, Hamed NA, Mansour FR (2021). Appl Spectrosc Rev. https://doi.org/10.1080/05704928.2021.1955702

Perinelli DR, Cespi M, Lorusso N, Palmieri GF, Bonacucina G, Blasi P (2020) Langmuir 36:5745

Poša M, Guzsvány V, Csanádi J (2010) Sens Electroanal 5:195

Li X, Wettig SD, Verrall RE (2005) J Colloid Interface Sci 282:466

Heerklotz H, Seelig J (2000) Biochim Biophys Acta - Biomembr 1508:69

Jaiswal S, Mondal R, Paul D, Mukherjee S (2016) Chem Phys Lett 646:18

Karumbamkandathil A, Ghosh S, Anand U, Saha P, Mukherjee M, Mukherjee S (2014) Chem Phys Lett 593:115

Braun AC, Ilko D, Merget B, Gieseler H, Germershaus O, Holzgrabe U, Meinel L (2015) Eur J Pharm Biopharm 94:559

Priev A, Zalipsky S, Cohen R, Barenholz Y (2002) Langmuir 18:612

Chauhan S, Kumar K, Singh K, Jyoti J (2014) J Surfactants Deterg 17:169

Chakraborty T, Chakraborty I, Ghosh S (2011) Arab J Chem 4:265

Savaroglu G, Genc L (2013) Thermochim Acta 552:5

Chauhan S, Sharma K, Rana DS, Kumar G, Umar A (2012) J Mol Liq 175:103

Savaroglu G, Yurt A (2011) J Chem Thermodyn 43:15526

Chauhan S, Sharma K, Rana DS, Kumar G, Umar A (2013) J Solution Chem 42:634

Dubey N (2013) J Mol Liq 184:60

Chauhan S, Chauhan MS, Sharma P, Rana DS (2013) J Mol Liq 187:1

Bhattacharya DM, Pratap UR, Wankhade AV, Zodape SP (2016) J Mol Liq 214:117

Thorsteinsson MV, Richter J, Lee AL, DePhillips P (2005) Anal Biochem 340:220

Mabrouk M, Hamed NA, Mansour FR (2021) J Chem Educ 98:2603

Becher P (1962) J Phys Chem 66:374

Domínguez A, Fernández A, Gonzalez N, Iglesias E, Montenegro L (1997) J Chem Educ 74:1227

Furton KG, Norelus A (1993) J Chem Educ 70:254

Ananthapadmanabhan KP, Goddard ED, Turro NJ, Kuo PL (1985) Langmuir 1:352

Huang X, Yang J, Zhang W, Zhang Z, An Z (1999) J Chem Educ 76:93

Kapoor RC, Chand P, Aggarwala VP (1972) Anal Chem 44:2107

Patist A (2002) Determining critical micelle concentration. Wiley, Minnesota

Cheng L, Mewes D, Luke A (2007) Int J Heat Mass Transf 50:2744

Tamamushi BI, Shinoda K, Nakagawa T, Isemura T (1963) Colloidal surfactants: some physicochemical properties. Academic Press, New York

Campanelli JR, Wang X (1997) J Colloid Interface Sci 190:491

Fainerman VB, Miller R (1995) J Colloid Interface Sci 175:118

Fainerman VB, Kazakov VN, Lylyk SV, Makievski AV, Miller R (2004) Colloids Surf A Physicochem Eng Asp 250:97

Scholz N, Behnke T, Resch-Genger U (2018) J Fluoresc 28:465

Fainerman VB, Möbius D, Miller R (2001) Surfactants—chemistry, interfacial properties, applications. Elsevier Inc, Amsterdam

Berry JD, Neeson MJ, Dagastine RR, Chan DYC, Tabor RF (2015) J Colloid Interface Sci 454:226

Akhlaghi N, Riahi S (2019) Appl Chem Res 14:91

Le TTY, Hussain S, Lin S-Y (2019) J Mol Liq 294:111582

Niraula TP, Bhattarai A, Chatterjee SK (2014) BIBECHANA 11:103

Chichkanov SV, Proskurina VE, Myagchenkov VA (2002) Butlerov Commun 3:33

Singh M (2005) Instruments Exp Tech 48:270

Friest J, Dowse B, Delaet D (2008) Am J Undergrad Res 6:1

Deodhar S, Rohilla P, Manivannan M, Thampi SP, Basavaraj MG (2020) Langmuir 36:8100

Sata N, Tyûzyô K (1953) Bull Chem Soc Jpn 26:177

Wu C, Li NJ, Chen KC, Hsu H-F (2014) Res Chem Intermed 40:2371

Stanley FE, Warner AM, Schneiderman E, Stalcup AM (2009) J Chromatogr A 1216:8431

Jha K, Bhattarai A, Chatterjee SK (2014) BIBECHANA 11:131

Singh M (2008) Surf Interface Anal 40:1344

Zdziennicka A, Szymczyk K, Krawczyk J, Jańczuk B (2012) Fluid Phase Equilib 322–323:126

Bielawska M, Chodzińska A, Jańczuk B, Zdziennicka A (2013) Colloids Surf A Physicochem Eng Asp 424:81

Mitsionis AI, Vaimakis TC (2012) Chem Phys Lett 547:110

Singh CD, Ogita M (2004) Appl Phys B Lasers Opt 79:103

Strop P, Brunger AT (2005) Protein Sci 14:2207

Yan S, Wei D, Tang M, Shi C, Zhang M, Yang Z, Du C, Cui H-L (2016) IEEE Trans Terahertz Sci Technol 6:532

