Abstract

This paper describes a simple, economical and practical optical sensor that has been developed using an ion imprinted polymer for detecting copper(II) ion using reflectance spectrometry. The imprinted polymer was synthesised in the presence of copper(II) ion using 4-vinylpyridine as monomer, 2-hydroxyethyl methacrylate as co-monomer, and ethylene glycol dimethacrylate as cross-linker in methanol via free radical polymerisation. The polymer formed was physically ground into fine particles, fabricated into a sensor probe and attached at the tip of an optical fibre bundle. The sensor operates optimally at pH 5 under constant stirring condition and has a linear dynamic range for copper(II) ion determination of 0.4–4.0 mM. The limit of detection for the sensor was 123 µM. The sensor has high selectivity for monitoring copper (II) ion in a multi-analyte environment, while also exhibiting better sensitivity compared to non-imprinted polymer. The response of the sensor can be regenerated fully without significant loss in its analytical signal for re-use. This reduces the consumable cost and at the same time making the operational process of such sensor simpler and more practical to be employed in real applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of molecular imprinting technique (MIT) has opened the path of producing various synthetic polymers with superior recognition properties, which are commonly known as the molecularly imprinted polymers (MIPs) [1, 2]. MIPs are produced via a simple one-step cross-linking process in the presence of templates, using considerably low cost ingredients, apparatus and setup. The template can be small neutral molecules, metal ions, amino acids, nucleotide bases and sugars [3]. Binding sites having specific shapes, sizes, and position of the functional groups are introduced once the incorporated templates are removed from the polymer matrix. Various studies have confirmed that MIPs can readily rebind the template with higher affinity compared to other molecules even of close similarity with respect to the structure and chemical functionality [4, 5]. Moreover it also has better stability at extreme conditions (high temperature, high pressure, strong basic or acid solutions, etc.), unlike the commonly used natural bio-receptors that have excellent recognition ability but are highly condition-sensitive.

Currently MIT has reached to a considerably successful level in producing MIPs with tailor-made properties. Therefore, effort now focuses more in finding and integrating new applications for the MIPs [6]. In optical sensing application, MIT is merged in optrode fabrication as a new technique compared to the current development trends. This is a very promising progress as MIPs show the capability in overcoming the present limitations encountered with optrodes produced using immobilising chelating reagents, chromophores, or bio-molecules on polymer or silica based support matrices. Direct immobilisation technique has no doubt been reported to give good responses with great sensitivity, but the optrodes produced often suffer from problems of leaching of reagents that cause serious sample contamination and the reduction of analytical signal over a period of time [7]. Besides, the selectivity of the optrodes is considerably low due to non-selective binding nature of the reagents that are immobilised [8].

Before the MIPs can fully portray the advantageous features identified for real optical sensing application, an integration of MIPs with optical instrumentation should be established. In this aspect, the consideration should not always emphasise the advancement in methodologies and equipments, but there is also necessity to consider the development from the aspects of cost effectiveness, simplicity, and practicality. This is a crucial bridge to open the opportunity for many developing countries especially those having insufficient financial resources for technologically advanced analytical equipments to utilise the features of MIPs for real sensing applications. In fulfilling these criteria, optical fibre-based sensor is one of the best choices, as it has well known attractive features; being low-cost, simple, capable of rapid real-time monitoring, robust, and reliable [9–11]. This type of sensor has achieved great successes in different applications [12].

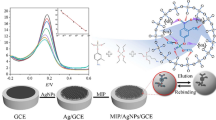

In this paper, all rounded aspects involved in ion imprinted polymer (IIP) development for optical sensor application were investigated; starting from solution investigation, polymer synthesis, sensor development, and sensing application. The demonstration was performed using Copper(II) ion-imprinted polymer (Cu-IP), synthesised via a simple cross-linking process of monomers and cross-linker in the presence of Copper(II) ion (Cu(II)). The polymer formed via free-radical polymerisation was crushed, sieved, washed, and the Cu(II) ion was leached out from the polymer using EDTA and the fine particles were incorporated as a sensing receptor at the tip of an optical fibre. Reflectance spectroscopic technique was employed to monitor the analytical response of the sensor due to its well known simplicity, low cost instrumentation and reliable signals. As far as we are concerned, there is no report of an IIP sensor for Cu(II) ion detection using this measurement technique. The system has a great potential to be developed into a portable, simple and cheap optical sensor for the monitoring of Cu(II) ion, a metal ion that is crucial to biological system and also a potential toxic environment pollutant [13, 14].

