Abstract

Two dimensional accordion-like Ti3C2Tx MXene, where Tx represents surface termination groups such as –OH, –O–, and –F, is synthesized by selective etching of aluminum layers from Ti3AlC2. This manuscript reports on the adsorption of organic molecules from head-space and aqueous environments containing Ti3C2Tx, a representative of the MXene family. Ti3C2Tx coated by gluing method on a stainless steel wire was successfully utilized as a highly sensitive and stable head-space solid-phase microextraction (SPME) fiber. A SPME method with the MXene as the adsorbent combined with gas chromatography with MS detector was used to determine the polycyclic aromatic hydrocarbons (PAHs) in water samples. Low detection limits in the range of 0.2–5 ng L−1, wide linearity and good reproducibility (RSD = 4.6 to 7.4% for n = 6) under the optimized extraction conditions was achieved. Finally, the MXene coated fiber was successfully used for the determination of PAHs in real water samples. The relative recoveries for six PAHs are from 91.3–105.0%, which proved the applicability of the method. Also, melamine was selected as a polar analyte and it has been shown that Ti3C2Tx MXene has good capability in extraction of melamine (the extraction recovery for melamine = 80.1%) from aqueous media by dispersive micro solid-phase extraction.

Two dimensional accordion-like Ti3C2 MXene was synthesized by selective etching of aluminum layers from Ti3AlC2. Ti3C2 MXene was employed as solid phase microextraction fiber coating for the extraction of polycyclic aromatic hydrocarbons from water samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-phase microextraction (SPME) is a sample pretreatment technology, which simplifies the sample preparation procedures and integrates both sampling and convenient introduction of extracted components to analytical instruments [1]. The most important point for SPME is the adsorbent, which plays roles of extraction and enrichment [2]. Therefore, the development of adsorbents is of great importance to achieve high extraction, efficiency, and selectivity. A lot of novel materials, e.g., metal organic frameworks (MOFs) [3], MOFs-derived nanoporous materials [4], covalent organic framework (COF) [5, 6], polymers [7,8,9,10], carbon-related materials [11,12,13], carbon nitride [14] and other materials have been developed as SPME coating materials for pursuing high adsorption performance [2]. Two dimensional (2D) materials have garnered great attention owing to their unique physical and chemical properties, which differ from their corresponding bulk counterparts since graphene was first produced by mechanical exfoliation into single-layers in 2004 [15].

MXenes, a group of two-dimensional (2D) materials composed of transition metal carbides and carbon nitrides with a general formula of Mn + 1XnTx, whereas M stands for transition metals atoms (such as Sc, Cr, V, Ti, Zr, Hf, Nb, Ta, Mo, etc.), X stands for carbon and/or nitrogen and T represents various metal surface termination functional groups including -O, -OH, and -F with n = 1, 2, or 3. MXenes have been fabricated via selective etching of the “A” layer by hydrofluoric acid (HF) or HF-containing or HF-forming etchants from layered ternary carbides and nitrides namely MAX phases with a formula Mn + 1AXn, (n = 1, 2, or 3), where A represents the Al or Si element. For example, Ti3C2Tx powder is synthesized by selective extraction of aluminum layers from Ti3AlC2 [16]. The etching process is mandatory owing to strong chemical bonds among A and M components in MAX phases since mechanical exfoliation is not suitable in this case. Since the discovery of Ti3C2Tx in 2011 by Gogotsi research group [17], around 20 various MXenes have been produced, and the structures and features of dozens more have been theoretically estimated, making it one of the fastest growing 2D material families [16]. Benefiting from their high electrical conductivity and 2D structure, Ti3C2Tx has been regarded as an energy storage material for anodes of Li-ion batteries (LIBs), lithium-sulfur batteries, and electrochemical-capacitors [18]. The unique morphology, dispersibility, and stability also make Ti3C2Tx attractive as adsorbents for heavy metal ions or dyes and as supports for catalysts [19]. Due to the abundant active sites on their surface, MXenes can adsorb metal ions through electrostatic and chemical interactions [19]. This suggests that MXenes can potentially be used as adsorbents, similar to other layered materials such as a study reported an outstanding sorption capacity of a modified MXene for lead ions [20]. In general, a hydrophilic surface is beneficial for the adsorption of polar or ionic species [21]. Also temperature treatments aid in removing functional groups from the MXene. The dehydroxylation of terminated OH groups and the detachment of grafting functional groups bonded to the MXene surface, which also revealed that the chemically grafted groups are stable up to at least 200 °C temperature [22,23,24].

