Abstract

We describe a nonenzymatic electrochemical sensor for uric acid. It is based on a carbon nanotube ionic-liquid paste electrode modified with poly(β-cyclodextrin) that was prepared in-situ by electropolymerization. The functionalized multi-walled carbon nanotubes and the surface morphology of the modified electrodes were characterized by transmission electronic microscopy and scanning electron microscopy. The electrochemical response of uric acid was studied by cyclic voltammetry and linear sweep voltammetry. The effects of scan rate, pH value, electropolymerization cycles and accumulation time were also studied. Under optimized experimental conditions and at a working voltage of 500 mV vs. Ag/AgCl (3 M KCl), response to uric acid is linear in the 0.6 to 400 μΜ and in the 0.4 to 1 mΜ concentration ranges, and the detection limit is 0.3 μΜ (at an S/N of 3). The electrode was successfully applied to the detection of uric acid in (spiked) human urine samples.

SEM images of (a) carbon ionic liquid electrode (CILE) (b) MWNT-CILE (c) β-CD/CILE (d) β-CD/ MWNT-CILE. The surfaces of carbon ionic liquid electrode (CILE) (a) and MWNT-CILE (b) were homogenous and no separated carbon layers can be observed; After β- cyclodextrin (CD) was modified on CILE and MWNT-CILE, the surfaces of β-CD modified electrodes (c and d) exhibited loose and porous morphologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

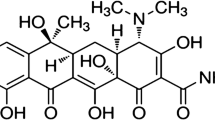

Uric acid (UA) is the end product of purine metabolism. The abnormal concentration levels of uric acid indicate the symptoms of diseases such as gout, hyperuricemia, and Lesch-Nyhan syndrome [1]. Therefore, it is important to detect uric acid selectively and simply in the diagnosis and treatment of diseases. The enzyme-based biosensors usually suffer from disadvantages such as complicated preparation, high costs, poor stability and low reproducibility. Recently, non-enzymatic electrochemical sensors have been developed for the determination of uric acid [2–4]. In order to improve the selectivity and sensitivity of non-enzymatic sensors, various materials are used for modifying basal electrodes.

Carbon composite electrodes have attracted the interest of many scientists in the relevant fields. In comparison with traditional carbon paste electrodes (CPE), carbon composite electrodes using ionic liquids as binders show high conductivity, provision of fast electron transfer and antifouling properties, resulting in the improvement of voltammetric signal (overpotential decrease, decrease in the difference between peak potentials and peak current increase) [5–8].

As a classical nanomaterial, carbon nanotubes have proved to be an excellent modifier due to their unique structural and electronic properties (such as large surface area, high electrical conductivity and so on). Recently, carbon nanotube ionic liquid paste electrodes have been developed for biological, environmental and pharmaceutical analysis [9–15]. Studies demonstrate that these electrodes can lower the overpotential, promote electron-transfer rate, accumulate important biomolecules, enhance the electrocatalytic reactivity and alleviate surface fouling effects.

Cyclodextrins (CDs) are oligosaccharides possessing a toroidal form with a hydrophobic inner cavity and a hydrophilic outer side [16]. As molecular receptors, cyclodextrins can form stable inclusion complexes or nanostructure supramolecular assemblies with a wide variety of organic and inorganic compounds in its hydrophobic cavity through host-guest interactions (such as hydrophobic effect, van der Waals interactions, hydrogen bonding and so on) [17], showing high molecular selectivity and enantioselectivity [18]. UA shows very strong electrochemical activity, and it can be irreversibly oxidized in aqueous solution [19]. As a guest molecule, uric acid can form inclusion complexes with cyclodextrins through hydrophobic and hydrogen-bonding interaction [20]. Therefore, cyclodextrins as modifiers can improve the sensitivity and selectivity of sensor.

We constructed a poly(β-cyclodextrin) modified multi-walled carbon nanotube ionic liquid paste electrode (β-CD/MWNT-CILE) for electrocatalytic oxidation of uric acid. On the one hand, β-CD can be easily modified on MWNT-CILE by electropolymerization, and the thickness of the polymer films can be controlled by the number of cycles. On the other hand, the polymer membranes on the surface of the modified electrodes are more compact and stable due to the synergy of carbon nanotubes and ionic liquid. In comparison to the reported β-CD modified electrodes [21, 22], β-CD/MWNTs-CILE exhibit wider linear ranges and lower detection limits. In addition, it was successfully applied to the determination of UA in human urine samples without any pretreatment and with satisfying results.

