Abstract

A voltammetric analytical assay for the selective quantification of vanillin is described. It is based on the use of a gold nanoparticle-modified screen-printed carbon electrode (SPCE) modified with graphene quantum dots (GQD) in a Nafion matrix. The GQD were synthesized by an acidic thermal method and characterized by UV-Vis, photoluminescence, and FTIR spectroscopy. The modified SPCE displays a strongly enhanced response to vanillin. Linear sweep voltammetry (LSV) and differential pulse voltammetry (DPV) were applied to optimize the methods. The analytical assay has linear responses in the 13 to 660 μM and 0.66 to 33 μM vanillin concentration ranges. The detection limits are 3.9 μM and 0.32 μM when using LSV and DPV, respectively. The analytical assay is selective and stable. It was applied to the determination of vanillin in several food samples with satisfactory results. Recoveries from spiked samples ranged between 92.1 and 113.0%.

The selective and sensitive quantification of vanillin is carried out by the use of a gold nanoparticle-modified screen-printed carbon electrode modified with graphene quantum dots in a Nafion matrix.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Screen-printing technology has emerged as a novel low-cost process to achieve significant advances in the electrochemical detection techniques, with many types of screen- printed carbon electrodes (SPCEs) commercially available [1]. There are many possibilities to customize them for a particular analytical challenge by the incorporation of modifiers such as enzymes, immuno-reagents or noble metals, but also´ by nanomaterials and nanocomposites [2, 3]. Graphene quantum dots (G-QDs) are a type of zero-dimensional carbon-based nanomaterials sharing characteristics from both graphene and carbon dots (CDs) [4, 5]. This fact confers them special and unique characteristics because of the quantum confinement and edge effects- similar to CDs- and excellent properties, such as their superiority in chemical inertness, photostability, biocompatibility, low toxicity, and low-cost compared to other nanomaterials, allowing applications in many fields [4]. Moreover, from an analytical point of view, their high water-solubility makes them potential analytical tools, especially in spectroscopy [6] and electrochemistry [7]. Analytical assays based on G-QDs can achieve a high level of performance. However, much effort is still needed to exploit the full potential of these nanomaterials to develop advanced sensing methods to be applied in several research fields. In this way, the use of G-QDs for the decoration of electrochemical SPCEs requires adequate assembly to improve the electrochemical response. Nafion is a material commonly used as cation conduction and electron barrier membrane; it prevents common interfering agents in the analytical determinations and also enhances the robustness of the NPs on the electrode surface [8]. These factors combine the advantages of G-QDs (higher electrical conductivity, enlarged active surface area) with the unique features of the Nafion film. Therefore, the assembly of G-QDs and Nafion nanocomposite (G-QD@Nafion) onto low-cost electrochemical devices can open new opportunities in the development of analytical electrochemical assay strategies involving nanomaterials for the determination of analytes of interest, improving sensitivity and selectivity.

Vanillin (4-hydroxy-3-methoxybenzaldehyde; pKa = 7.7) is considered one of the most widely used flavoring substances in food, perfumery or beverages. Its extraction from vanilla pods implies a long and expensive process, resulting in high prices in the market. As a result, the majority of the vanillin used is obtained from chemical synthesis, which leads to a lower quality of vanillin. Moreover, the resulting synthetic vanillin still needs further clean-up and extraction procedures to purify it [9], therefore the importance of the yield and purification of this substance. Many analytical methods have been reported for the determination of vanillin, including spectrofluorometry [10], spectrophotometry [11], high pressure liquid chromatography (HPLC) [12], capillary electrophoresis [13], gas chromatography [14], and electrochemistry [15,16,17,18]. Electrochemical methods have gained considerable attention because of their numerous advantages such as fast response, high sensitivity and selectivity, simple operation, and real-time detection under in situ conditions. However, some of the reported methods for vanillin determination required complicated and tedious modified electrochemical devices to achieve good electrochemical performances. This work aimed to contribute to the development of simple ways to improve and customize commercial electrochemical devices for a particular analytical application. To our knowledge, this is the first report involving the assembly of G-QDs and Nafion nanocomposite onto commercial AuNP-SPCEs (G-QD@Nafion/AuNP-SPCEs). Its potential application as an electrochemical assay for the determination of vanillin in several food samples has been demonstrated, achieving short analysis time, and good sensitivity and selectivity.