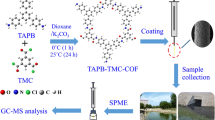

As far as we are aware no studies on solid-phase microextraction by MXenes have been published. We report on the first attempts to use an as-produced multilayered MXene as a potential adsorbent for HS-SPME and dispersive micro solid-phase extraction. For this purpose, we chose to investigate the interaction of Ti3C2Tx – to date, the most studied MXene. Ti3C2 -coated fiber prepared by gluing method on the surface of stainless steel wire and it showed high extraction efficiency and proper sensitivity for determination of polycyclic aromatic hydrocarbons (PAHs) by HS-SPME. Dispersive MXene was used in dispersive micro solid-phase extraction method to extract and enrich analytes from liquid samples. In dispersive micro solid-phase extraction, only small amounts of sorbent were added to liquid extracts [25]. Hence, to show Ti3C2Tx has the ability to extract polar analytes, melamine was selected as a polar model analyte in dispersive micro solid-phase extraction mode in an aqueous solution and showed high extraction efficiency.

Experimental section

Chemicals and reagents

All of the chemicals were analytical grade and used without any further purification. Potassium dihydrogen phosphate, dimethyl phthalate (DMP), diethyl phthalate (DEP), polycyclic aromatic hydrocarbons (PAHs) including naphthalene (Nap), acenaphthylene (AcPy), fluorene (Flu), anthracene (Ant), fluoranthene (Flt) and pyrene (Pyr) were obtained from Sigma-Aldrich (Milwaukee, WI, USA, www.sigmaaldrich.com). Additionally, all of the organic solvents like methanol and acetone were of HPLC grade and purchased from Duksan (Ansan, South Korea, www.duksan.kr). The stock standard solution (100 mg L−1) of each PAH analyte was provided in methanol. Standard solutions were obtained by dilution of the stock solution in methanol to desired concentration. Stock and working standards were stored at 4 °C in the refrigerator. The melamine stock solution was prepared by dissolving 50 mg of the material in 50 mL of methanol–water (1:1 v/v), respectively, and stored in the dark place at 4 °C. Working solutions were attained by direct dilution of the stock solution with methanol/water mixture (1:1 v/v) as solvent immediately before use.

The diameter of stainless steel wire used as the supporting substrate for preparation of SPME fiber was 250 μm. Clear silicone glue was purchased from the Gorilla Glue Company (www.gorillatough.com).

Instrumentation

Analysis of the model compounds was performed with an Agilent 7890A GC system (Agilent Technologies, Palo Alto, CA, USA, https://www.agilent.com) with an FID detector and 7890B GC followed by a 5977B MS equipped with a split/splitless injector. The injector was used in the splitless mode at 280 °C. The column used for the separation with GC-FID was a Varian wall coated fused silica capillary column (30 m *0.32 mm i.d. film thickness of 0.25 μm). The FID temperature was fixed at 300 °C. Ultrapure helium and nitrogen (>99.999%) were utilized as the carrier and makeup gas at 2 mL min−1 and 25 mL min−1, respectively. GC-MS separations were performed using an HP-5MS capillary column with a length of (30 m × 0.25 mm) with a film thickness of 0.25 μm. The mass spectrometer was run in the electron impact ionization mode with ionizing energy of 70 eV. The interface and ion source temperatures were both set at 300 °C. Separation of PAHs by GC-FID and GC-MS was achieved using temperature programs as follows: the oven temperature was initially held at 60 °C for 1 min and programmed at 7 °C min−1 to 180 °C; at 10 °C min−1 to 280 °C; held for 5 min. For dispersive micro solid-phase extraction, separation and determination of the analyte were accomplished using an Agilent 1260 HPLC system, equipped with a quaternary pump, a degasser, a 20 μL sample loop and a UV-Vis detector (Waldbornn, Germany). The ODS-3 column (250 mm × 4.6 mm, with a 5-μm particle size) from Hector (Daejeon, Korea, https://www.hichrom.com) was used for determination of melamine. The mobile phase was MeOH–50 mM KH2PO4 at pH 3.0 (30:70, v/v) and pumped through the column at a flow rate of 1 mL min−1. The detection wavelength was set at 214 nm.

