Abstract

A highly sensitive and selective glucose biosensor has been constructed by using highly dispersed NiO nanoparticles supported on well-aligned MWCNTs (NiO/MWCNTs) as sensing interface. The NiO/MWCNTs nanocomposite was synthesized by magnetron sputtering deposition of NiO nanoparticles on vertically aligned carbon nanotubes. The nanocomposite electrode showed high electrochemical activity towards the oxidation of glucose in 0.20 M NaOH solution. At an applied potential of +0.50 V, it gives a fast response time (< 5 s) and a linear dependence (R = 0.997) on the glucose concentration up to 7.0 mM with an extraordinarily high sensitivity of 1.77 mA mM-1 cm-2 and a detection limit of 2 μM. The interference by the oxidation of common interfering species such as ascorbic acid, dopamine, uric acid, lactose, and fructose is effectively avoided. The electrode was used to analyze glucose concentration in human serum samples. It allows highly sensitive, stable, and fast amperometric sensing of glucose, which is promising for the development of nonenzymatic glucose sensors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Determination of dissolved glucose is of great importance in various areas [1–3]. In general, glucose oxidase (GOx) which is selected as a model enzyme in glucose detection has the advantage of high sensitivity and selectivity [4–10], which catalyzes the oxidation of glucose in the presence of O2 to produce hydrogen peroxide for detection. However, because of the intrinsic nature of enzymes, the enzymatic glucose sensors often suffer from instability. For instance, the activity of GOx can be easily affected by temperature, pH value, humidity and toxic chemicals. In order to solve this problem, many nonenzymatic glucose sensors constructed by nanomaterials have been explored, which detect glucose based on its direct electrochemical oxidation [11–16]. Nanomaterials have become the focus of many scientific areas, including analytical science because of their unique electronic, optical, and catalytic properties [17].

Carbon nanotubes (CNTs) have been used as functional nanomaterials because of their distinctive physical and chemical properties. Application of CNTs in biological and medical fields, particularly in electrochemical biosensors, has been expanding rapidly [18–20]. Moreover, CNTs are able to promote fast electron transfer kinetics for glucose. Therefore, nonenzymatic glucose sensors such as noble metal-MWCNTs (containing Pt [15, 21] and Au [22, 23]), alloys-MWCNTs (containing Pt, Pb and Au [24, 25]) electrodes were constructed. However, these kinds of conventional electrodes have the shortcoming of low electrocatalytic activity towards the oxidation of glucose due to the adsorption of the interfering electroactive species such as ascorbic acid (AA), dopamine (DA), uric acid (UA) under physiological conditions, resulting in low sensitivity and poor selectivity [16, 26]. Metal oxide nanoparticles such as CuO [12, 27], ZnO [28], TiO2 [29] have been successfully used for glucose sensors. In our previous work, we have successfully modified well-aligned MWCNTs with MnO2 by electrodeposition for a glucose sensor [11].

In this paper, the MWCNTs are vertically aligned on Ta substrates [30–32], which efficiently simplifies the fabrication of electrode for electrochemical application. These stable, high-density, well-aligned MWCNTs with a large, electrochemically accessible surface area, high purity and high electrical conductivity, have been demonstrated to be high-performance electrode materials for electrochemical sensors [11, 25, 33, 34]. Here, we modified the well-aligned carbon nanotubes with NiO nanoparticles by magnetron sputtering deposition. The NiO/MWCNTs were directly used as an electrode to electrocatalyze the oxidation of glucose. The electrode takes the advantages of the electrocatalytic activity and high surface area of both NiO nanoparticles and carbon nanotubes. We have found that the electrode was very effective for glucose oxidation. Meanwhile, the interference from the oxidation of common interferents such as ascorbic acid, dopamine, and uric acid was also tested. All the above results indicate the NiO/MWCNTs nanocomposite electrode can be used as a novel candidate for nonenzymatic glucose sensors.