Experimental

Apparatus and instrumentations

Shimadzu UV-2400-PC spectrophotometer was used for recording absorbance of solutions using a standard quartz cell of 1.0 cm path length. All reflectance measurements were recorded using Ocean Optic optical fibre spectrophotometer (model HR2000), consisting of a tungsten halogen lamp as the radiation source, a CCD array detector, and optical fibres as light guides between components (Fig. 1). The optical fibre bundle to which the sensing layer was interfaced was split evenly into two strands (seven fibres each) one of which was connected to the light source and the other to the detector. The data acquisition was carried out using OOIBase32 spectrometer operating software. A digital pH meter (model HI 9815) with the accuracy of pH 0.1 was employed for all pH measurements.

Reagents and chemicals

All chemicals and reagents used are of analytical grade unless otherwise stated. Double-distilled deionised water and methanol (Aldrich, www.sigmaaldrich.com) were used as solvents. Copper(II) sulphate 5-hydrate, 99.0% (from BDH), 4-vinylpyridine (4VPy), 95% (from Alfa Aesar), ethylene glycol dimethacrylate (EGDMA), 98%, 2-hydroxyethyl methacrylate (HEMA), 98% (all from Sigma-Aldrich), 2,2′-azobisisobutyronitrile (AIBN), 97% (from BDH) were used as purchased. Buffer solutions were prepared using potassium hydrogen phthalate, di-sodium tetraborate and tris(hydroxymethyl)aminomethane (all from Sigma-Aldrich) and all pH values were adjusted using hydrochloride acid (from Fisher, www.fishersci.com) and sodium hydroxide (from BDH).

Synthesis of polymers

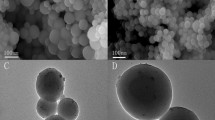

The Cu-IP was synthesised using free radical polymerisation by a thermally induced radical process. An amount of 4VPy (0.4550 mL) was diluted to 5.0 mL in methanol and in a separate 5.0 mL volumetric flask, 0.2497 g of Copper(II) sulphate 5-hydrate was dissolved in methanol. The Cu(II) ion solution was mixed into the 4VPy solution dropwise under constant stirring in a 25 mL borosilicate bottle. The pH of the mixture was adjusted to pH 2 using few drops of hydrochloric acid (1.0 M). The solution was further stirred for 20 min followed by the addition of 7.5 mL of EGDMA, 1.215 mL of HEMA and 0.100 g of AIBN. The mixture was further stirred for 30 min, followed by purging with nitrogen for 10 min before being sealed. The mixture was then transferred into a 70°C water bath and polymerisation was performed for 2 h. The Cu-IP formed was left for aging in a desiccator for 24 h before being crushed into small particles using a pestle and mortar. The particles were sufficiently rinsed with deionised water before being dried and made ready for use. The same procedure was used to synthesise the control polymer in the absence of Cu(II) ion.

Sensor design

The sensor tip design (insert, Fig. 1) was similar to that described previously [15] with slight modification. A polyamide mesh was attached to one end of a PTFE tube (25.0 mm long × 3.0 mm diameter) using a Norton Tygon® soft tubing (8.0 mm). Cu-IP was filled into the tube at the other end followed by the fibre bundle to sandwich the Cu-IP with the polyamide mesh to form a thinly distributed polymer layer (approximately 1.0 mm). Then the PTFE tube was held against the fibre bundle to fix the whole assembly using a heat-shrink tube.