Characterization

The morphology of Ti3C2Tx was observed with field emission scanning electron microscopy (FE-SEM) MIRA3TESCAN-XMU (Czech Republic). Transmission electron microscope (TEM) was observed on a JEOL Ltd. JEM-2100 spectrometer. X-ray powder diffraction (XRD) patterns of MXene and MAX were recorded on a Rigaku diffractometer using Cu Ka (λ = 0.154 nm). Thermogravimetric (TG) analysis was carried out using a thermogravimetric analyzer (Perkin Elmer model TG/DTA 6300, USA) from room temperature to 600 °C at a heating rate of 5 °C min−1 in an argon atmosphere.

Synthesis of Ti3C2Tx MXene

The synthesis of the Ti3AlC2 MAX phase has been described in previous studies [26, 27]. The detail of synthesis describe in the Electronic Supporting Material (ESM).

Fabrication of MXene fiber

Before producing the SPME coatings, first the stainless steel wires were cut into 3 cm pieces, and then ultrasonically treated successively in water, methanol, and acetone for 30 min. The treated wires were dried and after that, around 0.5 g silicone glue was dispersed in 1.0 mL toluene under ultrasound waves. Then, the pre-treated steel wire was immersed into the glue and removed instantaneously. A piece of filter paper has been used for removal of excess glue and formation of an extremely thin film of silicone glue on the surface of the steel wire. The glue containing wire then was rotated into the powder of the synthesized MXene to obtain the single-layer coating. Furthermore, the single-layer fiber was dried at 150 °C for 30 min in a vacuum oven to evaporate the solvent. The mentioned procedures were repeated twice. Before usage, the fabricated fiber coated with MXene was mounted into a homemade SPME device and then was aged in the GC injector under helium 99.999% at 280 °C with gradual rising temperature and kept at 300 °C for 2 h to avoid any contamination or carryover.

SPME procedure

For analysis, all extraction tests were done in a 10 mL working solution, which was introduced to a 20 mL amber vial capped with PTFE-coated septa. Magnetic stirring was utilized to stir the solution at 224 Relative Centrifugal Force (rcf or G-force) during extraction. The extraction temperature was controlled by a thermostatic water bath. In extraction procedure, the MXene coated SPME fiber was exposed to the headspace above the sample for a certain time. When extraction has been completed, the fiber was taken out from the vial and instantly introduced into GC injection port for thermal desorption. Before each use, the fiber was conditioned at 280 °C for 10 min.

Dispersive micro solid-phase extraction procedure

A 10 mL of sample aqueous solution including 100 ppb of melamine was prepared. 10 mg of MXene was added into the sample solution and magnetically stirred for 30 min. At this stage, the analyte was adsorbed on the dispersed sorbent. Subsequently, the MXene particles were separated from the solution through centrifugation at 5600 rcf for 5 min. The supernatant was easily discarded, 500 μL of eluting solution methanol–ammonia (95:5 v/v) was added to the residue and the mixture was vortexed for 2 min to desorb the retained melamine. After that, the mixture was centrifuged at 5600 rcf for 2 min and the volume of supernatant decreased to 50 μL under a nitrogen stream. 20 μL of this solution was introduced to HPLC-UV for the quantification [28].

Results and discussion

Choice of materials

Development of new coating material is of great importance to achieve high extraction efficiency, and selectivity. Two dimensional (2D) materials have garnered great attention owing to their unique physical and chemical properties. MXenes are a group of two-dimensional materials with the unique morphology, dispersibility, abundant active sites on their surface and stability. These features suggests that Ti3C2Tx can potentially be used as adsorbents for SPME. The main aim of the work is investigation of Ti3C2 MXene as a coating material for solid-phase microextraction.