Experimental

D-(+)-glucose, L-ascorbic acid (L-AA), uric acid (UA), dopamine (DA), D-fructose and lactose were obtained from Alfa Aesar (http://www.alfa.com/china) and were used as received. All other reagents were of analytical grade. All solutions were prepared with high quality deionized water (18.4 MΩ cm-1).

The growth and application of well-aligned MWCNTs for electrode have been reported elsewhere [30–34]. In the present work, the MWCNTs were modified with NiO nanoparticles by magnetron sputtering of metallic Ni in an atmosphere of O2 and Ar (3:1) [35, 36].

A field-emission scanning electron microscope (SEM) (JEOL JSM 6700F) was used to observe the NiO modified well-aligned MWCNTs arrays. Transmission electron microscopy (TEM) observation of NiO/MWCNTs was performed with a Philips CM 300 FEG instrument operated at 300 kV. X-ray diffraction (XRD) pattern was recorded on a Bruker GADDS diffractometer with an area detector operating under a voltage of 40 kV and a current of 40 mA using Cu Ka radiation (λ = 0.15418 nm). Electrochemical measurements were performed using CHI 660C electrochemical workstation (Shanghai Chenhua, China). A three-electrode system was employed with MWCNTs or NiO/MWCNTs electrode as working electrode, an Ag/AgCl (3 M KCl) electrode and a platinum wire served as reference electrode and counter electrode, respectively. All potentials were referred to Ag/AgCl (3 M KCl) electrode.

Results and discussion

Morphological characterization of NiO/MWCNTs nanocomposite

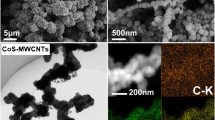

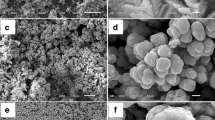

The typical SEM images of pristine MWCNTs and NiO/MWCNTs are shown in Fig. 1a and b, respectively. It can be seen that the surface of the MWCNTs are homogeneously coated after magnetron sputtering deposition. TEM observations were carried out for a more detailed characterization. Fig. 1c provides an overview of modified nanotubes, clearly showing that the nanotubes are uniformly coated with a thin layer of NiO nanoparticles. This is in agreement with the observation by SEM.

The crystal structure of the NiO/MWCNTs nanocomposite was studied by X-ray diffraction analysis, as shown in Fig. 1d. The XRD pattern shows diffractions of very strong peaks of the Ta substrate at 2θ of 38.5º, 55.6º, 69.6º, 94.9º and a very weak one at 2θ of 26.3º, which is graphite structure of MWCNTs ((002) planes). In addition, two small peaks at about 2θ of 43.3º and 37.3º, which belong to NiO (012), (101) planes, respectively, also appeared in the XRD pattern. The XRD result clearly indicates that NiO nanoparticles were deposited on the surface of MWCNTs.

CVs investigation of NiO/MWCNTs nanocomposite electrode

The electrocatalytic performance of both the bare MWCNTs and NiO/MWCNTs nanocomposite electrodes toward the oxidation of glucose was investigated by cyclic voltammetry (CV). Figure 2 shows the CV behaviors of the bare MWCNTs (A) and NiO/MWCNTs (B) electrodes in the absence (red lines) and presence (blue lines) of 6.0 mM glucose in 0.10 M NaOH solution at 50 mV s-1. As shown in Fig. 2a, only a small current for glucose oxidation without peak is observed at the bare MWCNTs electrode. When the NiO/MWCNTs nanocomposite electrode was used (Fig. 2b), a couple of oxidative and reductive peaks are observed in the absence of glucose. This can be attributed to the redox couple of Ni(II)/Ni(0). When adding 6.0 mM glucose, the oxidative peak current was dramatically increasing opposite to the reductive peak current. The anodic peak at +0.55 V is due to oxidation of glucose catalyzed by NiO nanoparticles. The cathodic peak at +0.37 V represents the reduction of Ni(II) to Ni. Compared to the bare MWCNTs electrode, we can see that the starting oxidative potential had no change but a dramatic increase of current signal was recorded at the NiO/MWCNTs electrode. This may result in the strong interaction between NiO nanoparticles and MWCNTs. The presence of NiO nanoparticles increased the effective surface area and active sites for glucose oxidation reaction, and also made the electrode surface more porous for facilitating electron transfer. The character of facilitated electron transfer at MWCNTs can further improve the electrochemical reaction at the NiO/MWCNTs nanocomposite electrode. Therefore, the NiO/MWCNTs nanocomposite showed high electrochemical activity to the oxidation of glucose.