Reflectance measurement

All the reflectance measurements were recorded and corrected against standard barium sulphate (BaSO4). In a sample holder, the polymer (approximately 0.2 g) was pressed against a quartz disc (20.0 mm diameter × 1.0 mm thick) with the fibre set on top of the sample holder (a position of 90° out of the plane of the glass) for recording the reflectance signal. To quantify the sensor response, the reflectance measured from the polymer was expressed as percentage (%Rs) relative to the reflectance of standard BaSO4 reference. In order to achieve higher accuracy, all the signals value including the standard reference were taken under the same experimental condition and setup as describes in the previous section. The (%Rs), is defined as:

where,

- \( {{\hbox{S}}_\lambda } \) :

-

Sample intensity at wavelength λ

- \( {{\hbox{D}}_\lambda } \) :

-

Dark intensity at wavelength λ

- \( {{\hbox{R}}_\lambda } \) :

-

Reference (BaSO4) intensity at wavelength λ

Kinetic approach has been adopted in this study in which the reflectance of the sample was monitored over a period of time after placing the sensor into the analyte solution. The reflectance was monitored at 750.0 nm due to the greatest divergence occurring at this wavelength before and after the sensor was immersed into the analyte solution. The regeneration of the sensor was carried out using EDTA using the same experimental setup.

Optimisation of sensor conditions

All the characterisation and optimisation studies of the Cu-IP were performed via reflectance measurements using the setup described in previous sections. The sensor tip was dipped into the analyte solution that was constantly stirred and the analytical reflectance signal was monitored. The analyte solution volume on each cycle of study was fixed at 5.0 mL, while the concentration of Cu(II) ion was varied accordingly by the dilution of the stock solution. All the above experimental parameters used were identical unless otherwise stated. The effects of pH, stirring, and binding kinetics on the intensity of the reflectance signal were also investigated.

Results and discussion

Solution investigations prior to imprinting

Complex formation

A crucial factor for the success of ion imprinting is the ability for ion to form strong interaction with the monomer prior to polymerisation. In this study, absorption spectrometry was employed to investigate such interaction. Initially, 4VPy was observed to give no absorbance band in the region of 400–900 nm, while the Cu(II) ion showed a broad absorbance band in the range of 600–900 nm with a λ max at 800 nm. A blue-shift of 120 nm in the Cu(II) ion λ max was observed when the 4VPy was added gradually (Fig. 2). This indicates the formation of a metal-ligand complex and pH 2.0 was found to be the most favoured conditions. Higher pH causes solvation of the Cu(II) ion by negatively charged species such as hydroxyl ion, which hinder complex formation. Similar observation has been reported by Safavi and Bagheri [16] in their study of complexation of Cu(II) ion with dithizone.

Stoichiometry of the complex

The formation of complex between Cu(II) ion and 4VPy was evidenced by the formation of a new strong absorption band with a λ max at 680 nm. The stoichiometry of the complex was studied using Job’s and Mole-ratio methods. In Job’s method, both Cu(II) ion and 4VPy stock solution concentrations were fixed at 5.0 mM and the working solutions were prepared from these by varying the volume ratios of the two reactants. The final volume for all the working solutions was maintained a constant and the absorbance at 550 nm was recorded for all the samples. At this wavelength, both of the reactants absorb weakly and therefore the absorbance measured will be mainly due to the complex. The most favoured stoichiometric ratio of the complex was estimated to be 1:4 (Cu(II) ion: 4VPy) although intermediate complexes of 1:1, 1:2 and 1:3 were observed from the Job’s plot. A similar observation has been made in studies of complexation for Cu(II) ion with pyridine [17, 18]. The stoichiometric ratio of 1:4 was further confirmed by Mole-ratio method that was carried out by fixing the concentration of Cu(II) ion (2.5 mM) while recording the absorbance intensity at 680 nm as the concentration of 4VPy was varied gradually.

Association constant of the complex

The molar absorptivity, ε of the complex was theoretically calculated using the Beer-Lambert relationship from the intersection point of the two extrapolated lines obtained in mole-ratio plot [19]. The ε of the complex at absorbance maximum (680 nm) was evaluated as 71.36 L mol−1 cm−1. In order to obtain the association constant, Ka, of the complex, the following expression was derived:

The concentration of the \( {\hbox{Cu}}\left( {\hbox{4VPy}} \right)_4^{2 + } \) at equilibrium can be directly calculated using the experimental absorbance intensity (A). The amount of Cu(II) ion and 4VPy at equilibrium were obtained by subtracting the initial amount of both the reactants added with the amount consumed for the formation of complex. Thus, the following expression can be derived for the evaluation of Ka, using absorbance measurements with the standard path length (\( \ell \)) of light of 1.0 cm.

