Abstract

We have synthesized water-dispersible CdTe quantum dots (QDs) capped with thioglycolic acid. Their quantum yield is higher than 54%. A sensitive electrochemiluminescence (ECL) method was established based on the modification of the composite of the QDs, carbon nanotubes and chitosan on indium tin oxide glass. The sensor displays efficient and stable anodic ECL which is quenched by dopamine. A respective sensor was designed that responds to dopamine linearly in the range of 50 pM to 10 nM, and the detection limit is 24 pM. Dopamine was determined with this sensor in spiked cerebro-spinal fluid with average recoveries of 95.7%.

The CdTe quantum dots have been synthesized and therefore developed an electrochemiluminescent sensor based on immobilizing its composite with carbon nanotubes and chitosan on indium tin oxide glass. The sensor responded toward dopamine linearly in the range of 50 pM to 10 nM with a detection limit of 24 pM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Quantum dots (QDs) have been extensively studied owing to their unique size-dependent optical, electronic, photo-physical and electrochemical properties [1–3]. Since the first report on electrochemiluminescent (ECL) behavior of Si nanocrystals (NCs) [4], growing attention has been paid to the ECL studies of semiconducting nano-materials, such as CdS QDs, CdSe QDs and CdTe QDs [5–14]. The immobilized QDs on the electrode surface could effectively react with co-reactants to generate ECL. Then the ECL sensors were developed [6, 8, 9, 12]. Recently, some ECL sensors based on the cathodic ECL of immobilized QDs have been developed using H2O2 [5], O2 [7] or S2O8 [6, 8, 9] as co-reactants. However, although the ECL intensity was enhanced, these oxidants would destroy the buffer condition and even oxidize the analytes, resulting in a loss of selectivity and biocompatibility [13].

The anodic ECL behavior of nano-materials was discussed less. There are only few reports concerning the CdTe QDs [10, 11, 14], co-reacting with SO 2-3 [11] or amines [14]. The main causations are the relatively weak anodic ECL emission and the difficulty to immobilize those monothiol compound-capped QDs on the electrode surface for sensor preparation due to their high solubility [12]. Carbon nanotubes (CNTs) have aroused a lot of attention due to their remarkable nanostructure, high electrical conductivity and good chemical stability [15]. It is once used to enhance the ECL of CdS QDs by reducing the electron injecting barrier [5].

In our present study, the water-dispersible CdTe QDs were synthesized with thioglycolic acid (TGA) as protective agent, which gave a quantum yield as high as 54%. Therefore an anodic ECL sensor was constructed based on the ECL performance of CdTe QDs after they were immobilized onto indium tin oxide (ITO) glass by composite of CNTs/chitosan. There the chitosan acted as film-forming material. Meanwhile it was a natural cationic polyelectrolyte with good biocompatibility. The ITO glass worked as basal working electrode due to its excellent optical transparency, high electrical conductivity, wide electrochemical window, low capacitive current and stable electrochemical and physical properties [16, 17]. After infrared heat-treatment, the developed ECL sensor exhibits high ECL efficiency and excellent stability with triethylamine (TEA) as co-reactant.

Dopamine (DA) plays a significant role in the functioning of the central nervous, renal, hormonal and cardiovascular systems. Some electrochemical methods served DA detection but lack sensitivity toward biomedical samples. Ju et al. have reported a more sensitive method for DA detection based on its quenching effect on ECL of CdTe QDs in solution [10]. In our present study, the developed ECL sensor is easily applied to more sensitive detection of DA. The results indicate that the sensor has excellent sensitivity and recovery for DA detection, and can be applied to the determination of real samples such as cerebro-spinal fluid.

Experimental

Apparatus

The electrochemical experiments were carried out on a CHI 660A electrochemical workstation (Shanghai CH Instruments Co., China, http://www.chinstruments.com) with an ITO working electrode, a platinum counter-electrode and a saturated calomel reference electrode (SCE). The ITO glass (1.1 mm thickness, 40 Ω resistance) was purchased from Suzhou NSG Electronics Co., Ltd. (Suzhou, China, http://www.nsg.co.jp). ECL emission was detected with an SGD-2 single-photon counter (Tianjin Gangdong Scientific & Technical Development Co., Ltd, China, http://www.tjgd.com). The photomultiplier tube (PMT) was powered by −800 V voltage.

