Abstract

A novel film consisting of multi-walled carbon nanotubes (MWCNTs) was produced by means of a flexographic printing process on polycarbonate substrate. The electrochemical response of this MWCNT-PC film towards oxidation of dopamine to dopamine-o-quinone was investigated in phosphate buffer solution (pH 7) by means of cyclic voltammetry and electrochemical impedance spectroscopy. The findings demonstrate that the MWCNT-PC film possesses good performance for the electrochemical oxidation of dopamine. Namely, the fabricated MWCNT-PC film having a detection limit and sensitivity of 4.06 μM and 0.823 A M−1 cm−2, respectively, seems to have greater detection ability towards dopamine/dopamine-o-quinone compared to other novel electrodes reported in the literature. The results of the present work are very promising and demonstrate that the MWCNT-PC film could be suitable for the electrochemical analysis of molecules with biological interest.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dopamine or 2-(3,4-dihydroxyphenyl)ethylamine (DA) is a member of the catecholamine family and one of the best known neurotransmitters that activates five known types of dopamine receptors (D1–D5) and their variants [1]. DA has a wide variety of functions in brain, including important roles in pleasure, behavior, understanding, controlled movement, motivation, sleep, mood, attention, working memory, and learning. In other words, DA regulates the flow of information and affects the way that the brain controls our movement. It is strongly associated with the pleasure system in the brain, and its release provides feelings of enjoyment and supports the activities that provide these feelings. Disorders in DA levels cause declines in neurocognitive functions like memory, attention, and problem-solving. Furthermore, lack of DA results in Parkinson’s disease, schizophrenia, and other related disorders [2–4]. Over the past several years, there has been great interest in developing sensitive and simple analytical methods, such as spectroscopy and chromatography, for the determination of DA and the diagnosis of some diseases [5–9]. However, it is well known that in clinical medicine it is often advantageous to develop an electro-analytical method for studying electron transfer processes. Since DA is an electrochemically active compound it can be easily determined by electrochemical methods based on its anodic oxidation. Consequently, numerous studies on the electrochemical determination of DA on various electrode materials have been reported [10–19]. In those studies a variety of novel electrode materials with greatly enhanced electrochemical performance were successfully used for the analysis of DA. However, a search of the literature failed to reveal any comprehensive studies on DA or other biomolecules on printed multi-walled carbon nanotube (MWCNT)-based electrodes, and thus, there is a pressing need to gain insights into the electrochemical behavior of such systems.

Our research activities at the TU Ilmenau currently involve the development of MWCNT-based electrodes by means of chemical vapor deposition (CVD). We have developed novel and rapid-response sensors based on carbon nanotube arrays that are able to selectively detect DA down to micromolar concentrations [20]. Furthermore, the research activities at TU Chemnitz are oriented towards the production of mass-printed sensors, and thus we have great experience concerning their fabrication processes and materials [21–23]. In the present work we extend our research activity into electrochemical studies on DA on printed MWCNT-based films. Specifically, the aim of the research work is the investigation of the electrochemical response of films fabricated upon printing of MWCNTs onto polycarbonate substrate towards the electro-oxidation of DA. The goal of the present article is to establish a simple and sensitive electrochemical method for the determination of DA from tissue in vivo and in vitro. The obtained results reveal that the novel printed MWCNT-based films exhibit an improved response and sensitivity towards the dopamine (DA)/dopamine-o-quinone (DAQ) redox couple and thus suggest the application of such materials in biomolecule sensing.