Experimental

Instruments and apparatus

UV-Vis absorption and fluorescence (FL) spectra were recorded using a spectrophotometer (SECOMAM UVI Light XS 2) and a fluorescence spectrophotometer (Photon Technology International (PTI) Inc. QuantaMaster 40), respectively, using 10 mm quartz cuvettes. Also, the fluorescence of G-QD samples was detected under a handheld UV lamp (model UVLS-28, 115 V ~ 60 Hz, 0.16 A) using a wavelength of 365 nm. FTIR spectra were obtained using an FTIR spectrophotometer (IRAffinity-1, Shimadzu Corporation International Marketing Division, Japan).

Electrochemical experiments were performed with a CHI842D Electrochemical analyzer from CH Instruments Inc. (Austin, Texas, USA). Measurements were performed using a three-electrode configuration, using screen printed (modified) carbon electrodes from Dropsens (Oviedo, Spain), with a carbon counter electrode, a silver pseudo-reference electrode, and a specific working electrode. The working electrodes (4 mm diameter) were carbon (DRP-110), multi-walled carbon nanotubes (DRP-110CNT), single-walled carbon nanotubes (DRP-110SWCNT), gold nanoparticles (DRP-C110GNP) and nanofibers (DRP-C110CNF).

An ultrasound bath (Selecta, Barcelona, Spain), a microcentrifuge Biosan Microspin 12 (LabNet Biotecnica S.L., Madrid, Spain), and a Basic 20 pH-meter with a combined glass electrode (Crison Instruments S.A., Barcelona, Spain) were also used.

Reagents and solutions

Uric acid (≥99.0%) was purchased from Alfa Aesar (www.alfa.com, Ward Hill, MA, USA). Sulfuric acid (ACS/FCC, BDH ARISTAR, 95.0–98%) and acetone (Hipersolv Chromanorm, 100%) were acquired from VWR (https://es.vwr.com/store/, Pittburgh, PA, USA); nitric acid (HNO3; ≥ 69%) was supplied by labkem (www.labbox.com, Mataró, Barcelona, Spain).

4-Hydroxy-3-methoxybenzaldehyde (Vanillin, ≥98%), vanillic acid (≥97%), and sodium tetraborate anhydrous were obtained from Fluka (www.sigmaaldrich.com, Steinheim, Germany). Nafion® 117 solution (5% in a mixture of lower aliphatic alcohols and water), acetic acid (≥99.7%), sodium acetate (≥99.0%), sodium hydroxide (98%), sodium citrate, 4-hydroxybenzaldehyde (98%), 4-hydroxybenzylalcohol (99%), and 4-hydroxy-3-methoxybenzylalcohol (98%) were purchased from Sigma-Aldrich (www.sigmaaldrich.com, Steinheim, Germany).

L-ascorbic acid (≥ 99.7%), methanol (99.9%), and disodium hydrogen phosphate anhydrous (99%) were purchased from Panreac (http://www.panreac.es, Barcelona, Spain). D(+)-maltose, fructose, D(+)-glucose anhydrous, soluble starch, sodium chloride, potassium chloride, Sunset yellow FCF (E-110), riboflavin (vitamin B2), pyridoxine (vitamin B6), sucrose, and lactose were obtained from Sigma-Aldrich (www.sigmaaldrich.com).

All aqueous solutions were prepared using 18.2 MΩ cm (25 °C) water purified with a Milli-Q system (Millipore, Bedford, MA, USA) and analytical grade reagents. Aqueous solutions of 0.02 mol L−1 vanillin were kept in the refrigerator in the darkness. G-QD@Nafion solution was prepared by dispersing the required weight of G-QDs in water, adding 0.5% Nafion (v:v); this solution was prepared by ultrasonication and protected from light until use.