The photoluminescence (PL) experiments were performed on an F-2500 fluorescence spectrophotometer (Hitachi, Japan, http://www.hitachi.com). The UV–vis absorption spectra were recorded with a 2810 UV–vis spectrophotometer (Hitachi). Scanning electron microscopy (SEM) was performed on an S-4700 scanning electron microanalyzer (Hitachi). Powder X-ray diffraction patterns were collected on a D/MAX-IIIC diffractometer (Rigaku Corporation, Japan, http://www.rigaku.com) with CuKα radiation (λ = 1.54956 Å). High-resolution transmission electron microscopy (HRTEM) images were performed on an FEI Tecnai F20 instrument (Philips Electron Optics, Netherland, http://www.fei.com) equipped with a Gatan UltraScan 4000 digital camera. Surface wettabilities were evaluated by the measurement of water contact angle, which was achieved through a sessile drop method with a JC2000C1 optical contact angle analyzer (Shanghai Zhongchen Digital technique Instruments Co, China, http://www.powereach.com).

Reagents

Multiwall carbon nanotubes (diameter 30–60 nm) were purchased from Nanoport Co. Ltd. (Shenzhen, China, http://www.nanotubes.com.cn). Before use, they were treated with concentrated nitric acid at 25 °C for 24 h under the agitation of ultrasonication, then filtered, washed with doubly distilled water several times until the filtrate became neutral and dried in an oven. Tellurium powder was obtained from Alfa Aesar China Ltd. (http://www.alfa.com). Dopamine and chitosan (MW 1.9–3.1 × 105, minimum 85% deacetylation) were purchased from Sigma Chemical Co. (St. Louis, MO, http://www.sigmaaldrich.com). A 0.10 wt.% chitosan solution was prepared by dissolution in 0.05 M acetic acid. Cadmium chloride (CdCl2∙2.5H2O), sodium borohydride (NaBH4) and triethylamine (TEA) were purchased from Sinopharm Chemical Reagent Co. Ltd (Shanghai, China, http://www.sinoreagent.com.cn). All other reagents were of analytical grade and used as received. A 0.1 M phosphate buffer solution containing 0.1 M KNO3 and 30 mM triethylamine was used throughout the work. Doubly distilled water was used throughout.

Synthesis and characterization of thioglycolic acid capped CdTe QDs

The TGA-capped water-dispersible CdTe QDs were synthesized using an improved method referred to in the literature [18–21]. After 190 μL of 48 mM TGA solution was piped into 50 mL of 20 mM CdCl2 solution, its pH was adjusted to 9.0 with 1 M NaOH. The resulting solution was bubbled with high purity N2 for 30 min, then 0.50 mL of 0.50 M NaHTe solution (produced by reaction of deoxygenated NaBH4 solution with Te powder) was slowly injected into it, stirring vigorously, under the protection of N2. This procedure produced a yellowish brown solution of TGA-capped CdTe QDs. Here the molar ratio of Cd2+/TGA/HTe- was optimized for 1:2.4:0.25. The different-sized QDs would therefore be obtained after different refluxing times and then dialyzed against doubly distilled water for 24 h. The final solid content of CdTe QDs in dispersoid is 0.577 g⋅L−1, which was evaluated from the material quantities of synthesis.

The particle size of QDs can be characterized according to the empirical equation [22] D(nm) = 9.8127 × 10−7 λ3-1.7147 × 10−3 λ2 +1.0064 λ-194.84, here λ (nm) is the wavelength of the first excitonic absorption peak on its UV–vis absorption spectrum.

The quantum yield (QY) of synthesized QDs was measured [23] with Rhodamine 6 G (QY = 95%) as a referential standard by the integral of fluorescence. The integral of fluorescence of six different concentrated ethanol solutions of Rhodamine 6 G and CdTe QDs solutions (absorbance at excitation wavelength <0.1) was detected respectively and then plotted vs. absorbance to obtain the regression lines. The slopes (Mx and Ms) of the obtained plots could be used to calculate the quantum yield according to the following equation:

Here the subscripts s and x denote the standard (Rhodamine 6G) and test sample, respectively. ϕ is QY, and η is the refractive index of the solvent. It ought to be noted that the excitation wavelength for measurements of the QY was set at the excitonic absorption peak of the CdTe QDs in experiments.