The value of Ka for the complex formation between Cu(II) ion and 4VPy was evaluated to be 1.91 × 1013 M−4. This value shows good binding interaction between Cu(II) ion with 4VPy indicating the possibility of better imprinting effect of specific binding site created on the polymer.

Polymer optical properties

The bulk Cu-IP formed was opaque and light blue in colour due to the \( {\hbox{Cu}}\left( {\hbox{4VPy}} \right)_4^{2 + } \) complex while the control polymer was just opaque and white. Due to this nature, direct recording of absorbance spectra was not possible and were obtained by converting the reflectance signals using Kubelka-Munk relationship [20, 21]. The result shows that the Cu-IP polymer before the removal of Cu(II) ion gives two absorption bands having λ max at 705 and 795 nm respectively. The band with higher intensity correlates to \( {\hbox{Cu}}\left( {\hbox{4VPy}} \right)_4^{2 + } \) and the λ max showed a bathochromic shift of 25 nm compared to that of the complex in solution media. This red shift was common and has been also observed with other immobilised reagents, which suggested changes in structural conformation of the molecule in different media [16]. The second weaker band could be due to some free Cu(II) ion that may be present in the polymer matrix (absorbing at around 800 nm). This assignment of the absorbing species was supported by the absorbance spectrum obtained from Cu-IP polymer that has been washed with EDTA. The spectrum showed that both of the peaks have disappeared indicating the dissociation of complex and the removal of free Cu(II) ion by the EDTA solution. Such phenomenon observed can be employed for sensing purposes as illustrated in Fig. 3.

Polymer ingredients and conditions

The blending of ingredients for the polymer formation was made according to the sensing requirements in this study. Besides the usage of 4VPy as monomer that interacts with Cu(II) ion, a co-monomer of HEMA was added to increase the hydrophilic characteristic of the polymer. Polyhema has been well adopted as hydrogel in many applications especially in biomedical and applied biology due to its good water permeation characteristics [22, 23]. It is also reported that synthetic polymer made from HEMA has the ability to allow cations and anions to pass through freely [24]. This factor is important in this study in order to achieve a good interaction of Cu(II) ion with the binding sites of the Cu-IP. In addition to the monomer, a cross-linker of EGDMA was selected to preserve the polymer conformation to a specific shape and orientation that can result in the availability of high number of binding affinity sites for Cu(II) ion. The presence of sufficient cross-linker is very important to secure a strong polymer structure that can uphold its conformation when used in different environments (e.g. extreme conditions). The free radical polymerisation was initiated using AIBN by increasing temperature to 70°C. The purging of nitrogen during the polymerisation process is to eliminate oxygen, as it can react with the free radical and terminate the polymerisation process.

Template removal

The removal of Cu(II) ion from the polymer matrix influenced greatly the success of the Cu-IP as sensing receptor. The Cu(II) ion should be removed to create cavities with highly specific conformation and serve as binding sites for the Cu(II) ion. In this respect, complete removal of Cu(II) ion from the polymer will create a maximum amount of binding sites and also avoid the bleeding phenomenon that could interfere seriously during the sensing application [25]. Practically, it is very difficult to remove entire quantity of ions from the polymer structure due to the fact that some of it would be highly cross-linked and imbedded inside the matrix. So it will be of advantage to monitor the maximum removal of Cu(II) ion to avoid any leaching that can occur during sensing application. Particularly in this study, EDTA was selected as the removal reagent and the amount of Cu(II) ion leached was determined optically by measuring the absorbance (at 568 nm) of the washing solution in batches. In this study, almost all of the removable Cu(II) ion was washed from the polymer after 5 cycles of rinsing with EDTA used at the ratio of 1: 50 [polymer (g) : EDTA (0.05 M) (mL)] at each wash. No significant removal of Cu(II) ion was observed with further washes as indicated by the constant reading in absorbance recorded. Thus the Cu-IP used in the characterisation work was washed at least five times in this study.