Results and discussion

For characterizing the electrochemical performance of the fabricated novel MWCNT-PC film towards oxidation of DA to DAQ, cyclic voltammetry (CV) experiments were performed in phosphate buffer solution (PBS, pH 7) at various scan rates (0.05–0.12 V s−1). For comparison reasons electrochemistry experiments were also performed on a film consisting of MWCNTs that were grown on oxidized silicon substrate. The MWCNT-based film (MWCNT-ACN) was fabricated by means of CVD with decomposition of acetonitrile (ACN) and using ferrocene as a catalyst [24, 25]. Representative CV curves recorded on MWCNT-PC and MWCNT-ACN films are shown in Fig. 1. It is apparent from the CV curves that there is an electrochemical response of MWCNT-PC film towards oxidation of DA that leads to the appearance of two couples of oxidation (I, III) and reduction (II, IV) CV waves. The double-peaked CV waves demonstrate the occurrence of more than one redox process involving DA. The mechanism of the electro-oxidation of DA at physiological pH is somehow complicated, and consequently, there is a lot of confusion concerning this redox process. However, detailed schemes showing the processes upon electro-oxidation of DA presented in the literature demonstrate that DA is firstly oxidized to the diketone dopamine-o-quinone that is transformed into the more readily oxidizable leucodopaminechrome which is further oxidized to dopaminechrome [14, 26, 27]. Specifically, upon the electrochemical treatment of DA one chemical and two redox procedures take place. The first redox process concerns the facile oxidation of DA to DAQ via two-electron transfer that leads to the anodic CV peak I at about +0.38 V (vs. Ag/AgCl) and the inverse procedure, namely the reduction of DAQ to DA which results to the cathodic CV peak II at about +0.10 V (vs. Ag/AgCl). The electrochemically formed DAQ undergoes nucleophilic attack of amine in the side chain and after an intramolecular proton transfer the generation of short-lived species occurs. Under the influence of water, the short-lived species undergo an elimination reaction to form the stable aromatic phenolate anion [28, 29]. Finally, upon protonation of phenolate anion, the electro-active compound 5,6-dihydroxyindoline or leucodopaminechrome (DHI) is formed that can be oxidized at about −0.19 V (vs. Ag/AgCl) via elimination of two electrons to form aminochrome or dopaminechrome (AC) (CV peak III). Thus, the cathodic CV peak IV which lies at about −0.44 V (vs. Ag/AgCl) can be attributed to the inverse process, namely the reduction of AC to DHI. As it can be seen in CV curves shown in Fig. 1 the MWCNT-ACN film exhibits a well-defined reproducible quasi-reversible redox response towards DA/DAQ, whereas the response of MWCNT-PC film seems to be irreversible. It is noticeable that at MWCNT-PC the cathodic peak current is much smaller than the anodic peak current showing that only a part of the initial DA, which still remains in the DAQ form, can be regenerated (CV wave II), whereas the rest is consumed owing to the competing chemical reaction and finally reduced at more negative potential (CV wave IV). In other words, it is obvious that the kinetics of the DA/DAQ redox couple at MWCNT-PC film are somehow slow and consequently the coupled chemical reaction for the conversion of DAQ to DHI prevails over its reduction at this particular electrode. The peak potential separation for the redox couple DA/DAQ on MWCNT-PC was estimated as ΔΕ p = 0.285 V, considering that the CV peaks I and II lie at about E oxp = +0.381 V and E redp = +0.096 V (vs. Ag/AgCl), respectively. The determined ΔΕ p value seems to be significantly greater from the expected ΔΕ p value for a two-electron transfer process (~0.059/n V, where n is the number of electrons transferred) and demonstrates slow electron transfer kinetics [30]. It is interesting that the ΔΕ p value obtained for DA/DAQ on MWCNT-PC seems to be about 0.130 V greater compared to that determined for the same redox couple on MWCNT-ACN (ΔΕ p = 0.155 V). According to theory [31, 32], the greater ΔE p reflects the slower kinetics of electron transfer reaction, specifically ΔE p is expected to be inversely related to the heterogeneous electron transfer rate constant (k s). Thus, the k s value determined by means of the electrochemical absolute rate relation for DA/DAQ on MWCNT-PC film (k s = 0.51 × 10−3 cm s−1) seems to be about four times smaller compared to that determined for the same redox couple on MWCNT-ACN (k s = 2.08 × 10−3 cm s−1). Furthermore, the electron transfer rate constant of k s = 2.25 × 10−3 cm s−1 obtained for DA/DAQ on modified carbon paste electrode [33] appears to be four times greater than that obtained on MWCNT-PC. In addition, the k s values of k s = 2.26 × 10−3 cm s−1 and k s = 3.10 × 10−3 cm s−1 obtained for DA/DAQ on a gold electrode modified with 3-amino-5-mercapto-1,2,4-triazole [34] and a poly(3,4-ethylenedioxythiophene)/tosylate microelectrode [35], respectively, are also greater than that measured on MWCNT-PC. The findings indicate that the reversibility of the redox couple DA/DAQ at MWCNT-PC is somehow weaker compared to other novel electrodes, something that may be related to the electrode fouling caused by the deposition of DA and its oxidation product on the electrode surface [36]. It is, nevertheless, interesting that the kinetics of the DA/DAQ couple on novel MWCNT-PC seem to be slightly faster from that measured on bare glassy carbon electrode (k s = 0.39 × 10−3 cm s−1) [37] and considerably faster from that obtained on boron-doped diamond film (2.08 × 10−5–6.60 × 10−5 cm s−1) [38]. Consequently, the final conclusion that can be made on the basis of this evidence is that the electrochemical response of the printed MWCNT-PC towards DA oxidation is quite good.