Sample preparation and general procedure

The following samples were purchased at local markets: white-milk chocolate, custard, and white sugar. Sample preparation was carried out as follows. Approximately 5 g of sample was ground to a fine powder. 0.25 g (white-milk chocolate), 0.20 g (white sugar) or 0.15 g (vanillin custard) was placed in a vial with 5 mL of ethanol and ultrasonicated for 30 min. The resulting mixture was centrifuged at 10397 rcf (10,000 rpm) for 10 min. Then, 1 mL of the resulting supernatant was concentrated to dryness under a N2 flow and reconstituted in 1 mL of 0.025 mol L−1 H2SO4. For vanillin determination, suitable concentrations of these samples (or stock solutions) were prepared in 0.025 mol L−1 of H2SO4 (supporting electrolyte). Then, the LSV (potential range: −0.1 to 0.8 V; scan rate: 150 mV s−1; accumulation time at 0.2 V for 20 s) and DPV (amplitude: 0.05 V; pulse: 0.05 s; period: 0.4 s) were recorded in the optimal conditions using a G-QD@Nafion/AuNP-SPCE. The peak height of the voltammograms was used as the analytical signal. All experiments were performed at room temperature.

To ensure the repeatability of the electrode in the voltammetric measurements, all SPCEs were preconditioned by applying five cyclic voltammograms measurements from −0.1 to 1 V in 0.025 mol L−1 H2SO4 as supporting electrolyte before use. This step also provided an adequate cleaning and activation of the electrode surface.

Synthesis of G-QDs and preparation of the modified SPCEs

G-QDs were obtained from uric acid powder as single precursor by acidic-based chemical treatment following a method previously reported in our laboratory [6]. Details are provided in ESM.

1 mg mL−1 G-QD@Nafion dispersion in water was used for the modification of the different SPCEs (DRP-110, DRP-110CNT, DRP-110SWCNT, DRP-C110GNP and DRP-C110CNF). Each modified electrode was prepared by casting 6 μL of the suspension of G-QD@Nafion onto the surface of the electrode. After drying under infrared light for 15 min, it was rinsed with deionized water before use.

Results and discussion

Selection and characterization of G-QD@Nafion/SPCE

G-QD nanoparticles were used to modify the surface of different commercial SPCEs to evaluate the improvement of their analytical response towards vanillin. Nafion (5% in a mixture of lower aliphatic alcohols and water) was added to G-QDs in water as attaching agent since the interfusion of G-QD nanoparticles into the Nafion film solution forms a homogeneous and stable suspension which increases the robustness of the NPs on the electrode surface. In addition, it also prevents their release from the electrode surface since G-QDs are very water-soluble [8]. To evaluate the effectiveness of the electrode surface modification, 6 μL G-QD@Nafion (1 mg mL−1) were dropped onto the SPCE surface and subsequently dried under IR lamp for 15 min. Then, the LSV at a scan rate of 100 mV s−1 was recorded. LSV was used instead of cyclic voltammetry (CV) because of the irreversible electrochemical reaction. The enhancement observed by the addition of G-QD@Nafion to each of the SPCEs tested is shown in Fig. 1 for 0.13 mmol L−1 vanillin in 0.1 mol L−1 phosphate buffer at pH 8. Even though differences are observed in all the SPCEs, the highest improvement in the electrochemical response is observed for AuNP-SPCE, observing no changes in the voltammogram profile. Therefore, this SPCE was selected for following experiments.

The volume and concentration of G-QDs dropped on AuNP-SPCE surface were also evaluated. Volumes between 6 and 10 μL were tested, observing that 6 μL completely covered the working electrode, hence selecting this volume. Three different dilutions of G-QD@Nafion were tested (0.5, 1, and 2 mg mL−1 GQDs). An enhancement of the analytical response was observed in the presence of 1 mg mL−1 of G-QD@Nafion, whereas no improvement was achieved for other concentrations. Therefore, this G-QD@Nafion concentration was selected for subsequent experiments.

The characterization of G-QDs and G-QD@Nafion/AuNP-SPCE was carried out. The fluorescence and absorbance spectra of G-QD are shown in Fig. 2. It can be seen a characteristic fluorescence emission at 452 nm (exciting at 362 nm) and absorbance spectra with an absorption peak at 260 nm. The FTIR spectrum of G-QDs, AuNP-SPCE, and G-QD@Nafion/AuNP-SPCE were also recorded to verify that G-QDs were efficiently deposited onto the surface of the SPCEs (Electronic Supplementary Material). Characteristic bands of the main functional groups of G-QD such as the υC-O at 1068 cm−1 or υC-H at 3075 cm−1 and 1407 cm−1 are observed [6]. Because of the unique properties of G-QDs and their high conductivity, these nanomaterials can be good candidates to improve the conductivity of SPCEs. This behavior may enhance and thus accelerate the electron transfer between the electrodes and target molecules, even improving the selectivity of the analytical method.