Research procedures

The pretreated CNTs were dispersed into a chitosan solution with 30 min ultrasonication to produce a homogenous mixture. Then the CdTe QDs dispersion was mixed with this CNTs/chitosan mixture at a volume ratio of 2:1 under sonication for 30 min to get a CdTe QDs/CNTs/chitosan nano-composite. 4 μL of that nano-composite was cast onto the surface of ITO glass, which was cut into 4 cm × 0.7 cm slices and covered with the ribbon tape. There was left a punched hole of 5 mm diameter for the electrode. Finally, the ECL sensor was heat-treated with an infrared lamp for drying.

The ECL performance of the developed sensor was characterized in 0.1 M phosphate buffer containing 30 mM TEA and 0.1 M KNO3. A pulse mode was applied for excitation of ECL in most of the experiments. The lower and upper potential limits were set to 0 V and 1.1 V, respectively, with a 20 s period with 10% of duty factor.

Cyclic voltammetry was used to excite ECL in order to more clearly discern the response of the ECL intensity to the potential and to differentiate the ECL performance on different electrodes.

The sensor was then applied to test its response to the concentration of DA and to two cerebro-spinal fluid samples from volunteers.

Pretreatment of cerebro-spinal fluid samples

Two cerebro-spinal fluid samples were firstly centrifuged at 12,000 rpm for 15 min to get the supernates. They were then further centrifuged at 12,000 rpm for 15 min after precipitation of the proteins by isometric acetonitrile. The final supernates were collected for assay.

Results and discussion

Properties of synthesized CdTe QDs

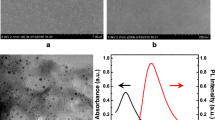

The absorption and photoluminescence (PL) emission spectra of the present synthesized CdTe QDs is shown in Fig. 1a. It reveals the monodisperse nanocrystals, as are the HRTEM image (B), the XRD curve (C) and the PL emission spectra (D) upon different reflux times. Figure 1(D) indicates that the size of the QDs is dependent on the reflux time. Finally, according to the empirical equation [22] and literature [11], 3.4 nm sized QDs were chosen for the best ECL performance.

a The spectra of (a) absorption and (b) photoluminescence with 360 nm of excitation wavelength of the prepared CdTe QDs. b The TEM image of the CdTe QDs. c XRD pattern of the TGA-capped CdTe QDs. (D) PL spectra of CdTe QDs which refluxed for (a) 0.5, (b) 1, (c) 2, (d) 3, (e) 4.5, (f) 6, (g) 8, (h) 10 and (i) 22 h at 100 °C during the synthesis

The quantum yield (QY) of the synthesized QDs was measured to be as high as 54%. This is significantly higher than the generally reported 5% to 10% [18]. As compared to previously reported conditions (the pH value was controlled at 11.2 and the mass ratio of Cd2+/TGA/HTe- as 1:2.4:0.5), the present method optimized the precursor ratio for 1:2.4:0.25 and decreased the pH to 9.0. The increased ratio of S and Cd to Te ensured a more perfect surface structure and better photoluminescence QY of the nanocrystals. The final QDs solution is stable for more than 3 months when kept it in a refrigerator at 4 °C.

Effect of CNTs and heat pretreatment for established ECL sensor

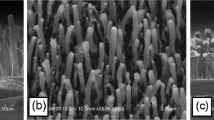

The ECL emission of the resulting sensor is shown in Fig. 2A–a. There are very stable ECL signals during the pulse electro-excitation if CNTs were used and after infrared heat treatment. For comparison, if no CNTs cooperated with CdTe QDs, an ECL percentage of only 3 to 4 was recorded. Without infrared pretreatment, the ECL intensity is unstable (see Fig. 2A–b). The chitosan acted as the bond material, the CNTs served as a very effective supporter for the loading mass amount of the CdTe QDs and as a conductor for the electrons. The SEM images of (Fig. 2C) also illustrated the densely compact integration of CdTe QDs on CNTs.