The oxidation of DA at MWCNT-PC film (E oxp = +0.381 V vs. Ag/AgCl) is shifted at about 0.092 V to more anodic potential compared to that at MWCNT-ACN (E oxp = +0.289 V vs. Ag/AgCl). This result shows that the ability of MWCNT-PC to decrease the overpotential of DA/DAQ is weaker compared to that of MWCNT-ACN. However, it is interesting that the oxidation potential of DA at MWCNT-PC seems to be less anodic compared to that measured on other electrode materials. For example, Robinson et al. [39] reported an oxidation potential of E oxp = +0.60 V (vs. Ag/AgCl) for DA on a carbon fiber microelectrode that seems to be more anodic compared to that measured on MWCNT-PC. Furthermore, Fujishima et al. [40] reported that the oxidation potential of DA on boron-doped diamond film is E oxp = +0.80 V (vs. SCE) or E oxp = +0.845 V (vs. Ag/AgCl) that is significantly more anodic compared to that measured on the MWCNT-PC electrode. These results demonstrate that MWCNT-PC favors the decrease of overpotential of DA.

The possibility of using the MWCNT-PC film for the determination of DA in practical samples was tested. For this purpose CVs for different concentrations of DA were recorded on MWCNT-PC film in PBS (pH 7). Representative CVs are shown in Fig. 2a. The results indicate that the anodic peak current was proportional to the concentration of DA in two intervals, namely in the concentration ranges of 0.035–0.155 and 0.155–0.292 mM with correlation coefficients of 0.9979 and 0.9986, respectively (Fig. 2b). This behavior can be explained by the saturation of PBS in DA at ~0.16 mM that leads to the decrease of the slope of the current versus concentration curve. The detection limit of MWCNT-PC towards DA was estimated to be 4.06 μM at a signal-to-noise ratio (S/N) of 3. DA was repeatedly determined several times on different MWCNT-PC samples in order to investigate the reproducibility of the fabricated printed films. Thus, the detection limit of an additional MWCNT-PC sample towards DA was determined as 3.97 μM in the concentration range of 0.004–0.060 mM (Fig. 3a, b). These findings demonstrate that the relative standard deviation for the detection limit is about 2.2 %, which is quite acceptable. It must be mentioned that the current versus concentration plots exhibit near-zero intercept indicating adsorption of DA on the electrode surface. Considering that the active surface area of the MWCNT-PC film is 5.98 cm2, the detection sensitivity of the MWCNT-PC film towards DA/DAQ was estimated to be 0.823 A M−1 cm−2. It is very interesting that the sensitivity of MWCNT-PC towards DA is greater compared to that of other electrodes reported in the literature. For instance, Cosnier et al. [41] reported that a polypyrrole-modified carbon fiber microelectrode incorporating polyphenol oxidase has a sensitivity towards DA of about 0.059 A M−1 cm−2, i.e., about 14 times smaller compared to that observed on MWCNT-PC. Furthermore, Védrine et al. [42] reported that a poly-3,4-ethylenedioxythiophene-modified glassy carbon electrode incorporating polyphenol oxidase exhibits a sensitivity to DA oxidation of about 0.133 A M−1 cm−2, i.e., about six times smaller compared to that determined for MWCNT-PC. This comparison confirms the good quality of the MWCNT-PC film.