Characterization of synthesized MXene

The synthesis procedure of MXene 2D material and fabrication of MXene fiber is schematically depicted in Fig. 1a. The following simplified reactions occur when Ti3AlC2 is immersed in HF [17]:

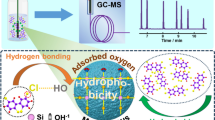

When reaction 1 took place, Al atoms were removed from the layers. Following this reaction, metallic bindings that holding the MAX phase integrated were disrupted which resulted in exfoliation of Ti3C2 layers. X-ray diffraction (XRD) patterns of the materials are shown in Fig. 1b. After Ti3AlC2 was etched by HF, (002) peak at 9.54° related to the MAX phase shift towards lower angles (9.02), etching away of Al layers and forming Ti3C2Tx phase was successfully confirmed [17, 26, 27]. As shown in Fig. 1c, FE-SEM image of the Ti3C2Tx powders after HF treatment exhibited accordion-like distinctly separated layered structure. This can be attributed to the fact that Al atom layers in the original Ti3AlC2 phase were selectively etched away. The FE-SEM image at higher magnification of Ti3C2Tx (Fig. 1d) confirms that Al atom layers can be selectively etched away, only leaving the periodic 2D interlayer space and indicates the clear layered structure. The Ti3C2 layers are almost parallel to each other, which indicates that the etching direction of Ti3AlC2 prefers along a certain orientation. The unique 2D layered structures can benefit molecule transport due to the shortened diffusion path and thus improve adsorption performance. X-ray energy dispersive spectroscopy (EDS) of the particles (Fig. 1e) shows that main elements (Ti, C) and surface terminations (O, F) with little Al, verified the elimination of Al and indicating that the surface functionalized MXene is evenly present on the framework. To further observe the morphology of Ti3C2 by TEM images, as displayed in Fig. 1f, g exhibit the two-dimensional nanosheets of Ti3C2Tx.

Figure 2 shows the thermogravimetric analysis (TGA) curve of Ti3C2Tx at Ar atmosphere. The temperature was raised from room temperature to 600 °C. The weight loss until 200 °C can be attributed to the removal of superficial and interstitial water and/or HF residue from the MXene surfaces [29]. Weight losses above 200 °C may originate from the dehydroxylation of terminated OH groups and the detachment of grafting functional groups bonded to the MXene surface. It also revealed that the chemically grafted groups are stable up to at least this temperature [22,23,24]. At temperatures >300 °C, no significant weight change was observed in the thermogram, which demonstrated that most volatile species were eliminated at temperatures below this threshold and Ti3C2 MXene is stable even up to 600 °C. The excellent thermal stability implies that Ti3C2 MXene will be suitable for high-temperature applications such as SPME where fibers are exposed to high temperatures in a GC inlet for analyte desorption.

Extraction ability of MXene

To study the extraction ability of the MXene nanosheet, analytical measurements were conducted in a GC-MS for SPME fiber. SPME fiber was prepared by gluing method. Gluing method is a universal method and simpler than other coating procedure, but it has a limitation. The self-made coating cannot be directly inserted into sample with complex matrix due to the exposed powdery material which is more prone to be scraped from the support [2]. MXene coated fiber was used to extract non-polar PAHs and more polar analytes rather than PAHs like DMP and DEP. The extraction efficiency of MXene towards PAHs is higher than that for DEP and DMP (Fig. 3). It should be noted that based on the discussion on TGA analysis in Fig. 2 and literature report, above 200 °C the dehydroxylation of terminated OH groups and the detachment of grafting functional groups bonded to the MXene surface was happened [22,23,24]. Also, in SPME, fibers were exposed to high temperatures in a GC inlet for analyte desorption, therefore MXene lost the functional group and it became more suitable for adsorption of PAHs in HS-SPME mode. Additionally, due to MXenes surfaces termination with –OH, –O–, and –F, in aqueous solution, MXene had good hydrophilicity and solution process ability [21, 30]. A hydrophilic surface was beneficial for the adsorption of polar or ionic species [21]. Hence, to show the ability of MXene for extraction of a polar analyte, extraction of melamine as a polar analyte was tested. Analytical measurements were conducted in an HPLC-UV for dispersive micro solid-phase extraction method. The extraction recovery for melamine by dispersive micro solid-phase extraction was obtained 80.1% (the details were described in Supplementary Information). Due to open interlayer structure melamine molecules easily entered the interlamellar space forming hydrogen bonds with the hydrophilic surface functional groups such as –OH and –O– on MXenes. This result shows that MXene is suitable for the adsorption of polar analyte in solution phase. Hence, their charged nature of the MXene layers, hydrophilic nature and abundant highly active surface sites, MXenes have been demonstrated to adsorb a variety of environmental pollutants, including heavy metal ions, organic dyes and radionuclidesand thus can be used for the removal of pollutants and even sensing [19].