Electrochemical behavior of vanillin

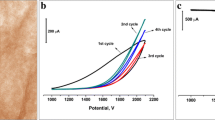

The CV of vanillin can be observed in Fig. 3; it shows the CV of 0.13 mmol L−1 vanillin in 0.025 mol L−1 H2SO4 at AuNP-SPCE with different modifications, at a scan rate of 100 mV s−1. The results show a main anodic peak of vanillin in the different electrodes – ranging from 0.36 to 0.46 V – and a secondary peak around 0.2 V. A cathodic peak is also observed in the reverse scan; this peak is also present in the absence of vanillin, although of weaker signal. This fact suggests that the electrochemical reaction is an irreversible process. As previously mentioned, the oxidation peak current value (Ip) of vanillin at G-QD@Nafion/AuNP-SPCE is incremented in a 30% compared with the unmodified AuNP-SPCE. These results indicate that the decoration of AuNP-SPCE with G-QD@Nafion improve the characteristics of vanillin oxidation significantly.

(a) LSV of increasing concentrations of vanillin from 6.6 to 657 μmol L−1 in 0.025 mmol L−1 H2SO4 as supporting electrolyte at G-QD@Nafion/AuNP-SPCE at scan rate of 150 mV s−1 and (b) DPV of increasing concentrations of vanillin from 0.33 to 49 μmol L−1 in 0.025 mmol L−1 H2SO4 as supporting electrolyte in the optimal conditions (amplitude: 50 mV; pulse: 0.05 s and period: 0.4 s) at G-QD@Nafion/AuNP-SPCE

The effect of the scan rate (υ) on the electrochemical response was studied between 25 and 600 mV s−1 using CV. A solution of 0.13 mmol L−1 vanillin in 0.025 mol L−1 H2SO4 was used in all experiments. The main oxidation peak current of vanillin (Ipa) increased with a scan rate increase; this increment was proportional to the square root of the scan rate from 25 to 200 mV s−1. The relationship plot equation was: Ipa (μA) = 1.209 x υ1/2 (mV1/2 s-1/2) + 0.108, with a coefficient of determination of R2 = 0.996. This fact indicates that the electrochemical reaction of vanillin is a diffusion-controlled process on the surface of the electrode. However, when the scan rate ranged from 250 to 600 mV s−1 the main oxidation peak current of vanillin was proportional to the scan rate. The relationship plot equation was: Ipa (μA) = 28.419 x υ (mV s−1) – 225.301; R2 = 0.997. This fact indicates that the electrode process in this scan rate interval is a surface reaction-controlled.

From these results it can be concluded that the electrochemical process of vanillin is a combination of diffusion and adsorption controlled processes, depending on the scan rate [19, 20]. Additionally, the dependence of peak potential to the scan rate suggests that vanillin reaction is electrochemically irreversible at the G-QD@Nafion/AuNP-SPCE.

Optimization of the method for the determination of vanillin

The following parameters were optimized for LSV and DPV, as required: (a) composition and concentration of supporting electrolyte (LSV and DPV); (b) accumulation potential and time (LSV); (c) pulse width and amplitude, and scan rate (DPV). Detailed data and figures are shown in the Electronic Supporting Material. The following parameters were selected as optimum: (a): 0.025 mol L−1 H2SO4 as supporting electrolyte; (b) accumulation potential of 0.2 V for 20 s; (c) pulse width of 50 ms and an amplitude of 50 mV at a scan rate of 20 mV s−1.