Experimental

Chemicals

The ionic liquid 1-butylpyridinium hexafluorophosphate (BPPF6) was purchased from Lanzhou Institute of Chemical Physics (Lanzhou, China, http://www.ionicliquid.org), graphite powder (spectrographic grade) was obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China, http://www.sinoreagent.com). Uric acid, dopamine (DA), ascorbic acid (AA) and β-cyclodextrin were purchased from Sigma (http://www.sigmaaldrich.com). Multi-walled carbon nanotubes with a diameter of about 10–30 nm were purchased from Nanjing XFNANO Materials Tech Co., Ltd. (Nanjing, China, http://www.xfnano.com). 0.2 M acetate buffer (ABS) of various pH values were used as the supporting electrolytes. All other reagents were of analytical grade, and were used without further purification.

Apparatus

All electrochemical measurements (except electrochemical impedance spectroscopy measurements) were performed using a CHI660E electrochemical workstation (Shanghai Chenhua Instruments Corporation, shanghai, China, http://www.chinstr.com). The electrochemical impedance spectroscopy (EIS) measurements were carried by a PARSTAT 4000 (Princeton Applied Research, America, http://www.par-solartron.com.cn). A three electrode system was used containing a poly(β-cyclodextrin) modified carbon nanotubes ionic liquid paste electrode (3.0 mm in diameter) as working electrode, a platinum wire as auxiliary electrode, and a Ag/AgCl (3 M KCl) electrode as reference electrode. All potentials were reported with respect to the reference electrode. A magnetic stirrer (Model 85–2) was used to stir the testing solution before measurements. The transmission electron micrographs (TEM) were obtained with a Hitachi H-7650 transmission electron microscopy (Hitachi Ltd., Tokyo, Japan). The scanning electron micrographs (SEM) were obtained with a Hitachi S-3400 scanning electron microscope (Hitachi Ltd., Tokyo, Japan). All the experiments were carried out at room temperature.

Pretreatment of multi-walled carbon nanotubes

Pretreatment of multi-walled carbon nanotubes (MWNTs) was carried out according to the reported method [23], MWNTs were firstly heated in air at 600 °C for 2 h, and then immersed in 6 M HCl solution for 24 h and centrifuged. The sediment was washed using ultrapure water, and then dried in air. The functionalized MWNTs were obtained by ultrasonic agitation for 10 h in a mixture of sulfuric acid and nitric acid (V/V, 3:1). Then MWNTs were rinsed with ultrapure water until pH value was 7.0. Finally, the functionalized MWNTs were separated by centrifuging three times and dried. The TEM image of the functionalized MWNTs was shown in Fig. 1.

Electrode preparation

The carbon nanotube-modified ionic liquid paste electrode (MWNT-CILE) was prepared as follows. Firstly, carbon nanotubes were mixed with graphite powder in a ratio of 6/94 (w/w). Secondly, the mixture and BPPF6 with a ratio of 1/1 (w/w) were ground in a mortar and then a portion of the resulting paste was packed firmly into the cavity (3.0 mm in diameter) of a Teflon holder. The electrode was then heated using a hair drier for 2 min. It was then left to cool to room temperature. The electric contact was established via a copper wire. A new surface was obtained by smoothing the electrode onto a weighing paper. For comparison, the carbon ionic liquid electrode (CILE) was prepared by mixing the graphite powder and BPPF6 with a ratio of 1/1 (w/w) without MWNTs. In addition, the traditional carbon paste electrode was made up of graphite powder and paraffin oils.

Electropolymerization of β-CD on MWNT-CILE or CILE was carried out by cyclic voltammetry (CV): Successive cycles was run in 1 M HClO4 solution containing 0.01 M of β-CD from - 0.80 V to 1.35 V, with a scan rate (v) of 50 mV s−1. The thickness of β-CD layer was controlled by the numbers of scanning cycles. After cycles, the modified electrode was moved from the solution and washed by ultrapure water. The final electrode was denoted as β-CD/MWNTs-CILE or β-CD/CILE. When not in use, the sensor was kept in air with a cover to protect it from dust.