Optimisation of reaction conditions

pH

The response obtained during the rebinding of Cu-IP with Cu(II) ion was investigated in the pH range from 2.0 to 10.0 using a fixed Cu(II) ion concentration of 1.0 mM. The result (Fig. 4) indicates that the Cu-IP gives the greatest relative reflectance signal divergence at pH 5.0 and this pH was selected for all the subsequent studies. The analytical response corresponded to the pH changes is basically similar to the result obtained in solution study except that the Cu-IP exhibited a wider optimum range within the acidic region. This mainly due to the pyridine moiety that has been fixed in an organised position which sustains greater pH changes before losing the capability to form complex with the Cu(II) ion. At pH> 5.0, the reflectance changes show a continuous decrease with increase in pH. This trend is very common and been reported mainly due to the masking of Cu(II) ion by the negative ions of the buffer from entering the binding cavity [26]. Another possible factor could be the common swelling effect of polymer at different pH of the media. In high pH environment, the proton from the side functional groups of the Cu-IP will be removed causing excess of negative charge that can repel each other. This causes a stretching force that can increase the size of binding cavity, which is highly unfavourable for rebinding of Cu(II) ion. Similar trend has also been observed in our previous work [27].

Effect of stirring

The sensor response was correlated to the change in the reflectance intensity of the Cu-IP due to the rebinding of Cu(II) ion. In order to achieve a fast response, the binding rate of the Cu(II) ion to the Cu-IP should be high before reaching the dynamic equilibrium. From the design of the sensor in this study, the binding rate of Cu(II) ion is controlled by the diffusion factor introduced by the physical nature of the polymer particles and the physical barrier of the polyamide mesh used to hold the polymer at the tip of the optical fibre. Stirring of the Cu(II) ion solution during the measurements is one of the methods that has been reported previously in order to increase the rate of diffusion [28, 29]. A simple and quick demonstration was carried out in recording the sensor response with (at 200 rpm) and without the stirring of Cu(II) ion solution. The result (Fig. 5) shows a remarkable outcome as the response rate is increased by about 57 times compared to the unstirred solution. All subsequence measurements were carried out in a fixed stirring condition (200 rpm) to ensure consistency in the results. Also by understanding this, any potential further development of the proposed method into advanced practical sensor should emphasis the incorporation of a stirring mechanism near the sensor tip. The design should be based on the targeted application and the stirring mechanism should provide constant and controllable movement of analyte solution near the sensor tips to generate better signal response. Such controlled condition can ensure the elimination of the limitation for repeated sensor calibration due to changes in parameters.

Time of response

The sensor response is influenced by different concentrations of Cu(II) ion and the residence time during which the sensor remains immersed into the analyte solution. It is important to give sufficient time for the Cu-IP to react with the Cu(II) ion in achieving stable and significant analytical signal for sensing application. Figure 6 shows the responses of sensor toward different concentrations of Cu(II) ion recorded at intervals of 30 s after immersing the sensor tip into the analyte solution. Generally, greater response was obtained with increasing reaction time. It was found that a minimum of 2 min was required before the signal can be correlated to the Cu(II) ion concentration. A high linearity of the response with the Cu(II) ion concentration occurs at a reaction time of 3 min and therefore this time was established as the response time for the sensor. Longer reaction time (>3 min) can also be used but this does not improve the sensing capability.

Recovery of response

The sensor response can be easily regenerated using EDTA as stripping agent, as used by other workers for Cu(II) ion based sensors [26, 29]. EDTA weakens the interaction that holds the Cu(II) ion in the imprinted sites and subsequently removes it from the cavity. The regeneration process can be monitored with the increase of relative reflectance signal. In this study, different concentrations of EDTA (0.001, 0.010, 0.050, and 0.150 M) were tested to regenerate the sensor. Higher concentration of EDTA as expected produced faster regeneration kinetics at the initial stage, but was found not useful in the complete regeneration of the sensor response to its baseline value. This might be due to the rapid complexation process that saturates the Cu-IP particle surface with EDTA-Cu complex and hinder further removal of Cu(II) ion. The regeneration of the sensor response was found to be successful as the EDTA concentration was lowered to 0.050 M, but required longer regeneration time as more dilute EDTA were used. Regeneration time is regarded to be the time needed for the reversal of sensor response to its initial value, which would be the reading recorded before the Cu-IP was contacted with Cu(II) ion solution. Similar observation has been reported for the regeneration of Cu(II) ion from immobilised salicylic acid by other workers [26]. From the results obtained (Fig. 7), 0.05 M EDTA solution was considered to be the best concentration in order to obtain the fastest and complete regeneration. In sensing application, such regeneration might be considered long for continuous monitoring applications, but the sensor could be applied for single use and thus become a disposable type.