Analytical performance of the method using G-QD@Nafion/AuNP-SPCE

The precision of the analytical signal and the stability of the G-QD@Nafion/AuNP-SPCE were evaluated for the determination of vanillin. To estimate the repeatability, the same SPCE was used for ten successive measurements of 0.13 mmol L−1 vanillin, and the relative standard deviation (RSD) of the oxidation peak current was 2.9% using DPV, which indicate the possibility of reusing the electrode. Additionally, the long-term stability of the electrode was also investigated over a period of four weeks. To this end, the same electrode was stored in a glass Petri dish at room temperature and protected from light. The anodic current peak recorded over the studied period retained 95% of its original response. This fact indicates the possibility of using the same electrode for a month without loss of significant sensitivity. To estimate the inter-electrode precision of the modification process of the SPCEs, three different SPCE were modified in the same conditions, and the signal for 0.13 mmol L−1 vanillin was recorded. A RSD value of 4.5% (n = 5) was obtained, which indicates the reliability of the modification procedure of the electrode and the repeatability in the determination of vanillin.

Under the optimized conditions, voltammograms for increasing concentrations of vanillin are shown in Fig. 3. Data were obtained using the maximum oxidation peak current value and fitted by standard least-squares calibration (Fig. S4, Electronic Supplementary Material). On the one hand, LSV detection and quantification limits (3σ and 10σ criterion) were 3.9 × 10−6 mol L−1 and 1.3 × 10−5 mol L−1. On the other hand, higher sensitivity was observed by DPV, obtaining detection and quantification limits of 3.2 × 10−7 mol L−1 and 6.6 × 10−7 mol L−1. The repeatability (n = 10) was lower than 5% with both detection techniques. All the analytical parameters are summarized in Table S1 (Electronic Supplementary Material). These results demonstrate that the method is well suited for the determination of vanillin in food. Although LSV presents satisfactory sensitivity, the use of DPV would lower the detection limits if necessary. However, LSV has been selected to carry out the interference study and analytical applications, due to its widespread use.

A comparison of the detection limit and characteristics of other electrodes for the quantification of vanillin is shown in Table 2. It can be observed that the detection limit of the present method is similar to some reported works, although higher sensitivity is observed in other electrochemical methods. In most cases, the synthesis and modification of the electrodes are complicated and time-consuming, whereas the preparation of the G-QD@Nafion/AuNP screen-printed electrode is straightforward and quick. However, a sample pre-treatment and pre-concentration would be required to analyze lower vanillin concentrations.

The potential interference in the analytical signal of vanillin was investigated for: a) compounds with similar structure (vanillic acid, 4-hydroxybenzaldehyde, 4-hydroxybenzyl alcohol, 4-hydroxy-3-methoxy benzylalcohol); b) other species that are likely to be present in the analyzed samples (colorant E-110, sugars, ions, etc.) (Table S2 in ESM). This study was carried out with a solution of 6.5 × 10−5 mol L−1 vanillin prepared in 0.025 mol L−1 H2SO4. No interferences were considered if the variation of the analytical signal was lower than 5%. All the results are detailed in Table S2 (ESM). Depending on the potential concentration of the interferents, different interferent/analyte ratios were tested. Although low interferent/ratios were obtained for some compounds, these ratios are suitable because those compounds would be present in very low amounts compared to vanillin. For instance, vanillic acid/vanillin ratio is 0.4, but vanillic acid is expected to be present at concentrations ten times lower than vanillin [16]. Although the potential interference effect was studied individually for each species, we also studied the matrix effect and used an HPLC reference method to confirm the accuracy of the results. Hence, the method can be successfully applied to the detection and determination of vanillin in food samples.

Analytical applications

The method was applied to the determination of vanillin in several foods: custard, white-milk chocolate, and white sugar. All the samples were firstly pretreated according to the procedure described in “Sample preparation and general procedure” section. Taking into account that there was matrix effect in some samples, we used the standard addition method for the analysis of all samples. Only custards presented vanillin at a quantifiable concentration. Therefore, recovery experiments were performed at different vanillin levels. Samples were spiked with a suitable volume of vanillin stock solution, homogenized, extracted as mentioned in “Sample preparation and general procedure” section, and analyzed. Recoveries ranging between 92.1 and 113.0% were observed. All samples were also analyzed with an HPLC reference method [28], observing no significant differences in the results.