Results and discussions

Choice of materials

All kinds of carbon materials have been used for the preparation of composite electrodes. In the past years carbon nanotubes have been widely applied in many fields due to their unique structural and electronic properties. Recently, graphene as a promising candidate has been rapidly developed. In the same experiment conditions we used a carbon nanotubes modified electrode and a graphene modified electrode for investigating the electrochemical behaviours of uric acid. In comparison to the graphene modified electrode, the carbon nanotubes modified electrode exhibited lower back ground current and better electrocatalytic activities toward to uric acid. Therefore, we chose carbon nanotubes as modified materials but not graphene.

Due to their high ionic conductivity and good viscosity, ionic liquids have been widely used for the construction of electrochemical sensors. They exhibit two states at room temperature, solid state and liquid state. When ionic liquids are used as binders for preparing carbon paste electrode instead of paraffin oil, we usually choose the ionic liquid in solid state. The electrode is then heated in order to melt the ionic liquid in the carbon paste. Because ionic liquids undergo the processes of melt-solidification, the structure of the ionic liquid modified electrode becomes more compact, and the back ground current remarkably decreases. In addition, we also need consider the melting point of solid state ionic liquids. The melting point of 1-butylpyridinium hexafluorophosphate (BPPF6) is about 75 °C, which is not too high or too low. The melting point is too high to melt by heating. However, melting point is too low, ionic liquids may partly melt at room temperature (especially in hot weather), which may make stability of the modified electrode worse.

Although molecular imprinting electrochemical sensors show better selectivity to template molecules, their preparation are complicated. The molecular imprinting synthesis process contains pre-arrangement step, copolymerization step and extraction step. However, cyclodextrins also show high molecular selectivity and enantioselectivity. Uric acid can form inclusion complexes with β-cyclodextrin through hydrophobic and hydrogen-bonding interaction. Considering that the modification of β-CD is simple, β-CD is used for improving the selectivity of the sensor.

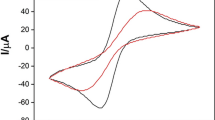

Electropolymerization of β-cyclodextrin

Figure 2 shows electropolymerization graphs of β-CD at CILE (a) and MWNT-CILE (b) in 1 M HClO4 containing 0.01 M β-CD. A pair of redox peaks appeared at about 0.45 V at both electrodes. In the electropolymerization process, redox peak currents increased gradually with successive scanning in the range of - 0.80 V to + 1.35 V, indicating that β-CD was successfully immobilized on the electrode surface. From the figure, during the electropolymerization process the last peak current (about 40.80 μA) at the MWNT-CILE was about 2.5 times than that of CILE (about 16.70 μA). The phenomenon may be ascribed to the following aspects: The effective surface area of the modified electrode increased as MWNTs were modified onto CILE, allowing more β-CD to polymerize on the surface of electrode; In addition, MWNTs with their good electrical conductivity improve the conductivity of the electrodes and promote the electron transfer between the electrode and analytes.

Morphological characterization

Scanning electron microscopy (SEM) was used for characterizing the surface morphologies of different electrodes. As shown in Fig. 3a, the surface of CILE was uniform and no separated carbon layers can be observed. Due to its high viscosity, ionic liquid was easily filled into the interstice between graphite layers and bridged the carbon flakes. However, carbon paste matrices incorporated with carboxylated MWNTs (Fig. 3b) showed a homogenous and uneven surface, and the tube morphologies of MWNTs disappeared, which indicated that the modifiers were embedded in the matrix. Figure 3c and d exhibited loose and porous morphologies at β-CD/CILE and β-CD/MWNTs-CILE. The changed surface confirmed that poly(β-CD) film was coated on the surface of CILE or MWNT-CILE. Compared with β-CD/CILE, a more dense film was observed on the surface of β-CD/MWNT-CILE. This indicated that more β-CD was polymerized on the surface.