The CVs of the NiO/MWCNTs nanocomposite electrode in different concentrations of glucose were also measured, as indicated in Fig. 3. The currents of the oxidative peak increased upon the increase of glucose concentration but opposite to the reductive peak current, since part of Ni(II) was reduced by glucose in the anodic process. Meanwhile, the oxidative potential shifted positively. In addition, the influence of scan rate on the current response for the anodic current (Ipa) of glucose oxidation was also studied (see Electronic Supplementary Material). At the NiO/MWCNTs electrode, the currents of the oxidative peak increased with the increase of scan rate, and the currents of the oxidative peak were linearly proportional to the scan rate in the range of 10–150 mV s-1, indicating a surface-controlled electrode process.

Amperometric response of glucose

The optimized potential for the electrochemical oxidation of glucose at the NiO/MWCNTs electrode was determined to be +0.50 V in 0.20 M NaOH (Fig. S2 and S3 in Electronic Supplementary Material). Figure 4A displays the amperometric response (at +0.50 V) at (a) the MWCNTs nanocomposite electrode and (b) the bare NiO/MWCNTs electrode to the successive addition of 1.0 mM glucose in 0.20 M NaOH solution. One can see that the NiO/MWCNTs nanocomposite electrode shows well defined response to the change of glucose concentration, producing steady-state signals within 5 s. The regression equation is ipa (μA) = 152.35 + 176.88c (mM), with R = 0.995. The NiO/MWCNTs nanocomposite electrode displays a linear range of 10 μM to 7.0 mM with a high sensitivity of 1,768.8 μA mM-1 cm-2, as illustrated in Fig. 4B. The detection limit is 2 μΜ with a signal/noise of 3. The sensitivity is higher than that of SWCNTs, MWCNTs, and nonenzymatic glucose sensors reported in the literature [11, 37–44], which are summarized in Table 1. The high performance of the NiO/MWCNTs electrode towards electroanalysis of glucose can be attributed to the increase of electroactive surface area and the synergistic electrocatalytic activity by combining NiO nanoparticles with well-aligned MWCNTs.

a Current–time response obtained on increasing the glucose concentration at 1.0 mM steps at (a) NiO/MWCNTs electrode and (b) MWCNTs electrode. b The dependence of the current response verses the concentration of glucose at (a) NiO/MWCNTs nanocomposite electrode and (b) MWCNTs electrode. Applied potential: +0.50 V

To evaluate the selectivity of the biosensor, many interfering biomolecules, AA, DA, UA, and other carbohydrates which normally co-exist with glucose in real samples (human blood) were examined. Considering that the concentration of glucose in the human blood is about 30 times that of AA, DA or UA, the amperometric response of the NiO/MWCNTs nanocomposite electrode towards the addition of 1.0 mM glucose and 0.05 mM AA, DA, UA and other carbohydrates such as D-fructose and lactose was examined in 0.20 M NaOH solution and the response currents are 227.8, 1.5, 2.7, 0.3, 0.8, and 3.3 μA, respectively (Fig. 5). The results indicate that the current response of the interferents is only 0.3–3.3% of that of glucose at the NiO/MWCNTs nanocomposite electrode. The current response of the interferents at the NiO/MWCNTs electrode is also much lower than that at the bare MWCNTs electrode. The selectivity was improved so much that the interference caused by the common interfering molecules, AA, DA, UA and other carbohydrates was negligible to the response of glucose at the NiO/MWCNTs nanocomposite electrode. Therefore, the selectivity of the NiO/MWCNTs nanocomposite electrode for glucose detection is satisfied at the presence of possible interfering reagents. The reproducibility and stability of the sensor were also evaluated. Three NiO/MWCNTs nanocomposite electrodes were identically investigated in the current response for 1.0 mM glucose at +0.50 V. The relative standard deviation (R.S.D.) was 5.2%, confirming that the sensors are highly reproducible. An electrode was measured 25 times and the yielded error is about 9%, showing that the sensor was stable without undergoing poisons by the oxidation product, and can be used for the repetitive detection of glucose. Moreover, the NiO/MWCNTs nanocomposite electrode was not affected by chlorine ion with its concentration up to 1.0 M, indicating that it can be used as a glucose sensor for many real samples.