a CVs recorded for DA at different concentrations (from inner to outer 0.004, 0.008, 0.021, 0.026, 0.031, 0.037, 0.046, 0.054, and 0.060 mM) on MWCNT-PC in PBS (pH 7) at v = 0.10 V s−1. b Effect of variation of concentration of DA on the anodic peak current in the concentration range of 0.004–0.060 mM

It would be very interesting to compare the detection ability of MWCNT-PC film towards the DA oxidation with that of other electrodes reported in the literature. The comparison shows that the novel MWCNT-PC film fabricated in the present work exhibits in general good detection capability towards DA. Specifically, Kurniawan et al. [43] reported that the detection limit of electrodes based on gold nanoparticles towards DA is 4.0 μM, i.e., comparable to the limit of detection measured for MWCNT-PC. Furthermore, Min and Yoo [44] reported a detection limit towards DA of about 5 μM for single-walled carbon nanotube-film modified with polypyrrole, which is slightly poorer compared to that determined on MWCNT-PC. In addition, Doyle et al. [45] published a detection limit towards DA of 20 μΜ for a platinum electrode modified with polypyrrole, i.e., significantly poorer compared to that obtained for MWCNT-PC film. It is also remarkable that a MWCNT electrode modified with polyaniline exhibits a detection limit of 38 μM towards DA [46], i.e., considerably poorer compared to that measured on MWCNT-PC film. However, it must be mentioned that the electrochemical response of MWCNT-PC seems to be significantly poorer compared to that of MWCNT-ACN. It is amazing that the detection capability of MWCNT-ACN seems to be about 100 times better compared to that of MWCNT-PC. A detailed comparison of the detection limits of novel MWCNT-PC film fabricated in the present work with those of numerous modified or unmodified electrodes reported in the literature is shown in Table 1. From the comparison it can be clearly seen that MWCNT-PC exhibits great detection capability towards DA confirming, thus, the strong catalytic function of MWCNTs for oxidation of DA.

The effect of concentration of DA on the kinetics of the electron transfer process was further tested by means of electrochemical impedance spectroscopy (EIS). Representative EIS spectra in the form of Nyquist diagrams recorded for DA on MWCNT-PC in the concentration range of 0.035–0.292 mM are displayed in Fig. 4. In EIS spectra the complex impedance is presented as a sum of the real (Z re) and imaginary (Z imag) components. As it can be observed in Fig. 4, in all cases similar shaped EIS spectra can be distinguished, namely one significantly depressed semicircle in mid-frequency range, a part of another depressed semicircle in the high-frequency range, and a 45° inclined straight line which lies in the low-frequency range can be observed. The high-frequency semicircle is due to the surface quality of the electrode, namely to its rough surface or to formation of passive film on its surface, whereas the mid-frequency semicircle corresponds to the electron transfer process that occurs at the surface of MWCNT-PC film. Furthermore, the straight line is attributed to the Warburg diffusion. It is well known that depressed semicircles are usually obtained owing to highly porous electrode/electrolyte interfaces and this effect can be usually considered by introducing a constant phase element (CPE) in the place of double layer capacitor [47]. It is interesting that when CPE was used in place of a pure capacitor an improved fit of the EIS data was observed [48]. It is well known that for rough and fractal-electrode surfaces the double layer capacitance is modified by an exponent n (it is also known as roughness exponent) [49, 50], which is directly connected to the effective fractal dimension (d) according to the relation n = 1/(d − 1). For rough electrode surfaces the fractal dimension is between 2 and 3 and consequently n < 1, whereas for smooth electrode surfaces the effective fractal dimension is d = 2 which leads to n = 1 [51]. The roughness exponent for MWCNT-PC film was determined to be ~0.47 implying that MWCNT-PC has a rough surface [52]. The simulation results indicate that the charge transfer resistance (R ct) decreases progressively from 326 to 230 Ω with the increase of the concentration of DA from 0.035 up to 0.099 mM, respectively, and attains the minimum value of 221 Ω at a concentration of about 0.128 mM. With further increase of DA concentration, R ct slightly increases up to 250 Ω and remains unaffected by higher DA concentrations (c > 0.206 mM). The greater R ct values determined for MWCNT-PC compared to that obtained for MWCNT-ACN (18 Ω) reflect the weaker electrochemical response of MWCNT-PC. However, comparable charge transfer resistance (R ct ≈ 278 Ω) was also reported for the oxidation of DA on a poly(3,4-ethylenedioxythiophene)-modified Pt electrode [53]. These findings reveal that the quality of the MWCNT-PC electrode can be considered quite acceptable.