Electrochemical characterization

The electrochemical performances of different electrodes were characterized by cyclic voltammetry. Figure 4 demonstrates the cyclic voltammograms of 5.0 mM Fe(CN)6 3−/4− solution containing 0.1 M KCl solution at CILE (a), MWNT-CILE (b), β-CD/CILE (c) and β-CD/MWNT-CILE (d), respectively. A pair of well-defined redox peaks was observed at the CILE (Curve a), indicating that ionic liquid in the carbon paste promote the electron transfer rate and improve the electrochemical performances due to its high ionic conductivity. After modification of MWNTs (Curve b), the anodic and cathodic peak currents both increased, indicating that MWNTs increased the electroactive surface area and the conductivity of the electrode. On the β-CD/CILE (Curve c) the redox peak currents were also enhanced together with an obvious increase of the peak-to-peak separation (ΔEp), which was attributed to the molecular recognition ability and poor conductivity of β-CD. Because of the synergetic effect of MWNTs and β-CD, the redox peak currents further increased at the β-CD/MWNT-CILE (Curve d), which indicated favorable electrochemical behaviors.

Electrochemical impedance spectroscopy measurements are employed for further characterization of the modified electrodes, and the results are shown in Fig. S1 (Electronic Supplementary Material, ESM). The inset of Fig. S1 exhibits the equivalent circuit for impedance spectroscopy, and it contains the solution/electrolyte resistance (Rs), capacitance (C), charge transfer resistance (Rct), and Warburg impedance (Zw). The capacitance changes are not sensitive as the Rct, and the Rct is directly related to the electron transfer kinetics of the redox probe at the surface of the electrode. The Rct value can be calculated by measuring the diameter of the high-frequency semicircle in the Nyquist plots, so it is used for investigating electron transfer rate of the modified electrode. The Rct value at the CPE was got as 27.9 KΩ. While on the CILE, the Rct value dramatically decreased to 13.7 Ω. The electron transfer rate of CILE was greatly enhanced, which might be attributed to the high conductive IL. The Rct value at the MWNTs-CILE further decreased to 3.9 Ω, it may be ascribed to the large surface area and the good conductivity of MWNTs. After β-CD was coated onto the CILE and MWNTs-CILE, the Rct values were increased to 19.9 Ω and 23.5 Ω, respectively. The phenomenons indicated that the β-CD hindered the diffusion of ferricyanide toward the electrode surface. The Rct value at the β-CD/MWNT-CILE was larger than that at the β-CD/CILE, which indicated that more β-CD with poor conductivity was polymerized on the surface of MWNT-CILE.

Surface area study

The surface areas of the CILE and MWNTs-CILE were discussed by cyclic voltammetry in 5.0 mmol L−1 [Fe(CN)6]3-/4- and 0.1 mol L−1 KCl solution. The cyclic voltammograms of CILE and MWNTs-CILE at different scan rates are shown in Fig. S2 (ESM). For a reversible process, the peak current (Ip) is linearly proportional to square root of scan rates (v1/2) as follows (the Randles-Sevcik formula) [24]:

where Ip refers to the anodic peak current (A), n is the electron transfer number, A is the surface area of the electrode (cm2), C0 is concentration of K3Fe(CN)6 (mol L−1) and v is the scan rate (V s−1). For K3Fe(CN)6, the electron transfer number n = 1 and the diffusion coefficient DR = 7.60 × 10−6 cm2 s−1 (0.1 mol L−1 KCl). Thus, from the slope of the anodic peak current (Ipa) versus square root of scan rate (v1/2) relation, the surface area of MWNT-CILE was calculated to be 0.4388 cm2, which was about 2.3 times greater than that for CILE (0.1917 cm2). The electrode geometric area is 0.0707 cm2, indicating that the effective electroactive surface of the modified electrode was remarkably increased in the presence of MWNTs and ionic liquids.