The stability improved by infrared pretreatment might be attributed to the decrease of wettability of the modified layer. After the heat treatment, the contact angle changes from native 33° to about 72° (Fig. 2B), which shows a more hydrophobic surface. This more hydrophobic surface will improve the stability of the modified layer due to the prohibition of the leach-out of QDs from the modified layer. Application of chitosan is also favorable for improving the stability. Its positive charging status acted well as the matrix for immobilization of negatively charged CNTs and QDs to obtain a homogeneous nano-composite.

The SEM observation is helpful in understanding the phenomenon, see (Fig. 2C). It reveals a great transformation in the morphological character of the QDs/CNTs/chitosan composite after heat treatment. It is found that the tubes of CNTs were straightened if QDs were present after heat treatment. It is well-known that TGA-stabilized CdTe is a kind of core-shell structural CdTe/CdS nanocrystal. The CdS shell is a thin atomic layer, and the sulfur atom on the surface is highly reactive. Referring to the discussion in the literature [24], it is not difficult to presume that the original surface of CdS is highly hydrophilic for water adsorption, and that the IR irradiation accelerated the transformation of the surface thiol groups, leading to a hydrophobic surface. Therefore the repulsive force that existed among lone electron pairs of sulfur caused the tube of the CNTs to be straightened.

Optimal conditions for sensor response

As illustrated in (Fig. 3A), the pH 10.5 phosphate buffer is the optimal medium for the ECL response of the developed sensor. Also, the concentration of TEA was optimized to 30 mM following the experiments (see Fig. 3B) to act as the co-reactant. In this medium, the anodic ECL can be recorded during the cyclic voltammetric process (see Fig. 3C–a) or with a pulse potential. In cyclic voltammetric mode, it is clear that the ECL response strongly depends on the potential until it exceeds 1.0 V (vs. SCE). In the absence of CdTe QDs no ECL signal was recorded (see Fig. 3C–b). The ECL properties of the sensor developed is illustrated in (Fig. 3D). There is a very strong ECL signal if the pulse is applied with an upper limiting potential of 1.1 V and a lower limiting potential of 0 V. In contrast, if there are no CNTs in the modified layer, the ECL response is only 3–4% in magnitude. This demonstrated the prerequisite of using the CNTs in the development of the ECL sensor. Figure 3(E) illustrates the anodic ECL and PL (excited at 360 nm) spectra of CdTe QDs in the above mentioned medium. It can be seen in Fig. 3(E) that the PL emission gives a symmetrical peak at a wavelength of 597 nm (Fig. 3E–a), while the ECL emission gives a slightly wider peak at a wavelength of 604 nm (Fig. 3E–b). Therefore it can be deduced that the emission of ECL came from the excitations of CdTe QDs.

The dependence of ECL intensity of the developed sensor on the (a) buffer pH and (b) concentration of TEA. c The ECL emission of (a) developed sensor and (b) without CdTe QDs during cyclic voltammetry. (D) The ECL emission of (a) developed sensor and (b) one without CNTs during a single pulse. e The spectra of (a) PL and (b) ECL of CdTe QDs. The PL excitation wavelength is 360 nm

Analytical performance of the developed sensor

The developed ECL sensor is very stable. The RSD of the ECL intensity for seven consecutive pulses is 0.12%, and for seven intermittent measures it is 0.34%. After storing for 1 month, no noticeable decline in ECL intensity, stability or reproducibility was observed.

The developed sensor can be applied in the determination of DA due to its quenching effect toward its ECL in phosphate buffer solution. Quenching was not caused directly by DA, but by an oxidized form, o-benzoquinone, under an electrochemical potential [10]. The interference of uric acid, ascorbic acid, alanine, glucose and lactate in the detection of DA were examined by measuring their quenching degree for ECL intensity. The results are shown in Table 1.