The method of the averaged recovery [29] was used to assess the accuracy of the method. In this test, the mean recovery is calculated from the individual recoveries (Table 1). This value is then tested for significance using the Student t-test. We obtained an experimental t value of 1.154 (n = 9), lower than the tabulated t value of 1.860 (n-1 degrees of freedom and a 95% confidence level). The method was thus considered accurate. All the results are shown in Table 1. This method exhibits several advantages over other used techniques, such as low environmental impact, low-cost and rapid procedure.

Conclusions

A novel approach to improve and customize commercial electrochemical devices, based on their modifications with novel nanoparticles, has been proposed for the determination of vanillin. The assembly of G-QD@Nafion nanocomposite onto commercial AuNP-SPCE showed excellent analytical performance, highlighting the signal enhancement of 30% of the electrochemical response of vanillin. Although other electrochemical methods (Table 2) presented higher sensitivity, the rapid modification of the commercial screen-printed electrodes compensates the lower sensitivity. Also, the precision and accuracy of this analytical method were demonstrated by inter-electrode tests, interference study, and comparison with an HPLC reference method. The analytical assay here reported makes G-QD@Nafion/AuNP-SPCE interesting candidates to be used in the building of novel electrochemical assays for other substances, considering that additional modifications and sample treatments would be required according to the intended applications. We hope that this approach can open new ways of modifications of commercial electrodes, increasing their analytical potential.

References

Jubete E, Loaiza OA, Ochoteco E, Pomposo JA, Grande H, Rodríguez J (2009) Nanotechnology: a tool for improved performance on electrochemical screen-printed (bio)sensors. J Sens. https://doi.org/10.1155/2009/842575

Buleandra M, Rabinca AA, Tache F, Moldovan Z, Stamatin I, Mihailciuc C, Ciucu AA (2017) Rapid voltammetric detection of kojic acid at a multi-walled carbon nanotubes screen-printed electrode. Sensors Actuators B Chem 241:406–412

Punrat E, Maksuk C, Chuanuwatanakul S, Wonsawat W, Chailapakul O (2016) Polyaniline/graphene quantum dot-modified screen-printed carbon electrode for the rapid determination of Cr(VI) using stopped-flow analysis coupled with voltammetric technique. Talanta 150:198–205

Shen JH, Zhu YH, Yang XL, Li CH (2012) Graphene quantum dots: emergent nanolights for bioimaging, sensors, catalysis and photovoltaic devices. Chem Commun 48:3686–3699

Zhu SJ, Tang SJ, Zhang JH, Yang B (2012) Control the size and surface chemistry of graphene for the rising fluorescent materials. Chem Commun 48:4527–4539

Duran GM, Benavidez TE, Contento AM, Ríos A, Garcia CD (2017) Analysis of Penicillamine using cu-modified graphene quantum dots synthetized from uric acid as single precursor. J Pharm Anal 7:324–331

Lim CS, Hola K, Ambrosi A, Zboril R, Pumera M (2015) Graphene and carbon quantum dots electrochemistry. Electrochem Commun 52:75–79

Pang P, Yan F, Li H, Li H, Zhang Y, Wang H, Wu Z, Yang W (2016) Graphene quantum dots and Nafion composite as an ultrasensitive electrochemical sensor for the detection of dopamine. Anal Methods 8:4912–4918

Ramachandra Rao S, Ravishankar GA (2000) Vanilla flavour: production by conventional and biotechnological routes. J Sci Food Agric 80:289–304

Durán GM, Contento AM, Ríos A (2015) β-Cyclodextrin coated CdSe/ZnS quantum dots for vanillin sensoring in food samples. Talanta 131:286–291

Ni Y, Zhang G, Kokot S (2005) Simultaneous spectrophotometric determination of maltol, ethyl maltol, vanillin and ethyl vanillin in foods by multivariate calibration and artificial neural networks. Food Chem 89:465–473

Pyell U, Pletsch-Viehmann B, Ramus U (2002) Component analysis of vanilla extracts and vanilla containing commercial preparations by micellar electrokinetic chromatography or high-performance liquid chromatography – a method comparison. J Sep Sci 25:1035–1042

Ohashi M, Omae H, Hashida M, Sowa Y, Imai S (2007) Determination of vanillin and related flavor compounds in cocoa drink by capillary electrophoresis. J Chromatogr A 1138:262–267