Method validation

MXene-coated fiber followed by gas chromatography-mass spectrometry (GC-MS) was used for extraction and analysis of the analytes. Generally, there are several parameters that can affect the SPME efficiency of the fiber. For obtaining high extraction efficiency, the effect of various parameters such as the extraction temperature, desorption temperature, extraction time, and salt concentration were optimized. The optimization results are shown in Fig. S1. Under the optimized extraction conditions, the linearity, correlation coefficient, relative standard deviations (RSD), and limits of detection (LOD) of the proposed method were studied. As shown in Table 1, wide linearity is obtained. The correlation coefficients are within the range of 0.9990 and 0.9998. The LODs are between 0.2–5 ng L−1. Furthermore, the RSDs of the single MXene fiber for all PAH analytes are found to be within the range of 4.6% to 7.4%, while the fiber-to-fiber reproducibility are between 6.2% to 9.8%. On the whole, the suggested SPME route shows broad linear ranges, low LODs along with good reproducibility for determination and quantification of PAHs. In comparison to literature survey this method is comparable to the other reported methods for the analysis of PAHs in terms of sensitivities (Table 2). The current method is close to or better than the other methods in respects of the LODs.

Analysis of real sample

To evaluate the capability of the method for determination of polycyclic aromatic hydrocarbons in real samples, PAHs were quantified in two water resources including tap water and sea water samples.

As exhibited in Table 3, three PAHs containing naphthalene, anthracene, and pyrene were found in the seawater sample with the concentrations of 5.3, 18.4, and 160 ng L−1, respectively. The relative recoveries were found to be within the range of 91.3 to 105.0% (the details were described in Supplementary Information). Figure 4 portrays the typically extracted chromatogram of PAHs of seawater sample detected by the developed method. PAHs were not found in the tap water sample, and the spiking recoveries were between 91.7–109.4%. In addition, the fiber can be reused for more than 70 times without observable decrease in the extraction performance.

Conclusions

In conclusion, an accordion-like Ti3C2Tx nanosheets material to date, the most studied MXene, has been prepared by HF treatment from Ti3AlC2 powders etching Al layers. Clearly, after the aluminum layer removal from Ti3AlC2, an opened interspace was formed and the layered structure can be obviously observed. Ti3C2 MXene was used for the adsorption of organic molecules from head-space and aqueous environments containing. The head space SPME-GC-MS method exhibited low detection limits, wide linear ranges along with good recoveries in extraction and quantification of PAHs in real water resources. Also, melamine was selected as a polar analyte and it was shown that Ti3C2Tx MXene has good capability in extraction of melamine from aqueous media by dispersive micro solid-phase extraction. MXene may be useable for direct and in-tube SPME. Also Ti3C2 has good biocompatibility [21, 39, 40], MXenes can be used for in-vivo SPME analysis. We believe that other MXene family materials and their composites with other adsorbents can be fabricated and further developed for the application in microextraction in the future.