Under the optimal conditions, the quenching degree (I0/I) linearly responds to the logarithm of DA concentration within the range of 50 pM to 10 nM (r = 0.992) with a detection limit of 24 pM (S/N = 3). The regression equation is \( {{\text{I}}_{{0}}}{\text{/I = }} - {1}{.17 + 1}{\text{.33log}}\,\left[ {\text{DA}} \right] \).

The results show that DA detection tolerated more than 100-fold quantities of the interfering species. The developed sensor was applied to the detection of two cerebro-spinal fluid samples from volunteers. 20 μL aliquots were injected into 1 mL of phosphate buffer and detected with the sensor. The DA contents of two samples and the recoveries are listed in Table 2.

When compared with other methods for dopamine detection (Table 3), the one developed here provides a satisfactory response toward DA over a wide range of concentrations.

Table 3 suggests that the significant advantage of this method is the extremely low detection (as low as 24 pM), which is several orders of magnitude lower than those reported in other papers (usually at the nM level). This is probably connected with the high QY of the prepared CdTe QDs. The low detection limit makes the detection of real samples relatively easy due to the high possible dilution that diminishes the interference. The analytical performance and application indicates the potential applicability of the method for practical detections.

Conclusion

A novel sensitive electrochemiluminescent sensor based on modification of TGA-capped CdTe QDs/CNTs/chitosan nano-composite on ITO glass was constructed. After IR pretreatment and with TEA as co-reactant, the nano-composite film displayed a high ECL intensity and good stability. The ECL mechanism can be expressed as the following equations and Scheme 1:

The sensor provides an excellent background for the determination of certain compounds which induced no matter enhancing or quenching effect. In this study, the dopamine is found to be an efficient quenching compound for the ECL of CdTe QDs. It responded sensitively to the developed ECL sensor. The linear range of the sensor for determination of dopamine is from 50 pM to 10 nM with a detection limit of 24 pM. Also the sensor was applied to detect the dopamine content in cerebro-spinal fluid samples with satisfactory results.

References

Burda C, Chen XB, Narayanan R, El-Sayed MA (2005) Chemistry and properties of nanocrystals of different shapes. Chem Rev 105:1025

Wang F, Hu SS (2009) Electrochemical sensors based on metal and semiconductor nanoparticles. Microchim Acta 165:1

Guyot-Sionnest P (2008) Charging colloidal quantum dots by electrochemistry. Microchim Acta 160:309

Ding ZF, Quinn BM, Haram SK, Pell LE, Korgel BA, Bard AJ (2002) Electrochemistry and electrogenerated chemiluminescence from silicon nanocrystal quantum dots. Science 296:1293

Ding SN, Xu JJ, Chen HY (2006) Enhanced solid-state electrochemiluminescence of CdS nanocrystals composited with carbon nanotubes in H2O2 solution. Chem Commun 3631

Jie GF, Liu P, Wang L, Zhang SS (2010) Electrochemiluminescence immunosensor based on nanocomposite film of CdS quantum dots-carbon nanotubes combined with gold nanoparticles-chitosan. Electrochem Commun 12:22

Jiang H, Ju HX (2007) Enzyme-quantum dots architecture for highly sensitive electrochemiluminescence biosensing of oxidase substrates. Chem Commun 404

Jie GF, Zhang JJ, Wang DC, Cheng C, Chen HY, Zhu JJ (2008) Electrochemiluminescence immunosensor based on CdSe nanocomposites. Anal Chem 80:4033

Jie GF, Li LL, Chen C, Xuan J, Zhu JJ (2009) Enhanced electrochemiluminescence of CdSe quantum dots composited with CNTs and PDDA for sensitive immunoassay. Biosens Bioelectron 24:3352

Liu X, Jiang H, Lei JP, Ju HX (2007) Anodic electrochemiluminescence of CdTe quantum dots and its energy transfer for detection of catechol derivatives. Anal Chem 79:8055

Liu X, Ju HX (2008) Coreactant enhanced anodic electrocherniluminescence of CdTe quantum dots at low potential for sensitive biosensing amplified by enzymatic cycle. Anal Chem 80:5377

Cheng LX, Liu X, Lei JP, Ju HX (2010) Low-potential electrochemiluminescent sensing based on surface unpassivation of CdTe quantum dots and competition of analyte cation to stabilizer. Anal Chem 82:3359