a EIS recorded on MWCNT-PC for different concentrations of DA in PBS (pH 7): c 1 = 0.035 mM (filled square), c 2 = 0.068 mM (filled circle), c 3 = 0.099 mM (open upward triangle), c 4 = 0.128 mM (open downward triangle), c 5 = 0.155 mM (open square), c 6 = 0.206 mM (open circle), c 7 = 0.251 mM (multiplication sign), and c 8 = 0.292 mM (plus sign); Inset equivalent electrical circuit (R s + C f + (C dl/R ct) + Z w) used for analysis of EIS spectra (software Thales, version 4.15). b Zoom of EIS in the high-frequency region

Conclusions

The present work describes an experimental procedure for the analytical determination of DA on printed MWCNT-PC films. The fabricated MWCNT-PC films exhibit good electrochemical response with a relatively low detection limit (4.06 μΜ) and high sensitivity (0.823 A M−1 cm−2) towards DA oxidation that make them very useful for construction of simple devices for the determination of DA in clinical and pharmaceutical preparations. It is hoped that this method will be suitable for application in electrochemical studies on biological systems.

Experimental

Reagents

Dopamine (>99.0 %) was purchased from Aldrich and used as received. All measurements were carried out by using phosphate buffer solution (pH 7.0). The aqueous PBS was prepared immediately prior the electrochemical experiments by using doubly distilled water having a specific conductivity of 0.1 μS cm−1. A stock solution of DA (1.0 mM) was prepared in PBS medium and the measured solutions, in the concentration range from 0.004 to 0.292 mM, were prepared directly in the electrochemical cell by progressive addition of an appropriate volume of stock solution in PBS medium.

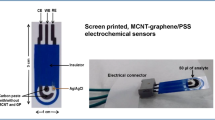

Apparatus and procedures

The cyclic voltammograms (CVs) were recorded using a computer-controlled system Zahner (model IM6/6EX). The experiments were carried out using a three-electrode cell configuration. The working electrode was MWCNT-PC film (active surface area 5.98 cm2), the counter electrode was a Pt plate (geometric area 2.0 cm2), and the reference electrode was Ag/AgCl (sat. KCl). For the electrochemistry experiments, a three-compartment electrochemical cell specially designed to minimize the distances between the electrodes with a total solution volume of 30 cm3 was used. Before each measurement process the solution was purged with high purity argon to eliminate interference from oxygen. The CVs were recorded in the potential range from −0.8 to +0.8 V (vs. Ag/AgCl) with scan rates ranging from 0.05 to 0.10 V s−1. All measurements were carried out at room temperature (22 °C). The electrochemical impedance spectra (EIS) were recorded with a computer-controlled system Zahner (model IM6/6EX) by applying very a small amplitude of the alternate voltage (10 mV) in the frequency range from 0.1 Hz to 100 kHz at room temperature (22 °C). All electrochemistry experiments were performed with the same three-electrode system used for CV. The EIS spectra were recorded at the oxidation potential of the investigated redox couple DA/DAQ (+0.381 V vs. Ag/AgCl). The recorded EIS spectra were analyzed by means of the equivalent electrical circuit (R s + C f + (C dl/R ct) + Z w) (software Thales, version 4.15) (inset Fig. 4). The elements of the circuit can be explained as follows: R s is a resistor representing the uncompensated resistance of the cell that includes the resistance of electrolyte, separator, current collectors, and electrical leads; R ct is a resistor representing the charge transfer resistance of the redox reaction; C dl and C f are capacitors corresponding to the double layer capacitance that arises at the electrode interface with electrolyte solution and the electrode surface capacitance, respectively; and Z w represents the Warburg diffusion impedance. The mean and maximum modified impedance errors derived from the simulation process were estimated to be in all cases less than 0.4 and 7.2 %, respectively.