Electrochemical behaviors of uric acid

The electrochemical behaviors of uric acid on different electrodes were investigated by linear sweep voltammetry. Figure 5 shows linear sweep voltammograms of 50 μM uric acid in 0.2 M acetate buffer (pH 5.0) on the CILE (a), MWNT-CILE (b), β-CD/CILE (c) and β-CD/MWNT-CILE (d), respectively. A small peak is observed at a bare CILE (Curve a). Compared with CILE, at a MWNT modified electrode (MWNT-CILE, Curve b) and a β-CD modified electrode (β-CD/CILE, Curve c), the peak current signals of uric acid both enhanced significantly. These phenomenons may be explained as follows: MWNTs showed strong catalytic activity toward the oxidation of uric acid due to their good conductivity and large surface area; β-CD also showed the ability of molecular recognition for analytes, namely UA and β-CD could form UA: β-CD inclusion complex, resulting in enhancement of surface accumulation of uric acid. From the Fig. 5d, a large oxidation peak is observed at the β-CD/MWNT-CILE. The enhancement in current response is attributed to the synergetic effect of MWNTs and β-CD.

Effect of scan rate

The influence of scan rate (from 10 to 100 mV s−1) on the oxidation peak current of uric acid at the β-CD/MWNT-CILE was studied using linear sweep voltammetry (not shown). The peak current of uric acid varied linearly with the scan rate, and the linear regression equation was: I(μA) = 0.5050 ν (mV s−1) + 4.1504 (r2 = 0.9966), indicating that electrochemical behavior of uric acid at the modified electrode was controlled by adsorption. At higher scan rate, the dependence of the peak potential (Epa) and ln(ν) showed a linear relationship with a regression equation of:

According to the following equations [5, 25]:

With

where Epa is the oxidation peak potential, E0’ is the formal potential, v is the sweep rate, ks is the electron transfer rate constant, α is the electron transfer coefficient, na is the electron transfer numbers (na = 2 in this paper), R = 8.314 J mol−1 K−1, T = 298 K and F = 96,485 C mol−1. The value of m was calculated to be 0.0562. Therefore, the electron transfer coefficient (α) was approximately 0.77 for the irreversible electrode process.

Optimization of the experimental conditions

The experimental conditions, which affect the determination of uric acid, including the pH of supporting electrolyte (shown in Fig. S3, ESM), film thickness (shown in Fig. S4, ESM) and accumulation time (shown in Fig. S5, ESM) were optimized. The data and results are shown in the Supporting Information.

Calibration plot and limit of detection

Figure 6 shows linear sweep voltammograms for different concentrations of uric acid in the presence of 0.25 mM ascorbic acid at the modified electrode. In a 0.2 M acetate buffer (pH 5.0), the oxidation peaks of uric acid and ascorbic acid are well separated. The sensor showed good catalytic ability to a low concentration of uric acid but exhibited poor sensitivity to a high concentration of ascorbic acid. The possible explanations can be described as follows: Ascorbic acid existed in the anionic form, while uric acid existed in the neutral form in a solution of pH 5.0. β-CD more strongly interacted with neutral uric acid than anionic ascorbic acid, so it encapsulated uric acid while repelled ascorbic acid. Due to the formation of UA: β-CD inclusion complexes, the modified electrode presented excellent accumulation and electrocatalytic activities toward the oxidation of uric acid. Therefore, the modified electrode can be used for selective detection of uric acid in the presence of ascorbic acid, which was consistent with that in the previous report [21].

As shown in Fig. 6, peak current increased with the increase of uric acid concentration. The sensor responded to uric acid linearly over concentration range of 0.6 μΜ - 400 μΜ and 400 μΜ - 1000 μΜ, and the linear regression equations were expressed as: I (μA) = 0.3552 C (μM) + 3.1314 (r2 = 0.9949) and I (μA) = 0.1993 C (μM) + 60.1036 (r2 = 0.9943), respectively. With the further increase of uric acid concentration, the peak current increased slowly. The detection limit was estimated to be 0.3 μM for uric acid at the signal to noise ratio of 3. Table S1 (ESM) shows figures of merit of comparable methods for determination of uric acid. In comparison with the nonenzyme or enzyme-based electrodes reported in the literatures, β-CD/MWNT-CILE exhibited comparable linear ranges and detection limit.

Reproducibility, stability and selectivity study

The relative standard deviation (RSD) of the same electrode in six successive measurements was 2.0 % for 50 μM uric acid, and six different electrodes fabricated by the same procedure were used for detecting 50 μM uric acid and the RSD was 4.1 %, indicating that the modified electrode had excellent reproducibility. Furthermore, the stability of the modified electrode was investigated. The peak current retained 91.7 % of its initial response after its storage in air for a month. The results revealed the good stability of the sensor.