Real serum samples measurement

The NiO/MWCNTs electrode was applied to the determination of glucose in real blood serum samples. 40.0 μL of serum sample was added to 10.0 mL of 0.20 M NaOH solution, and the current response was recorded at +0.50 V, as indicated in Fig. 6. Table 2 summarizes the result of determination of glucose in three serum samples. The experimental results indicate that the NiO/MWCNTs electrode is promising for practical application as glucose sensor.

Conclusion

In summary, a glucose biosensor based on NiO/MWCNTs nanocomposite was successfully fabricated by magnetron sputtering deposition of NiO nanoparticles on the vertically aligned carbon nanotubes. Because of synergistic electrocatalytic activity by combining NiO nanoparticles with MWCNTs, the NiO/MWCNTs nanocomposite electrode displays higher electrochemical activity for the glucose oxidation than the bare MWCNTs electrode, showing a fast response time (< 5 s) and a linear dependence (R = 0.995) in the glucose concentration range of 10 μM to 7 mM with a very high sensitivity of 1768.8 μA mM-1 cm-2 at an applied potential of +0.50 V. The detection limit is 2 μΜ with a signal/noise of 3. Meanwhile, the interference from the oxidation of common interfering species such as ascorbic acid, dopamine, uric acid and other carbohydrates is effectively avoided. Thus, the NiO/MWCNTs nanomaterials are promising for the fabrication of novel nonenzymatic glucose sensors.

References

Newman JD, Turner APF (2005) Home blood glucose biosensors: a commercial perspective. Biosens Bioelectron 20:2435

Wilson GS, Gifford R (2005) Biosensors for real-time in vivo measurements. Biosens Bioelectron 20:2388

Aoun SB, Bang GS, Koga T, Nonaka Y, Sotomura T, Taniguchi I (2003) Electrocatalytic oxidation of sugars on silver-UPD single crystal gold electrodes in alkaline solutions. Electrochem Commun 5:317

Zang JF, Li CM, Cui XQ, Wang JX, Sun XW, Dong H, Sun CQ (2007) Tailoring zinc oxide nanowires for high performance amperometric glucose sensor. Electroanalysis 19:1008

Liu J, Agarwal M, Varahramyan K (2008) Glucose sensor based on organic thin film transistor using glucose oxidase and conducting polymer. Sensor Actuat B-Chem 135:195

Tang H, Chen JH, Yao SZ, Nie LH, Deng GH, Kuang YF (2004) Amperometric glucose biosensor based on adsorption of glucose oxidase at platinum nanoparticle-modified carbon nanotube electrode. Anal Biochem 331:89

Tsai YC, Li SC, Chen JM (2005) Cast thin film biosensor design based on a nafion backbone, a multiwalled carbon nanotube conduit, and a glucose oxidase function. Langmuir 21:3653

Chu X, Duan DX, Shen GL, Yu RQ (2007) Amperometric glucose biosensor based on electrodeposition of platinum nanoparticles onto covalently immobilized carbon nanotube electrode. Talanta 71:2040