References

Arthur CL, Pawliszyn J (1990) Solid phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem 62(19):2145–2148. https://doi.org/10.1021/ac00218a019

Zheng J, Huang J, Yang Q, Ni C, Xie X, Shi Y, Sun J, Zhu F, Ouyang G (2018) Fabrications of novel solid phase microextraction fiber coatings based on new materials for high enrichment capability. TrAC Trends Anal Chem 108:135–153. https://doi.org/10.1016/j.trac.2018.08.021

Bagheri H, Amanzadeh H, Yamini Y, Masoomi MY, Morsali A, Salar-Amoli J, Hassan J (2017) A nanocomposite prepared from a zinc-based metal-organic framework and polyethersulfone as a novel coating for the headspace solid-phase microextraction of organophosphorous pesticides. Microchim Acta 185(1):62. https://doi.org/10.1007/s00604-017-2607-3

Wei F, He Y, Qu X, Xu Z, Zheng S, Zhu D, Fu H (2019) In situ fabricated porous carbon coating derived from metal-organic frameworks for highly selective solid-phase microextraction. Anal Chim Acta 1078:70-77. https://doi.org/10.1016/j.aca.2019.05.061

Gao W, Tian Y, Liu H, Cai Y, Liu A, Yu Y-L, Zhao Z, Jiang G (2019) Ultrasensitive determination of Tetrabromobisphenol A by covalent organic framework based solid phase microextraction coupled with constant flow desorption ionization mass spectrometry. Anal Chem 91(1):772–775. https://doi.org/10.1021/acs.analchem.8b04884

Yang X, Wang J, Wang W, Zhang S, Wang C, Zhou J, Wang Z (2019) Solid phase microextraction of polycyclic aromatic hydrocarbons by using an etched stainless-steel fiber coated with a covalent organic framework. Microchim Acta 186(3):145. https://doi.org/10.1007/s00604-019-3258-3

Zhu X, Hua R, Zhang D, Wu X, Wang Y, Xue J (2019) A polyurethane-based thin film for solid phase microextraction of pyrethroid insecticides. Microchim Acta 186(9):596. https://doi.org/10.1007/s00604-019-3708-y

Mehrani Z, Ebrahimzadeh H, Aliakbar AR, Asgharinezhad AA (2018) A poly(4-nitroaniline)/poly(vinyl alcohol) electrospun nanofiber as an efficient nanosorbent for solid phase microextraction of diazinon and chlorpyrifos from water and juice samples. Microchim Acta 185(8):384. https://doi.org/10.1007/s00604-018-2911-6

Dargahi R, Ebrahimzadeh H, Alizadeh R (2018) Polypyrrole coated ZnO nanorods on platinum wire for solid-phase microextraction of amitraz and teflubenzuron pesticides prior to quantitation by GC-MS. Microchim Acta 185(2):150. https://doi.org/10.1007/s00604-018-2692-y

Abolghasemi MM, Habibiyan R, Jaymand M, Piryaei M (2018) A star-shaped polythiophene dendrimer coating for solid-phase microextraction of triazole agrochemicals. Microchim Acta 185(3):179. https://doi.org/10.1007/s00604-017-2639-8

Cheng H, Song Y, Bian Y, Ji R, Wang F, Gu C, Yang X, Ye M, Ouyang G, Jiang X (2019) Meso−/microporous carbon as an adsorbent for enhanced performance in solid-phase microextraction of chlorobenzenes. Sci Total Environ 681:392–399. https://doi.org/10.1016/j.scitotenv.2019.05.150

Cheng H, Song Y, Wang F, Ji R, Li X, Fu Y, Yang X, Bian Y, Jiang X (2018) Facile synthesis of hierarchical porous carbon from crude biomass for high-performance solid-phase microextraction. J Chromatogr A 1548:1–9

Cheng H, Song Y, Bian Y, Ji R, Wang F, Gu C, Yang X, Jiang X (2018) Sustainable synthesis of nanoporous carbons from agricultural waste and their application for solid-phase microextraction of chlorinated organic pollutants. RSC Adv 8(29):15915–15922. https://doi.org/10.1039/C8RA02123F

Ghaemmaghami M, Yamini Y, Amanzadeh H, Hosseini Monjezi B (2018) Electrophoretic deposition of ordered mesoporous carbon nitride on a stainless steel wire as a high-performance solid phase microextraction coating. Chem Commun 54(5):507–510. https://doi.org/10.1039/C7CC08273H

Sajjad S, Khan Leghari SA, Iqbal A (2017) Study of Graphene oxide structural features for catalytic, antibacterial, gas sensing, and metals decontamination environmental applications. ACS Appl Mater Interfaces 9(50):43393–43414. https://doi.org/10.1021/acsami.7b08232