Tan CH, Huang ZJ, Huang XG (2010) Anal Biochem 401:144

Topel Ö, Çakir BA, Budama L, Hoda N (2013) J Mol Liq 177:40

Carnero Ruiz C, Hierrezuelo JM, Molina-Bolivar JA (2008) Colloid Polym Sci 286:1281

Thévenot C, Grassl B, Bastiat G, Binana W (2005) Colloids Surf A Physicochem Eng Asp 252:105

Paillet S, Grassl B, Desbrières J (2009) Anal Chim Acta 636:236

Rehman N, Ullah H, Alam S, Khaliq Jan A, Khan SW, Tariq MH (2017) J Mater Environ Sci 8:1161

Khamis M, Bulos B, Jumean F, Manassra A, Dakiky M (2005) Dyes Pigm 66:179

Aguiar J, Carpena P, Molina-Bolívar JA, Carnero Ruiz C (2003) J Colloid Interface Sci 258:116

Zhang T, Lu Q, Lü Y, Wu G (2015) Polym Bull 72:2215

Li N, Liu S, Luo H (2002) Anal Lett 35:1229

Reis S, Moutinho CG, Matos C, De Castro B, Gameiro P, Lima JLFC (2004) Anal Biochem 334:117

Liu S, Luo H, Li N, Liu Z, Zheng W (2001) Anal Chem 73:3907

Shi Y, Luo HQ, Li NB (2011) Spectrochim Acta - Part A Mol Biomol Spectrosc 78:1403

Cieśla J, Koczańska M, Narkiewicz-Michałek J, Szymula M, Bieganowski A (2017) J Mol Liq 233:15

Horiuchi S, Choda N, Takahashi H, Sato T, Taira H, Mukai K (2016) J Pharm Sci 105:2349

Esteves R, Dikici B, Lehman M, Mazumder Q, Onukwuba N (2016) Beyond Undergrad Res J 1(January):4

Mu JH, Li GZ, Zhang WC, Wang ZW (2001) Colloids Surf A Physicochem Eng Asp 194:1

Troncoso J, Zemánková K, Jover A (2017) J Mol Liq 241:525

Valstar A, Almgren M, Brown W, Vasilescu M (2000) Langmuir 16:922

Nesměrák K, Němcová I (2006) Anal Lett 39:1023

Domínguez A, Fernández A, González N, Iglesias E, Montenegro L (1997) J Chem Educ 74:1227

Goronja JM, Ležaić AMJ, Dimitrijević BM, Malenović AM, Stanisavljev DR, Pejić ND (2016) Hem Ind 70:485

Carpena P, Aguiar J, Bernaola-Galván P, Carnero Ruiz C (2002) Langmuir 18:6054

Koya PA, Wagay TA, Ismail K (2015) J Solut Chem 44:100

Součková J, Skopalová J, Muller L, Vymětalíková M, Barták P (2011) Talanta 84:187

Di Anibal CV, Moroni MA, Verdinelli V, Rodríguez JL, Minardi R, Schulz PC, Vuano B (2009) Colloids Surf A Physicochem Eng Asp 348:276

Yan Z, Zhang Q, Li W, Wang J (2010) J Chem Eng Data 55:3560

Al-Hatem AA (2020) Baghdad Sci J 17:255

Akbaş H, Kartal Ç (2006) Colloid J 68:125

Bhattarai A (2015) J Solution Chem 44:2090

Manna K, Panda AK (2011) J Surfactants Deterg 14:563

Tiecco M, Corte L, Roscini L, Colabella C, Germani R, Cardinali G (2014) Chem Biol Interact 218:20

Mandavi R, Sar SK, Rathore N (2008) Orient J Chem 24:559

Song Y, Sun R, Zhao K, Pan X, Zhou H, Li D (2015) Colloid Polym Sci 293:1525

Skoog D, Crouch S, Holler J (2007) Principles of instrumental analysis, 6th edn. Thomson Brooks/Cole, Belmont

Javadian S, Gharibi H, Sohrabi B, Bijanzadeh H, Safarpour MA, Behjatmanesh-Ardakani R (2008) J Mol Liq 137:74

Ghasemi S, Darestani MT, Abdollahi Z, Hawkett BS, Gomes VG (2014) Colloids Surf A Physicochem Eng Asp 441:195

Racaud C, Groenen Serrano K, Savall A (2010) J Appl Electrochem 40:1845

Kao LT, Shetty GN, Gratzl M (2008) Anal Bioanal Chem 392:1391

Yilong Z, Dean Z, Daoliang L (2015) Int J Electrochem Sci 10:1144

Terabe S, Otsuka K, Ichikawa K, Tsuchiya A, Ando T (1984) Anal Chem 56:111

Petr J (2017) J Sep Sci 40:1421

Nakamura H, Sano A, Matsuura K (1998) Anal Sci 14:379

Holmberg K (2002) Handbook of applied surface and colloid chemistry. Wiley, Hoboken

Khan A (2008) J Chem Soc Pakistan 30:186

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mabrouk, M.M., Hamed, N.A. & Mansour, F.R. Physicochemical and electrochemical methods for determination of critical micelle concentrations of surfactants: a comprehensive review. Monatsh Chem 153, 125–138 (2022). https://doi.org/10.1007/s00706-022-02891-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-022-02891-2