Zou YJ, Xiang CL, Sun LX, Xu F (2008) Glucose biosensor based on electrodeposition of platinum nanoparticles onto carbon nanotubes and immobilizing enzyme with chitosan-SiO2 sol-gel. Biosens Bioelectron 23:1010

Wang SG, Zhang Q, Wang RL, Yoon SF, Ahn J, Yang DJ, Tian JZ, Li JQ, Zhou Q (2003) Multi-walled carbon nanotubes for the immobilization of enzyme in glucose biosensors. Electrochem Commun 5:800

Chen J, Zhang WD, Ye JS (2008) Nonenzymatic electrochemical glucose sensor based on MnO2/MWNTs nanocomposite. Electrochem Commun 10:1268

Zhuang ZJ, Su XD, Yuan HY, Sun Q, Xiao D, Choi M (2008) An improved sensitivity non-enzymatic glucose sensor based on a CuO nanowire modified Cu electrode. Analyst 131:126

Bai Y, Yang WW, Sun Y, Sun CQ (2008) Enzyme-free glucose sensor based on a three-dimensional gold film electrode. Sensor Actuat B-Chem 134:471

Holt-Hindle P, Nigro S, Asmussen M, Chen AC (2008) Amperometric glucose sensor based on platinum-iridium nanomaterials. Electrochem Commun 10:1438

Rong LQ, Yang C, Qian QY, Xia XH (2007) Study of the nonenzymatic glucose sensor based on highly dispersed Pt nanoparticles supported on carbon nanotubes. Talanta 72:819

Wang J, Thomas DF, Chen A (2008) Nonenzymatic electrochemical glucose sensor based on nanoporous PtPb networks. Anal Chem 80:997

He L, Toh CS (2006) Recent advances in analytical chemistry-A material approach. Anal Chim Acta 556:1

Balasubramanian K, Burghard M (2006) Biosensors based on carbon nanotubes. Anal Bioanal Chem 385:452

Rubianes MD, Rivas GA (2005) Enzymatic biosensors based on carbon nanotubes paste electrodes. Electroanalysis 17:73

Wang SG, Wang RL, Sellin PJ, Zhang Q (2004) DNA biosensors based on self-assembled carbon nanotubes. Biochem Bioph Res Commun 325:1433

Li LH, Zhang WD (2008) Preparation of carbon nanotubes supported platinum nanoparticles by organic colloidal process for nonenzymatic glucose sensing. Microchim Acta 163:305

Jia F, Shan CS, Li FH, Niu L (2008) Carbon nanotube/gold nanoparticles/polyethylenimine-functionalized ionic liquid thin film composites for glucose biosensing. Biosens Bioelectron 24:945

Deng L, Wang YZ, Shang L, Wen D, Wang FA, Dong SJ (2008) A sensitive NADH and glucose biosensor tuned by visible light based on thionine bridged carbon nanotubes and gold nanoparticles multilayer. Biosens Bioelectron 24:951

Kang XH, Mai ZB, Zou XY, Cai PX, Mo JY (2007) A novel glucose biosensor based on immobilization of glucose oxidase in chitosan on a glassy carbon electrode modified with gold–platinum alloy nanoparticles/multiwall carbon nanotubes. Anal Biochem 369:71

Cui HF, Ye JS, Liu X, Zhang WD, Sheu FS (2006) Pt–Pb alloy nanoparticle/carbon nanotube nanocomposite: a strong electrocatalyst for glucose oxidation. Nanotechnology 17:2334

Sun YP, Buck H, Mallouk TE (2001) Combinatorial discovery of alloy electrocatalysts for amperometric glucose sensors. Anal Chem 73:1599

Luque GL, Rodriguez MC, Rivas GA (2005) Glucose biosensors based on the immobilization of copper oxide and glucose oxidase within a carbon paste matrix. Talanta 66:467

Sun XW, Wang JX, Wei A (2008) Zinc oxide nanostructured biosensor for glucose detection. J Mater Sci Technol 24:649