Analytical characteristics

Under optimum and controlled operation condition, the sensor response was recorded over a range of Cu(II) ion concentrations to obtain a calibration plot. The plot of relative reflectance signal vs. the Cu(II) ion concentration shows that the dynamic response of the system was linear in the Cu(II) ion concentration range of 0.4–40 mM with a linear regression equation of %Rs = −1069.8[Cu(II)] + 83.911 (R 2 of 0.9962, n = 3). The analytical dynamic response was comparable with those previously reported reflectance based copper sensors but the range of linear detection has been successfully extended by at least 1-fold compared to these sensors [26, 28, 29]. Although the sensor responds only to millimolar concentrations, its application is still widely open especially in the areas such as mining, copper based industries, and environmental monitoring, which often deal with high concentrations of metal ions. Direct measurement can be carried out in-situ without the need for dilution of the sample or separation of possible interfering ions, due to high binding affinity. Besides, this linear range was obtained directly from the signal changes without converting the data into different scale such as a log scale, which can offer great simplicity to the sensor in real application. Within the dynamic linear range, the limit of detection (LOD) for the system was calculated to be 123 µM using \( \frac{{3\sigma }}{s} \) where σ is the standard deviation (n = 6) and s is the sensitivity of the analytical method [30].

Merit of imprinting

Repeatability

In this study, the sensor response is readily regenerated using EDTA and the Cu-IP can be reused for sensing of Cu(II) ion. It is crucial to investigate the reliability of the sensor response during the repeated application under similar conditions. To establish this, 5 repeated sensing cycles were carried out under identical conditions with two fixed concentrations of Cu(II) ion of 0.4 and 1.6 mM. The responses of the sensor recorded after immersing in the Cu(II) ion solution for 3 min give relative standard deviations (RSD) of 4.93% and 2.91% respectively. This value was far lower and better compared to other copper sensors based on immobilised reagent and reflectance spectroscopy (reported RSD in the range of 5–15%) [26, 28, 29]. These low RSD values indicate that the Cu-IP can be reused without significant loss of analytical signal and indeed offer advantages as a robust and reusable sensor. The repeatability of the sensor was also tested over a period of 4 days with a fixed Cu(II) ion concentration of 2.0 mM. The responses obtained gave a RSD value of 3.57%, which again indicated that the reliability of the sensor is high and does not suffer from deterioration caused by photo-beaching or leaching of the immobilised reagent that were commonly reported for sensors of this type [29].

Sensitivity

The sensitivity was compared between the Cu-IP and the control polymer by recording the change in reflectance obtained under same concentration of Cu(II) ion and similar reaction conditions. Three different concentrations of Cu(II) ion of 0.4, 2.0, and 4.0 mM respectively were treated individually with the polymers. The results obtained (Fig. 8) demonstrates that the effect of imprinting has enhanced the sensitivity (at least 1-fold) compared to the control polymer at all Cu(II) ion concentrations investigated. This observation further supports the idea of molecular imprinting as an art of creating specific binding sites within a polymer matrix giving superior affinity toward the template [31, 32]. In this case, the control polymer also gives response due to the existence of lone pair electron at the 4VPy moiety that can interact with the Cu(II) ion. However, this moiety was statistically distributed all over the matrix with no structural arrangement that can lead to binding thus resulting non-specific binding sites for Cu(II) ion with low affinity.

Sensitivity comparison of the sensor fabricated with Cu-IP and the control polymer (non-imprinted) at three different concentrations of Cu (II) ion. The bar represents the changes in reflectance reading while the line indicates the sensitivity enhancement evaluated by using the signal of the control polymer as reference

Selectivity

The interference caused by some possible interfering ions that usually co-exist with Cu(II) ion was evaluated. In this study, the interference effect in the molar ratio of 1:1 (Cu(II) ion: interference ion) was tested with the interfering ions. Table 1 summarises the degree of interference caused by the possible interfering ions which was evaluated using the signal recorded for Cu(II) ion only (in the absence of possible interfering ions) as standard compared to those recorded with possible interfering ions. The tolerable interference limit of possible interfering ion was taken as a relative error not greater than 5.0%, as obtained from the repeatability studies. The results show a great reduction in the interference for Cu-IP compared to the control polymer. This also indicates that the Cu-IP has binding site with higher affinity towards Cu(II) ion over the possible interfering ions tested. Such high superior selectivity is also observed in other works related in the imprinting of metal ions [33, 34].