Wang Y, Lu J, Tang LH, Chang HX, Li JH (2009) Graphene oxide amplified electrogenerated chemiluminescence of quantum dots and its selective sensing for glutathione from thiol-containing compounds. Anal Chem 81:9710

Zhang LH, Zou XQ, Ying EB, Dong SJ (2008) Quantum dot electrochemiluminescence in aqueous solution at lower potential and its sensing application. J Phys Chem C 112:4451

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56

Stotter J, Show Y, Wang SH, Swain G (2005) Comparison of the electrical, optical, and electrochemical properties of diamond and indium tin oxide thin-film electrodes. Chem Mater 17:4880

Zudans I, Paddock JR, Kuramitz H, Maghasi AT, Wansapura CM, Conklin SD, Kaval N, Shtoyko T, Monk DJ, Bryan SA, Hubler TL, Richardson JN, Seliskar CJ, Heineman WR (2004) Electrochemical and optical evaluation of noble metal- and carbon-ITO hybrid optically transparent electrodes. Electroanal Chem 565:311

Gaponik N, Talapin DV, Rogach AL, Hoppe K, Shevchenko EV, Kornowski A, Eychmuller A, Weller H (2002) Thiol-capping of CdTe nanocrystals: an alternative to organometallic synthetic routes. J Phys Chem B 106:7177

Mandal A, Tamai N (2008) Influence of acid on luminescence properties of thioglycolic acid-capped CdTe quantum dots. J Phys Chem C 112:8244

Zhao K, Li J, Wang HZ, Zhuang JQ, Yang WS (2007) Stoichiometric ratio dependent photoluminescence quantum yields of the thiol capping CdTe nanocrystals. J Phys Chem C 111:5618

Li MY, Ge YX, Chen QF, Xu SK, Wang NZ, Zhang XJ (2007) Hydrothermal synthesis of highly luminescent CdTe quantum dots by adjusting precursors’ concentration and their conjunction with BSA as biological fluorescent probes. Talanta 72:89

Yu WW, Qu LH, Guo WZ, Peng XG (2003) Experimental determination of the extinction coefficient of CdTe, CdSe, and CdS nanocrystals. Chem Mater 15:2854

Demasa JN, Crosby GA (1971) The measurement of photoluminescence quantum yields. J Phys Chem 75:991

Miyauchi M, Kieda N, Hishita S, Mitsuhashi T, Nakajima A, Watanabe T, Hashimoto K (2002) Reversible wettability control of TiO2 surface by light irradiation. Surf Sci 511:401

Zhang YF, Li BX, Chen XL (2010) Simple and sensitive detection of dopamine in the presence of high concentration of ascorbic acid using gold nanoparticles as colorimetric probes. Microchim Acta 168:107–113

Troiani ED, Faria RC (2010) The influence of the cathodic pretreatment on the electrochemical detection of dopamine by poly(1-aminoanthracene) modified electrode. Electroanalsyis 22:2284

Bustos EB, Jimenez MGG, Diaz-Sanchez BR, Juaristi E, Chapman TW, Godinez LA (2007) Glassy carbon electrodes modified with composites of starburst-PAMAM dendrimers containing metal nanoparticles for amperometric detection of dopamine in urine. Talanta 72:1586

Hu YY, Wu X, Su YY, Zhang JY (2009) Capillary zone electrophoresis hyphenated with laser-induced fluorescence detection for sensitive determination of noradrenaline and dopamine with 5-(4, 6-dichloro-s-triazin-2-ylamino) fluorescein as fluorescent label. Microchim Acta 166:289–294

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Nos. 20275025 and 20675055), Natural Science Foundation of Jiangsu Province (BK2009111) and Project of Science and Technology of Suzhou (SYJG0901).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, C., Yan, J. & Tu, Y. Electrochemiluminescent sensing of dopamine using CdTe quantum dots capped with thioglycolic acid and supported with carbon nanotubes. Microchim Acta 175, 347–354 (2011). https://doi.org/10.1007/s00604-011-0666-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-011-0666-4