The influences of possible interfering substances on the determination of uric acid were investigated. The tolerance limit was taken as the maximum concentration of the foreign substances which caused an approximately ± 5 % relative error in the determination. The results showed that at concentrations 1000 times of Li+, Na+, K+, Ca2+, Mg2+, Zn2+, Cl−, Br−, CO3 2−, SO4 2−, PO4 3−, methanol and ethanol, 500 times of ascorbic acid, 200 times of glucose, fructose, lactose and sucrose, 100 times of urea, lactic acid, glutamic acid, valine, hystidine, alanine, phenylalanine, methionine, glycine and citric acid, 50 times of dopamine did not obviously interfere with the determination of uric acid.

Real sample analysis

In order to evaluate the analytical applicability, the modified electrode was applied to the determination of uric acid in human urine samples. All samples were diluted with 0.2 M acetate buffer (pH 5.0) by 50 times before detection, which reduces the matrix effect of the urine samples. To ascertain the correctness of the results, the samples were spiked with certain amounts of uric acid. The results obtained from three samples are listed in Table 1. The recovery rates of the spiked samples were investigated and ranged between 96.9 % and 103.4 % for urine.

Conclusions

A carbon nanotube ionic liquid paste electrode was modified with β-CD by a facile and controlled growth method. The combination of MWNTs and ionic liquids would enlarge electrochemical effective surface area and facilitate the electron transfer. Based on host-guest recognition between β-CD and uric acid, the electrode enables selective detection of uric acid in the presence of ascorbic acid. Compared to some reported modified electrodes, the suggested method provides comparable linear ranges and lower detection limit. The sensor was successfully applied to uric acid analysis in real samples.

References

Raab LS, Decker GL, Jonas AJ, Kaetzel MA, Dedman JR (1991) Glucocorticoid regulation of rat liver urate oxidase. J Cell Biochem 47:18–30

Chen XM, Wu GH, Cai ZX, Oyama M, Chen X (2014) Advances in enzyme-free electrochemical sensors for hydrogen peroxide, glucose, and uric acid. Microchim Acta 181:689–705

Tian L, Zhang BX, Sun D, Chen RZ, Wang BB, Li TJ (2014) A thin poly(acridine orange) film containing reduced graphene oxide for voltammetric simultaneous sensing of ascorbic acid and uric acid. Microchim Acta 181:589–595

Rafati AA, Afraz A, Hajian A, Assari P (2014) Simultaneous determination of ascorbic acid, dopamine, and uric acid using a carbon paste electrode modified with multiwalled carbon nanotubes, ionic liquid, and palladium nanoparticles. Microchim Acta 181:1999–2008

Elyasi M, Khalilzadeh MA, Karimi-Maleh H (2013) High sensitive voltammetric sensor based on Pt/CNTs nanocomposite modified ionic liquid carbon paste electrode for determination of Sudan I in food samples. Food Chem 141:4311–4317

Karimi-Maleh H, Rostami S, Gupta VK, Fouladgar M (2015) Evaluation of ZnO nanoparticle ionic liquid composite as a voltammetric sensing of isoprenaline in the presence of aspirin for liquid phase determination. J Mol Liq 201:102–107

Baghizadeh A, Karimi-Maleh H, Khoshnama Z, Hassankhani A, Abbasghorbani M (2015) A voltammetric sensor for simultaneous determination of Vitamin C and Vitamin B6 in food samples using ZrO2 nanoparticle/ionic liquids carbon paste electrode. Food Anal Methods 8:549–557

Bijad M, Karimi-Maleh H, Khalilzadeh MA (2013) Application of ZnO/CNTs nanocomposite ionic liquid paste electrode as a sensitive voltammetric sensor for determination of ascorbic acid in food samples. Food Anal Methods 6:1639–1647

Khani H, Rofouei MK, Arab P, Gupta VK, Vafaei Z (2010) Multi-walled carbon nanotubes-ionic liquid-carbon paste electrode as a super selectivity sensor: application to potentiometric monitoring of mercury ion(II). J Hazard Mater 183:402–409