Wei F, He Y, Qu X, Xu Z, Zheng S, Zhu D, Fu H (2019) In situ fabricated porous carbon coating derived from metal-organic frameworks for highly selective solid-phase microextraction. Anal Chim Acta 1078:70–77. https://doi.org/10.1016/j.aca.2019.05.061

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, Hultman L, Gogotsi Y, Barsoum MW (2011) Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv Mater 23(37):4248–4253. https://doi.org/10.1002/adma.201102306

Pang J, Mendes RG, Bachmatiuk A, Zhao L, Ta HQ, Gemming T, Liu H, Liu Z, Rummeli MH (2019) Applications of 2D MXenes in energy conversion and storage systems. Chem Soc Rev 48(1):72–133. https://doi.org/10.1039/C8CS00324F

Zhang Y, Wang L, Zhang N, Zhou Z (2018) Adsorptive environmental applications of MXene nanomaterials: a review. RSC Adv 8(36):19895–19905. https://doi.org/10.1039/C8RA03077D

Peng Q, Guo J, Zhang Q, Xiang J, Liu B, Zhou A, Liu R, Tian Y (2014) Unique lead adsorption behavior of activated hydroxyl group in two-dimensional titanium carbide. J Am Chem Soc 136(11):4113–4116. https://doi.org/10.1021/ja500506k

Meng F, Seredych M, Chen C, Gura V, Mikhalovsky S, Sandeman S, Ingavle G, Ozulumba T, Miao L, Anasori B, Gogotsi Y (2018) MXene sorbents for removal of urea from dialysate: a step toward the wearable artificial kidney. ACS Nano 12(10):10518–10528. https://doi.org/10.1021/acsnano.8b06494

Liu R, Li W (2018) High-thermal-stability and high-thermal-conductivity Ti3C2Tx MXene/Poly(vinyl alcohol) (PVA) composites. ACS Omega 3(3):2609–2617. https://doi.org/10.1021/acsomega.7b02001

Wang H, Zhang J, Wu Y, Huang H, Jiang Q (2018) Chemically functionalized two-dimensional titanium carbide MXene by in situ grafting-intercalating with diazonium ions to enhance supercapacitive performance. J Phys Chem Solids 115:172–179. https://doi.org/10.1016/j.jpcs.2017.12.039

Mariano M, Mashtalir O, Antonio FQ, Ryu W-H, Deng B, Xia F, Gogotsi Y, Taylor AD (2016) Solution-processed titanium carbide MXene films examined as highly transparent conductors. Nanoscale 8(36):16371–16378. https://doi.org/10.1039/C6NR03682A

Tsai W-H, Huang T-C, Huang J-J, Hsue Y-H, Chuang H-Y (2009) Dispersive solid-phase microextraction method for sample extraction in the analysis of four tetracyclines in water and milk samples by high-performance liquid chromatography with diode-array detection. J Chromatogr A 1216(12):2263–2269. https://doi.org/10.1016/j.chroma.2009.01.034

Yan J, Ren CE, Maleski K, Hatter CB, Anasori B, Urbankowski P, Sarycheva A, Gogotsi Y (2017) Flexible MXene/Graphene films for ultrafast supercapacitors with outstanding volumetric capacitance. Adv Funct Mater 27(30):1701264. https://doi.org/10.1002/adfm.201701264

Alhabeb M, Maleski K, Anasori B, Lelyukh P, Clark L, Sin S, Gogotsi Y (2017) Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem Mater 29(18):7633–7644. https://doi.org/10.1021/acs.chemmater.7b02847

Wang X, Fang Q, Liu S, Chen L (2012) The application of pseudo template molecularly imprinted polymer to the solid-phase extraction of cyromazine and its metabolic melamine from egg and milk. J Sep Sci 35(12):1432–1438. https://doi.org/10.1002/jssc.201200096

Mashtalir O, Naguib M, Dyatkin B, Gogotsi Y, Barsoum MW (2013) Kinetics of aluminum extraction from Ti3AlC2 in hydrofluoric acid. Mater Chem Phys 139(1):147–152. https://doi.org/10.1016/j.matchemphys.2013.01.008