The interference study was performed in the presence of both the Cu(II) ion and possible interfering ion to obtain a more accurate interpretation. First, this type of mixture mimics more accurately the condition of a real sample where all ions are usually present together in the same solution. Competitive binding can occur when more than one type of ions is present in the system and should not be ignored. Secondly, as the detection method uses changes in reflectance, the wavelength monitored at 750 nm only corresponds to the binding of Cu(II) ion. Therefore, if the Cu(II) ion is not in the mixture where possible interfering ions are present, interaction between the binding sites with the possible interfering ions will not be observed. However, in the presence of Cu(II) ion, the binding sites that are occupied or hindered by the possible interfering ions will cause a decrease in the sensor signal at 750 nm, which can be directly correlated to the interference effect.

Conclusions

We have demonstrated an approach filling the gap between the advancement of imprinted materials with their practical uses for real sensing applications. Although this laboratory demonstration was carried out using basic imprinting ingredients and simple fibre based instrumentation, the outcomes are impressive and show better results compared to similar type of sensors previously reported by other workers [26, 28, 29]. For instance, the linear range of detection has been successfully extended by at least 1-fold with lower and better repeatability value. The sensor developed using MIP has also demonstrated to be very selective, of high simplicity and low cost, which is a real merit for the sensor.

References

Mosbach K (1994) Molecular imprinting. Trends Biochem Sci 19:9–14

Spegel P, Schweitz L, Nilsson S (2002) Molecularly imprinted polymers. Anal Bioanal Chem 372:37–38

Wizeman WJ, Kofinas P (2001) Molecularly imprinted polymer hydrogels displaying isomerically resolved glucose binding. Biomaterials 22:1485–1491

Feng Q, Zhao L, Lin J-M (2009) Molecularly imprinted polymer as micro-solid phase extraction combined with high performance liquid chromatography to determine phenolic compounds in environmental water samples. Anal Chim Acta 650:70–76

Tamayo FG, Titirici MM, Martin-Esteban A, Sellergren B (2005) Synthesis and evaluation of new propazine-imprinted polymer formats for use as stationary phases in liquid chromatography. Anal Chim Acta 542:38–46

Olof Ramström RJA (1998) Molecular imprinting technology: challenges and prospects for the future. Chirality 10:195–209

Plaschke M, Czolk R, Ache HJ (1995) Fluorimetric determination of mercury with a water-soluble porphyrin and porphyrin-doped sol-gel films. Anal Chim Acta 304:107–113

Oehme I, Wolfbeis OS (1997) Optical sensors for determination of heavy metal ions. Mikrochim Acta 126:177–192

Marazuela M, Moreno-Bondi M (2002) Fiber-optic biosensors—an overview. Anal Bioanal Chem 372:664–682

Narayanaswamy R (1993) Tutorial review—Optical chemical sensors: transduction and signal processing. Analyst 118:317–322

Wolfbeis OS (1987) Annual Chemical Congress: new spectroscopic sensors and techniques. Anal Proc 24:14–24

Wolfbeis OS (2004) Fiber-optic chemical sensors and biosensors. Anal Chem 76:3269–3284

Uriu-Adams JY, Keen CL (2005) Copper, oxidative stress, and human health. Mol Aspects Med 26:268–298

Sidhu KS, Nash DF, Mcbride DE (1995) Need to revise the national drinking water regulation for copper. Regul Toxicol Pharmacol 22:95–100

Ahmad M, Narayanaswamy R (1994) Fibre optic reflectance sensor for the determination of aluminium(III) in aqueous environment. Anal Chim Acta 291:255–260

Safavi A, Bagheri M (2005) Design of a copper (II) optode based on immobilization of dithizone on a triacetylcellulose membrane. Sens Actuators B Chem 107:53–58