Perez-Silva A, Odoux E, Brat P, Ribeyre F, Rodriguez-Jimenes G, Robles-Olvera V (2006) GC–MS and GC–olfactometry analysis of aroma compounds in a representative organic aroma extract from cured vanilla (Vanilla Planifolia G. Jackson) beans. Food Chem 99:728–735

Liu Y, Liang Y, Lian H, Zhang C, Peng J (2015) Sensitive Voltammetric determination of vanillin with an electrolytic manganese dioxide−graphene composite modified electrode. Int J Electrochem Sci 10:4129–4137

Huang L, Hou K, Jia X, Pan H, Du M (2014) Preparation of novel silver nanoplates/graphene composite and their application in vanillin electrochemical detection. Mater Sci Eng C 38:39–45

Bettazzi F, Palchetti I, Sisalli S, Mascini M (2006) A disposable electrochemical sensor for vanillin detection. Anal Chim Acta 555:134–138

Silva TR, Brondani D, Zapp E, Vieira IC (2015) Electrochemical sensor based on gold nanoparticles stabilized in poly(Allylamine hydrochloride) for determination of vanillin. Electroanalysis 27:465–472

Gao F, Cai X, Wang X, Gao C, Liu S, Gao F, Wang Q (2013) Highly sensitive and selective detection of dopamine in the presence of ascorbic acid at graphene oxide modified electrode. Sensors Actuators B Chem 186:380–387

Yanga S, Lia G, Yinb Y, Yangb R, Lib J, Qu L (2013) Nano-sized copper oxide/multi-wall carbon nanotube/Nafion modified electrode for sensitive detection of dopamine. J Electroanal Chem 703:45–51

Yardım Y, Gülcan M, Şentürk Z (2013) Determination of vanillin in commercial food product by adsorptive stripping voltammetry using a boron-doped diamond electrode. Food Chem 141:1821–1827

Zhao Y, Du Y, Lu D, Wang L, Ju DMT, Wu M (2014) Sensitive determination of vanillin based on an arginine functionalized graphene film. Anal Methods 6:1753–1758

Wu W, Wang H, Yang L, Zhao F, Zeng B (2016) Sensitively Voltammetric determination of vanillin with a molecularly imprinted ionic liquid polymer-carboxyl SingleWalled carbon nanotubes composite electrode. Int J Electrochem Sci 11:6009–6022

Shang L, Zhao FQ, Zeng BZ (2014) Sensitive voltammeric determination of vanillin with an AuPd nanoparticles-graphene composie modified electrode. Food Chem 151:53–57

Deng P, Xu Z, Zeng R, Ding C (2015) Electrochemical behavior and voltammetric determination of vanillin based on an acetylene black paste electrode modified with graphene-polyvinylpyrrolidone composite film. Food Chem 180:156–163

Kalaiyarasi J, Meenakshi S, Pandian K, Gopinath SCB (2017) Simultaneous voltammetric determination of vanillin and guaiacol in food products on defect free graphene nanoflakes modified glassy carbon electrode. Microchim Acta 184:2131–2140

Sivakumar M, Sakthivel M, Chen S-M (2017) Simple synthesis of cobalt sulfide nanorods for efficient electrocatalytic oxidation of vanillin in food samples. J Colloid Interface Sci 490:719–726

Waliszewski KN, Pardio VT, Ovando SL (2006) A simple and rapid HPLC technique for vanillin determination in alcohol extract. Food Chem 101:1059–1062

González AG, Herrador MA, Asuero AG (1999) Intra-laboratory testing of method accuracy from recovery assays. Talanta 48:729–736

Acknowledgments

The Spanish Ministry of Economy and Competitiveness (MINECO) is gratefully acknowledged for funding this work with Grant CTQ2016-78793-P. E.J. Llorent-Martínez acknowledges the financial support from the UCLM Research Plan. Gema M. Durán also acknowledges the financial support from the JCCM research contract.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 767 kb)

Rights and permissions

About this article

Cite this article

Durán, G.M., Llorent-Martínez, E.J., Contento, A.M. et al. Determination of vanillin by using gold nanoparticle-modified screen-printed carbon electrode modified with graphene quantum dots and Nafion. Microchim Acta 185, 204 (2018). https://doi.org/10.1007/s00604-018-2738-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-018-2738-1