Chen X, Dong SJ (2003) Sol-gel-derived titanium oxide/copolymer composite based glucose biosensor. Biosens Bioelectron 18:999

Zhang WD, Wen Y, Liu SM, Tjiu WC, Xu GQ, Gan LM (2002) Synthesis of vertically aligned carbon nanotubes on metal deposited quartz plates. Carbon 40:1981

Zhang WD, Thong JTL, Tjiu WC, Gan LM (2002) Fabrication of vertically aligned carbon nanotubes patterns by chemical vapor deposition for field emitters. Diamond Related Mater 11:1638

Zhang WD, Yang F, Gu PY (2005) Carbon nanotubes grow to pillars. Nanotechnology 16:2442

Ye JS, Wen Y, Zhang WD, Gan LM, Xu GQ, Sheu FS (2003) Selective voltammetric detection of uric acid in the presence of ascorbic acid at well-aligned carbon nanotube electrode. Electroanalysis 15:1693

Ye JS, Wen Y, Zhang WD, Gan LM, Xu GQ, Sheu FS (2004) Nonenzymatic glucose detection using multi-walled carbon nanotube electrodes. Electrochem Commun 6:66

Zhang WD, Xu B (2009) A solid-state pH sensor based on WO3-modified vertically aligned multiwalled carbon nanotubes. Electrochem Commun 11:1038

Ye JS, Bai YC, Zhang WD (2009) Modification of vertically aligned carbon nanotube arrays with palladium nanoparticles for electrocatalytic reduction of oxygen. Microchim Acta 165:361

Wang JX, Sun XW, Cai XP, Lei Y, Song L, Xie SS (2007) Nonenzymatic glucose sensor using freestanding single-wall carbon nanotube films. Electrochem Solid-State Lett 10:J58

Park S, Chung TD, Kim HC (2003) Nonenzymatic glucose detection using mesoporous platinum. Anal Chem 75:3046

Li Y, Song YY, Yang C, Xia XH (2007) Hydrogen bubble dynamic template synthesis of porous gold for nonenzymatic electrochemical detection of glucose. Electrochem Commun 9:981

Ye JS, Wen Y, Zhang WD, Gan LM, Xu GQ, Sheu FS (2004) Nonenzymatic glucose detection using multi-walled carbon nanotube electrodes. Electrochem Commun 6:66

Yuan JH, Wang K, Xia XH (2005) Highly ordered platinum-nanotubule arrays for amperometric glucose sensing. Adv Funct Mater 15:803

Cui HF, Ye JS, Zhang WD, Li CM, Luong JHT, Sheu FS (2007) Selective and sensitive electrochemical detection of glucose in neutral solution using platinum-lead alloy nanoparticle/carbon nanotube nanocomposites. Anal Chim Acta 594:175

Lu LM, Zhang L, Qu FL, Lu HX, Zhang XB, Wu ZS, Huan SY, Wang QA, Shen GL, Yu RQ (2009) A nano-Ni based ultrasensitive nonenzymatic electrochemical sensor for glucose: Enhancing sensitivity through a nanowire array strategy. Biosens Bioelectron 25:218

Li MG, Xu SD, Ni F, Wang YL, Chen SH, Wang L (2009) Fast and sensitive non-enzymatic glucose concentration determination using an electroactive anionic clay-modified electrode. Microchim Acta 166:203

Acknowledgements

The authors thank Natural Science Foundation of China (No. 20773041), the Research Fund for the Doctoral Program of Higher Education (No. 20070561008), and Ministry of Science and Technology of China (2008AA06Z311) for financial support.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 1711 kb)

Rights and permissions

About this article

Cite this article

Zhang, WD., Chen, J., Jiang, LC. et al. A highly sensitive nonenzymatic glucose sensor based on NiO-modified multi-walled carbon nanotubes. Microchim Acta 168, 259–265 (2010). https://doi.org/10.1007/s00604-010-0288-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-010-0288-2