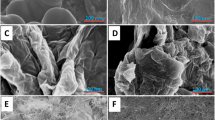

Production of printed MWCNT-PC films

The printed MWCNT-PC film was fabricated by means of a mass flexographic printing process based on transfer of water-dispersed MWCNTs onto polymer substrate. The material CarboDis TN (Future Carbon GmbH), used for the experiments, consisted of an aqueous dispersion of MWCNTs (2 wt %) and electrically neutral surfactant. For the printing procedure the printing parameters (printing speed, contact pressure), the properties of surfaces that make contact with the printing ink during the printing process (substrate, printing unit), and the ink’s properties (dynamic viscosity, surface tension) were carefully controlled. Printing tests were carried out on a flexographic test printing press FlexiProof 100–630 (Erichsen, Germany). Using a print layout in the form of areas with dimensions of 35 × 50, 40 × 60, and 50 × 70 mm2, we transferred the dispersed MWCNTs onto flexible PC film (thickness 1.7 mm) by means of printing plate nyloflex ACE (Flint Group, Germany) with printing factor of 20 (number of printing steps). The ceramic anilox roller used had a scooping capacity of 25 cm3 m−2. The printing speed for rotation of the impression cylinder substrate was varied from 25 to 50 m min−1. The device-specific gap between the plate cylinder and the impression cylinder was set to 0.74. In order to construct the working electrode for electrochemical measurements, the MWCNT-PC film was connected to the platinum wire by using the silver conducting coating. Once the silver coating was dried (after 24 h), the silver conducting part of the MWCNT-PC film was fully covered with varnish protective coating. However, it is important to mention that a difficulty regarding the electrode’s stability was experienced during the measurements. Namely, it was observed that after repeated handlings a part of the MWCNT forest collapsed resulting in a significant weakening of the electrode’s performance and therefore making the MWCNT-PC films essentially single-use electrodes.

References

Huffman ML, Venton BJ (2009) Analyst 134:18

Garris PA, Wightman RM (1994) J Physiology 478:239

Wightman RM, May LJ, Michael AC (1988) Anal Chem 60:769A

Mo JW, Ogoreve B (2001) Anal Chem 73:1196

Sarre S, Michotte Y, Herregodts P, Deleu D, De Klippel N, Ebinger G (1992) J Chromatogr B 575:207

Guan CL, Ouyang J, Li QL, Liu BH, Baeyens WRG (2000) Talanta 50:1197

Kang TF, Shen GL, Yu RQ (1997) Anal ChimActa 354:343

Seçkin ZE, Volkan M (2005) Anal ChimActa 547:104

Dayton MA, Ewing AG, Wightman RM (1980) Anal Chem 52:2392

Goyal RN, Gupta VK, Bachheti N, Sharma RA (2008) Electroanal 20:757

Zhang R, Jin GD, Chen D, Hu XY (2009) Sens Actuators B 138:174

Castro SSL, Mortimer RJ, de Oliveira MF, Stradiotto NR (2008) Sensors 8:1950

De Oliveira Matos I, Andrade Alves W (2011) ACS Appl Mater Interfaces 3:4437

Majewska UE, Chmurski K, Biesiada K, Olszyna AR, Bilewicza R (2006) Electroanal 18:1463

Rekha, Swamy BEK, Deepa R, Krishna V, Gilbert O, Chandra U, Sherigara BS (2009) Int J Electrochem Sci 4:832

Huang J, Liu Y, Hou H, You T (2008) Biosens Bioelectron 24:632

Ensafi AA, Dadkhah-Tehrani S, Rezaei B (2010) J Serb Chem Soc 75:1685

Farhadi K, Kheiri F, Golzan M (2008) J Braz Chem Soc 19:1405

Zhang L, Wu J (2011) Sens Lett 9:1755

Tsierkezos NG, Ritter U (2012) J Solid State Electrochem 16:2217

Meier B, Egermann L, Voigt S, Stanel M, Kempa H, Hübler AC (2011) Thin Solid Films 519:6610