Mashtalir O, Cook KM, Mochalin VN, Crowe M, Barsoum MW, Gogotsi Y (2014) Dye adsorption and decomposition on two-dimensional titanium carbide in aqueous media. J Mater Chem A 2(35):14334–14338. https://doi.org/10.1039/C4TA02638A

Zhang S, Du Z, Li G (2011) Layer-by-layer fabrication of chemical-bonded graphene coating for solid-phase microextraction. Anal Chem 83(19):7531–7541. https://doi.org/10.1021/ac201864f

Wei S, Lin W, Xu J, Wang Y, Liu S, Zhu F, Liu Y, Ouyang G (2017) Fabrication of a polymeric composite incorporating metal-organic framework nanosheets for solid-phase microextraction of polycyclic aromatic hydrocarbons from water samples. Anal Chim Acta 971:48–54. https://doi.org/10.1016/j.aca.2017.04.005

Zheng J, Liang Y, Liu S, Ding Y, Shen Y, Luan T, Zhu F, Jiang R, Wu D, Ouyang G (2015) Ordered mesoporous polymers in situ coated on a stainless steel wire for a highly sensitive solid phase microextraction fibre. Nanoscale 7(27):11720–11726. https://doi.org/10.1039/c5nr02674a

Wang F, Zheng J, Qiu J, Liu S, Chen G, Tong Y, Zhu F, Ouyang G (2017) In situ hydrothermally grown TiO<inf>2</inf>@C core−shell nanowire coating for highly sensitive solid phase microextraction of polycyclic aromatic hydrocarbons. ACS Appl Mater Interfaces 9(2):1840–1846. https://doi.org/10.1021/acsami.6b14748

Gutiérrez-Serpa A, Schorn-García D, Jiménez-Moreno F, Jiménez-Abizanda AI, Pino V (2019) Braid solid-phase microextraction of polycyclic aromatic hydrocarbons by using fibers coated with silver-based nanomaterials in combination with HPLC with fluorometric detection. Microchim Acta 186(5):311. https://doi.org/10.1007/s00604-019-3452-3

Zhang X, Zang XH, Wang JT, Wang C, Wu QH, Wang Z (2015) Porous carbon derived from aluminum-based metal organic framework as a fiber coating for the solid-phase microextraction of polycyclic aromatic hydrocarbons from water and soil. Microchim Acta 182(13):2353–2359. https://doi.org/10.1007/s00604-015-1566-9

Jiang H, Hu X, Li Y, Qi J, Sun X, Wang L, Li J (2019) Large-pore ordered mesoporous carbon as solid-phase microextraction coating for analysis of polycyclic aromatic hydrocarbons from aqueous media. Talanta 195:647–654. https://doi.org/10.1016/j.talanta.2018.11.090

Kong J, Zhu F, Huang W, He H, Hu J, Sun C, Xian Q, Yang S (2019) Sol–gel based metal-organic framework zeolite imidazolate framework-8 fibers for solid-phase microextraction of nitro polycyclic aromatic hydrocarbons and polycyclic aromatic hydrocarbons in water samples. J Chromatogr A 1603:92–101. https://doi.org/10.1016/j.chroma.2019.06.063

Dai C, Lin H, Xu G, Liu Z, Wu R, Chen Y (2017) Biocompatible 2D titanium carbide (MXenes) composite nanosheets for pH-responsive MRI-guided tumor hyperthermia. Chem Mater 29(20):8637–8652. https://doi.org/10.1021/acs.chemmater.7b02441

Lin H, Chen Y, Shi J (2018) Insights into 2D MXenes for versatile biomedical applications: current advances and challenges ahead. Adv Sci 5(10):1800518. https://doi.org/10.1002/advs.201800518

Acknowledgements

The authors gratefully acknowledge financial support from Tarbiat Modares University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 348 kb)

Rights and permissions

About this article

Cite this article

Ghaemmaghami, M., Yamini, Y. & Mousavi, K.Z. Accordion-like Ti3C2Tx MXene nanosheets as a high-performance solid phase microextraction adsorbent for determination of polycyclic aromatic hydrocarbons using GC-MS. Microchim Acta 187, 151 (2020). https://doi.org/10.1007/s00604-020-4123-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-020-4123-0