Ozutsumi K, Kawashima T (1992) Exafs and spectrophotometric studies on the structure of pyridine complexes with copper(II) and copper(I) ions in aqueous solution. Polyhedron 11:169–175

Ottaviani MF (1984) An ESR study on the interaction of copper(II) with pyridine and poly(2-vinylpyridine) in ethanol solutions. Colloids Surf 12:305–318

Brewer S (1980) Solving problems in analytical chemistry. Wiley, New York

Guthrie AJ, Narayanaswamy R, Russell DA (1988) Application of Kubelka-Munk diffuse reflectance theory to optical fibre sensors. Analyst 113:457–461

Grum F, Wightman TE (1977) Rapid communications: absolute reflectance of Eastman White Reflectance Standard. Appl Opt 16:2775–2779

Arica MY, Bayramoglu G, Yalçin E, Arica B, Ito K, Yagci Y (2005) Novel hydrogel membrane based on copoly(hydroxyethyl methacrylate/p-vinylbenzyl-poly(ethylene oxide)) for biomedical applications: properties and drug release characteristics. Macromol Biosci 5:983–992

Abraham S, Brahim S, Ishihara K, Guiseppi-Elie A (2005) Molecularly engineered p(HEMA)-based hydrogels for implant biochip biocompatibility. Biomaterials 26:4767–4778

Hamilton CJ, Murphy SM, Atherton ND, Tighe BJ (1988) Synthetic hydrogels: 4. The permeability of poly(2-hydroxyethyl methacrylate) to cations—an overview of solute-water interactions and transport processes. Polymer 29:1879–1886

Ellwanger A, Berggren C, Bayoudh S, Crecenzi C, Karlsson L, Owens PK, Ensing K, Cormack P, Sherrington D, Sellergren B (2001) Evaluation of methods aimed at complete removal of template from molecularly imprinted polymers. Analyst 126:784–792

Sundari R, Ahmad M, Heng LY (2006) Development of an optical fibre reflectance sensor for copper (II) detection based on immobilised salicylic acid. Sens Actuators B Chem 113:201–206

Ng SM, Narayanaswamy R (2006) Fluorescence sensor using a molecularly imprinted polymer as a recognition receptor for the detection of aluminium ions in aqueous media. Anal Bioanal Chem 386:1235–1244

Mahendra N, Gangaiya P, Sotheeswaran S, Narayanaswamy R (2003) Investigation of a fibre optic copper sensor based on immobilised [alpha]-benzoinoxime (cupron). Sens Actuators B Chem 90:118–123

Mahendra N, Gangaiya P, Sotheeswaran S, Narayanswamy R (2002) Investigation of a Cu(II) fibre optic chemical sensor using fast sulphon black F (FSBF) immobilised onto XAD-7. Sens Actuators B Chem 81:196–201

Vanatta LE, Coleman DE (1997) Calculation of detection limits for a single-laboratory ion-chromatographic method to determine parts-per-trillion ions in ultrapure water. J Chromatogr A 770:105–114

Zhu X, Cui Y, Chang X, Zou X, Li Z (2009) Selective solid-phase extraction of lead(II) from biological and natural water samples using surface-grafted lead(II)-imprinted polymers. Mikrochim Acta 164:125–132

Wang Z, Wu G, He C (2009) Ion-imprinted thiol-functionalized silica gel sorbent for selective separation of mercury ions. Mikrochim Acta 165:151–157

Wang L, Zhou M, Jing Z, Zhong A (2009) Selective separation of lead from aqueous solution with a novel Pb(II) surface ion-imprinted sol-gel sorbent. Mikrochim Acta 165:367–372

Wang S, Zhang R (2006) Selective solid-phase extraction of trace copper ions in aqueous solution with a Cu(II)-imprinted interpenetrating polymer network gel prepared by ionic imprinted polymer (IIP) technique. Mikrochim Acta 154:73–80

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, SM., Narayanaswamy, R. Demonstration of a simple, economical and practical technique utilising an imprinted polymer for metal ion sensing. Microchim Acta 169, 303–311 (2010). https://doi.org/10.1007/s00604-010-0357-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-010-0357-6