Kempa H, Hambsch M, Reuter K, Stanel M, Schmidt GC, Meier B, Hübler AC (2011) IEEE Trans Electron Dev 58:2765

Hübler AC, Trnovec B, Zillger T, Ali M, Wetzold N, Mingebach M, Wagenpfahl A, Deibel C, Dyakonov V (2011) Adv Energy Mater 1:1018

Tsierkezos NG, Ritter U (2010) J Solid State Electrochem 14:1101

Szroeder P, Tsierkezos NG, Scharff P, Ritter U (2010) Carbon 48:4489

Hawley MD, Tatawawadi SV, Piekarski S, Adams RN (1967) J Am Chem Soc 89:447

Zhu M, Huang XM, Li J, Shen HX (1997) Anal Chim Acta 357:261

Hawley MD, Tatawawadi SV, Piekarski S, Adams RN (1967) J Am Chem Soc 89:447

Sternson AW, McCreery R, Feinberg B, Adams RN (1973) J Electroanal Chem Interfacial Electrochem 46:313

Kadish KM, Larson G (1977) Bioinorg Chem 7:95

Nicholson RS (1965) Anal Chem 37:1351

Nicholson RS, Shain I (1964) Anal Chem 36:706

Ardakani MM, Talebi A, Naeimi H, Barzoky MN, Taghavinia N (2009) J Solid State Electrochem 13:1433

Yixin S, Wang SF (2006) Microchim Acta 154:115

Larsen ST, Vreeland RF, Heien ML, Taboryski R (2012) Analyst 137:1831

Salimi A, Mam-Khezri H, Hallaj R (2006) Talanta 70:823

Yamaguchi T, Komura T, Hayashi S, Asano M, Niu GY, Takahashi K (2006) Electrochemistry 74:32

Teófilo RF, Ceragioli HJ, Peterlevitz AC, Da Silva LM, Damos FS, Ferreira MMC, Baranauskas V, Kubota LT (2007) J Solid State Electrochem 11:1449

Robinson DL, Venton BJ, Heien MLAV, Wightman RM (2003) Clin Chem 49:1763

Fujishima A, Rao TN, Popa E, Sarada BV, Yagi I, Tryk DA (1999) J Electroanal Chem 473:179

Cosnier S, Innocent C, Allien L, Poitry S, Tsacopoulos M (1997) Anal Chem 69:968

Vedrine C, Fabiano S, Tran-Minh C (2003) Talanta 59:535

Kurniawan F, Tsakova V, Mirsky VM (2009) J Nanosci Nanotechnol 9:2407

Min K, Yoo YJ (2009) Talanta 80:1007

Doyle R, Breslin CB, Rooney AD (2009) Chem Biochem Eng Q 23:93

Sabzi RE, Rezapour K, Samadi N (2010) J Serb Chem Soc 75:537

Park JY, Kwon SH, Park JW, Park SM (2008) Anal Chim Acta 619:37

Moulton SE, Barisci JN, Bath A, Stella R, Wallace GG (2004) Electrochim Acta 49:4223

Rammelt U, Reinhard G (1990) Electrochim Acta 35:1045

Oliveira-Brett AM, Silva LA, Farace G, Vadgama P, Brett MAC (2003) Bioelectrochemistry 59:49

Mulder WH, Sluyters JH, Pajkossy T, Nyikos L (1990) J Electroanal Chem 285:103

Los P, Zabinska G, Kisza A, Christie L, Mount A, Bruce PG (2000) Phys Chem Chem Phys 2:5449

Atta NF, Galal A, Ahmed RA (2011) Bioelectrochemistry 80:132

Acknowledgments

The authors would like to thank Mrs. D. Schneider (TU Ilmenau). The present research work was finally supported by BMBF (CarbonSens, contract number 16SV5326).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsierkezos, N.G., Wetzold, N., Ritter, U. et al. Analysis of dopamine on printed polymer thin film consisting of multi-walled carbon nanotubes. Monatsh Chem 144, 581–588 (2013). https://doi.org/10.1007/s00706-012-0914-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-012-0914-2