Faridbod F, Ganjali MR, Larijani B, Norouzi P (2009) Multi-walled carbon nanotubes (MWCNTs) and room temperature ionic liquids (RTILs) carbon paste Er(III) sensor based on a new derivative of dansyl chloride. Electrochim Acta 55:234–239

Mazloum-Ardakani M, Khoshroo A (2013) An electrochemical study of benzofuran derivative in modified electrode-based CNT/ionic liquids for determining nanomolar concentrations of hydrazine. Electrochim Acta 103:77–84

Dai H, Wang YM, Wu XP, Zhang L, Chen GN (2009) An electrochemiluminescent sensor for methamphetamine hydrochloride based on multiwall carbon nanotube/ionic liquid composite electrode. Biosens Bioelectron 24:1230–1234

Afkhami A, Khoshsafar H, Bagheri H, Madrakian T (2014) Construction of a carbon ionic liquid paste electrode based on multi-walled carbon nanotubes-synthesized Schiff base composite for trace electrochemical detection of cadmium. Mater Sci Eng C 35:8–14

Beitollah H, Goodarzian M, Khalilzadeh MA, Karimi-Maleh H, Hassanzadeh M, Tajbakhsh M (2012) Electrochemical behaviors and determination of carbidopa on carbon nanotubes ionic liquid paste electrode. J Mol Liq 173:137–143

Afkhami A, Madrakian T, Shirzadmehr A, Tabatabaee M, Bagheri H (2012) New Schiff base-carbon nanotube-nanosilica-ionic liquid as a high performance sensing material of a potentiometric sensor for nanomolar determination of cerium(III) ions. Sens Actuator, B 174:237–244

Rekharsky MV, Inoue Y (1998) Complexation thermodynamics of cyclodextrins. Chem Rev 98:1875–1918

Szejtli J (1998) Introduction and general overview of cyclodextrin chemistry. Chem Rev 98:1743–1754

Samuel PK, Kimio S, Toshiyuki K, Takashi I, Toshio S (2004) Synthesis and characterization of an ultrathin polyion complex membrane containing β-cyclodextrin for separation of organic isomers. J Membr Sci 230:171–174

Zhang L, Lin XQ (2001) Covalent modification of glassy carbon electrode with glutamic acid for simultaneous determination of uric acid and ascorbic acid. Analyst 126:367–370

Wu SG, Wang TL, Gao ZY, Xu HH, Zhou BN, Wang CQ (2008) Selective detection of uric acid in the presence of ascorbic acid at physiological pH by using a β-cyclodextrin modified copolymer of sulfanilic acid and N-acetylaniline. Biosens Bioelectron 23:1776–1780

Zheng LZ, Wu SG, Lin XQ, Nie L, Rui L (2001) Selective determination of uric acid by using a β-cyclodextrin modified electrode. Electroanalysis 13:1351–1354

Ramírez-Berriozabal M, Galicia L, Gutiérrez-Granados S, Cortes JS, Herrasti P (2008) Selective electrochemical determination of uric acid in the presence of ascorbic acid using a carbon paste electrode modified with β-cyclodextrin. Electroanalysis 20:1678–1683

Kim B, Sigmund WM (2004) Functionalized multiwall carbon nanotube/gold nanoparticle composites. Langmuir 20:8239–8242

Xu Q, Wang SF (2005) Electrocatalytic oxidation and direct determination of L-Tyrosine by square wave voltammetry at multi-wall carbon nanotubes modified glassy carbon electrodes. Microchim Acta 151:47–52

Najafi M, Khalilzadeh MA, Karimi-Maleh H (2014) A new strategy for determination of bisphenol A in the presence of Sudan I using a ZnO/CNTs/ionic liquid paste electrode in food samples. Food Chem 158:125–131

Acknowledgments

This research was supported by the Ningxia Higher School Scientific Research Project (No. NGY2013080).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 152 kb)

Rights and permissions

About this article

Cite this article

Li, Y., Zhai, X., Wang, H. et al. Non-enzymatic sensing of uric acid using a carbon nanotube ionic-liquid paste electrode modified with poly(β-cyclodextrin). Microchim Acta 182, 1877–1884 (2015). https://doi.org/10.1007/s00604-015-1522-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-015-1522-8